Phenolic positive photoresist with etching resistance

A photoresist and etching-resistant technology, applied in the field of photoresist, can solve the problems of complex operation of two-layer film or multi-layer film process, high temperature resistance of photoresist, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

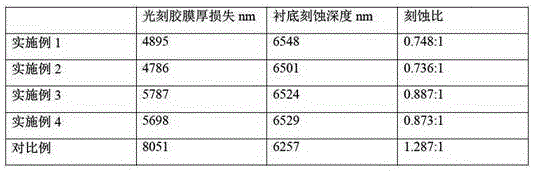

Examples

Embodiment 1

[0031] 43g novolac resin, 10g 2,1,4-diazonaphthoquinone sulfonate, 16g 2-methylcyclopentadiene manganese tricarbonyl, 1g γ-aminopropyltriethoxysilane, 100g propylene glycol methyl ether acetic acid Esters are mixed, fully dissolved, and then filtered through a filter membrane with a pore size of 0.02 micron to obtain photoresist 1.

[0032] The structure of novolak resin in the present embodiment is as follows:

[0033] Wherein R is methyl, n=50.

Embodiment 2

[0035] 43g novolac resin, 10g 2,1,5-diazonaphthoquinone sulfonate, 16g zirconium propionate, 1g N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 100g propylene glycol methyl Ether acetate was mixed, fully dissolved, and then filtered through a filter membrane with a pore size of 0.02 micron to obtain photoresist 2.

[0036] The structure of novolak resin in the present embodiment is as follows:

[0037] Wherein, R1 is propyl group, n=30.

Embodiment 3

[0039] 65g of novolac resin, 15g of 1,2-benzoquinonediazide-4-sulfonic acid, 8g of iron trifluoroacetylacetonate (CAS: 14526-22-8), 2g of γ-aminopropyltriethoxysilane, 40g of benzene and 80g of propylene glycol methyl ether acetate were mixed, fully dissolved, and then filtered through a filter membrane with a pore size of 0.02 micron to obtain photoresist 3.

[0040] The structure of novolak resin in the present embodiment is as follows:

[0041] Wherein R is methyl, n=50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com