Conductive composite body, conductive polymer composition and electronic component using the conductive polymer composition

A conductive polymer and conductive technology, applied in the direction of non-metallic conductors, organic material conductors, etc., can solve problems such as low performance, achieve excellent performance, excellent ESR performance, and enhance the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

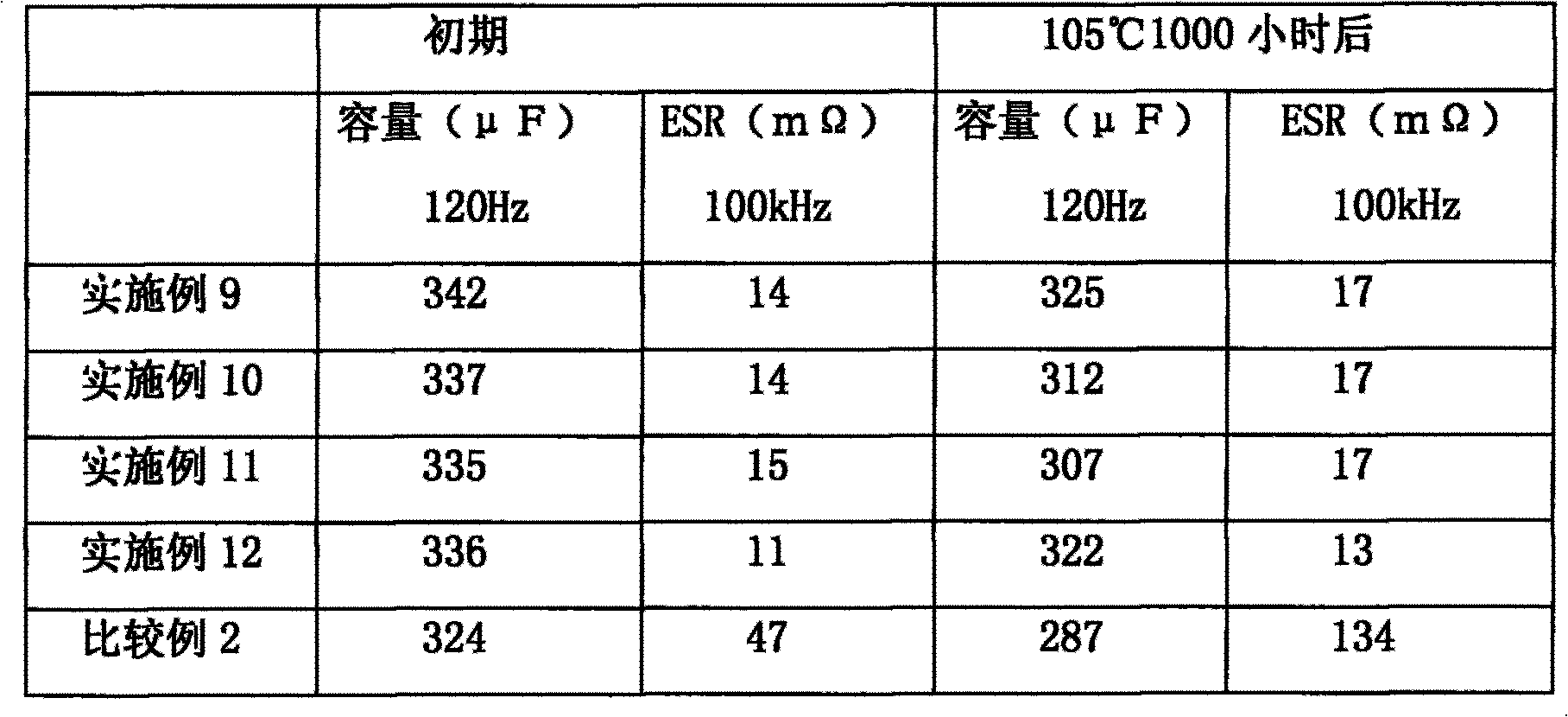

Examples

Embodiment 1

[0098] After mixing 3g of 3,4-ethylenedioxythiophene, 300g of 3wt% polystyrenesulfonic acid aqueous solution, 6g of sodium persulfate, 1g of ferric sulfate and 500ml of pure water, it was stirred for 3 hours. After adding 2 g of acrylic acid (AA) and 4 g of hydroxyethyl acrylate (HEA) to this reaction solution, it was heated and stirred for 3 hours.

[0099] After letting cool, remove residual ion in the solution with ion exchange resin, obtain dark blue 1.5wt% polystyrenesulfonic acid-poly(3,4-ethylenedioxy) thiophene and polyacrylic acid-polyhydroxyethyl acrylate aqueous solution (hereinafter referred to as: aqueous solution 1).

[0100] After mixing 1 g of aqueous solution 1 and 9 g of ethanol, mixed ethanol aqueous solution 1 was obtained. After coating the ethanol aqueous solution 1 on the polyester film and drying it in an oven at 120°C for 30 minutes, the conductive thin coating film was obtained. Table 1 shows the results of evaluating the resistivity of the conducti...

Embodiment 2

[0102] 3g of 3,4-ethylenedioxythiophene, 300g of 3wt% polystyrene sulfonic acid aqueous solution, 6g of sodium persulfate, 1g of ferric sulfate and 500ml of pure water were mixed, stirred for 3 hours to obtain a reaction Liquid 1.

[0103] After mixing 1.5 g of pyrrole, 100 g of 3 wt % polystyrene sulfonic acid aqueous solution, 5 g of sodium persulfate, 1 g of ferric sulfate and 500 ml of pure water, stirred for 30 minutes to obtain reaction solution 2.

[0104] Add 2 g of acrylic acid hydroxamide and 6 g of sodium styrene sulfonate to the reaction solution 1, heat and stir for 1 hour, add the aforementioned reaction solution 2 to the reaction solution, and continue stirring for 1 hour.

[0105] After cooling, remove the residual ions in the solution with an ion exchange resin to obtain blue-black 1.5wt% polystyrenesulfonic acid-poly(3,4-ethylenedioxy)thiophene-polypyrrole and polyacrylic acid-acrylic acid hydroxyethyl Aqueous solution of ester (hereinafter referred to as: a...

Embodiment 3

[0108] The same method as in Example 1, except that 2g of acrylic acid (AA) and 4g of hydroxyethyl acrylate (HEA) are changed into 6g of hydroxyethylacrylamide, the same as in Example 1 to obtain 1.5wt% polystyrene Sulfonic acid-poly(3,4-ethylenedioxy)thiophene-polyhydroxyethylacrylamide (hereinafter referred to as: aqueous solution 3).

[0109] In the same manner as in Example 1, a conductive thin coating film was produced, and the resistivity of the conductive thin coating film was evaluated. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com