Patents

Literature

55results about How to "Strong bridging ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

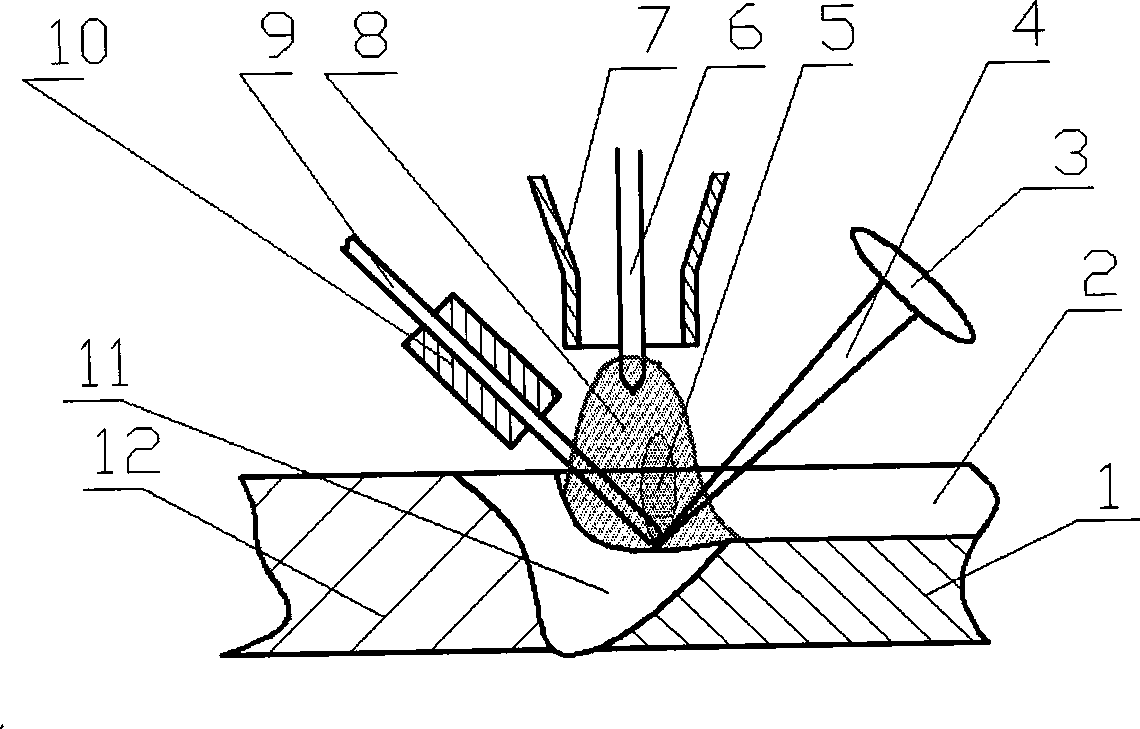

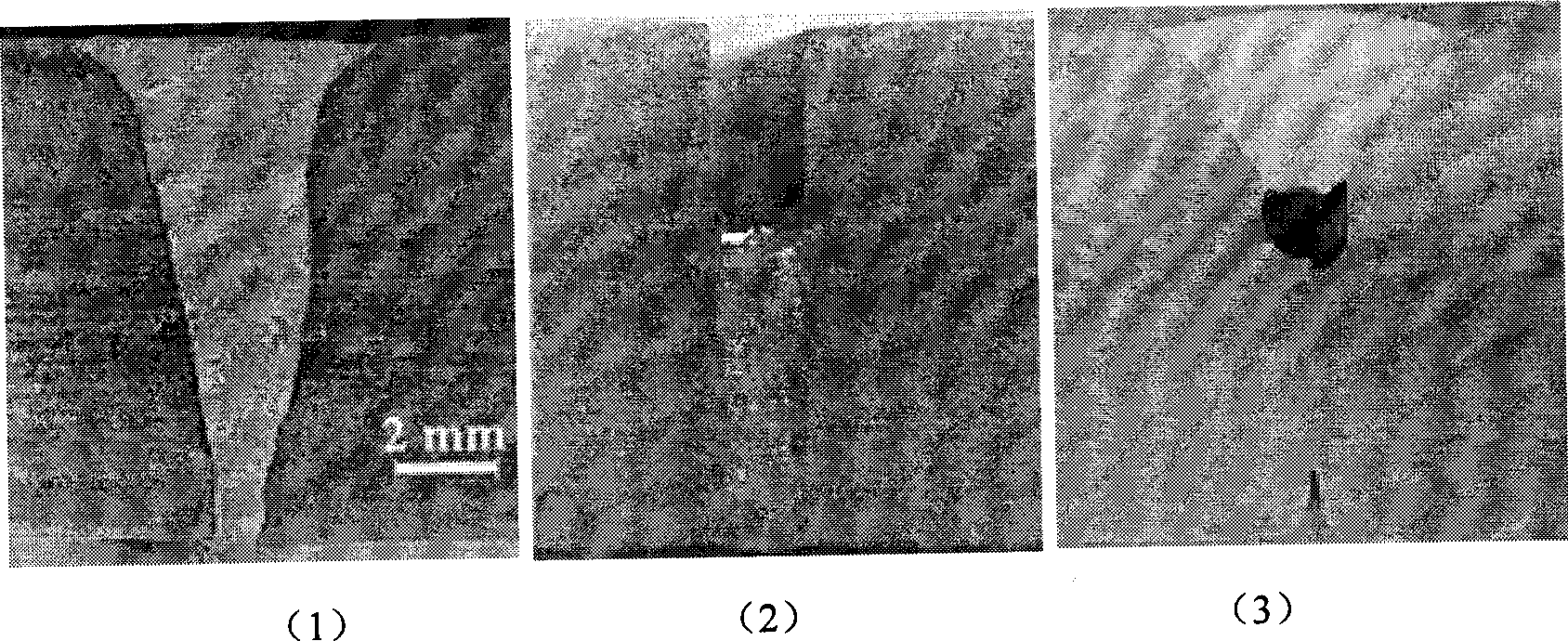

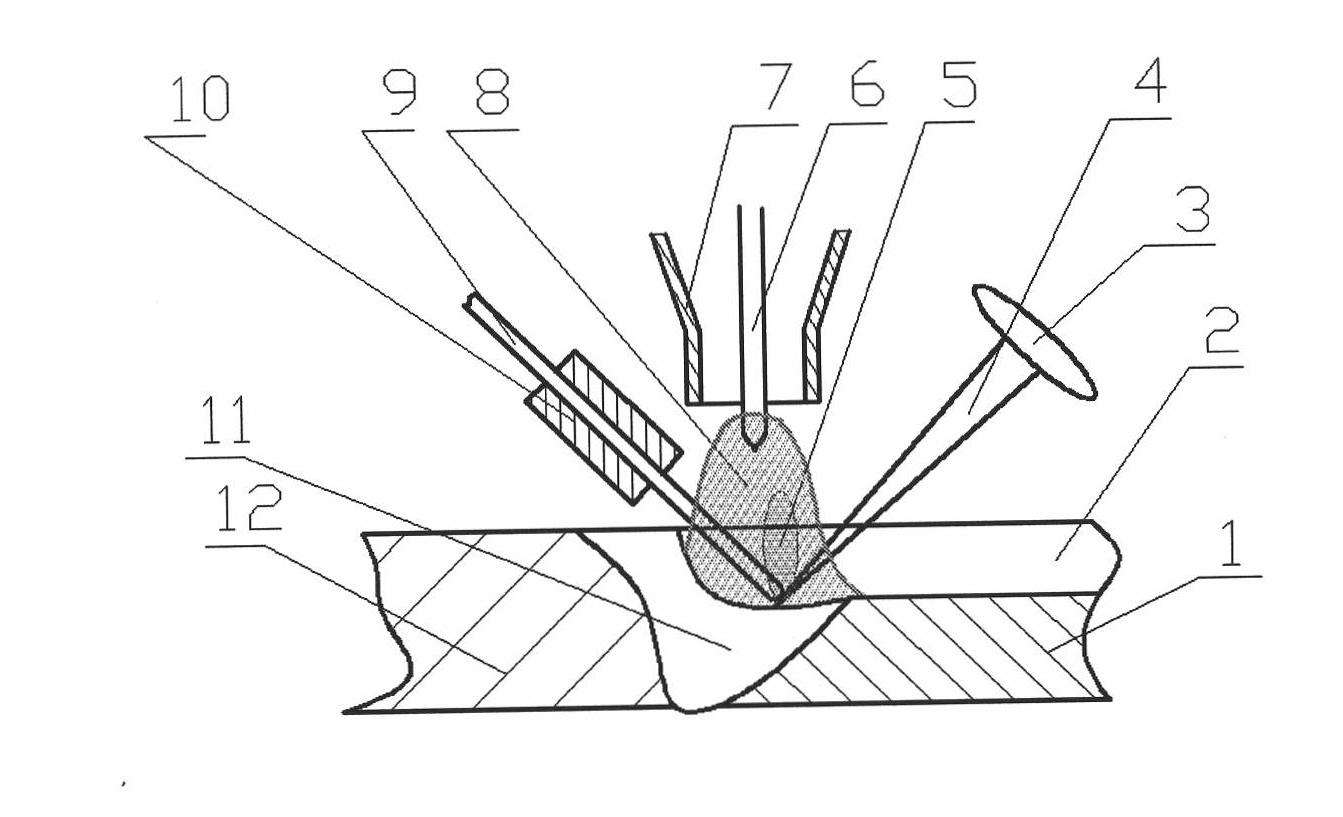

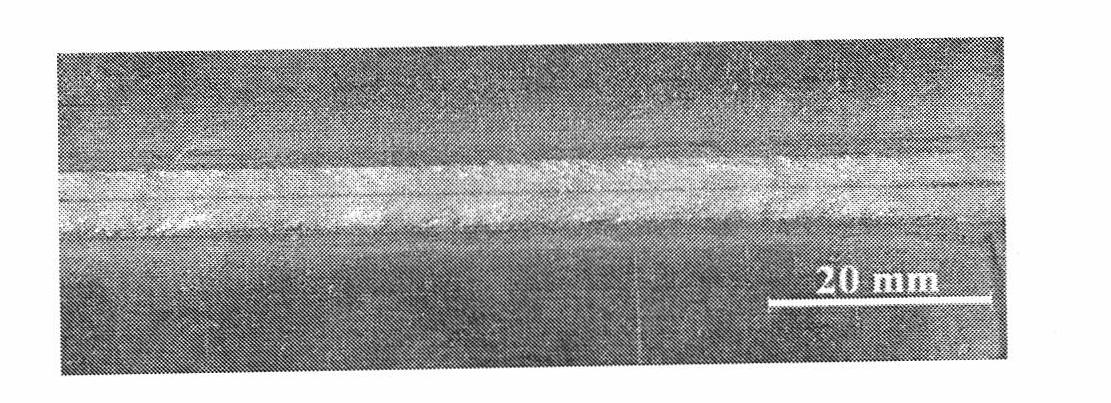

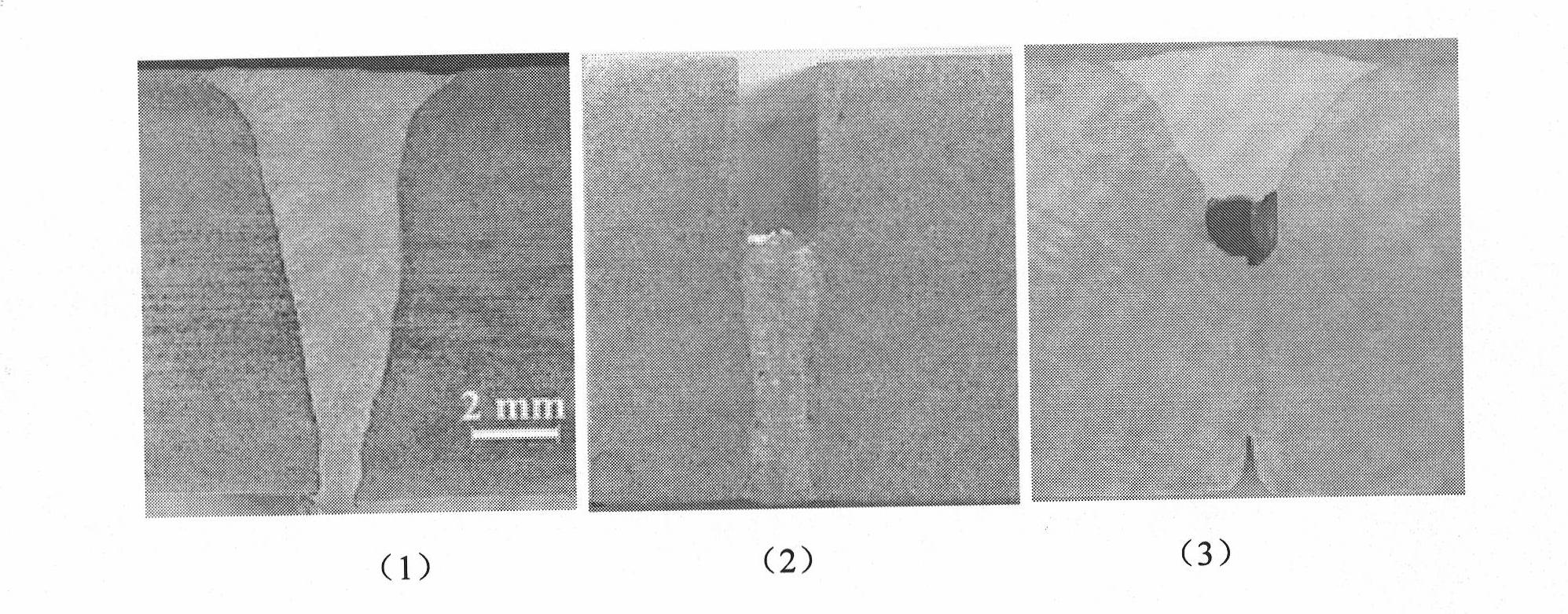

Narrow gap laser-arc hybrid welding method using filler wire

InactiveCN101474726AImprove welding efficiencySimple welding processLaser beam welding apparatusHigh power lasersEngineering

The invention relates to a narrow gap laser-arc composite welding method adopting a filler wire, belonging to the technical field of laser materials processing. The method adopts a high-power laser and an laser arc hybrid, and the arrangement mode thereof is that a laser bean and a welding wire are arranged in opposite directions corresponding to an electric arc, wherein the laser bean enters slantwise from the front part of the electric arc, and the welding wire is led into a divided edge gap from the rear of the electric arc, and after fusing the welding wire, a composite thermal source fills the gap, thereby realizing the single pass welding shaping of a work piece. The method fully utilizes the penetration fusion property of the laser and the high filling efficiency of the electric arc; and under the mutual actions of laser and arc, the stability of a welding process is improved, and the welding efficiency is increased.

Owner:BEIJING UNIV OF TECH

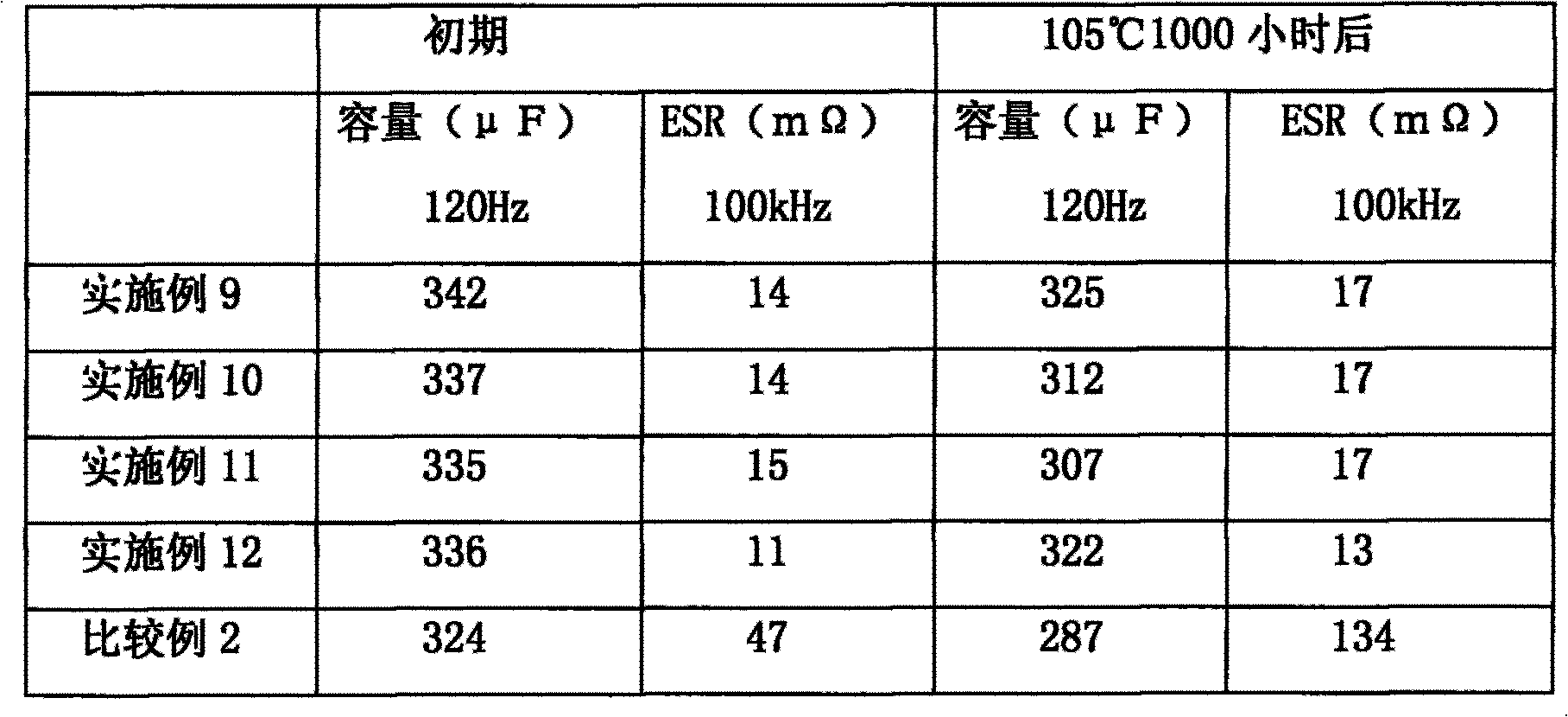

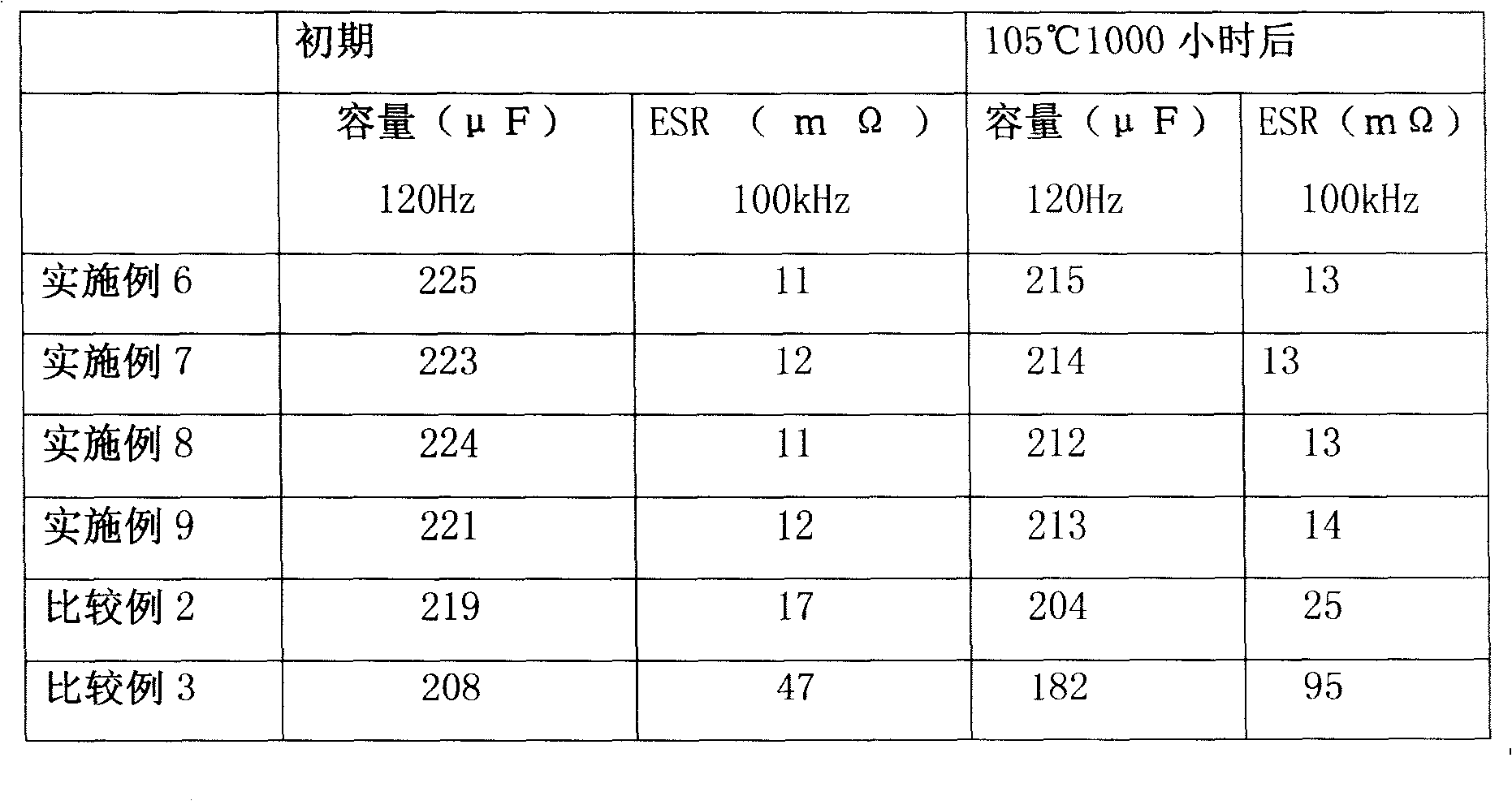

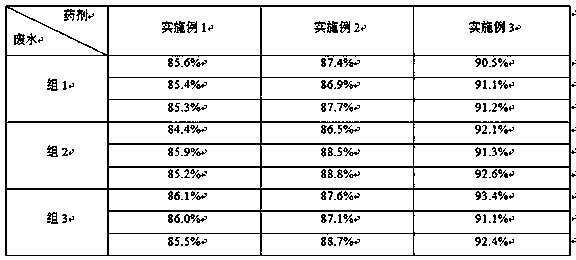

Conductive composite body, conductive polymer composition and electronic component using the conductive polymer composition

InactiveCN101302340AImprove long-term stabilityExcellent solvent solubilityOrganic conductorsConductive polymerDisplay device

The invention provides a conducting complex which is combined by a conducting polymer A and a compound B except for the conducting polymer, and also can comprise polyanion, wherein, the compound B is polyethylene and derivates thereof, polyvinyl ether and derivates thereof, polyacrylamide and derivates thereof, polyacrylic acid and derivates thereof, etc. The conducting complex improves clinging property and filming property for matrix, and can maintain low specific resistance in a high-temperature environment. A conducting polymer composition comprises the conducting complex, has reduced specific resistance, and can maintain low specific resistance in a high-temperature environment. The invention also provides an electronic element with excellent performance through using a coating of the conducting complex and the conducting polymer composition. The coating of the conducting complex or the conducting polymer composition can be used in a solid electrolytic capacitor, a solar cell, an organic light emitting diode, an electroluminance, a display, an electrostatic copying part, a transfer printing part, a battery, epaper, a touch panel, an organic thin-filmtransistor, a field emission display (FED) and so on.

Owner:ZHENGZHOU TAIDA ELECTRONICS MATERIAL TECH

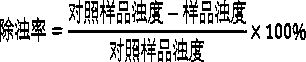

Nano highly effective amendment for sludge dehydration

InactiveCN1621370AHigh floc strengthLow floc strengthSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationSulfateSludge

The present invention discloses one kind of Z's nanometer efficient sewage dewatering amendment. The Z's nanometer efficient sewage dewatering amendment consists of polymerized ferric sulfate 85-98 weight portions, polyacrylamide 0.5-6 weight portions, hydroxymethyl cellulose sodium 0.5-6 weight portions and nanometer material 0.5-3 weight portions. The present invention has powerful neutralizing capacity, bridging capacity and permeating capacity and thus has high sewage dewatering effect.

Owner:曾智勇 +1

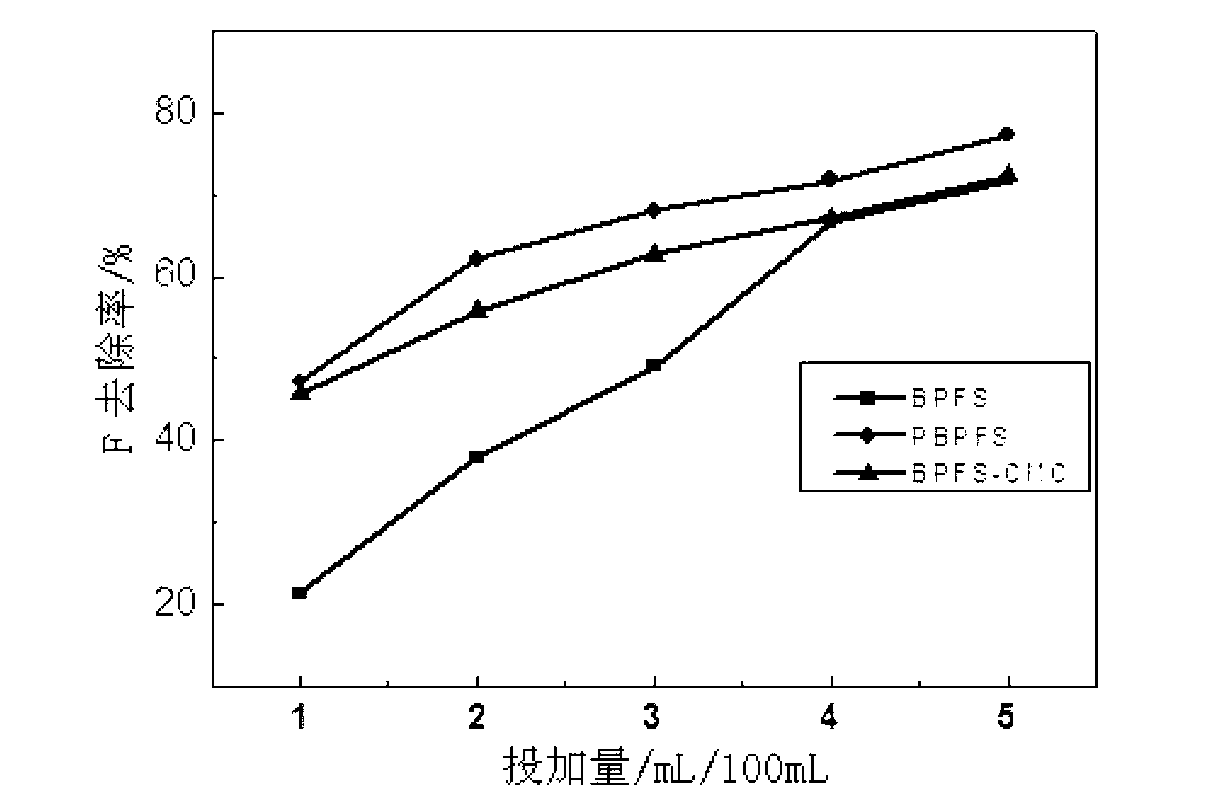

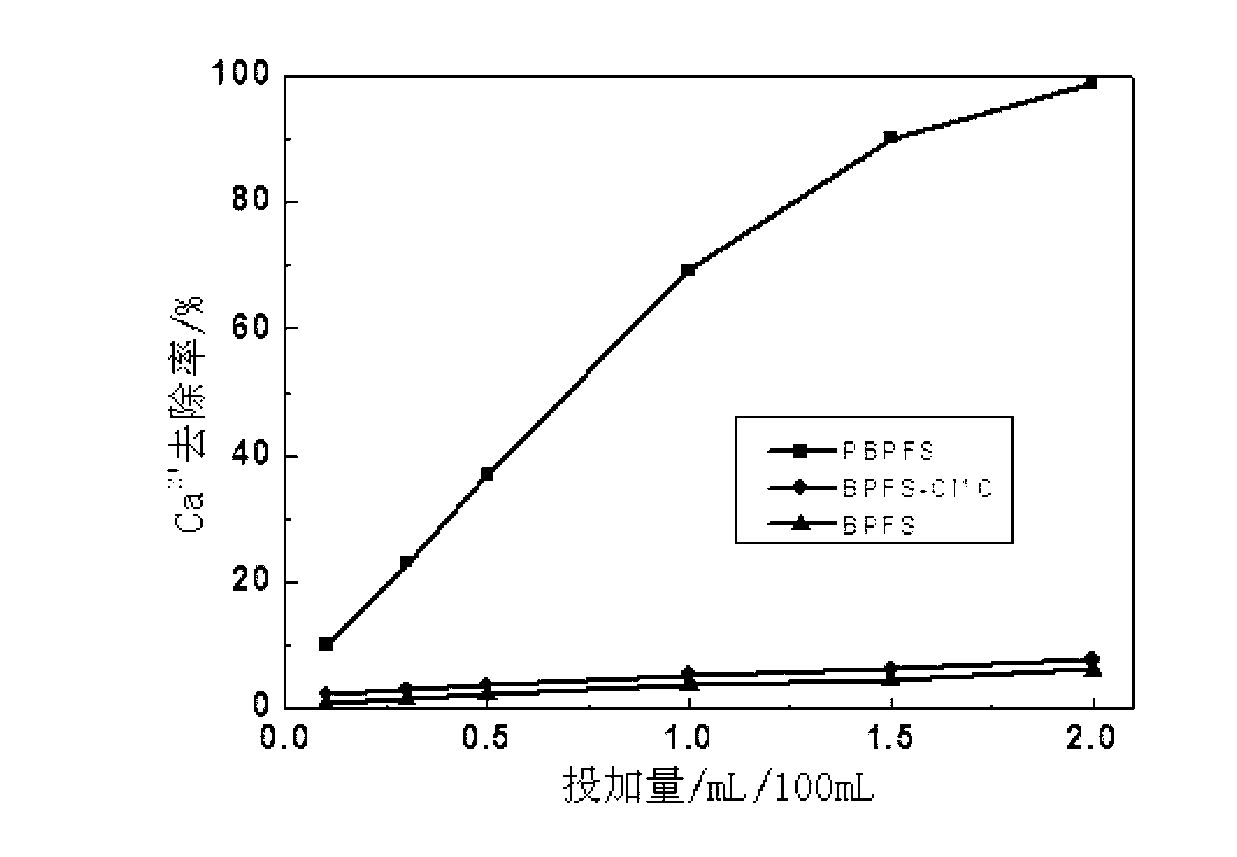

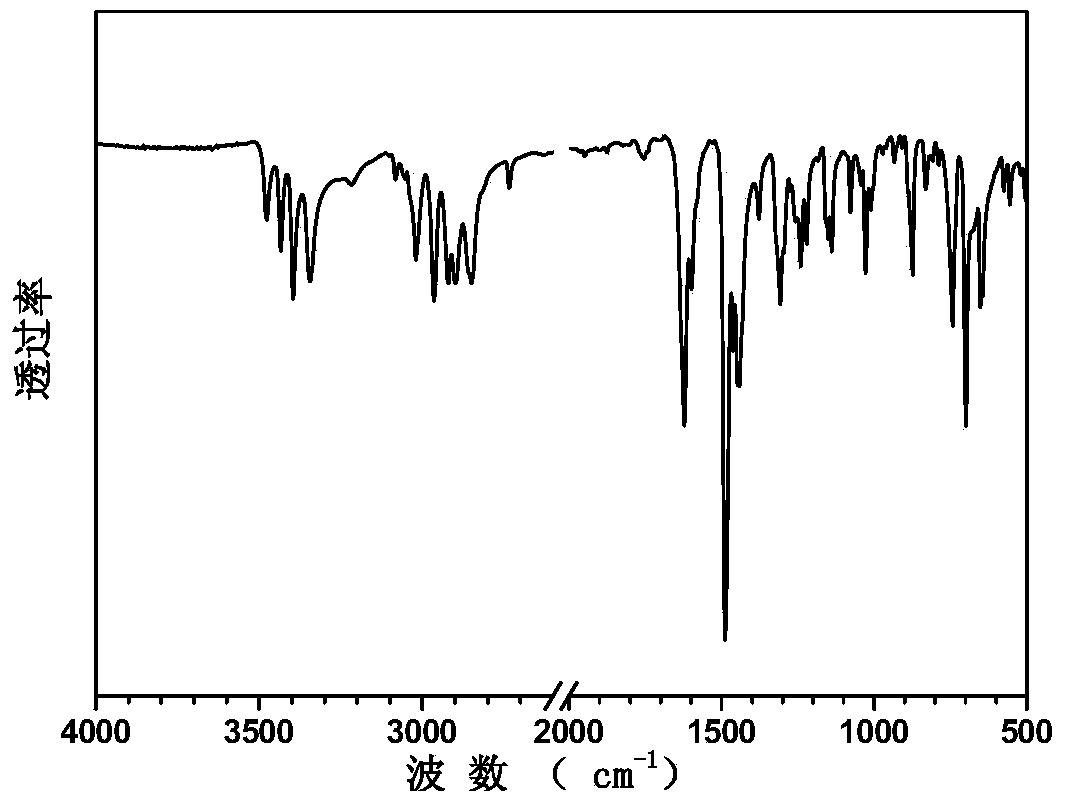

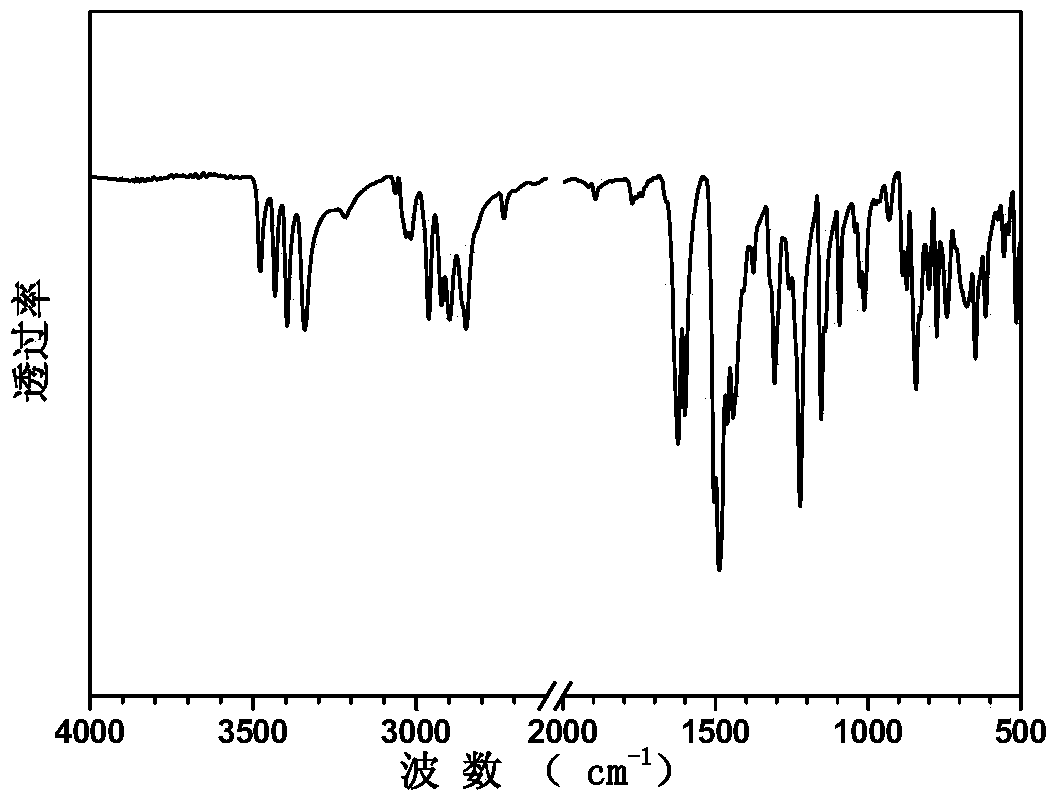

Biological flocculant for processing fluorine and calcium in wastewater and preparation and application methods thereof

InactiveCN103274507AGood flocculation performanceCoarse alumBacteriaWater contaminantsIonHeavy metals

The invention relates to a biological flocculant for processing fluorine and calcium in wastewater and preparation and application methods thereof. A phosphoric-acid-modified iron-based biological flocculant is obtained through reacting a liquid iron-based biological flocculant with a phosphoric acid solution. The biological flocculant is clean, is free of secondary pollution, can be used for efficiently processing wastewater containing fluorine and calcium, particularly complex multi-metal wastewater containing fluorine and calcium, and can enable the concentration of all heavy metal ions and fluorine and calcium ions to meet the lead and zinc industrial pollutant emission standards (GB25466-2010).

Owner:CENT SOUTH UNIV +1

Nano coagulant for swimming pool

InactiveCN1626452ALarge specific surface areaHuge surface energyWater/sewage treatment by flocculation/precipitationAluminium sulfateSuspended matter

Owner:曾智勇 +1

Oilfield sewage treatment method

InactiveCN105016495AEnhances flocculation and bridgingGood foaming performanceWaste water treatment from quariesScale removal and water softeningOil contentHigh concentration

Owner:张哲夫

Moisture permeation and water proofing fabric, and preparation process thereof

InactiveCN102619092ASolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentCoated surfaceMoisture permeation

The present invention discloses a moisture permeation and water proofing fabric, and a preparation process thereof. According to the fabric, a prime coat comprises: a polyurethane resin, butanone, toluene, water, 1,6-diisocyanatohexane and N-methylethanolamine; a first surface coating and a second surface coating comprise a polyurethane resin, butanone, toluene, water and N-methylethanolamine. The preparation process comprises: mixing 1,6-diisocyanatohexane and a main resin; mixing water and butanone to form a solvent; adding the solvent to the main resin mixing solution in at least 6 times; filtering the resulting mixed solution with a nylon net to obtain a filtered main resin solution; carrying out a deaeration treatment to form a prime coat slurry; blending a surface coating slurry with a matching solution viscosity of 3500-6000 mpas; coating the prime coat slurry on the surface of the base cloth to form the prime coat, and drying; coating the surface coating slurry on the surface of the prime coat in 2 times to form the surface coatings, and drying. In the prior art, micropores in the hydrophilic moisture permeation processing coating fabric are not uniform, and are easily expanded when contacting the water. With the present invention, the disadvantages in the prior art are solved, and the moisture permeation performance of the fabric is improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

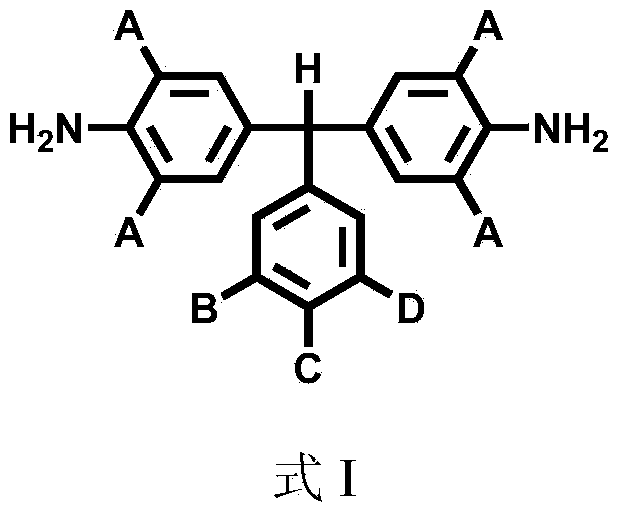

Sulfonated aromatic diamine compound as well as preparation method and application thereof

ActiveCN103864648AImprove hydrophilic/hydrophobic propertiesHigh activityDewatering/demulsification with chemical meansSulfonic acid preparationFunctional monomerBenzaldehyde

The invention discloses a sulfonated aromatic diamine compound as well as a preparation method and application thereof. The sulfonated aromatic diamine compound is as shown in the formula I in the specification. The preparation method of the sulfonated aromatic diamine compound as shown in the formula I comprises the following steps: (1) in the presence of acid, reacting a phenylamine compound as shown in a formula II with a benzaldehyde compound as shown in a formula III in water, after the reaction is accomplished, neutralizing the reaction system by using alkali, and recrystallizing to obtain an aromatic diamine compound as shown in a formula IV; (2) under an ice-bath condition, adding the aromatic diamine compound as shown in the formula IV into concentrated sulfuric acid, and subsequently adding fuming sulfuric acid for reaction so as to obtain the sulfonated aromatic diamine compound as shown in the formula I. As a key initiating agent or functional monomer of a novel efficient demulsifying agent or water clarifier, the sulfonated aromatic diamine compound disclosed by the invention has important values in treating polymer flooding produced liquids.

Owner:CHINA NAT OFFSHORE OIL CORP +1

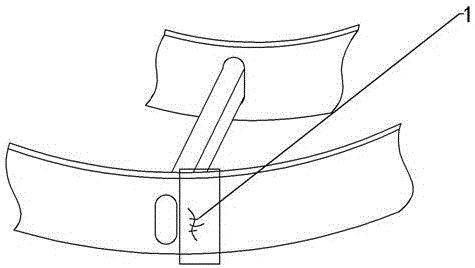

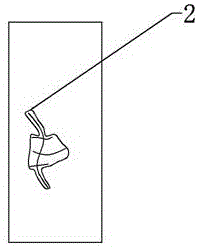

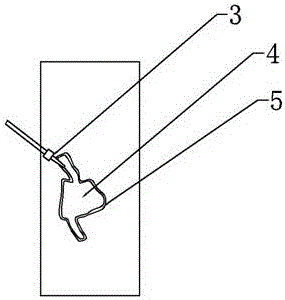

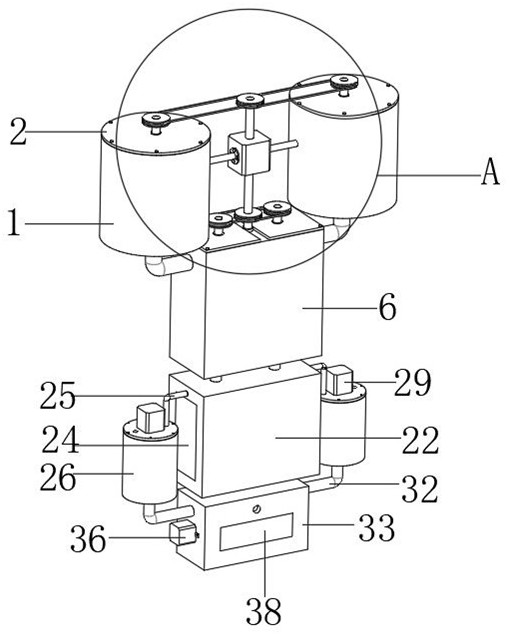

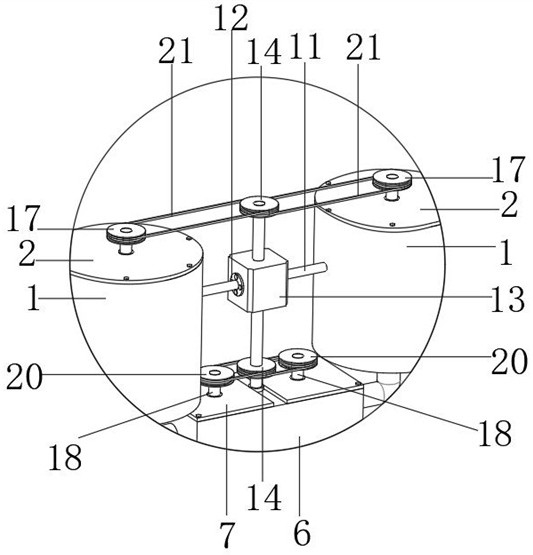

Thin-wall component recombining and restoring method based on pulse welding and laser augmented material restoring

The invention discloses a thin-wall component recombining and restoring method based on pulse welding and laser augmented material restoring. The method is characterized in that firstly, the distribution and trend of cracks and other penetrating damage are determined through a coloring check method; secondly, grinding treatment is conducted through a hard alloy rotary file, and a penetrating groove in a relatively regular shape is formed; thirdly, optimal grinding of a pulse welding groove is conducted; fourthly, cleaning of the penetrating groove and a groove body of the penetrating groove is conducted; fifthly, pulse welding bridging restoring of the penetrating groove is conducted; sixthly, a bridging welding restored body is ground and cleaned; and seventhly, laser augmented material restoring is conducted on a damaged structure. The method has the following advantages that the pulse welding restoring bridging capability is high, a base plate does not need to be additionally designed or manufactured, the restoring technology process of a penetrating damage component can be simplified, and the restoring efficiency is improved. A pulse welding restoring control system outputs data stably and accurately, heat input in the restoring process can be accurately controlled, the deformation of the restored workpiece can be reduced, and the restoring precision is high. Three-dimensional forming restoring of the damaged component can be automatically achieved through laser deposition restoring, the restoring efficiency is improved, and the stability and consistency of the restoring technology are good.

Owner:SHENYANG AEROSPACE UNIVERSITY

Method for destabilization coagulating treatment of well drilling waste liquid

ActiveCN102320699AReduce thicknessLow energy barrierMultistage water/sewage treatmentSolid phasesPolyacrylamide

The invention relates to a method for destabilization coagulating treatment of well drilling waste liquid for carrying out innocent treatment on the well drilling waste liquid in oil-gas field well drilling. The method can be used for carrying out innocent treatment on the well drilling waste liquid and increasing a treatment effect. In a technical scheme, the method comprises the following stepsof: firstly, adding a destabilizing agent into a reaction tank filled with well drilling waste liquid, wherein the destabilizing agent is prepared by preparing a mixture of 85 percent of CaCl2 and 15percent of MgCl2 into a solution with the concentration of 20 percent; stirring and mixing for 10-15 minutes to make destabilize the well drilling waste liquid; adding a coagulating agent into the tank, wherein the coagulating agent is prepared by preparing a mixture of 95 percent of polyAlCl3 and 5 percent of polyacrylamide into a solution with the concentration of 20 percent; stirring and mixing for 15-20 minutes; and finally, inputting the mixture into a solid-liquid separating device, wherein after the mixture is separated, a liquid phase reaches an emission standard and a curing agent isadded into a solid phase for carrying out curing treatment. Treatment agents used in the invention have good destabilizing and coagulating effects on the well drilling waste liquid and are low in dosage and convenient for operation; and the method has the advantages of low cost and economy and is used for innocent treatment of the well drilling waste liquid.

Owner:FD PETROL GRP

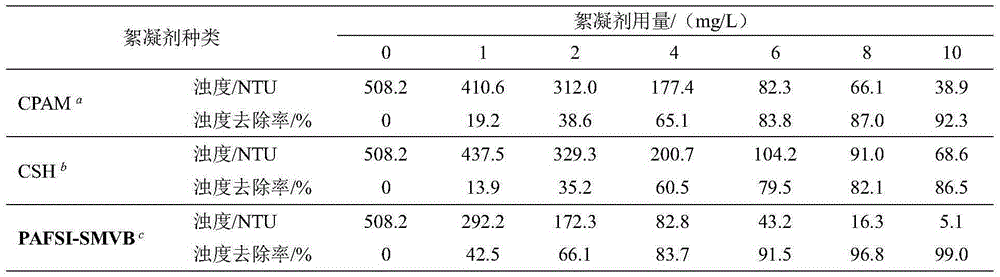

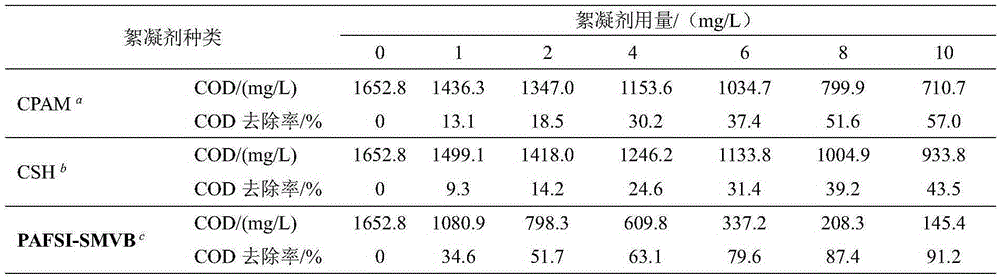

Preparation method of namometer PAFSI (polyaluminum ferric silicate)-graft modified starch hybrid flocculent

InactiveCN105417655AImprove solubilityGood electrical neutralizationWater/sewage treatment by flocculation/precipitationIonAluminum silicate

The invention discloses a preparation method of a namometer PAFSI-graft modified starch hybrid flocculent. The preparation method is characterized by comprises the steps that 20 parts of Na2SiO3 and 350 parts of deionized water are added to a reaction bottle, the pH value ranges from 2 to 5, the room temperature reaction is performed for 2-3 h, and activated silicic acid is prepared; a certain amount of AlCl3 and FeCl3 ethylene glycol solution is added slowly in 20 parts of activated silicic acid for reaction, 1-5 parts of CTAC (cetanecyl trimethyl ammonium chloride) is added after cooling, curing is performed, and namometer PAFSI is prepared; 20 parts of starch and 20-400 parts of deionized water are added to the reaction bottle, N2 is fed, the starch is cooled to 30 DEG C after gelatinized for 0.5-1 h under stirring and at the temperature of 65 DEG C to 90 DEG C, 0.5-6.0 parts of CTAC is added, 2-10 parts of nanometer PAFSI is added, the pH value ranges from 5 to 7, 0.05-0.5 part of potassium persulfate and 0.02-0.3 part of sodium sulphite are added at the temperature of 30 DEG C to 55 DEG C, 3-10 parts of cationic monomers and 2-10 parts of macromonomers are added slowly, N2 is fed, the reaction is performed for 4-8 h, and the namometer PAFSI-graft modified starch hybrid flocculent is prepared.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Industrial oily wastewater treatment method

InactiveCN104986813AReduce dosageHigh oil removal rateWater/sewage treatment by flocculation/precipitationFlocculationHigh concentration

The present invention relates to an industrial oily wastewater treatment method. The method comprises: adding an oily wastewater treatment agent to wastewater in which the oil content is 700-1200 mg / L, wherein the added volume is 10 mg / L; and after stirring the mixture for 20-40 minutes, performing separation by standing, wherein the oily wastewater treatment agent consists of a demulsifier, a flocculant and a surfactant and a solvent; and components in parts by mass are: 25-35 parts of the demulsifier, 5-10 parts of the flocculant, 5-10 parts of the surfactant, and 50-80 parts of the solvent. The oily wastewater treatment agent can simultaneously have effects of demulsification, flocculation, bridging and bubbling. According to the treatment method of the present invention, the composite oily wastewater treatment agent has high efficiency in removing oil with small dosage, and is particularly applicable to treatment of wastewater that contains high concentration of oil.

Owner:李平兰

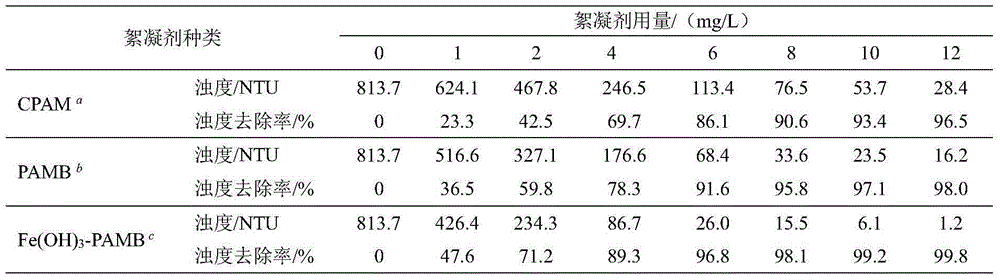

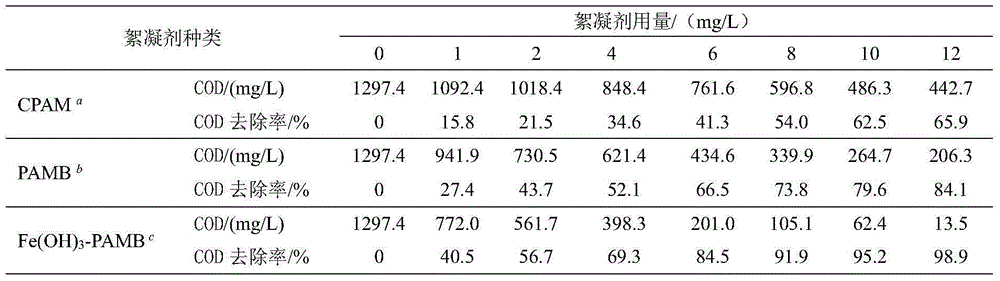

Preparation method of nano-Fe(OH)3-containing acrylamide-grafted copolymer flocculant

InactiveCN105218758AWill not cause secondary pollutionHigh molecular weightWater/sewage treatment by flocculation/precipitationPotassium persulfateReaction temperature

The invention discloses a preparation method of a nano-Fe(OH)3-containing acrylamide-grafted copolymer flocculant. The method is characterized in that 100 mL of a 100 g / L FeCl3 ethylene glycol solution is added to a three-neck reaction flask, 90-300 ml of a 40 g / L NaOH ethylene glycol solution is slowly added in the stirring state, the mixture reacts at the reaction temperature of 120-160 DEG C for 2-4 h in the rapid stirring state and then the product after reaction is cooled to the room temperature, reaction products are centrifugally separated and washed with deionized water, and nano-Fe(OH)3 is prepared; 20 parts of acrylamide are added to the three-neck reaction flask, then 150-600 parts of deionized water and 1.0-12 parts of trimethyl hexadecyl ammonium chloride are added, the mixture is stirred, 0.5-8 parts of the nano-Fe(OH)3 are added in the stirring state, 8-40 parts of cationic monomers and 0.8-10 parts of macromonomers are added, the mixture is stirred for 30 min, the pH value is 5-8, N2 is introduced for 30 min, 0.02-0.6 parts of an initiator, namely, potassium persulfate, is added at the temperature of 50-75 DEG C, the mixture reacts for 8-24 h, and the nano-Fe(OH)3-containing acrylamide-grafted copolymer flocculant Fe(OH)3-PAMB with excellent coagulation performance is prepared.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Multifunctional treating agent for oilfield sewage

InactiveCN105084435AReduce dosageHigh oil removal rateWaste water treatment from quariesFatty/oily/floating substances removal devicesHigh concentrationFlocculation

The invention relates to a multifunctional treating agent for oilfield sewage, which is composed of the following components in parts by weight: 15-25 parts of demulsifier, 10-20 parts of flocculant, 20-25 parts of corrosion inhibitor, 5-10 parts of surfactant and 5-8 parts of bactericide. The treating agent can simultaneously perform the functions of demulsification, flocculation, bridging, foaming, corrosion and scale inhibition, and sterilization. The composite oily sewage treating agent has the advantages of low consumption, high oil removal rate and obvious corrosion and scale inhibition effects, and is especially suitable for treating high-concentration oilfield sewage.

Owner:张哲夫

Conductivity composite material and capacitor

InactiveCN101303910AImprove heat resistanceImprove long-term stabilitySolid electrolytic capacitorsHybrid capacitor electrodesElectrolysisConductive polymer

A conductive composite material comprises a conductive polymer and a dielectric body with the dielectric constant above 3. The conductive composite material has the advantages of enhancing clinging performance, membrane manufacturing performance and bridging performance on a substrate, fine stability of conductivity against external environment, heat resistance and long-term stability. A solid electrolytic layer of a solid electrolytic capacitor comprises the conductive polymer and the dielectric body with the dielectric constant above 3. The solid electrolytic capacitor can get the solid electrolytic capacitor with low ESR and high capacity and the performance of the solid electrolytic capacitor can be maintained even under the condition of a high temperature.

Owner:宁俊禄 +1

Composite sludge dehydrating conditioner prepared from papermaking sludge and preparation method of composite sludge hydrating conditioner

InactiveCN104445862ARealize resource utilizationAchieve reuseSludge treatment by de-watering/drying/thickeningLignin derivativesResource utilizationPapermaking

The invention belongs to the fields of environmental protection and resource utilization of solid waste papermaking sludge, and particularly relates to a method of preparing a sludge dehydrating conditioner by taking papermaking sludge as a main raw material and compounding the papermaking sludge with poly(aluminum chloride) and polyacrylamide. The method comprises the following steps: dissolving lignin in the papermaking sludge by using water and a sodium hydroxide liquid; acidifying the filtrate by a sulfuric acid solution, filtering and drying precipitates to obtain the lignin; and uniformly mixing the lignin with the poly(aluminum chloride) and polyacrylamide in a weight part ratio of (8-16) to (0.8-2.4) to (0.02-0.04) to obtain the composite sludge dehydrating conditioner. The composite sludge dehydrating conditioner takes the papermaking sludge as the main raw material, the whole preparation process is simple, and the raw material is solid waste, so that not only is a pollution problem of the papermaking sludge on the environment solved, but also the specific resistance of the sludge can be obviously reduced and the moisture content of the sludge can be lowered by virtue of the conditioner, and therefore, a purpose of recycling the papermaking sludge to treat waste with waste is realized.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

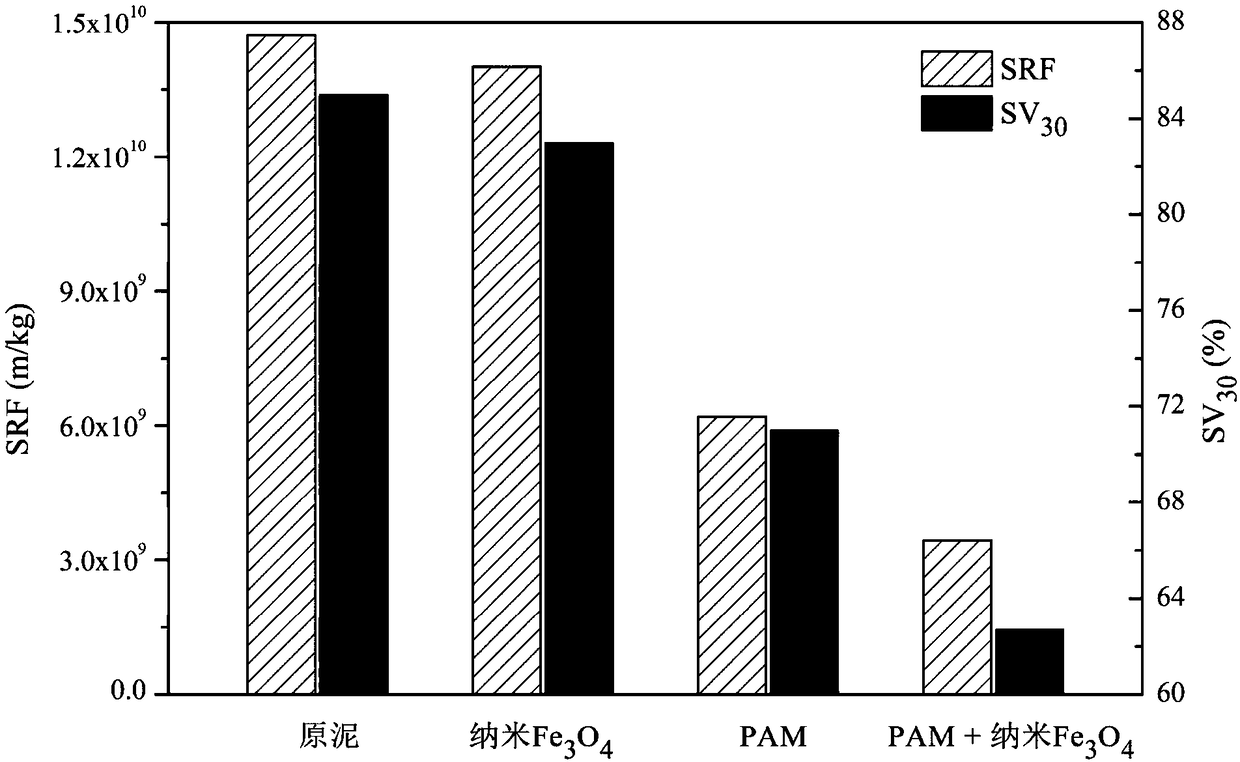

Treatment method for rapidly improving settling and dewatering performances of sludge

InactiveCN109467303ASettling fastImprove the coagulation effectSludge treatment by de-watering/drying/thickeningFiltrationSludge

The invention belongs to the technical field of sludge treatment, and specifically relates to a method for rapidly improving the settling and dewatering performances of sludge. The method comprises the following steps: adjusting the sludge water content and pH; mixing sludge and cationic polyacrylamide (PAM), continuously adding nanometer ferroferric oxide (Fe3O4), performing suction filtration dewatering on conditioned sludge, and performing rapid settling under magnetic action. The method cooperatively treats the sludge through charge neutralization and net capturing of polyacrylamide in combination with the adsorption effect of the nanometer ferroferric oxide, can obviously improve the settling and dewatering performances of the sludge, and realizes sludge rapid settling, and the promotion of the method has important environmental ecological significance on sludge treatment and disposal in China.

Owner:HUNAN UNIV

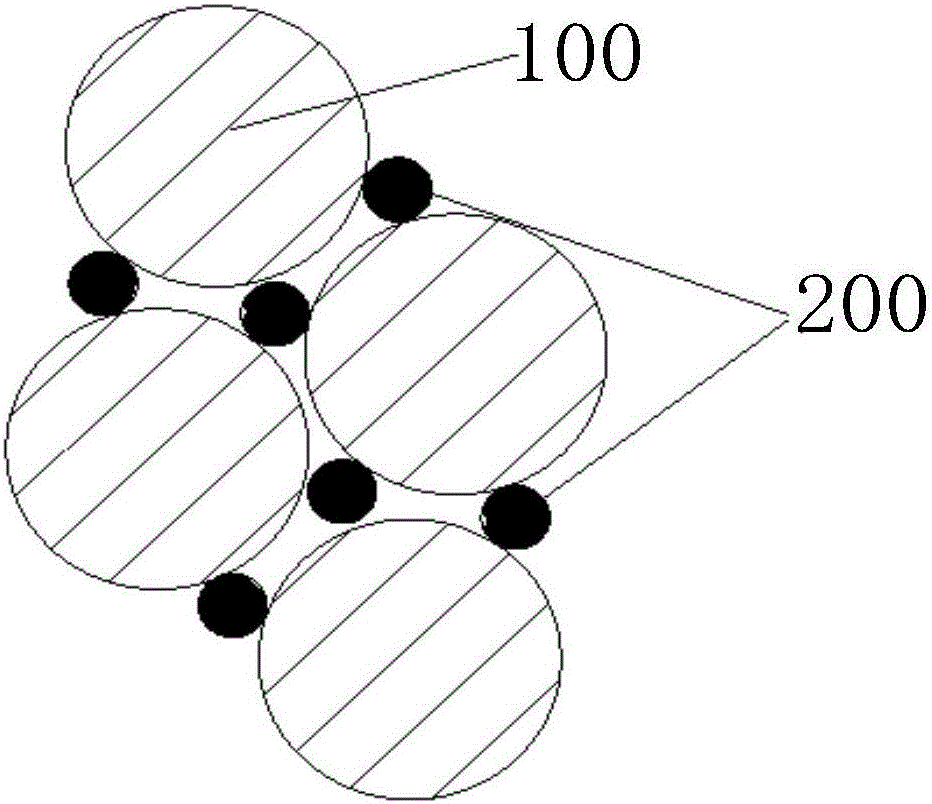

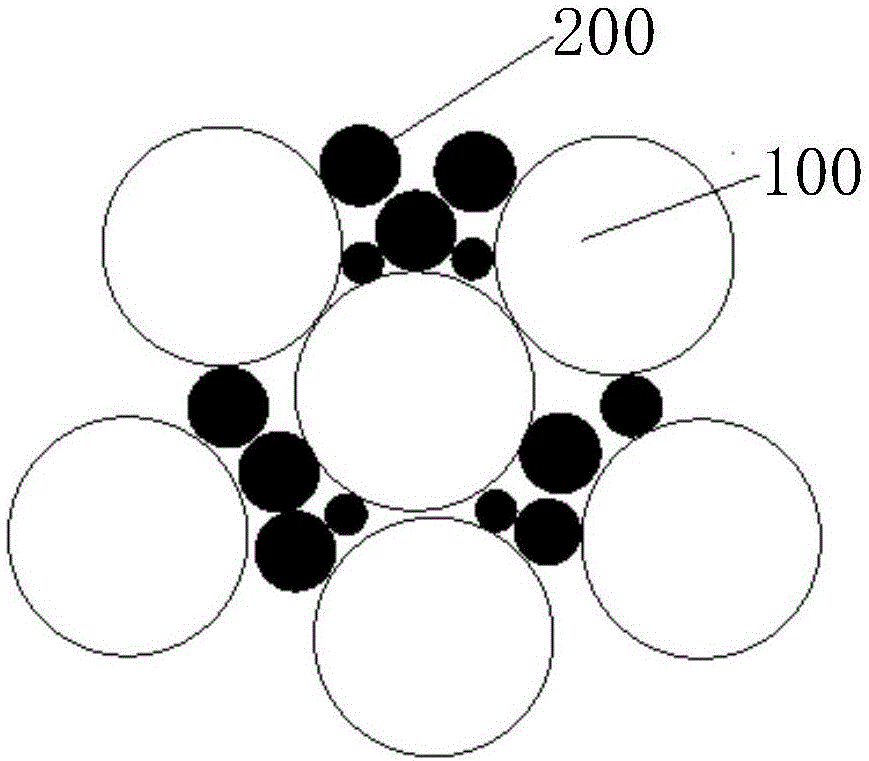

High-speed tool steel for sintering procedure of metal injection molding

InactiveCN106702281ASolve the problem of narrow sintering windowImprove mechanical propertiesTransportation and packagingMetal-working apparatusAlloyMetal powder

The invention discloses high-speed tool steel for the sintering procedure of metal injection molding. The high-speed tool steel comprises a first powder body and a second powder body. The first powder body is the mother alloy phase metal powder body, and the second powder body is the ultrafine metal powder body or the nanometer metal powder body. According to the high-speed tool steel for the sintering procedure of metal injection molding, by adding the ultrafine metal powder body or the nanometer metal powder body of the proper proportion, the sintering temperature of the high-speed tool steel material is lowered, the problem of the narrow sintering window of the high-speed tool steel is solved, the product density is increased, and mechanical performance is improved; and the irregular metal powder bodies of the proper proportions play a bridging role among the components, so that deformation in the sintering process is avoided.

Owner:深圳市卡德姆科技有限公司

Natural composite polyaluminium chloride water treatment agent and preparation method thereof

PendingCN111573798ALarge specific surface areaGood water solubilityWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionEnvironmental chemistryPolyacrylamide

The invention provides a natural composite polyaluminium chloride water treatment agent and a preparation method thereof. The water treatment agent is mainly prepared from polyaluminium chloride, polyacrylamide modified starch, etherified modified chitosan and glacial acetic acid. The quaternary ammonium salt modified starch is good in water solubility and can play a role in charge neutralizationand bridge adsorption with particles in water, so that the particles in the system are destabilized and flocculated, and etherified modified chitosan is stronger in electropositivity and more beneficial to flocculation. According to the method, colloidal particles in the water body can be strongly adsorbed through electric neutralization, adsorption bridging and net capturing effects by utilizingthe bridging effect of natural polymer substances and combining the charge neutralization effect of polyaluminum chloride, so that the colloid is flocculated and settled, the solubility of a treatmentagent is improved, the residual quantity of aluminum ions is reduced, and secondary pollution is avoided.

Owner:NANNING XIAYANG CHEM TECH CO LTD

Treatment method of acidic heavy metal wastewater

InactiveCN111995167AReduce solid wasteReduce dosageWater treatment compoundsWater contaminantsIron sulfateMagnesium salt

The invention provides a treatment method of acidic heavy metal wastewater. The method comprises the following steps: firstly, adding magnesium oxide with less slag amount as an acid removing agent into the acid wastewater to treat the acid wastewater; adjusting a pH value, removing most heavy metals capable of being precipitated and removed, and oxidizing and breaking complex metals and reducinghigh-valence chromium under the cooperative effect of a Fenton reagent; and adding polyacrylamide and polyferric sulfate coagulants to deeply remove the heavy metals. The method is suitable for treating acid heavy-metal-containing wastewater in the industries of metallurgy, electroplating and the like, can realize standard discharge of heavy metal pollutants and greatly reduces subsequent solid waste treatment cost due to the fact that the amount of generated solid waste is greatly reduced; and a magnesium salt in the wastewater can be crystallized and recycled.

Owner:NANNING XIAYANG CHEM TECH CO LTD

Conductive composite body, electric charge transmission material and organic luminous diode

InactiveCN101302352AFit closelyExcellent film performanceSolid-state devicesSemiconductor/solid-state device manufacturingTransport layerSolvent

The invention provides a conductive complex which is formed by a conducting polymer and a reactant of an unsaturated compound. The reaction of the unsaturated compound occurs in a solution containing a conducting polymer, a solvent, an oxidizer or catalyst. The conductive complex can enhance the close adherence and masking to a substrate and can maintain a low specific resistance even in a high temperature environment. A charge transport layer of an organic light emitting diode contains the conducting polymer and the reactant of the unsaturated compound. The organic light emitting diode of the conductive complex has high efficiency and long-term stability.

Owner:ZHENGZHOU TAIDA ELECTRONICS MATERIAL TECH

Narrow gap laser-arc hybrid welding method using filler wire

InactiveCN101474726BImprove welding efficiencySimple welding processLaser beam welding apparatusHigh power lasersEngineering

Owner:BEIJING UNIV OF TECH

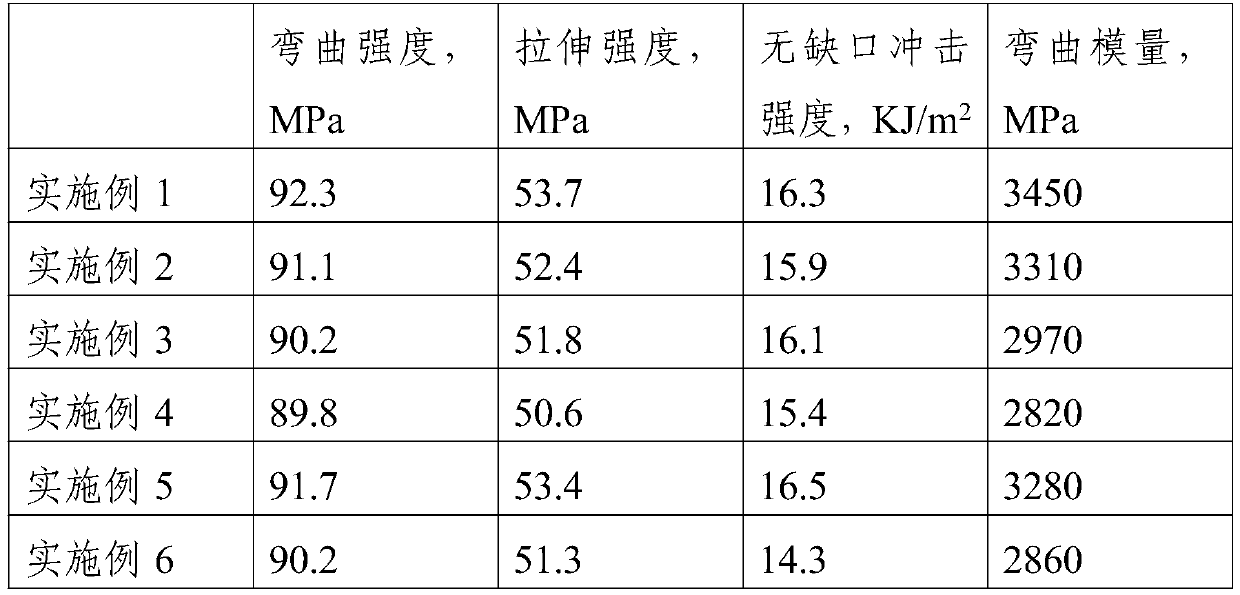

Light high-strength ABS wood-plastic foamed board and preparation method thereof

InactiveCN111073327AImprove reaction binding abilityImprove mechanical propertiesFoaming agentAcid anhydride

The invention provides a light high-strength ABS wood-plastic foamed board and a preparation method thereof. The wood-plastic foamed board is prepared from the following components in parts by weight:20-30 parts of ABS resin particles, 10-20 parts of maleic anhydride grafted ABS resin particles, 40-60 parts of wood flour, 5-10 parts of coated flame-retardant polypropylene fibers, 5-7 parts of modifier and 2-5 parts of foaming agent and 0-6 parts of a filler. Reasonable raw material selection and self-made pretreatment of part of raw materials are carried out, the reaction combination effect between the materials is effectively improved and the performance effect is higher; and the ABS is adopted as a board substrate, the comprehensive quality is good, the applicability is high, the prepared board is light, high in strength and excellent in corrosion resistance, mildew resistance, acid and alkali resistance, water resistance, heat preservation, flame retardance and the like, the mechanical property is remarkably improved, and the popularization and application value is high.

Owner:安徽智晟通讯科技有限公司

Preparation method of copper plating brightening agent

The invention relates to a preparation method of a copper plating brightening agent, and belongs to the technical field of additives for copper plating. Firstly, sodium hydroxide is used for activating chitosan to improve the activity, and is mixed with sorbitol and anacardol; through use of the mixture and through mixing, the chitosan and epoxy chloropropane are cross-linked to improve the bridging capacity; meanwhile, the anacardol is used as raw materials, and is combined with the modified chitosan; then, sulfamic acid is used to form an anacardol type anionic active agent under the catalyst effect; and meanwhile, acrylamide is polymerized to form polymerized acrylamide, which is combined on biomass negative ions. Products are used for absorbing copper ions in use; under the effect of the modified chitosan, the growth of crystal nucleuses is accelerated; and dodecylbenzene sulfonic acid is used for improving the dispersivity, so that the growth speed of grains is lower than the growth speed of the crystal nucleuses, the crystal refining is improved, and the brightening effect is improved.

Owner:江西鹏凯环保工程设备有限公司

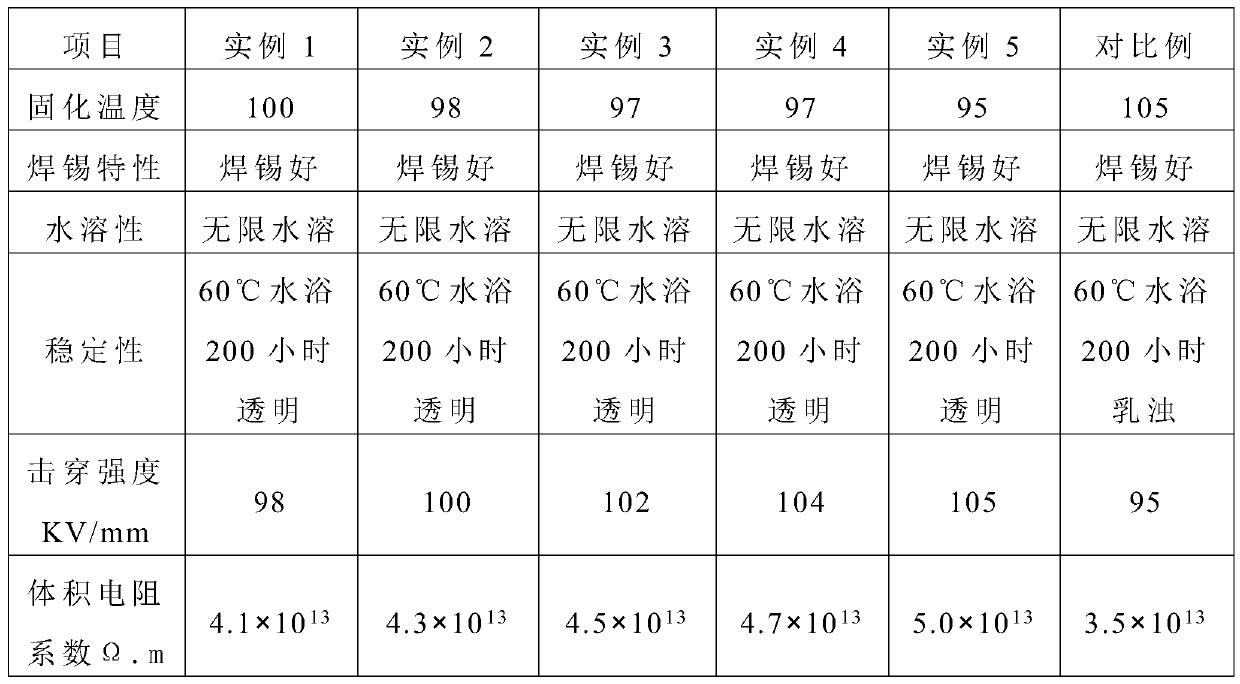

A kind of water-based insulating varnish and preparation method thereof

ActiveCN108997932BSimple manufacturing methodRaw materials are easy to getFireproof paintsAnti-corrosive paintsPolymer scienceBoron fiber

The invention provides a water-based insulating varnish. The water-based insulating varnish is prepared from the following components in parts by weight: 60-70 parts of polyether modified imidazolidinedione organosilicon polycondensate, 20-30 parts of polyurethane modified hyperbranchedpolyethyleneimine, 5-10 parts of surface-modified boron nanofiber, 1-5 parts of a defoaming agent, 1-5 parts of aflatting agent, 1-3 parts of a neutralization stabilizer, 1-5 parts of a cosolvent, and 20-30 parts of water. The invention further discloses a preparation method of the water-based insulating varnish. The prepared water-based insulating varnish has more excellent electric performance, heat resistance, chemical resistance, mechanical performance and fire resistance, and the use is safer and environment-friendly.

Owner:山东晟宇涂业股份有限公司

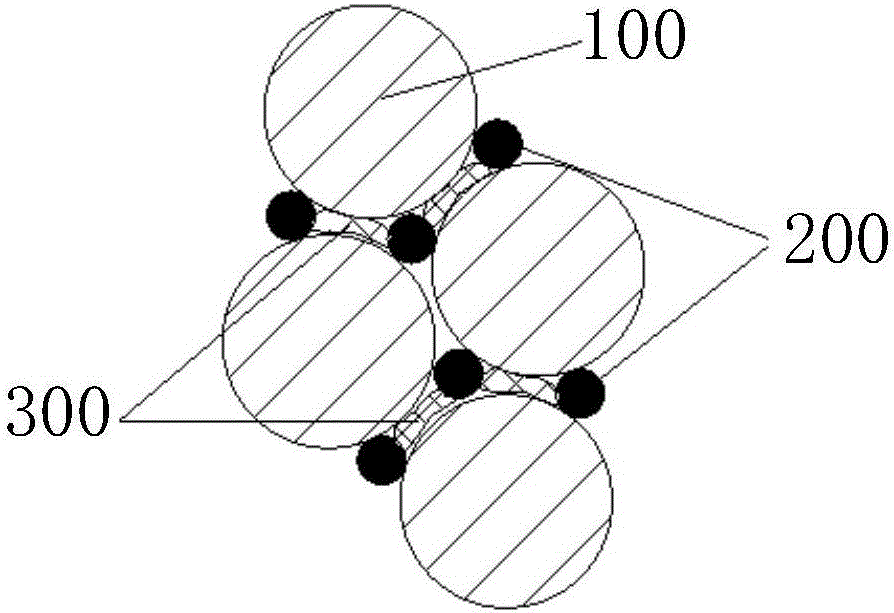

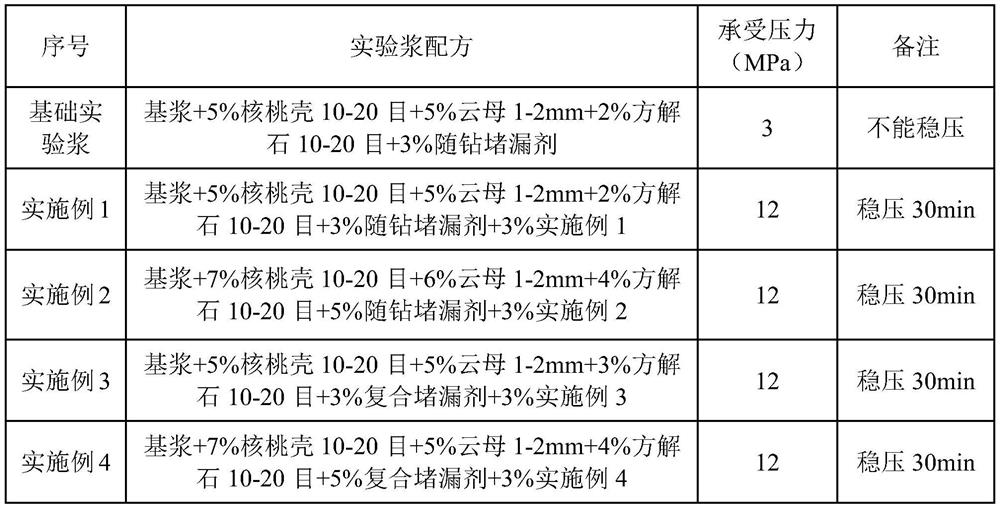

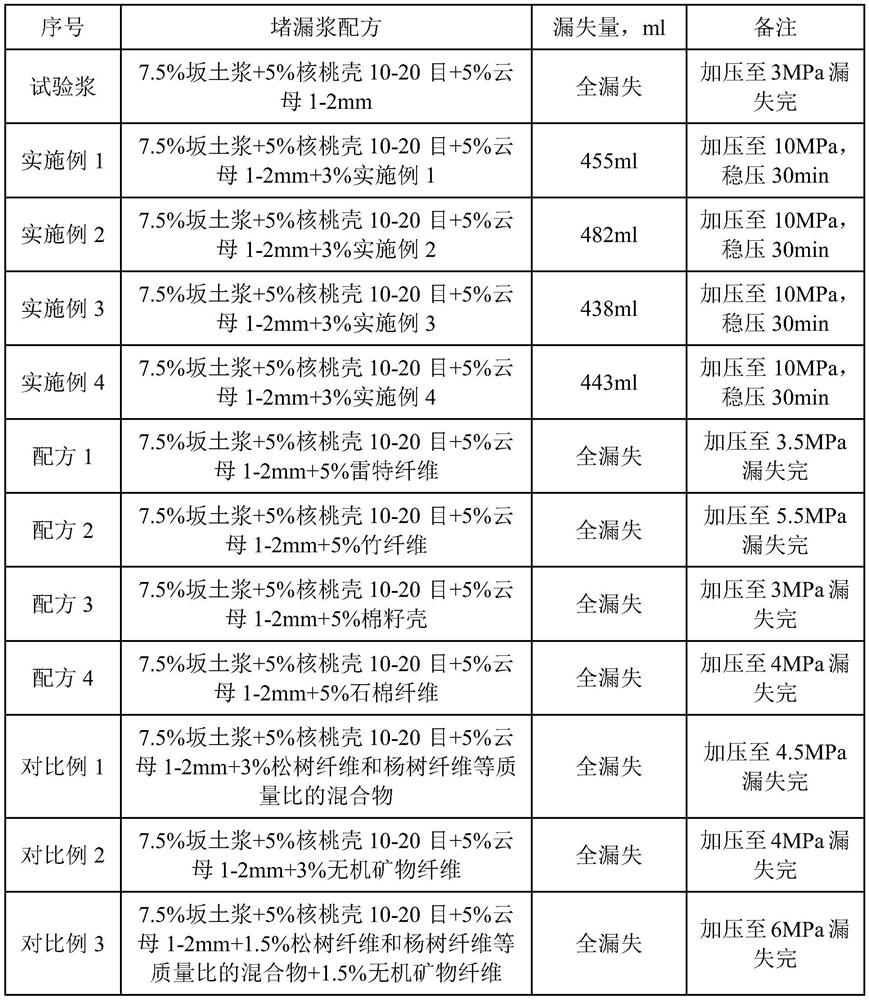

Bridge plugging synergist for drilling fluid

PendingCN112480885AImprove plugging success rateStrong bridging abilityDrilling compositionCarbon fibersPhysical chemistry

The invention discloses a bridge plugging synergist for drilling fluid. The bridge plugging synergist comprises the following components in percentage by mass: 20-40% of wood fibers, 35-40% of inorganic mineral fibers, 20-30% of inorganic rigid particles and 5-10% of an inorganic reinforcing agent. The inorganic rigid particles are resin sand with the particle size of 200 meshes or a compound of the resin sand and ceramic powder; the inorganic mineral fiber is a combination of brucite fibers, aluminum silicate fibers and carbon fibers, wherein the brucite fibers are 1-3 mm in length and 0.5-16[mu] m in diameter, the aluminum silicate fibers are 2-4 mm in length and 0.7-20 [mu] m in diameter, and the carbon fibers are 1-4 mm in length and 0.5-18 [mu] m in diameter; wherein the mass ratio of the brucite fibers to the aluminum silicate fibers to the carbon fibers is 5: 4: 1. According to the bridge plugging synergist disclosed by the invention, through the cooperative use of the microfibers and the microparticles, microcracks can be effectively plugged, and the compactness of a bridge plug is improved, so that the pressure bearing capacity is enhanced.

Owner:ASTAR PETROTECH

Papermaking wastewater treatment method

ActiveCN105036429AReduce dosageImprove adsorption capacityMultistage water/sewage treatmentWaste water treatment from plant processingHigh concentrationLiquid waste

The invention relates to a papermaking wastewater treatment method. The papermaking wastewater treatment method comprises the following steps: (1) enabling papermaking wastewater to pass through a grating at first to filter large-sized impurities in wastewater and then to flow into an adjusting sedimentation tank; (2) adding diacetone acrylamide, polyoxyethylene alkyl amine, polyacrylamide and tetradecyl dimethyl ammonium chilride, and leaving to stand after stirring; (3) adding etherified starch, bentonite, potassium alginate and sodium 3-nitrobenzene sulfonate into papermaking wastewater, and leaving to stand after stirring; (4) adding a polyoxypropylene diol I, pentaerythritol, polyoxyethylene fatty alcohol, a polyoxypropylene diol II and alpha-aminoisocaproic acid, leaving to stand after stirring, and carrying out filtering to remove sediments and impurities; (5) feeding filtering clear liquid obtained in the step (4) into an ultraviolet disinfection tank for ultraviolet sterilization and disinfection. The papermaking wastewater treatment method is low in consumption of a treating agent, and particularly suitable for treating high-concentration papermaking wastewater.

Owner:深圳研源环境科技有限公司

Catalyst for alkaline hydrolysis of pyraclostrobin production wastewater, preparation method of catalyst and pretreatment method of pyraclostrobin production wastewater

ActiveCN111774092AImprove adsorption capacityStrong loadTreatment using aerobic processesOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMetal catalyst

The invention discloses a catalyst for alkaline hydrolysis of pyraclostrobin production wastewater, a preparation method of the catalyst and a pretreatment method of the pyraclostrobin production wastewater. The catalyst is obtained by curing modified biomass charcoal, an iron-based metal catalyst and sodium alginate which serve as raw materials under the crosslinking action of a crosslinking agent. The catalyst is used for pretreating pyraclostrobin production wastewater. The catalyst disclosed by the invention has the advantages of low cost, large specific surface area, large number of active sites, good dispersity, good stability, good catalytic performance and the like; the problems of poor activity, poor dispersion effect and the like in the existing iron-based metal catalyst are solved; the disclosed catalyst can achieve favorable treatment effect and enhance the biodegradability of the wastewater when being used for treating pyraclostrobin production wastewater, and has the advantages of high use value and favorable application prospects. The preparation method of the catalyst has the advantages of simple preparation process, mild preparation conditions, low cost, no secondary pollution and the like, is suitable for large-scale preparation, and is beneficial to industrial application.

Owner:HUNAN HAILI CHEM IND

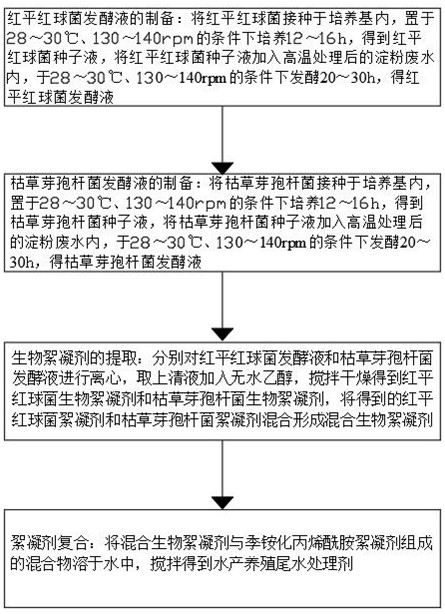

Aquaculture tail water treatment agent as well as preparation process and preparation device thereof

InactiveCN113072156ARealize integrationEasy to prepareBioreactor/fermenter combinationsBiological substance pretreatmentsAdsorption effectRhodococcus erythropolis

The invention discloses an aquaculture tail water treatment agent, which is prepared from the following ingredients in parts by weight: 30 to 40 parts of rhodococcus erythropolis flocculant, 20 to 30 parts of bacillus subtilis flocculant and 10 to 20 parts of quaternized acrylamide flocculant. The rhodococcus erythropolis flocculant and the bacillus subtilis flocculant are mixed to form a mixed biological flocculant, the mixed biological flocculant and the quaternized acrylamide flocculant are compounded to produce the aquaculture tail water treatment agent, and the prepared aquaculture tail water treatment agent has the advantages of being non-toxic, harmless, biodegradable and free of secondary pollution. The quaternized acrylamide flocculant is beneficial to improving the bridging effect and the characteristic adsorption effect of the aquaculture tail water treatment agent, and the flocculation performance is improved; meanwhile, the addition amount of the quaternized acrylamide flocculant is small, the raw materials of the mixed biological flocculant are low in price and easy to obtain, and the preparation cost is reduced; in addition, the preparation method is simple, rapid production of enterprises is facilitated, and the production cost of the enterprises is reduced.

Owner:济宁鑫惠生水产养殖专业合作社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com