Narrow gap laser-arc hybrid welding method using filler wire

A filling welding wire and composite welding technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that the joint quality is difficult to meet the use requirements, the stability of the welding process is difficult to guarantee, and the stability of the arc is affected. Assembly requirements, low welding cost, and the effect of increasing bridging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

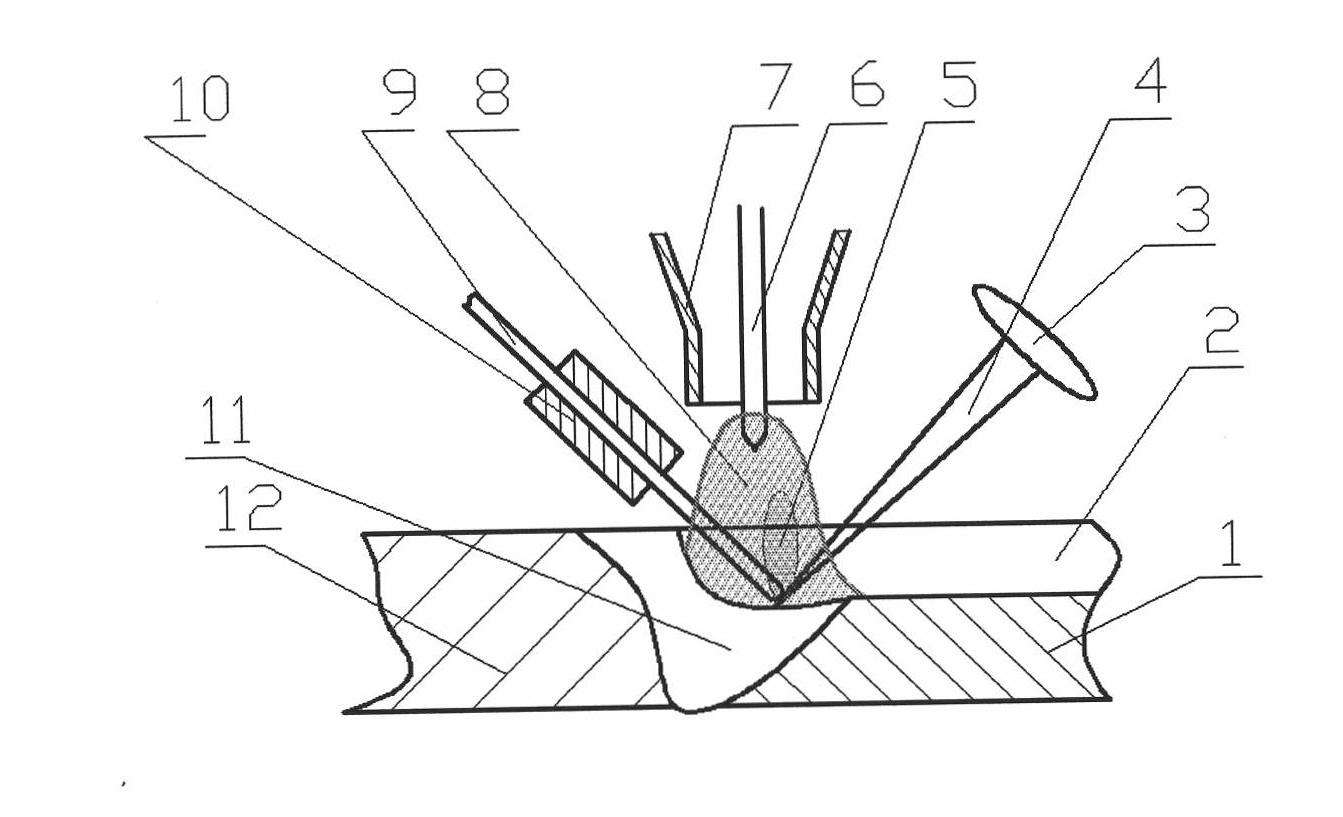

[0020] For the technical solution of this embodiment, refer to the appended figure 1 , Before welding, the workpiece is pre-grooved 2. During welding, the laser beam 4 and the welding wire 9 are longitudinally arranged symmetrically with respect to the TIG arc 8 , and the arc 8 is perpendicular to the surface of the workpiece 1 . The angle between the laser beam 4 and the surface of the workpiece 1 is 45°, and it is obliquely incident from the front of the arc 8 . The welding wire 9 is fed into the groove gap 2 from the rear of the arc 8, and the composite heat source composed of the laser beam 4 and the electric arc 8 melts the welding wire and fills the groove 2 to realize the single-pass welding of the workpiece 1.

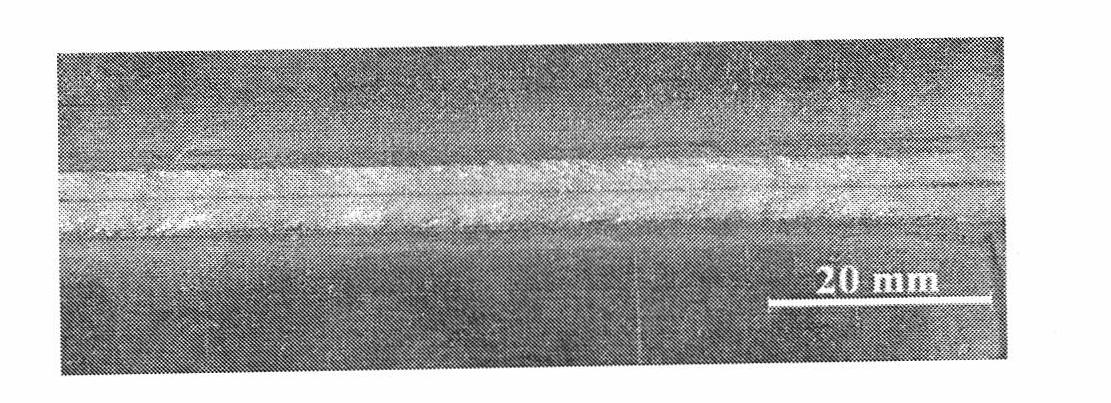

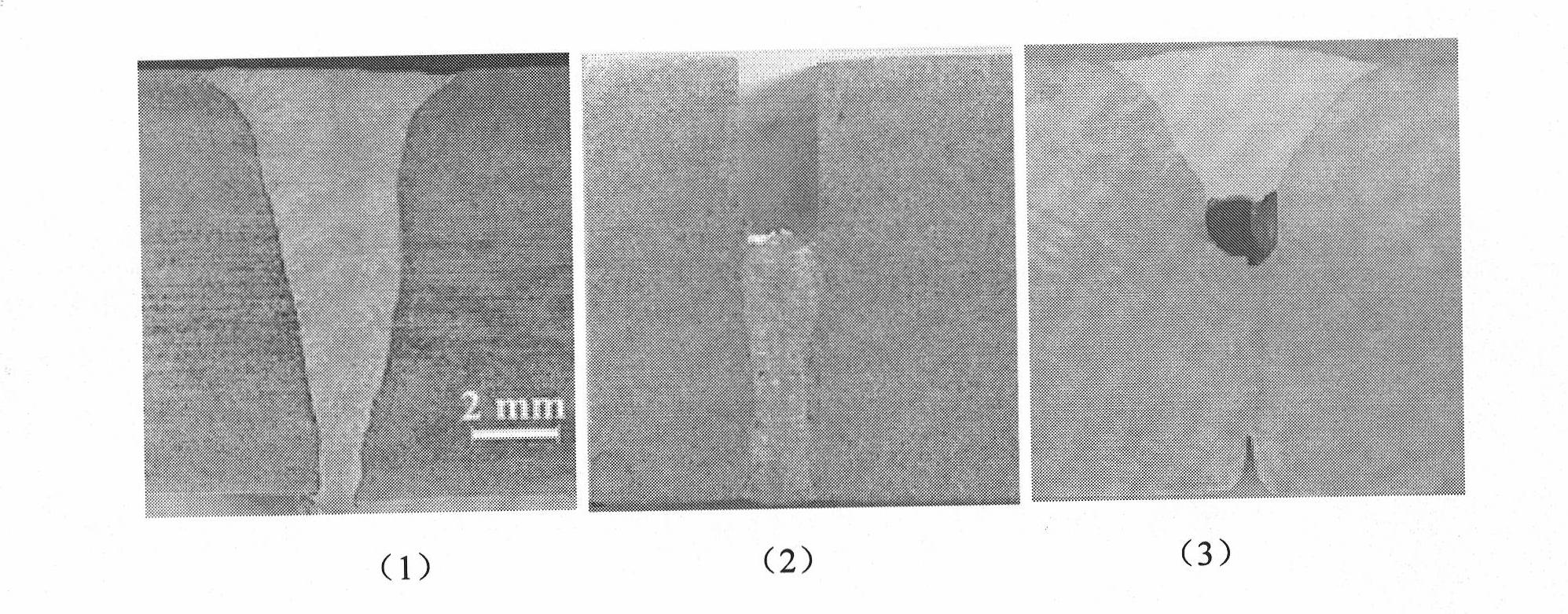

[0021] In this embodiment, the workpiece is a stainless steel plate with a thickness of 10 mm, the shape of the groove 2 is a U-shaped groove with a blunt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com