A kind of water-based insulating varnish and preparation method thereof

A kind of insulating paint, water-based technology, applied in the direction of coating, anti-corrosion coating, fire-proof coating, etc., can solve the problems of poor electrical insulation performance, accelerated bearing rust, poor storage stability, etc., to achieve improved adhesion and bridging ability , High water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

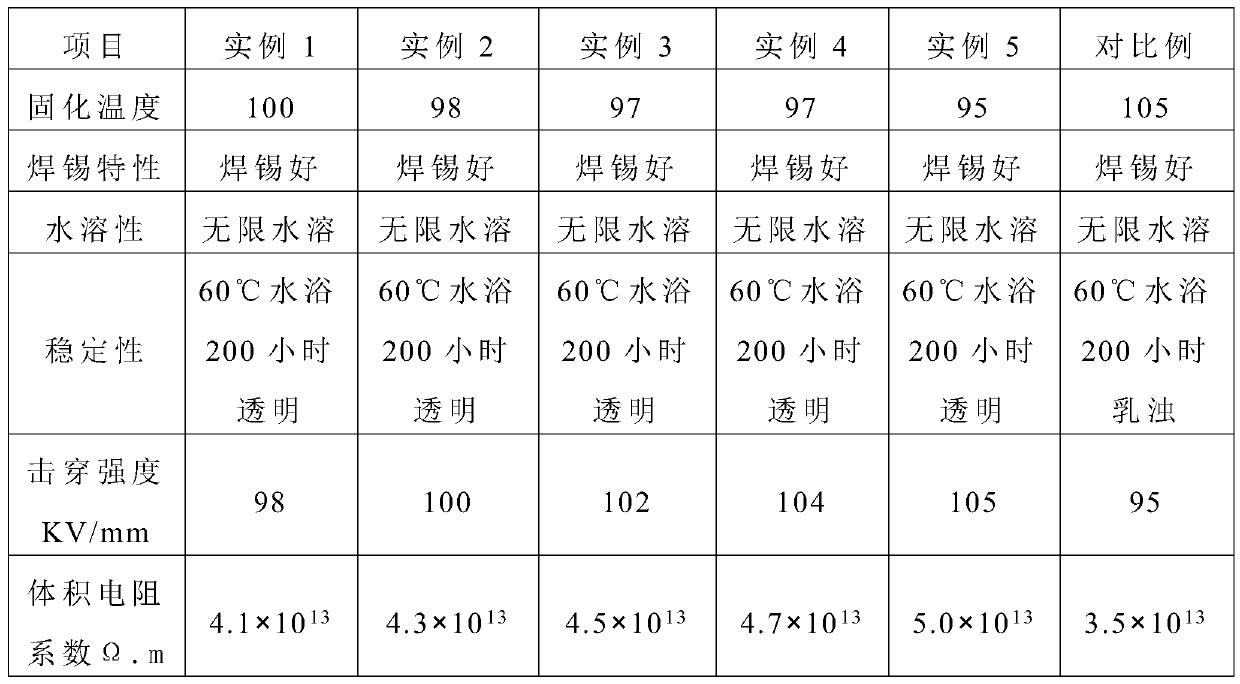

Examples

Embodiment 1

[0027] A water-based insulating varnish, made of the following components in parts by weight: 60 parts of polyether modified dimethylolhydantoin silicone polycondensate, 20 parts of polyurethane modified hyperbranched polyethyleneimine, surface modified nano boron fiber 5 parts, 1 part of polyoxyethylene polyoxypropanol amine ether, 1 part of polyacrylate leveling agent, 1 part of 2-amino-2-methyl-1-propanol, 1 part of ethanol, 20 parts of water.

[0028] The preparation method of polyether modified dimethylol hydantoin polycondensate comprises the steps of:

[0029] ⅠIn a three-neck flask equipped with a stirrer, a thermometer and a constant pressure dropping funnel, add 10g of dimethylolhydantoin, 11.2g of 1-chloropropylmethyldiethoxysilane, 60g of dimethyl sulfoxide and a catalyst 3g of dibutyltin dilaurate, raise the temperature to 75°C, add 1g of distilled water dropwise, stir and react at 90°C for 15 hours, and then remove dimethyl sulfoxide by rotary evaporation to obta...

Embodiment 2

[0035]A water-based insulating varnish, made of the following components in parts by weight: 63 parts of polyether-modified dimethylolhydantoin silicone polycondensate, 23 parts of polyurethane-modified hyperbranched polyethyleneimine, surface-modified nano boron fiber 6 parts, 2 parts of polydimethylsiloxane, 2 parts of cellulose acetate leveling agent, 2 parts of triethanolamine, 2 parts of isopropanol, 23 parts of water.

[0036] The preparation method of polyether modified dimethylol hydantoin polycondensate comprises the steps of:

[0037] ⅠIn a three-neck flask equipped with a stirrer, a thermometer, and a constant pressure dropping funnel, add 10 g of dimethylolhydantoin, 11.2 g of 1-chloropropylmethyldiethoxysilane, and N,N-dimethyl Formamide 70g and catalyst dibutyltin dilaurate 4g, raise the temperature to 78°C, then add 2g of distilled water dropwise, stir and react at 93°C for 16 hours, and then spin evaporate to remove N,N-dimethylformamide to obtain intermediate ...

Embodiment 3

[0043] A water-based insulating paint, made of the following components in parts by weight: 65 parts of polyether-modified dimethylolhydantoin silicone polycondensate, 25 parts of polyurethane-modified hyperbranched polyethyleneimine, surface-modified nano boron fiber 8 parts, polyoxypropylene glyceryl ether 3 parts, polyvinyl butyral leveling agent 3 parts, dimethylethanolamine 3 parts, ethylene glycol 3 parts, water 25 parts.

[0044] The preparation method of polyether modified dimethylol hydantoin polycondensate comprises the steps of:

[0045] ⅠIn a three-necked flask equipped with a stirrer, a thermometer and a constant pressure dropping funnel, add 10g of dimethylolhydantoin, 11.2g of 1-chloropropylmethyldiethoxysilane, 80g of N-methylpyrrolidone and The catalyst is 5g of dibutyltin dilaurate, raise the temperature to 80°C, then add 3g of distilled water dropwise, stir and react at 95°C for 16.5 hours, and then spin evaporate to remove N-methylpyrrolidone to obtain an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com