Bridge plugging synergist for drilling fluid

A technology of synergist and drilling fluid, applied in the field of drilling fluid plugging, can solve the problems of unreasonable particle gradation, unreasonable gradation, leakage and pressure bearing capacity, etc., so as to enhance the retention capacity and improve the success rate. , the effect of enhancing the ability of bridging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

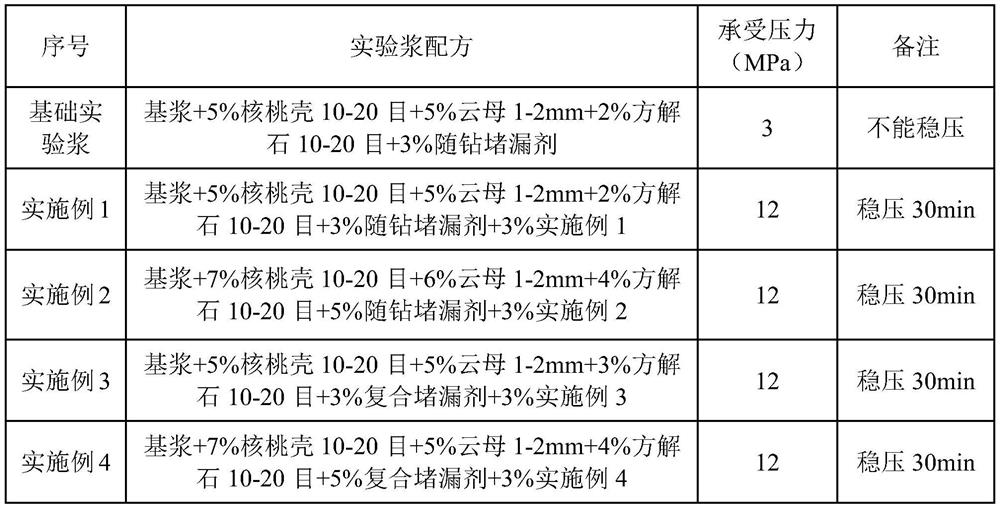

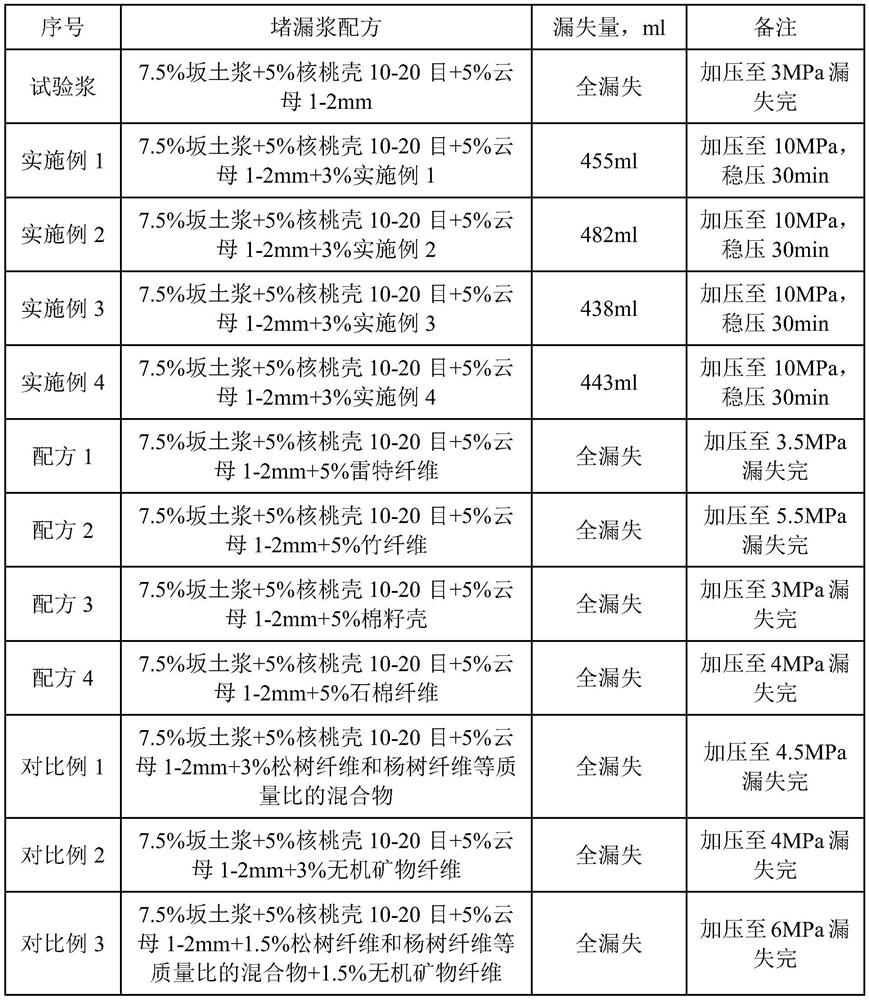

Examples

Embodiment 1

[0021] Components and mass ratio of a bridge plugging synergist for drilling fluid: 30% pine wood fiber, 40% inorganic mineral fiber, 25% resin sand, 5% inorganic reinforcing agent; wherein the gradation of inorganic mineral fiber is as follows: water magnesium Stone fiber: aluminum silicate fiber: carbon fiber = 5:4:1.

[0022] The product can be obtained after all components are mixed uniformly.

Embodiment 2

[0024] Components and mass ratio of a bridging synergist for drilling fluid: 40% poplar wood fiber, 30% inorganic mineral fiber, 20% compound of resin sand and ceramic powder in equal mass ratio, 10% inorganic reinforcement wherein the inorganic mineral fiber gradation is as follows: brucite fiber: aluminum silicate fiber: carbon fiber=5:4:1; wherein the ceramic powder particle gradation ratio is as follows: ceramic powder (2500 mesh): ceramic powder ( 1500 mesh): ceramic powder (800 mesh) = 4:4:2

[0025] The product can be obtained after all components are mixed uniformly.

Embodiment 3

[0027] Components and mass ratio of a bridging synergist for drilling fluid: 35% mixture of pine fiber and poplar fiber in equal mass ratio, 35% inorganic mineral fiber, 20% resin sand, 10% inorganic reinforcing agent; The mineral fiber gradation is as follows: brucite fiber: aluminum silicate fiber: carbon fiber = 5:4:1. The product can be obtained after all components are mixed uniformly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com