Low-pressure leakage layer blocking agent and preparation method thereof

A plugging agent and leakage technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as leakage, serious formation deficit, and poor anti-scourability of slurry, so as to prevent formation leakage and improve plugging The effect of missed success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

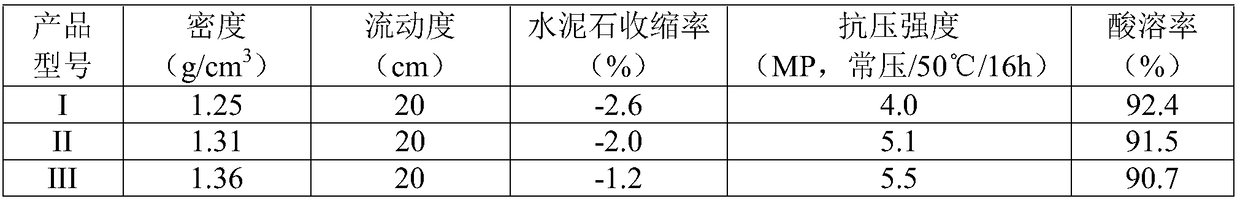

Embodiment 1

[0018] Weigh sodium bentonite and 1000-1500 mesh blast furnace slag at a weight ratio of 1:9 and mix to obtain 50 parts by weight of cementitious material, 50 parts by weight of limestone powder of 200-500 mesh, 8 parts by weight of sepiolite fiber of 1-2 mm, 0.1 part by weight of a stabilizer formed by mixing azodicarbonamide and p-toluenesulfonylhydrazide at a weight ratio of 1:3 and 1 part by weight of sodium carboxymethylcellulose, and mix it uniformly to obtain a uniformly mixed Solid mixture; take water glass and sodium hydroxide and mix to obtain 10 parts by weight of activator according to the weight ratio of 1:1.5, and add 139 parts of water, stir until completely dissolved, pour into the slurry cup of the corrugated mixer, and start Corrugated agitator motor and maintain a speed of 4000r / min±200r / min, slowly pour the uniformly mixed solid mixture into the mixing cup, stir evenly, and finally cover the lid of the mixing cup, and set the temperature at 12000r / min±500r / m...

Embodiment 2

[0020] Weigh sodium bentonite and 1000-1500 mesh blast furnace slag at a weight ratio of 1:7 to prepare 60 parts by weight of cementitious material, 50 parts by weight of 200-500 mesh limestone powder, and 7 parts by weight of sepiolite fiber of 1-2 mm , 0.1 parts by weight of a stabilizer and 1.5 parts by weight of sodium carboxymethylcellulose mixed by azodicarbonamide and p-toluenesulfonyl hydrazide in a weight ratio of 1:3, and mix it uniformly to obtain a uniform mixture The solid mixture of 1:1.5 by weight takes water glass and sodium hydroxide and mixes the activator that makes 8.5 parts by weight, and adds 125 parts of water, stirs to after dissolving completely, pours in the slurry cup of corrugated stirrer, Start the motor of the corrugated mixer and maintain the speed of 4000r / min±200r / min, slowly pour the evenly mixed solid mixture into the mixing cup, stir evenly, and finally cover the lid of the mixing cup, and set it at 12000r / min±500r Stirring was continued for...

Embodiment 3

[0022] Weigh sodium bentonite and 1000-1500 mesh blast furnace slag at a weight ratio of 1:7 to prepare 75 parts by weight of cementitious material, 60 parts by weight of 200-500 mesh limestone powder, and 5 parts by weight of sepiolite fiber of 1-2 mm , 0.2 parts by weight of a stabilizer mixed with azodicarbonamide and p-toluenesulfonylhydrazide in a weight ratio of 1:3 and 1 part by weight of sodium carboxymethyl cellulose, and mix it uniformly to obtain a uniform mixture The solid mixture of 1:1.3 by weight takes water glass and sodium hydroxide and mixes the activator that makes 9 parts by weight, and adds 135 parts of water, after stirring to fully dissolving, pour in the slurry cup of corrugated stirrer, Start the motor of the corrugated mixer and maintain the speed of 4000r / min±200r / min, slowly pour the evenly mixed solid mixture into the mixing cup, stir evenly, and finally cover the lid of the mixing cup, and set it at 12000r / min±500r Stirring was continued for 35 s ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com