Modified brine workover fluid and preparation method thereof

A technology for workover fluid and brine, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as easy leakage, and achieve the effect of easy flowback and good leakage blocking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0099] In the second aspect, the embodiment of the present invention provides a method for preparing the above-mentioned modified brine workover fluid, which specifically includes the following steps:

[0100] According to the proportion, add the modifier that prevents brine scaling into the brine and stir it evenly, then add the viscosifying suspending agent, stir the viscosifying suspending agent until it is evenly dispersed, then add the salt-resistant loss-stopping agent, oil-soluble resin and drilling The unidirectional pressure sealing agent is used for the liquid and the mixture is stirred and dispersed evenly to obtain the modified brine workover fluid.

[0101] It can be understood that different modifiers for preventing brine scaling are added according to different brines. For the preparation method of the modifier that prevents brine scaling, refer to the Chinese patent application with the above-mentioned application number of 201510907377.X and the title of the i...

Embodiment 1

[0112] This example provides the formulation and preparation method of the salt-resistant leakage plugging agent, and evaluates the performance of the salt-resistant leakage plugging agent.

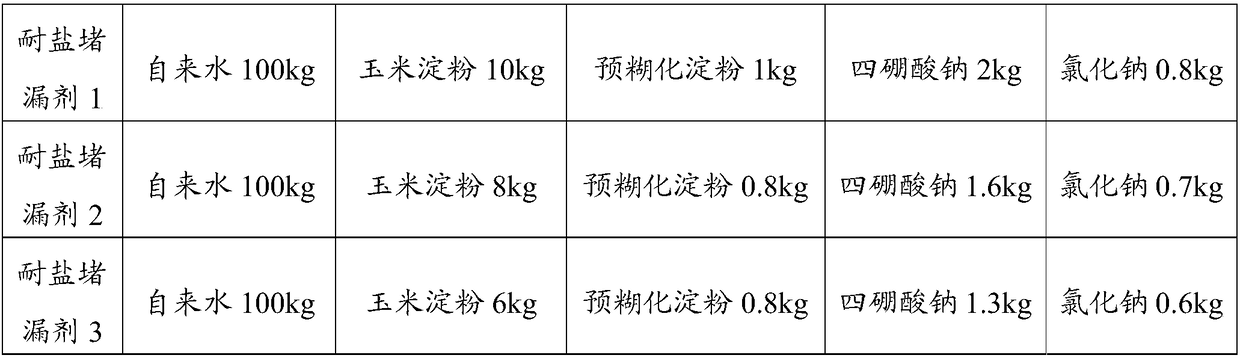

[0113] Table 1 shows the raw material formulation of the salt-resistant leak-stopping agent in this example.

[0114] Table 1

[0115]

[0116] The preparation method of the salt-resistant leak-stopping agent of the present embodiment is as follows:

[0117] Step 1, add 75kg of tap water to iron bucket A, then heat to boiling.

[0118] Step 2, add 25kg of tap water in the iron bucket B, then add sodium tetraborate according to the formula in Table 1, stir to dissolve the sodium tetraborate, then add pregelatinized starch and cornstarch, and stir to make the pregelatinized starch and cornstarch. Dissolve, then add sodium chloride and continue stirring to obtain an emulsion-like mixed solution.

[0119] Step 3, add the mixed solution obtained in the iron bucket B into the iron bucket ...

Embodiment 2

[0129] This example provides the formulation and preparation method of the thickening suspending agent, and evaluates the performance of the thickening and suspending agent.

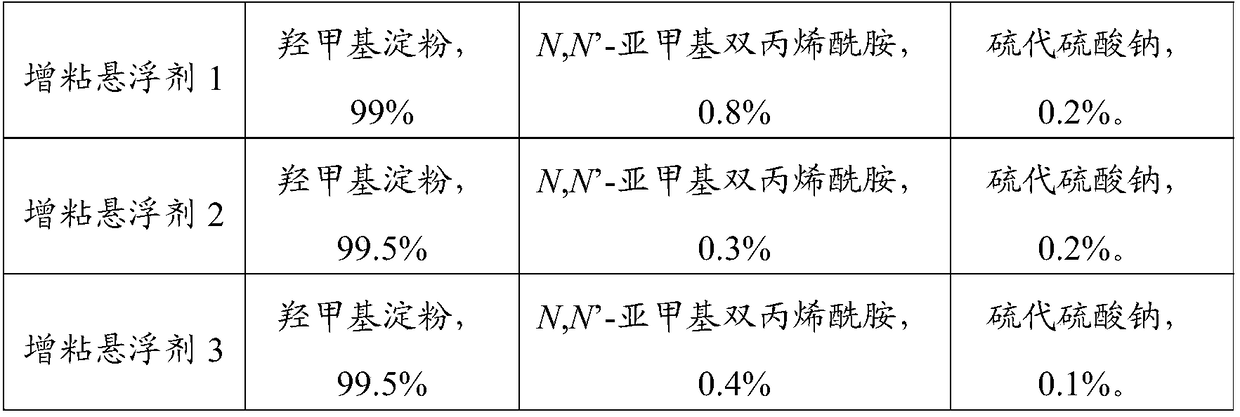

[0130] The formula of the thickening suspending agent of this example is shown in Table 3.

[0131] In this embodiment, the hydroxymethyl starch used is the product of Renqiu High-tech Chemical Materials Co., Ltd.

[0132] table 3

[0133]

[0134]

[0135] After mixing hydroxymethyl starch, N,N'-methylenebisacrylamide and sodium thiosulfate uniformly according to the formula in Table 3, the viscosity-increasing suspension modifier of the present embodiment is obtained. It is a white powdery solid.

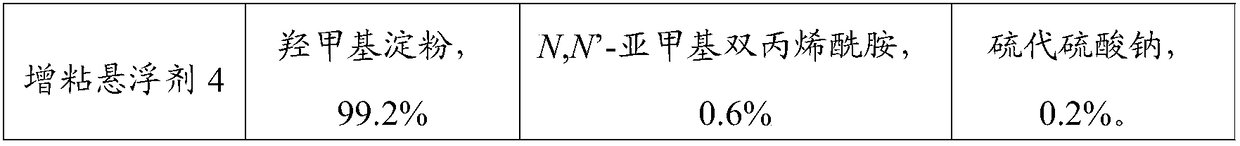

[0136] The viscosity-increasing effect of the viscosity-increasing suspending agent 4 in this example on brine workover fluid is evaluated below, and compared with partially hydrolyzed polyacrylamide (HPAM).

[0137] The viscosity-increasing suspending agent 4 was added to the brine and calcium brin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Salinity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com