Preparation and application of anionic clean fracturing liquid and gel breaker thereof

A technology for cleaning fracturing fluids and anions, which can be used in drilling compositions, production fluids, boreholes/well components, etc., and can solve the problem of high cost of zwitterionic surfactants, increased resistance to oil and gas flow, and difficulty in large-scale promotion and use and other problems, to achieve the effect of good sand carrying performance, high safety, and satisfying large-scale promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Dissolve 15g of sodium lauryl polyoxyethyl ether sulfate in 437g of water as liquid A, dissolve 110g of sodium chloride in 437g of water as liquid B, add liquid A into liquid B and stir fully to obtain a viscoelastic fluid and stir until uniform, forming The clear and translucent anion cleaning fracturing fluid of the present invention has a certain viscosity.

[0039] After the fracturing is completed, weigh 2 g of sodium dimethylbenzene sulfonate, and add the weighed sodium dimethylbenzene sulfonate into water of the same volume as the proppant used in the actual site to form a clear and transparent gel breaker.

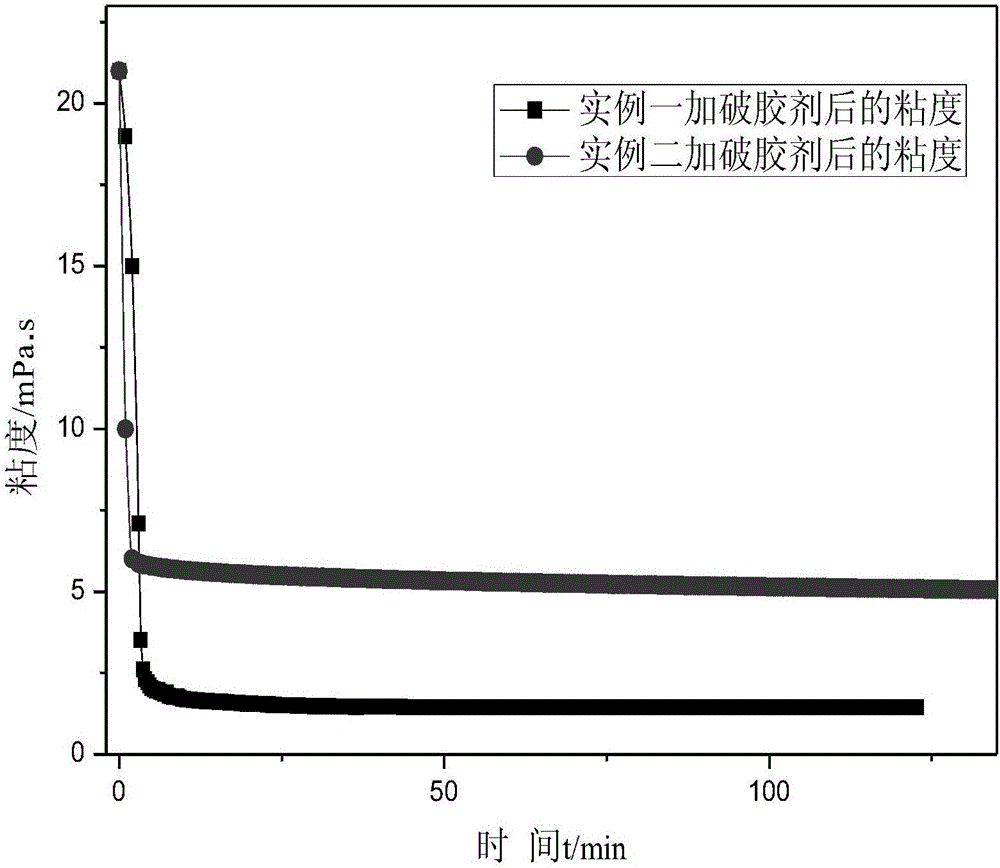

[0040] During fracturing, the pre-fluid, sand-carrying fluid, and displacement fluid are injected in sequence, and the clean fracturing fluid of the present invention is used for the pre-fluid, sand-carrying fluid, and displacement fluid. The rheological curve of the viscoelastic fluid after adding the breaker is as follows figure 1 shown.

Embodiment 2

[0042] Dissolve 15g of sodium lauryl polyoxyethyl ether sulfate in 457g of water as liquid A, dissolve 70g of potassium chloride in 457g of water as liquid A, add liquid A into liquid B and stir fully to obtain a viscoelastic fluid and stir until uniform, forming The clear and translucent anion cleaning fracturing fluid of the present invention has a certain viscosity.

[0043]After the fracturing is completed, weigh 1g of cetyltrimethylammonium bromide, and add the weighed cetyltrimethylammonium bromide into water with the same volume as the proppant used in the actual site to form a clarified Transparent breaker. During fracturing, the pre-fluid, sand-carrying fluid, and displacement fluid are injected in sequence, and the clean fracturing fluid of the present invention is used for the pre-fluid, sand-carrying fluid, and displacement fluid. The rheological curve of the viscoelastic fluid after adding the breaker is as follows figure 1 shown.

Embodiment 3

[0045] Dissolve 15 g of sodium lauryl polyoxyethyl ether sulfate in 437 g of water as liquid A, and dissolve 110 g of ammonium chloride in 437 g of water as liquid B. Add liquid A into liquid B and stir thoroughly to obtain a viscoelastic fluid. Stir until uniform, forming The clear and translucent anion cleaning fracturing fluid of the present invention has a certain viscosity.

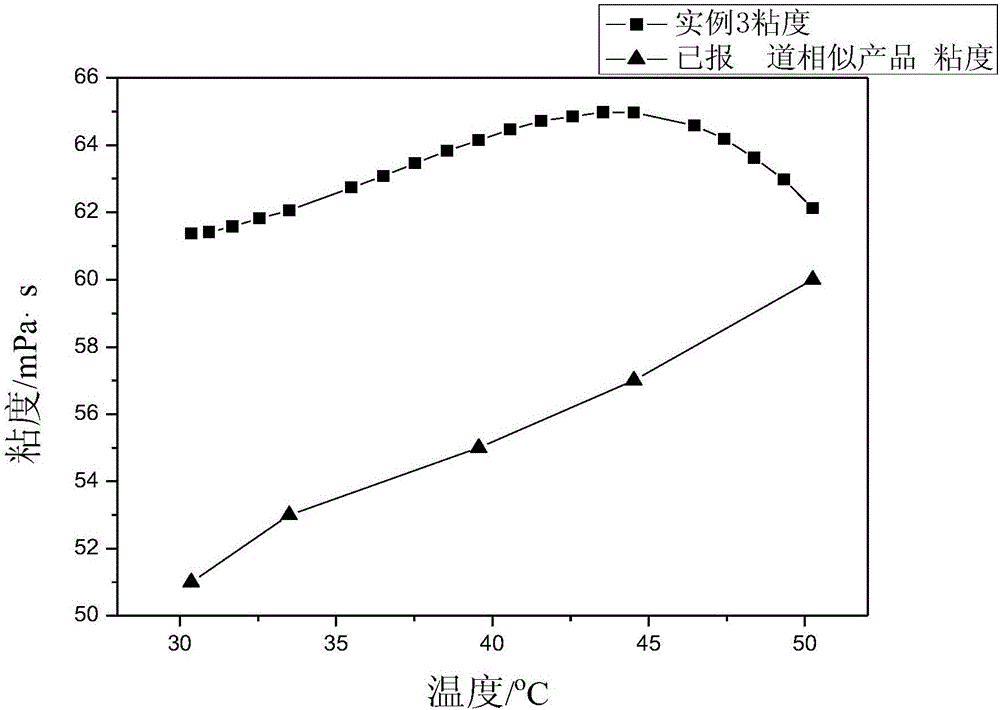

[0046] The preparation and injection sequence of the gel breaker is the same as in Example 1. During fracturing, the pre-fluid, sand-carrying fluid, and displacement fluid are injected in the order, and the pre-fluid, sand-carrying fluid, and displacement fluid all use the clean fracturing fluid of the present invention . The viscosity-temperature curve of anionic viscoelastic fluid fracturing fluid is as follows: figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com