Enhanced plugging gel and preparation method thereof

An enhanced, gel-based technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of difficult to achieve effective plugging and low jelly strength, so as to improve the success rate and pressure bearing capacity, and improve Effect of jelly strength and shear toughness, excellent penetrating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

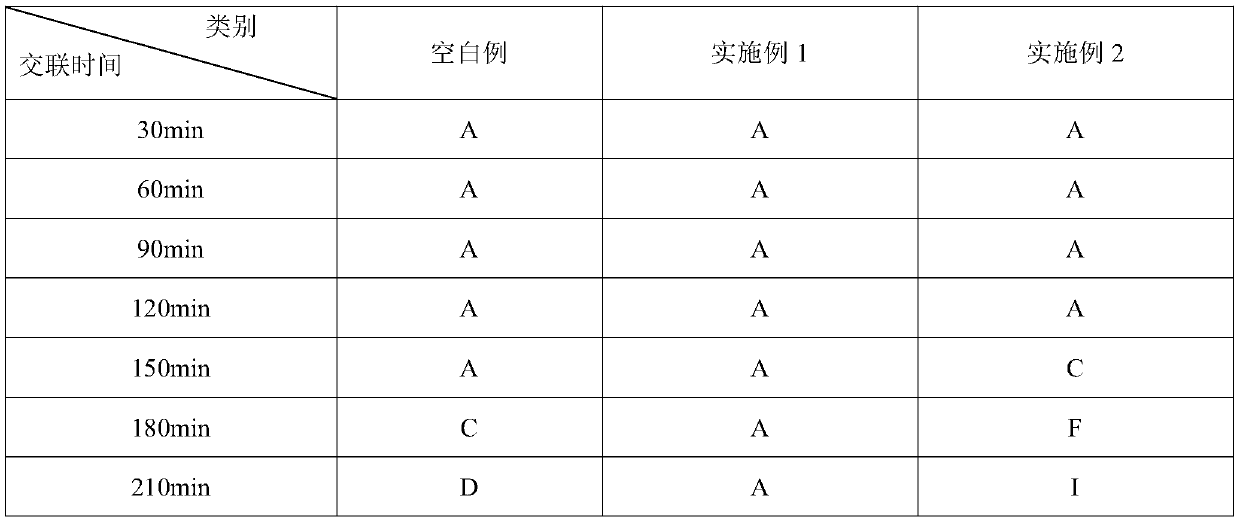

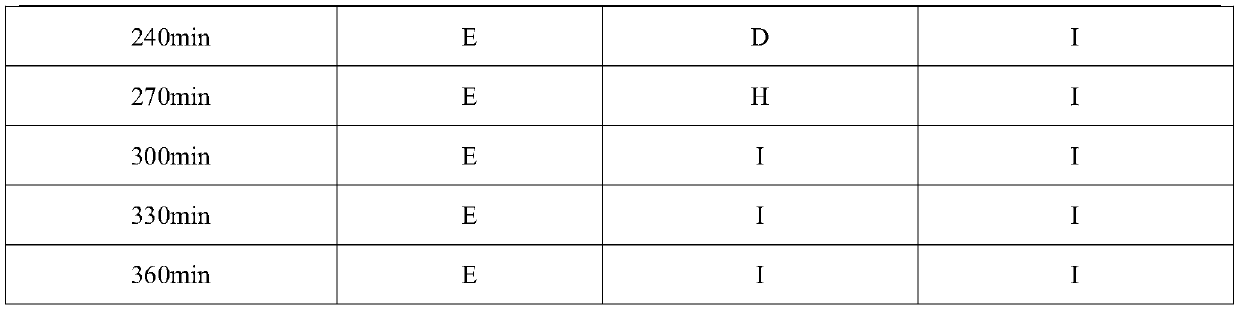

Embodiment 1

[0023] Dissolve 0.1wt% of thiourea in clear water, then add 0.8wt% of acrylamide and tert-butyl acrylate (PAtBA) with a molecular weight of 1.5 million and a degree of hydrolysis of 10wt% and 2wt% of 50nm silica powder , 1.2wt% 40-80 mesh walnut shell powder, 3wt% water-soluble phenolic resin cross-linking agent are fully mixed and dispersed into clean water, and continuously stirred for 0.5-1h to fully dissolve in the circulation temperature of 20-60°C to enhance The enhanced plugging gel base liquid is cross-linked for 2-12 hours to obtain the enhanced plugging gel material.

Embodiment 2

[0025] Dissolve 0.2wt% sodium bisulfite in clear water. Then, 1.5wt% of acrylamide with a molecular weight of 1 million and a degree of hydrolysis of 15wt% is cross-linked with acrylic acid and 3wt% of 40nm titanium dioxide powder, 3wt% of 40-80 mesh coconut shell powder, and 2.5wt% of water-soluble phenolic resin After the agent is fully mixed, it is dispersed into clear water, and it is continuously stirred for 0.5-1h to fully dissolve it at a circulating temperature of 90°C to obtain an enhanced plugging gel base fluid, which is cross-linked for 2-12h Finally, the enhanced plugging gel material is obtained.

Embodiment 3

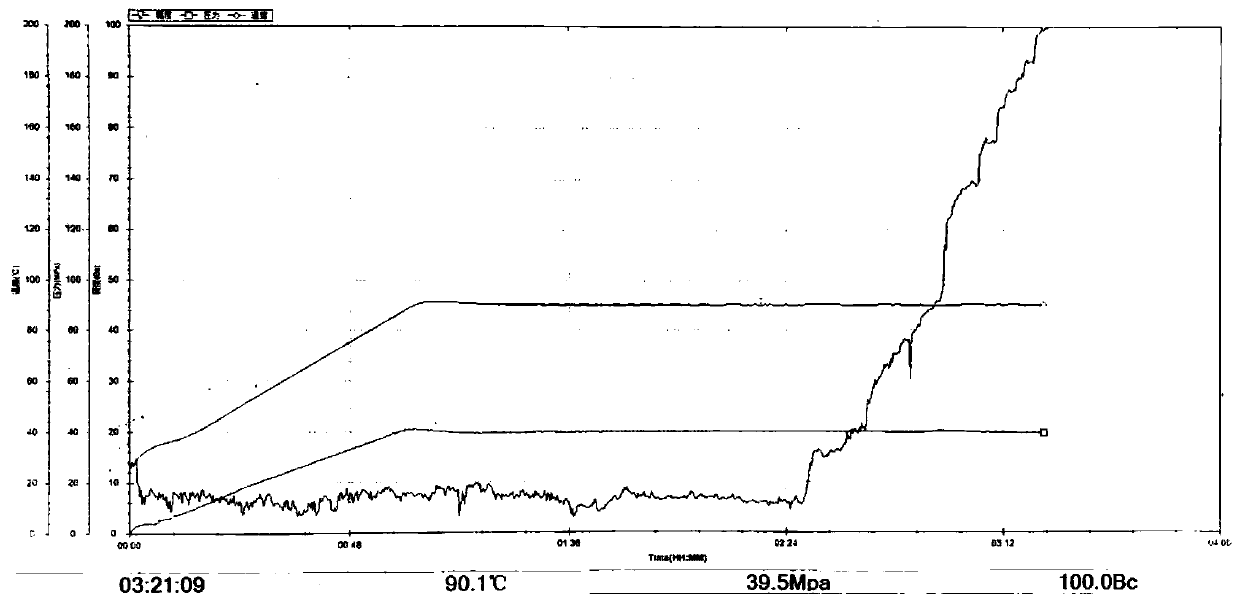

[0027] The enhanced plugging gel base fluid prepared in Example 1 was subjected to a high temperature and high pressure thickening test at 90°C and 40 MPa, and the crosslinking time was 200 minutes. The test results are as follows: figure 1 shown. From figure 1 It can be seen that under the dual effects of the existing cross-linking agent and composite reinforcing agent, on the one hand, the controllability of the cross-linking time of the gel is taken into account; The strength is effectively improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com