Patents

Literature

129results about How to "High oil removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complex microbial inoculant for restoring petroleum-contaminated soil in loess highlands and restoring method thereof

ActiveCN102794296AHigh oil removal rateEasy to handleContaminated soil reclamationMicroorganismDiammonium phosphate

The invention discloses a complex microbial inoculant for restoring petroleum-contaminated soil in loess highlands and a restoring method thereof. The microbial body of the complex microbial inoculant comprises Pseudomonas aeruginosa, Pseudomonas fulva, Acinetobacter lwoffii, Nocardioides luteus and Streptomyces flavoviridis. The invention provides a method for restoring petroleum-contaminated soil in loess highlands by using the complex microbial inoculant, which comprises the following steps of (1) carrying out pretreatment on contaminated soil; (2) degrading the contaminated soil; (3) covering a plastic film on the soil; and (4) adding water, urea, diammonium phosphate and the complex microbial inoculant. By using the method disclosed by the invention, the process is simple, the cost is low, and the degradation effect is significantly increased.

Owner:PETROCHINA CO LTD

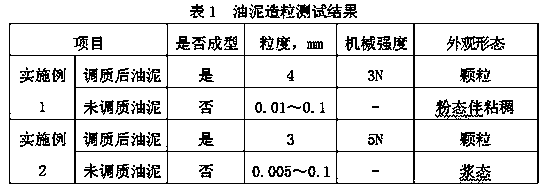

Method for oil sludge tempering and solidification pelletizing

ActiveCN105498625AHigh oil removal rateGood compatibilitySludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFlocculationResource utilization

The invention discloses a method for oil sludge tempering and solidification pelletizing. The method comprises the steps that oil sludge is injected into an oil sludge concentration pot to be subjected to demulsification, flocculation, settling and separation, oil sludge containing water on the lower portion and a flocculation modifying agent are mixed and then enter a horizontal type spiral centrifugal machine to be separated, separation liquid enters a pressure filter to be filtered under pressure, an obtained filter cake and an oil sludge cake obtained through centrifugal separation are mixed to be used as oil sludge to be treated, and the oil sludge, a solidifying agent and a tempering addition agent are mixed to form an uniform-form material to be added into a pelletizer to be pelletized. The compatibility and miscible adsorbability are improved, a guarantee is provided for harmless treatment and resource utilization of oil sludge, and economic and environmental protection comprehensive benefits are remarkable.

Owner:SHAANXI YANCHANG PETROLEUM GRP

Technique and device for purifying oil-containing exhaust

InactiveCN101485938AReduce operating loadEfficient recyclingDispersed particle filtrationPump componentsHelical lineGas compressor

The invention discloses a process and a device for purifying oil-containing tail gas with good purification effect. The process comprises that: the oil-containing tail gas is absorbed from an air inlet of the purification device, subjected to oil removal, filtration and purification by an indirect cooling spiral, and exhausted from an exhaust port. The purification device comprises a purification channel between the air inlet and the exhaust port; the purification channel is provided with an indirect cooling and separation device, a filter, a differential pressure alarm, an air suction fan, and the like; and the indirect cooling and separation device is preferably provided with a tail gas channel and a cooling medium channel with spiral trend. The purification device has compact structure, small volume, running air resistance of less than 4,000 Pa, high purification efficiency, and simple operation, can effectively recycle lubricant, reduce environmental pollution, and can be used as matched equipment of large gas compressors and turbines.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

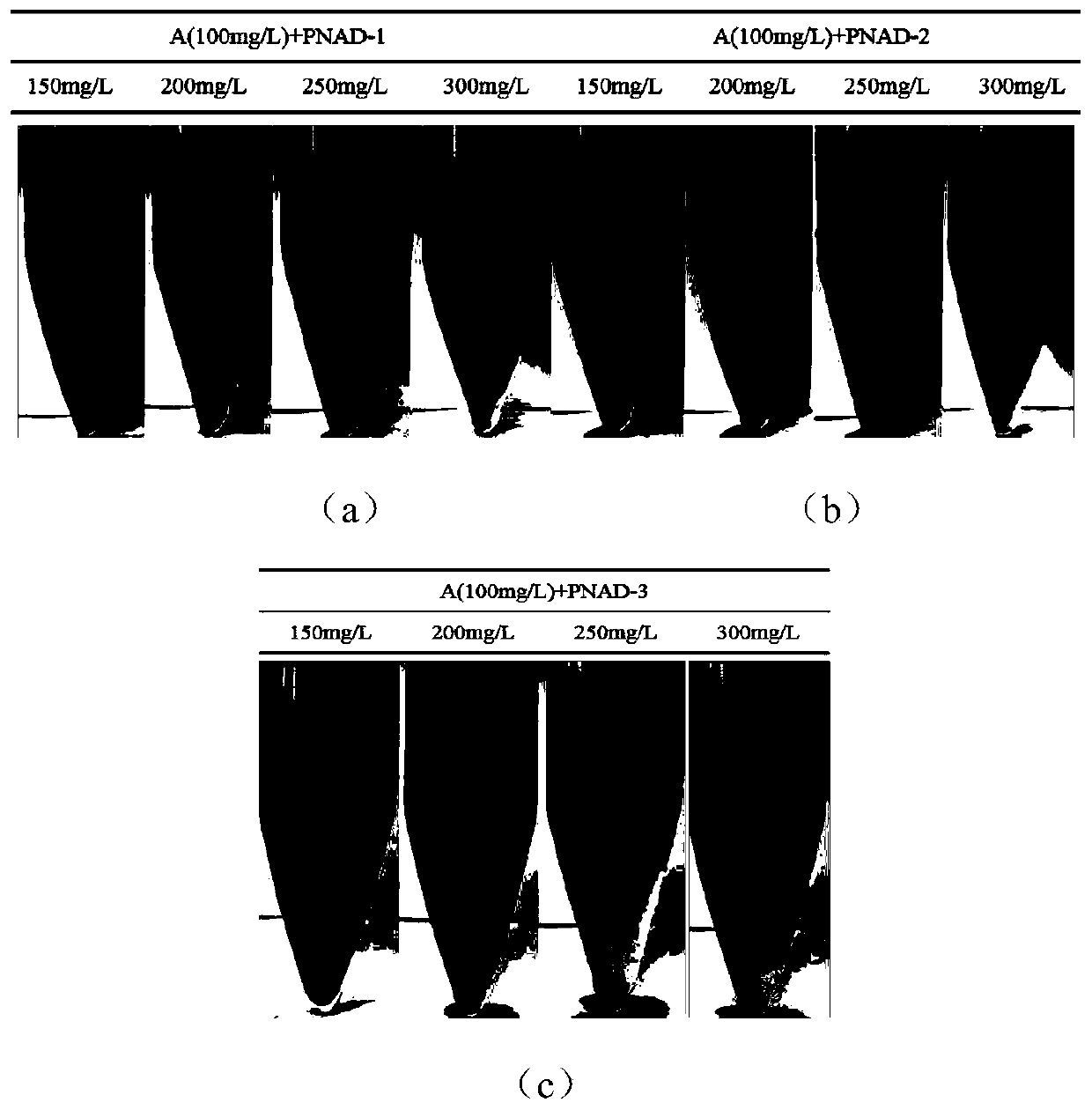

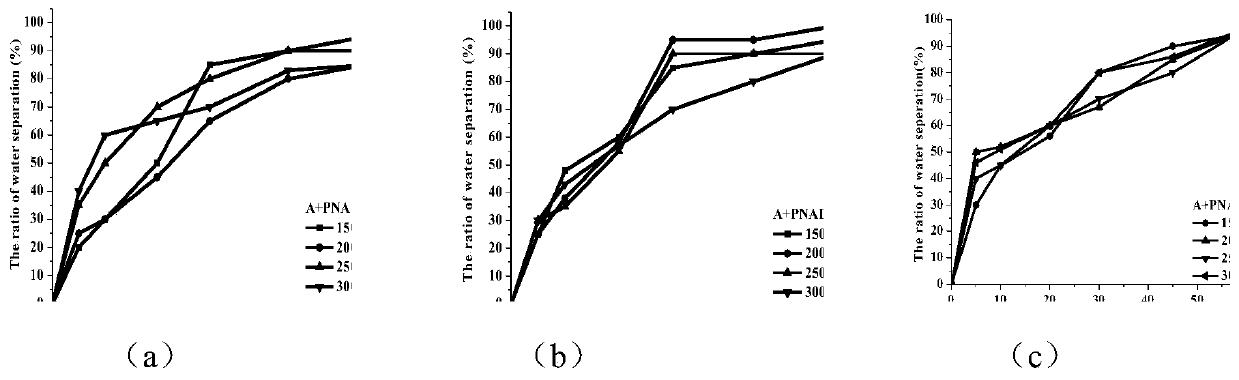

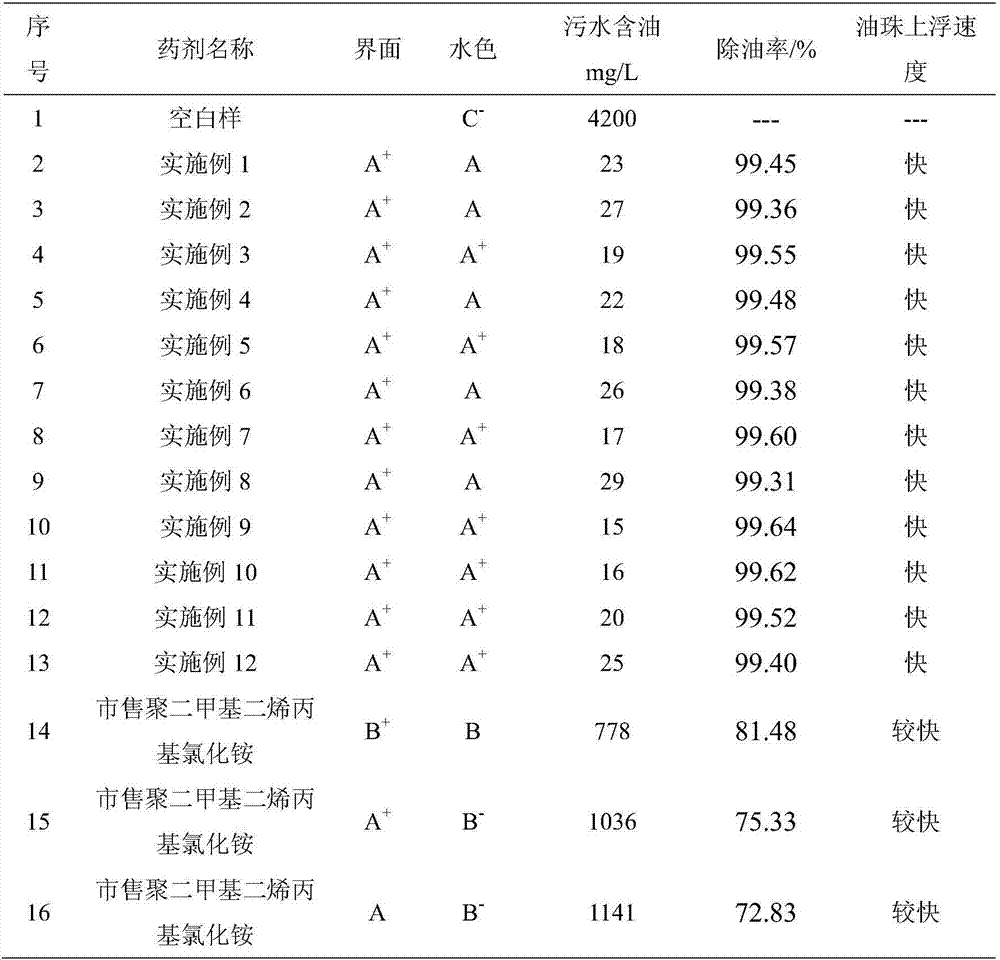

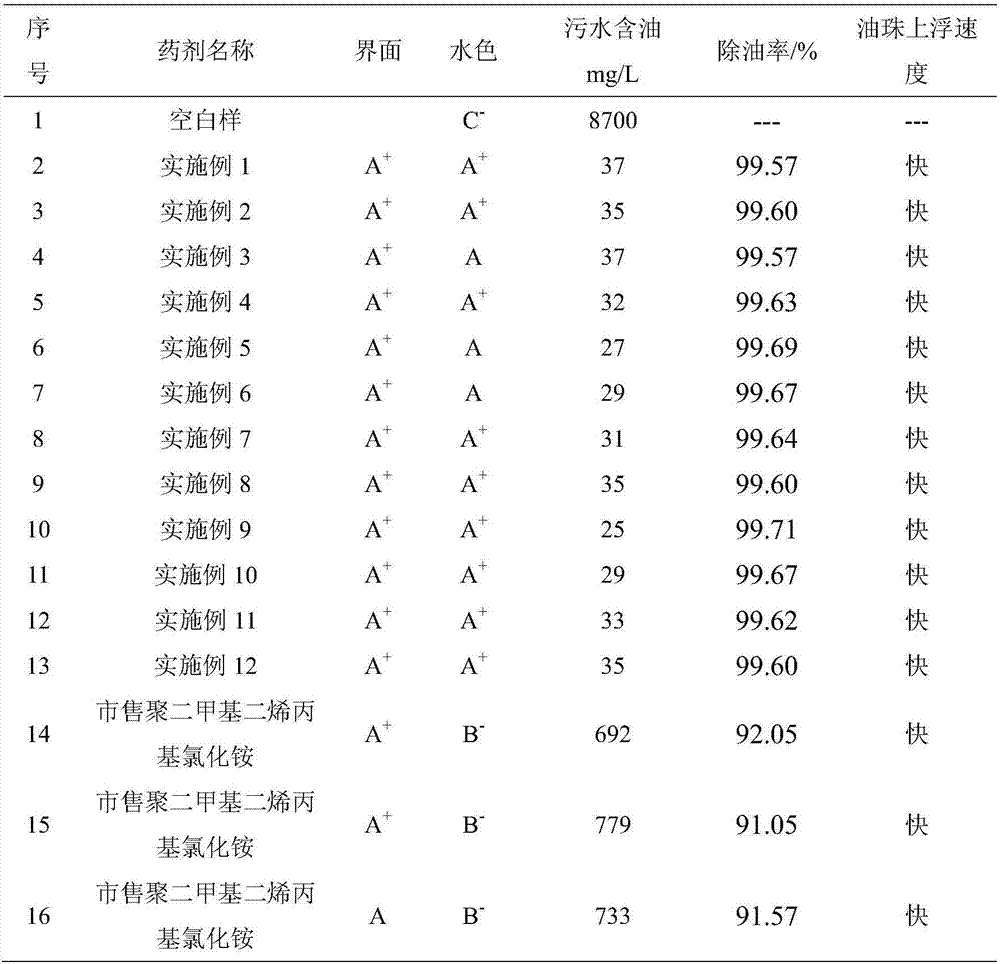

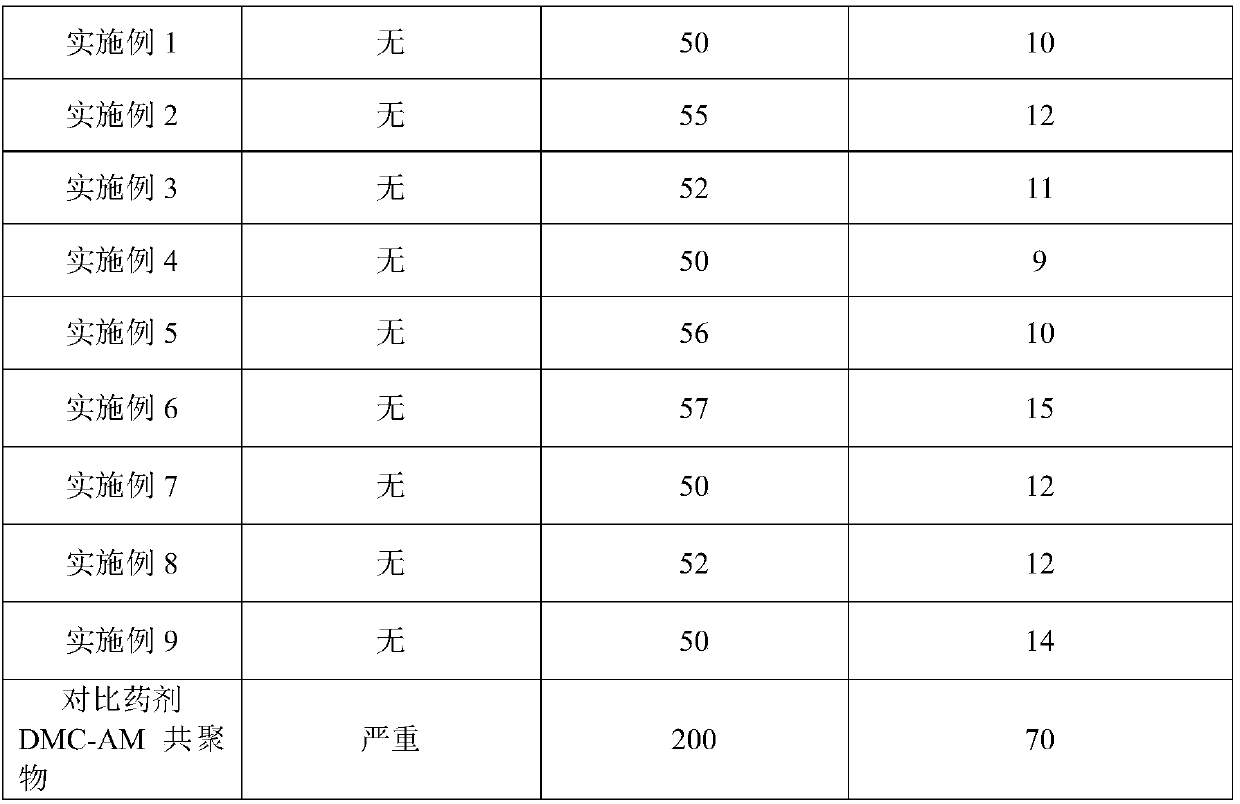

Polymer and its preparation method and application, and processing method for oily sewage

ActiveCN102850480AHigh oil removal rateShort processing timeWater/sewage treatment by flocculation/precipitationPolymer scienceSewage

The invention provides a polymer and its preparation method and application, and a processing method for oily sewage. The structural unit of polymer is composed of a acrylic acid hydrophilic structural unit, a cation structural unit, and an acrylate hydrophobic structural unit, with content being (by weight percentage) 50-67, 30-48, and 2-10. Intrinsic viscosity of polymer is 33-362 mL / g. The preparation method of the polymer includes contacting acrylic acid hydrophilic structural unit, methacryloxyethyltrimethyl ammonium chloride and acrylate hydrophobic structural unit in existence of initiator. The polymer can be used in oily sewage treatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

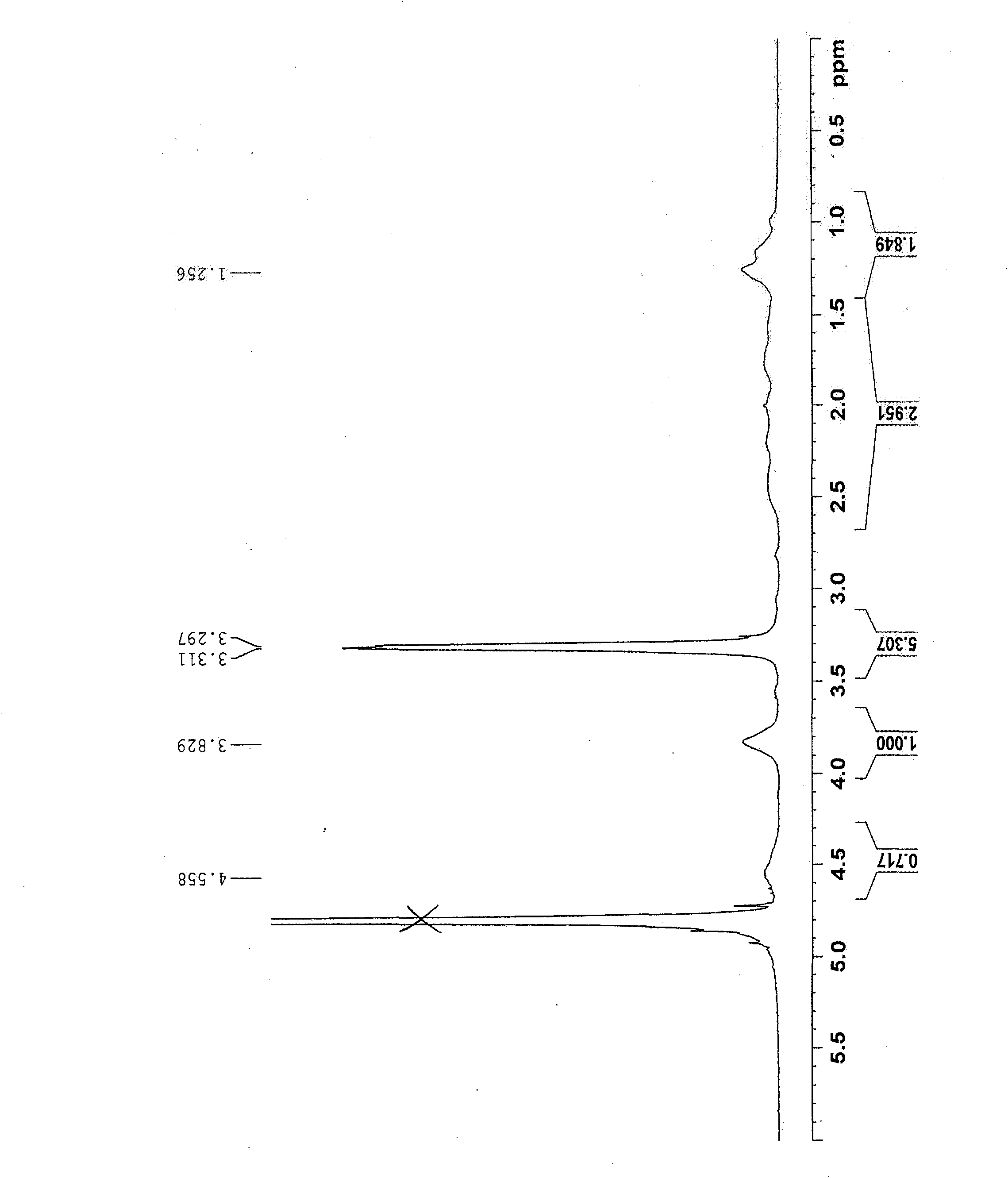

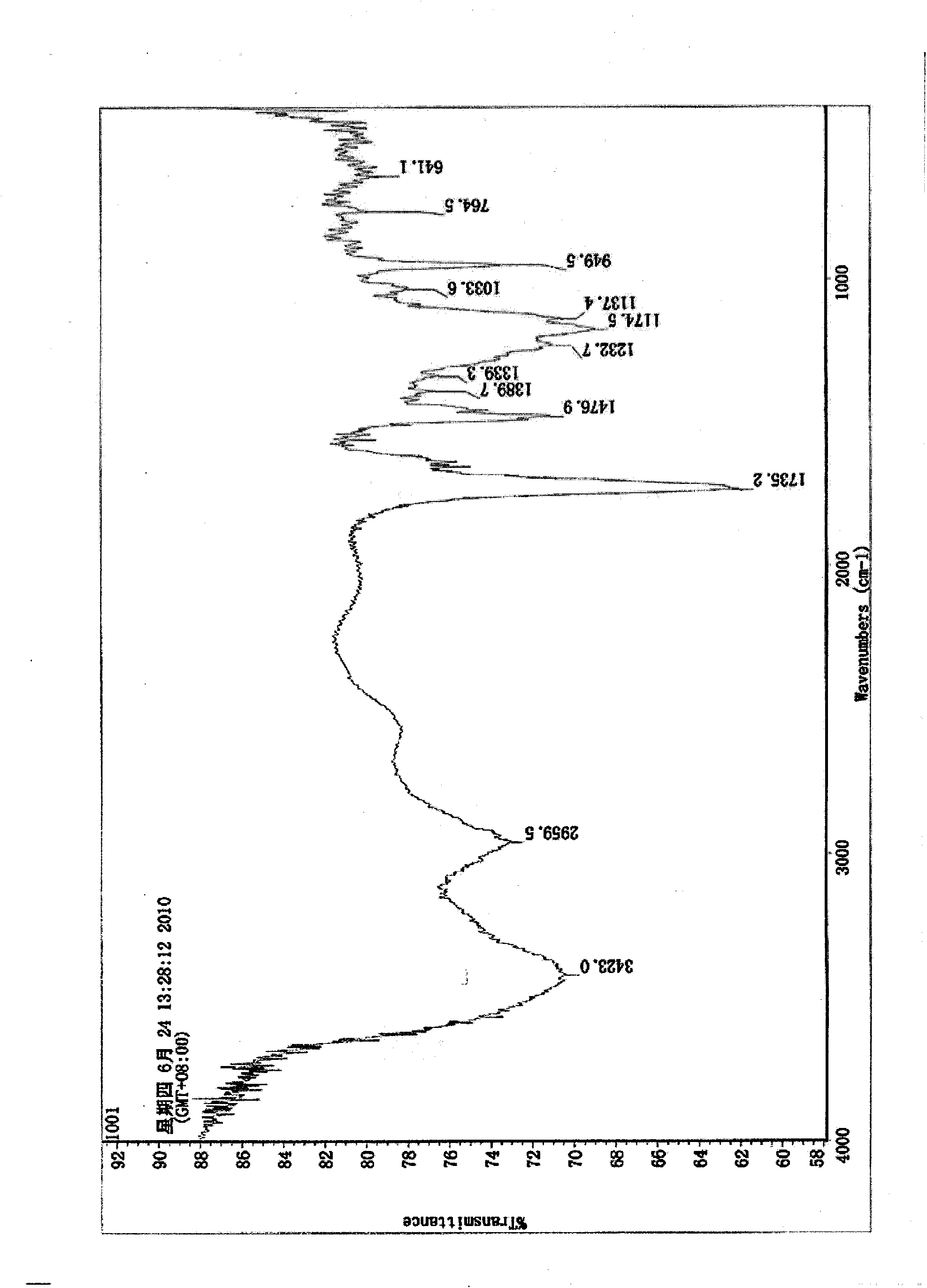

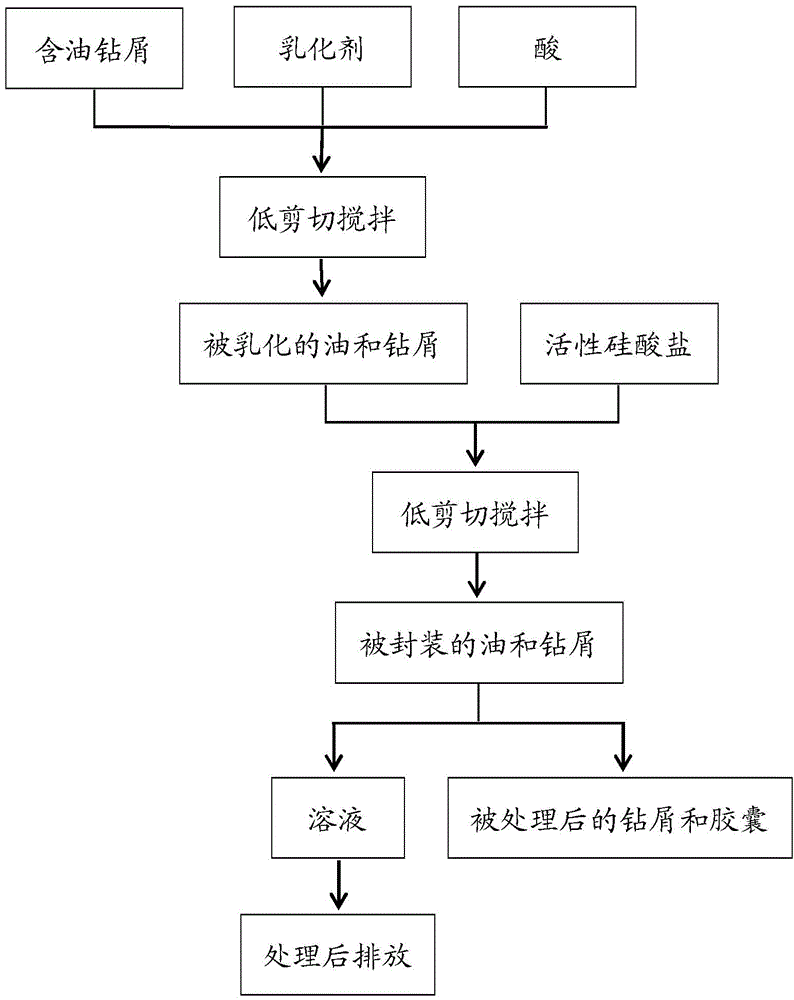

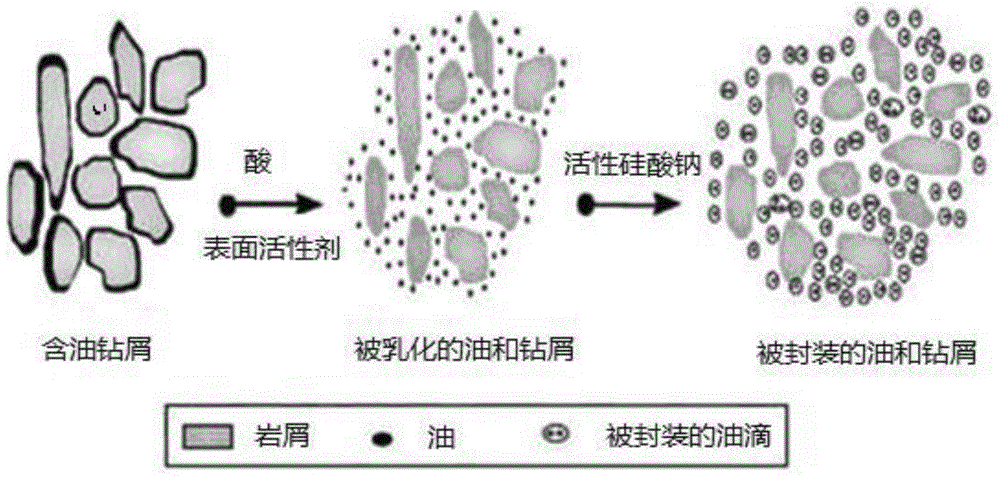

Oil removing method of oil-base drilling cuttings

The invention relates to an oil removing method of oil-base drilling cuttings. The method comprises the steps of feeding an emulsifying agent and acid into a solution of oily drilling cuttings, carrying out low-shear mixing for a period of time, and gradually separating hydrocarbon substances from the drilling cuttings to form small liquid drops, wherein the emulsifying agent has hydrophilia and comprises dispersed liquid drops, so that the effect of oil in water can be achieved; then, feeding active silicate, adjusting the pH value, and carrying out low-shear mixing to enable silicate to act with hydrogen ions to generate silicic acid, wherein silicic acid can be separated out from the solution due to the very low solubility; attaching silicic acid on the emulsified oil drops under the action of mixing to package the oil drops and form microcapsules, wherein the densities of the microcapsules are larger than the density of the solution, so that the microcapsules deposit at the bottom of the solution, and the aim of removing oil is achieved. According to the treatment method of the oil-base drilling fluid drilling cuttings, the cost is low, the oil removal rate is high and the technology is simple; according to the method, the problem of pollution caused by the drilling cuttings can be solved, the oil resources are recovered, and economical and effective innocent treatment is realized, and therefore, the oil removing method has a certain industrial popularization value.

Owner:SOUTHWEST PETROLEUM UNIV

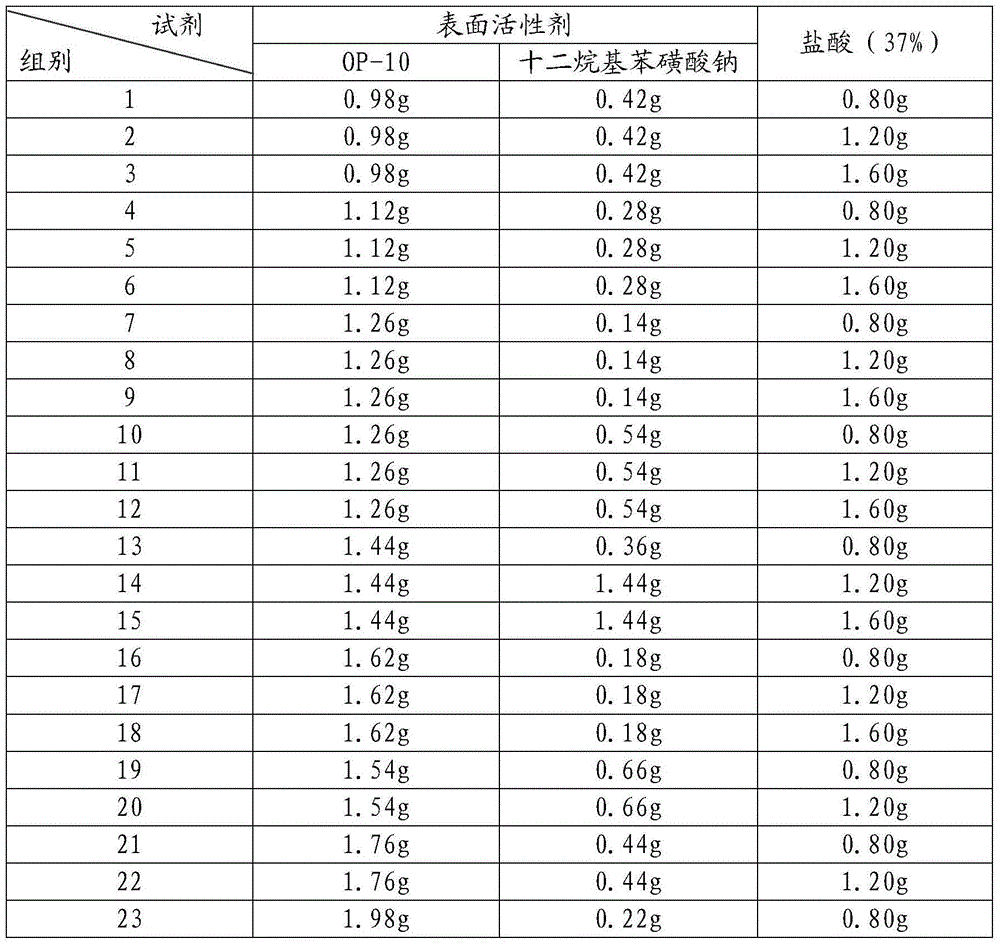

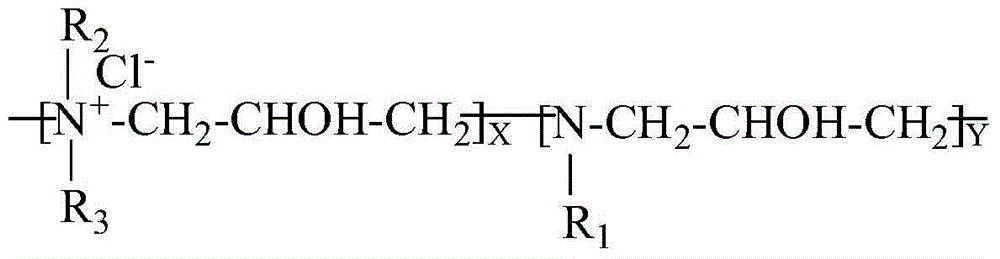

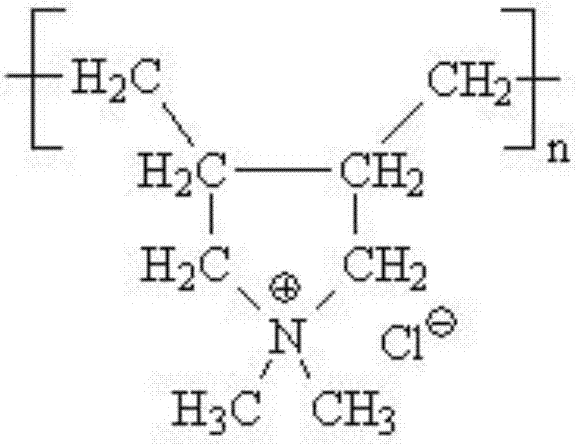

Composite type emulsion breaking flocculant

ActiveCN104817150AAchieve separationReach turbidityWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationDemulsifierAluminium chlorohydrate

The invention relates to a composite type emulsion breaking flocculant, comprising 60-80wt% of a cationic demulsifier, 10-20wt% of poly-dimethyl-diallyl-ammonium chloride and 5-10wt% of aluminium polychlorid, as well as 5-10wt% of polymethylacrylic acid, wherein the cationic demulsifier is a polymer having a chemical formula shown in the specification, wherein R1 can be -(CH2)2NH2, -(CH2)3N(CH3)2, -(CH2)6NH2 and (CH2)9CH3; R2 can be -CH3, -CH2NH2, -C2H5, -CH2NHCH2NH2; R3 can be -CH3, -CH2NH2, -C2H5, -CH2NHCH2NH2; X is between 10 and 50; Y is between 1 and 5. The composite type emulsion breaking flocculant disclosed by the invention can be used for finishing the operations of emulsion breaking, flocculation, oil removal and sewage purification and has the advantages of low reaction temperature, high reaction speed, high oil removal rate and capability of greatly reducing turbidity of water with oil removed.

Owner:EAST CHINA UNIV OF SCI & TECH

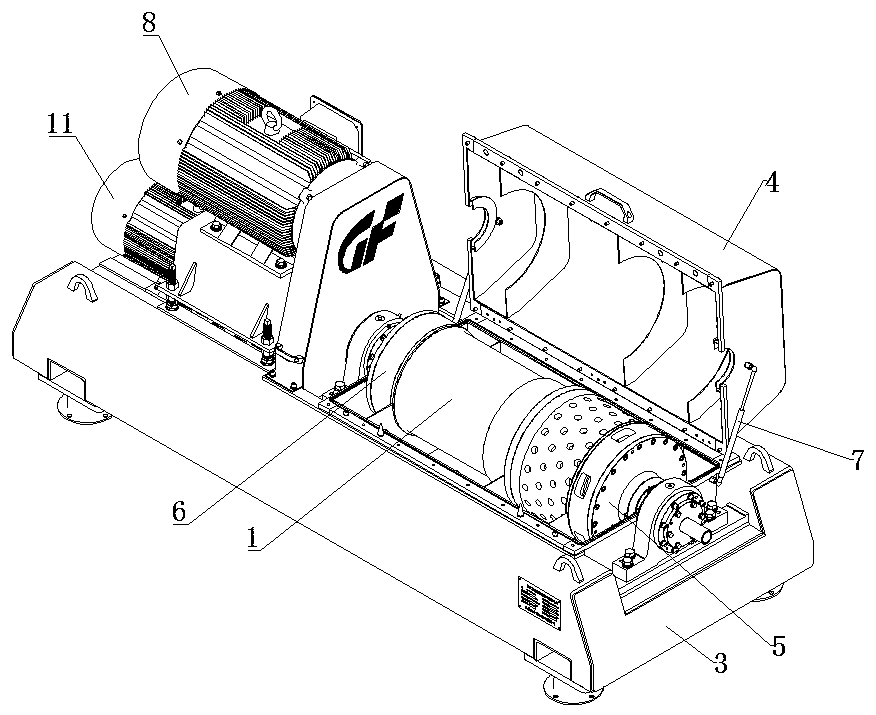

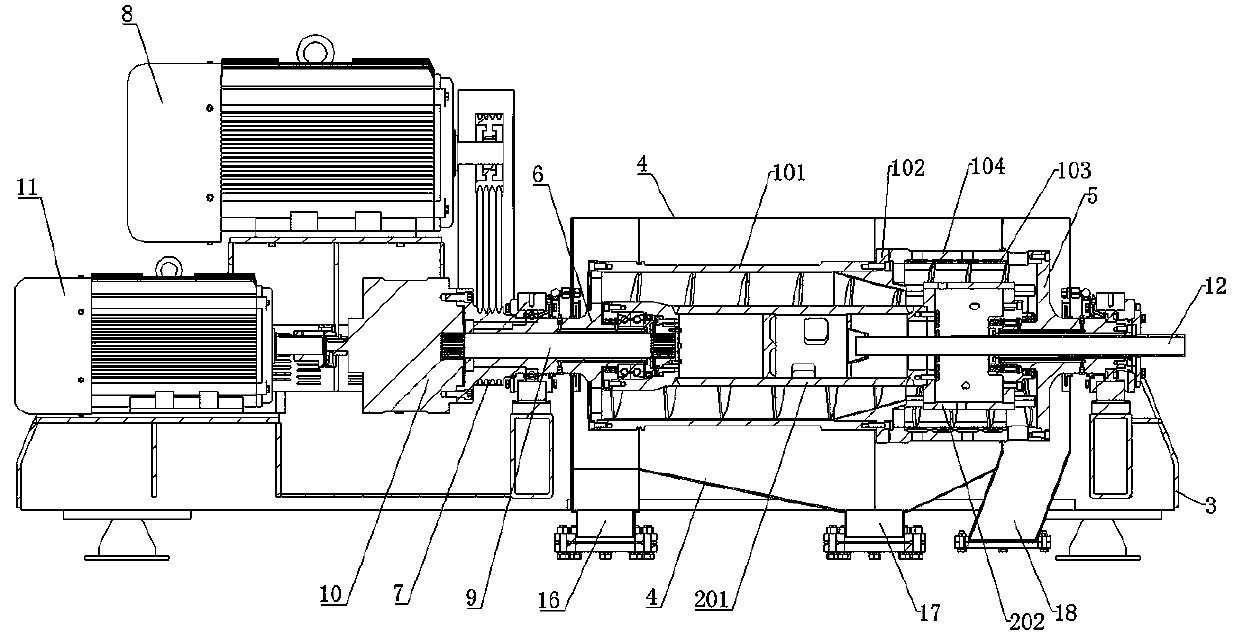

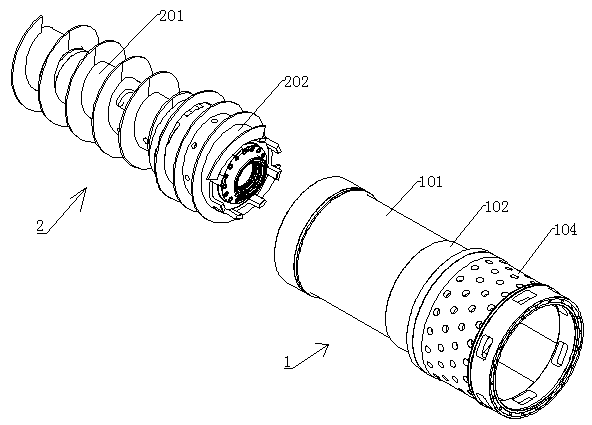

Horizontal spiral discharge sedimentation filtration centrifuge and secondary separation process thereof

PendingCN110339950AImplement the second clothSecond separationRotary centrifugesFiltrationButt joint

The invention relates to a horizontal spiral discharge sedimentation filtration centrifuge. The horizontal spiral discharge sedimentation filtration centrifuge comprises a drum part, a spiral materialpusher, a machine base and a cover shell, wherein the cover shell is arranged on the machine base; a drum component is arranged in the cover shell, the drum component is internally provided with thespiral material pusher, and the drum component comprises a straight-section drum, a butt-joint flange drum and a screen drum which are sequentially arranged from left to right; a screen is arranged inthe screen drum, and the butt-joint flange drum is provided with a conical cavity; the spiral material pusher comprises spiral material pusher components I and spiral material pusher components II, and seam allowances of the spiral material pusher components I and the spiral material pusher components II are in fit connection; the spiral material pusher components I are positioned in the straight-section drum and the butt-joint flange drum, and material feeding bins and material feeding holes are formed in the spiral material pusher components I; and the spiral material pusher components II are positioned in the screen drum, and a plurality of through holes are formed in the inner walls of spiral material pusher components II. The invention further discloses a secondary separation processof the horizontal spiral discharge sedimentation filtration centrifuge. The horizontal spiral discharge sedimentation filtration centrifuge has the beneficial effects that the separation effect is improved, the liquid outlet rate is high, the leakproofness is good, and the maintenance cost is low.

Owner:成都高分离心机有限公司

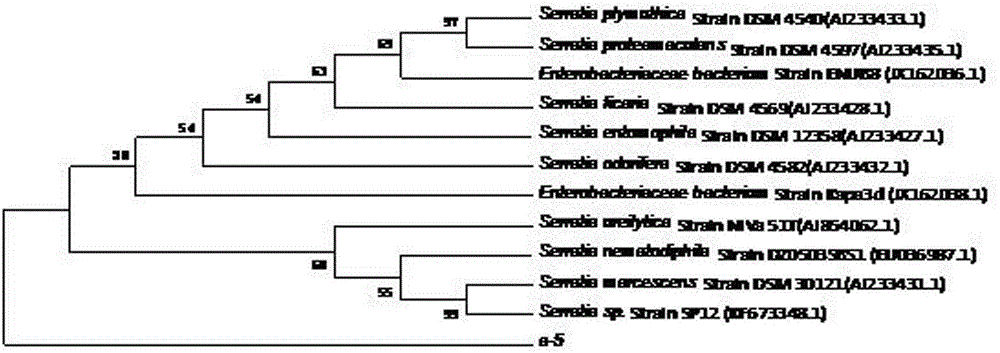

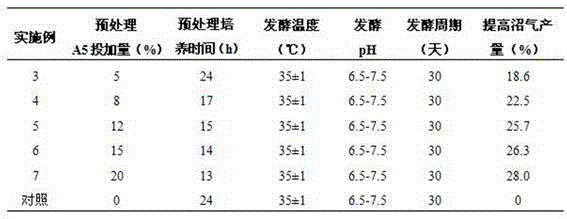

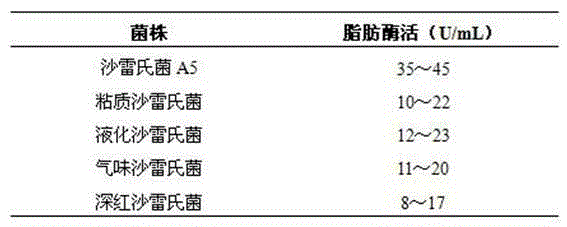

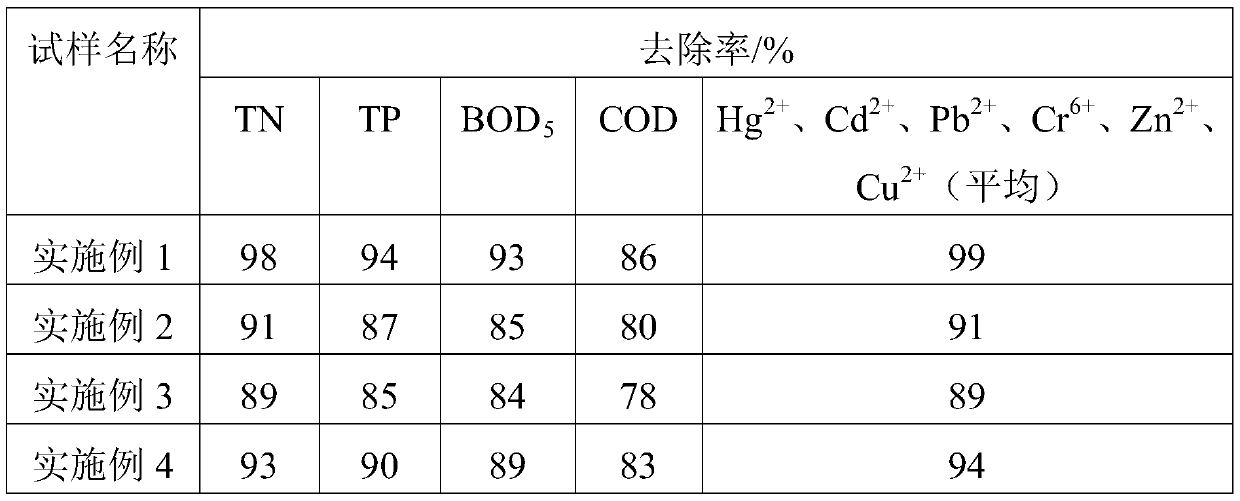

Serratia sp. A5 and uses thereof

ActiveCN104371951ADisinhibition effectImprove hydrolysis efficiencyBacteriaMicroorganism based processesBiotechnologyOil and grease

The present invention relates to Serratia sp. A5 and applications thereof. The Serratia sp. A5 is preserved in the China General Microbiological Culture Collection Center on August 28, 2014, and the preservation number is CGMCC No.9621. According to the present invention, the Serratia sp. A5 is isolated from soil, the suitable growth temperature is 25-35 DEG C, the pH value is 7.0-7.5, and the Serratia sp. A5 has the lipase production ability; and the Serratia sp. A5 can be applied for degrading grease, relieving the inhibition effect of the grease in food waste anaerobic fermentation, increasing the biogas yield by 15-30%, and effectively increasing anaerobic fermentation hydrolysis and biogas production efficiency of other waste containing fat and the like or waste water, and further provides important significance for promotion of harmless, resource and energy utilization of organic waste.

Owner:河北绿茵生化科技有限公司

Purificant for purifying oily sewage

InactiveCN101538082ABreak interface energyFloating fastWater/sewage treatment by flocculation/precipitationEmulsionChemistry

The invention relates to a water purification agent, in particular to an oily sewage purificant used for treating oily sewage in oil fields, which consists of the following components according to weight percentage: 30 to 40 percent of aluminum chloride hexahydrate, 10 to 25 percent of epoxypropyl polyquaternary amine and 35 to 50 percent of poly(diallyldimethylammonium chloride. The oily sewage purificant is mainly used for the emulsion breaking and oil removing of oily sewage emulsion liquid or other 0 / W sewage, has enough strong electrophilicity to neutralize negative charge formed by an emulsifier, has enough strong flocculation capability to flocculate particles in the emulsion liquid for facilitating the formation of large vanadium flowers, and has enough strong surface activity to break the interfacial energy of the emulsion liquid. The purificant is characterized by high deoiling rate, limpid water of dehydration, quick floating upwards of oil clots and even oil-water boundary. In addition, the purificant has the advantages of low dosage, low cost and broad application prospect.

Owner:唐山市金沙工贸有限公司

Water treatment agent and preparation method thereof

InactiveCN105502568AReduce dosageHigh oil removal rateFatty/oily/floating substances removal devicesWater contaminantsPotassiumSurface-active agents

The invention discloses a water treatment agent and a preparation method thereof. The water treatment agent is prepared from the following raw materials in parts by weight: 35-45 parts of zeolite, 5-15 parts of quartz, 5-15 parts of potash feldspar, 0.1-0.5 part of polyacrylamide, 0.5-1.5 parts of lauryl alcohol polyoxyethylene and 0.1-0.5 part of a surface active agent. The water treatment agent disclosed by the invention is prepared from the environment-friendly raw materials, and is high in inorganic filler specific surface area, high in activity, high in dispersibility and high in adsorbability; meanwhile, the water treatment agent can play roles of demulsification, flocculation, bridging and foaming; the water treatment agent disclosed by the invention is small in using amount and high in oil removal rate, and is suitable for treatment of domestic sewage, industrial wastewater and oily sewage.

Owner:轩脉家居科技(上海)有限公司

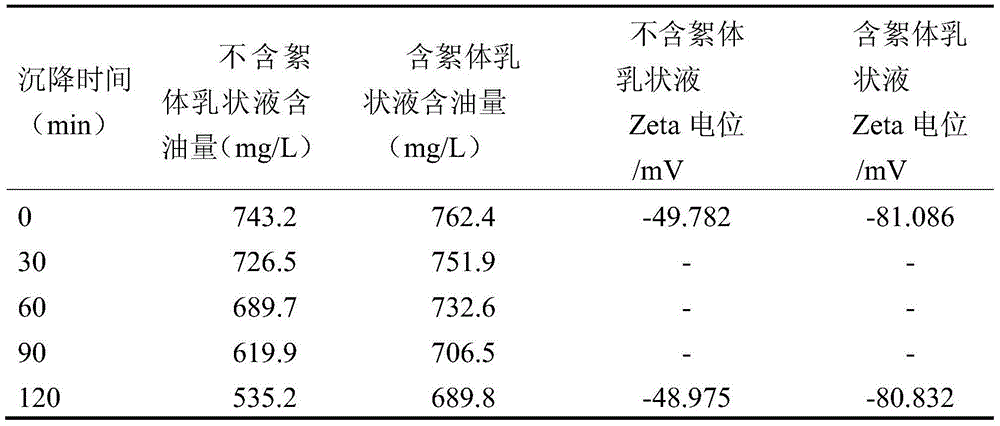

Industrial oily wastewater treatment method

InactiveCN104986813AReduce dosageHigh oil removal rateWater/sewage treatment by flocculation/precipitationFlocculationHigh concentration

The present invention relates to an industrial oily wastewater treatment method. The method comprises: adding an oily wastewater treatment agent to wastewater in which the oil content is 700-1200 mg / L, wherein the added volume is 10 mg / L; and after stirring the mixture for 20-40 minutes, performing separation by standing, wherein the oily wastewater treatment agent consists of a demulsifier, a flocculant and a surfactant and a solvent; and components in parts by mass are: 25-35 parts of the demulsifier, 5-10 parts of the flocculant, 5-10 parts of the surfactant, and 50-80 parts of the solvent. The oily wastewater treatment agent can simultaneously have effects of demulsification, flocculation, bridging and bubbling. According to the treatment method of the present invention, the composite oily wastewater treatment agent has high efficiency in removing oil with small dosage, and is particularly applicable to treatment of wastewater that contains high concentration of oil.

Owner:李平兰

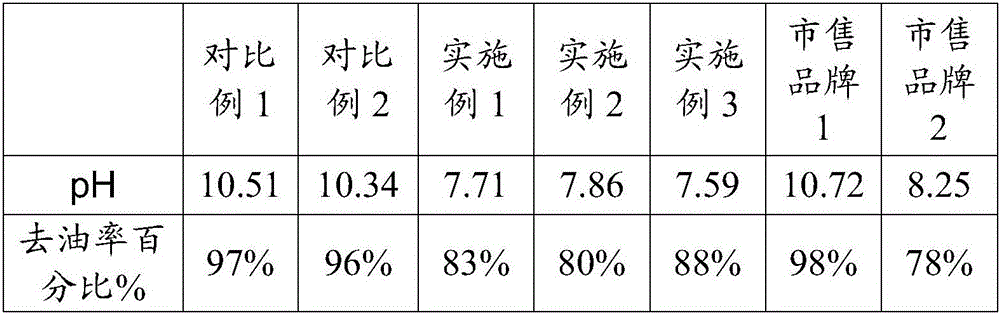

Oil stain cleaning agent for kitchens

InactiveCN111440671AHigh oil pollution treatment efficiencyHigh oil removal rateNon-ionic surface-active compoundsOrganic detergent compounding agentsPreservativeActive agent

The invention relates to the technical field of cleaning agents, in particular to an oil stain cleaning agent for kitchens. The cleaning agent at least comprises the following preparation raw materials in parts by weight: 35-50 parts of an alkaline auxiliary agent, 5-15 parts of a surfactant, 0.5-1.5 parts of a chelating agent, 0.5-2 parts of a builder, 0.05-0.2 parts of a preservative and the balance of water, totaling 100 parts. According to the oil stain cleaning agent for kitchens provided by the invention, edible alkali, the surfactant, the chelating agent, the builder, essence and the like are adopted, so that the prepared oil stain cleaning agent for kitchens is fragrant in smell, high in oil stain treatment efficiency, high in oil stain removal rate and free of any harmful effect on a human body, and the requirement of environmental protection is met. In addition, the cleaning agent provided by the invention not only can be used for cleaning kitchen range hoods, but also can beused for cleaning kitchen walls, cooking stoves and floors.

Owner:山东海天生物化工有限公司

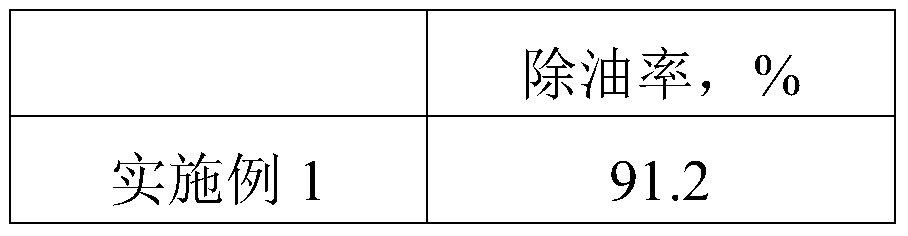

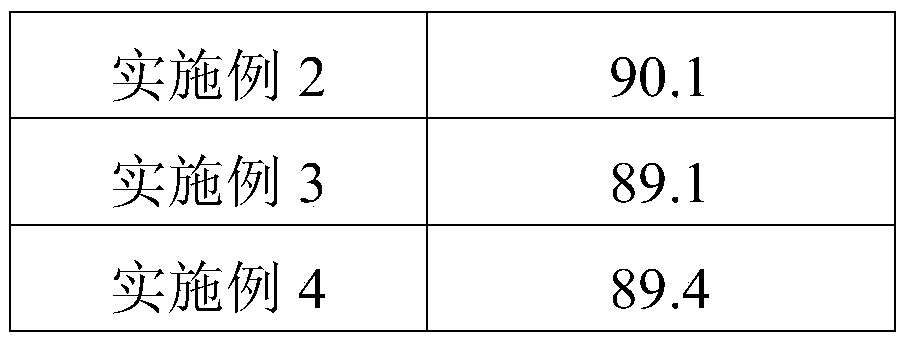

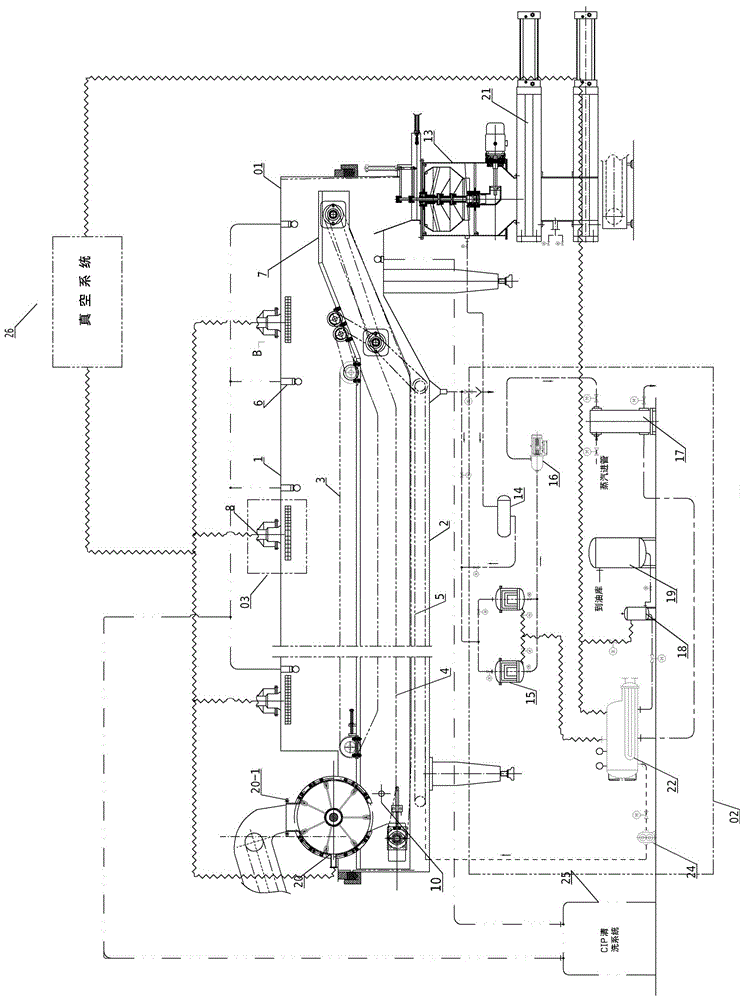

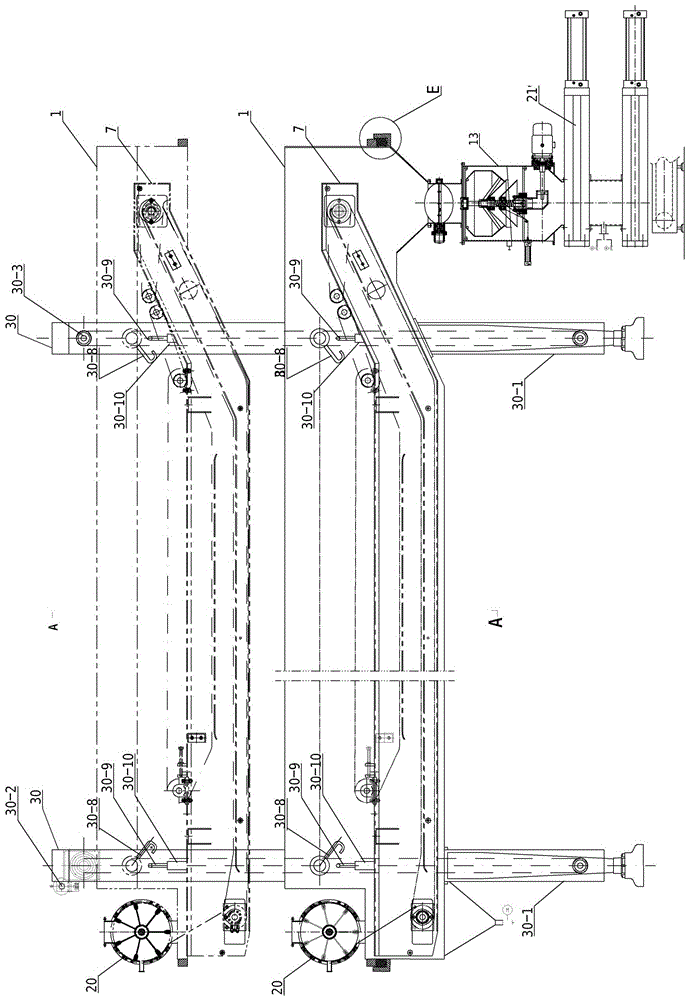

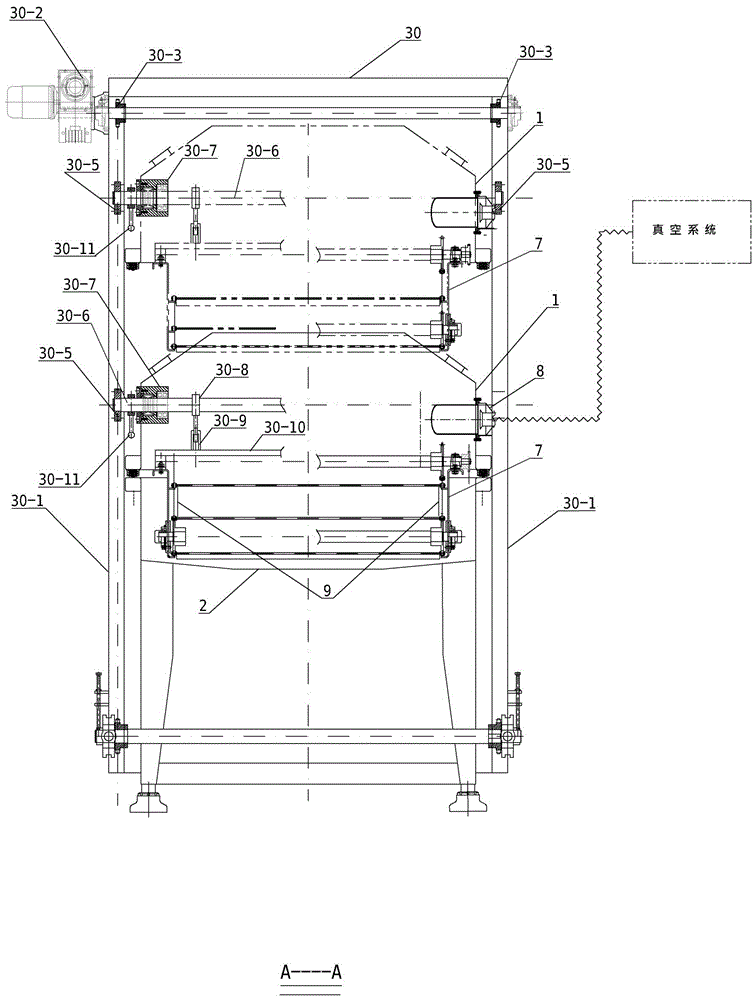

Efficient continuous vacuum fryer

InactiveCN106417420AHigh oil removal rateDegreasing fastBaking ovenOil/fat bakingEngineeringHeating cycle

The invention discloses an efficient continuous vacuum fryer. High-vacuum-degree stability can be continuously kept under the condition of continuous feeding and discharging. The efficient continuous vacuum fryer is composed of a frying bin, a rotating hub type sealing device, a wedge disc type sealing device, a deoiler, a portal frame type chain lifting device, a CIP cleaning system, an oil filtering system, an oil heating cycle system, an oil-steam separating device and a vacuum system. The frying bin is composed of a frying bin upper bin, a frying bin lower bin, a frying bin sealing strip, a mesh belt rack, a conveying mesh belt, a pressing mesh belt, a striker plate and a residue scraping device. The deoiler is high in deoiling efficiency, oil residues can be automatically cleaned away through continuous filtering, oil filtering density is high, the fryer achieves grease cyclic heat exchange and automatic oil replenishing, the use period of grease can be prolonged, the CIP cleaning system automatically cleans equipment, the production equipment do not need to be detached, and the advantages that operation is easy, the portal frame type chain lifting device is convenient to maintain, and production efficiency is high are achieved.

Owner:陈长清

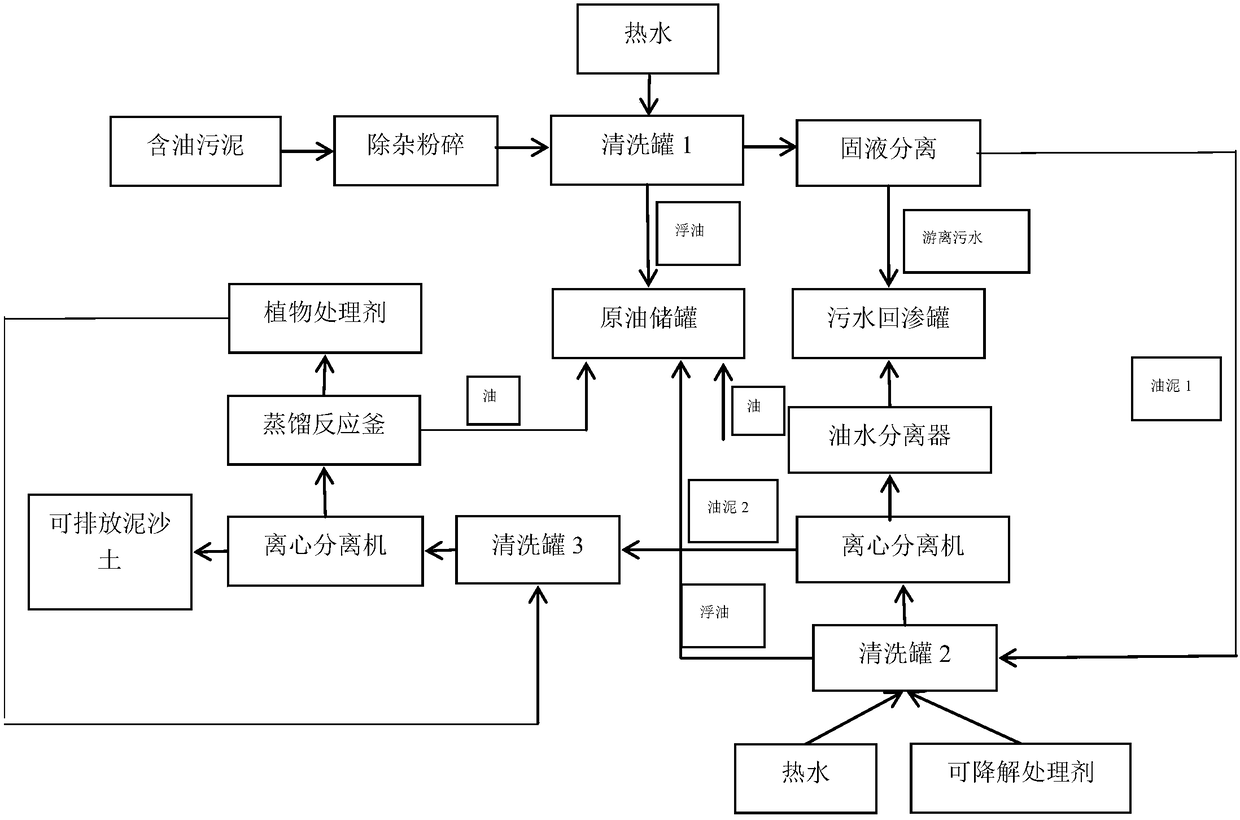

Harmless recycling treatment method for oily sludge

ActiveCN108558155AEasy to operateHigh oil removal rateWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningSludgeWastewater

The invention provides a harmless recycling treatment method for oily sludge. The harmless recycling treatment method comprises the following steps: carrying out crushing treatment on the oily sludge;uniformly blending the oily sludge with water and stirring; after standing and layering, overflowing and separating out upper-layer floating oil to a petroleum recycling tank; treating a residual solid-liquid phase and carrying out centrifugal solid-liquid separation to obtain free water and infiltrating the free water to use; carrying out second-time decrement treatment on a residual solid phase; adding water and a degradable treatment agent and stirring; after standing and layering a system, overflowing the upper-layer floating oil into the petroleum recycling tank; centrifuging and separating a mixture obtained by the decrement treatment and carrying out oil-water separation on an obtained liquid phase; conveying an oil phase into the petroleum recycling tank and conveying the water phase into a sewage infiltration tank for circular utilization; carrying out harmful treatment on the residual solid phase; centrifuging and separating; distilling the liquid phase to recycle a plant treatment agent; conveying residual oil into the petroleum recycling tank and drying residual sludge. The harmless recycling treatment method for the oily sludge is simple to operate and has a wide application range and an extremely high oil removal rate; wastewater is recycled and the treated sewage can be directly used for farmland planting.

Owner:任航

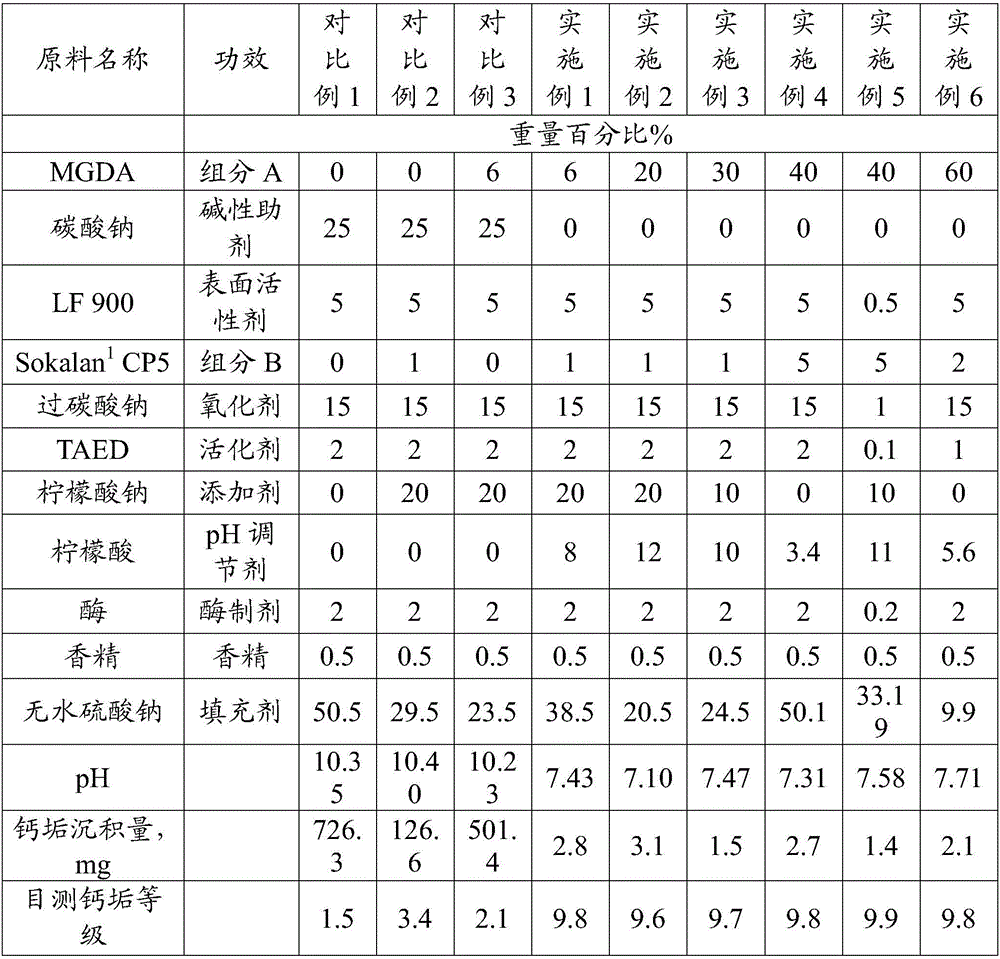

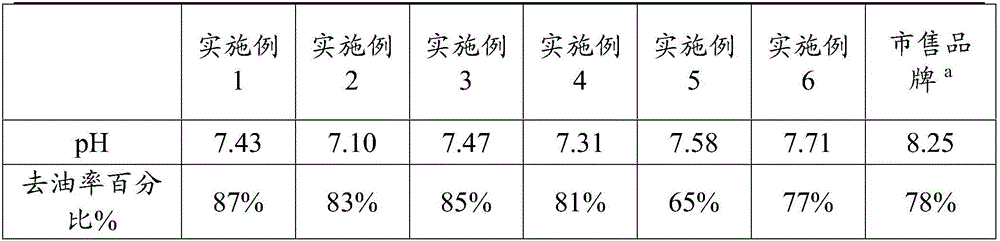

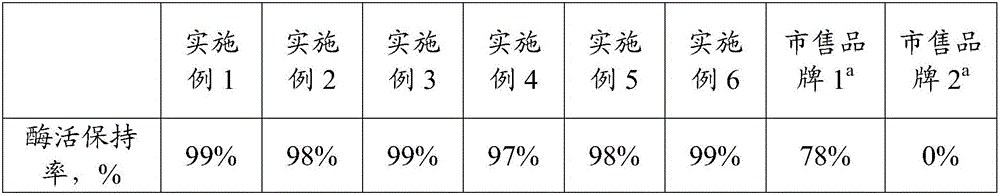

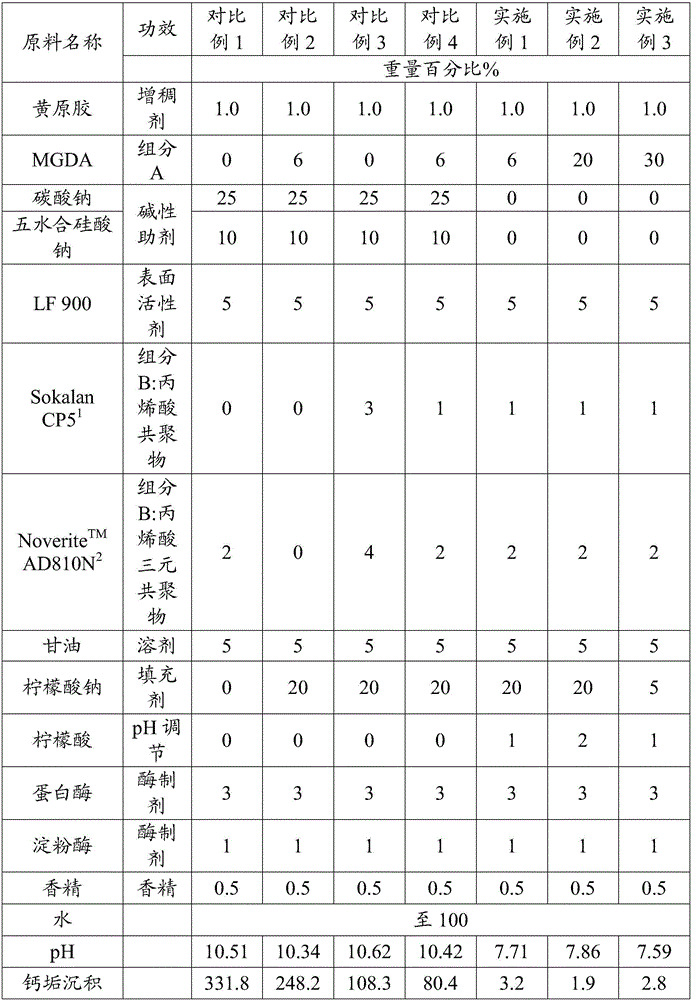

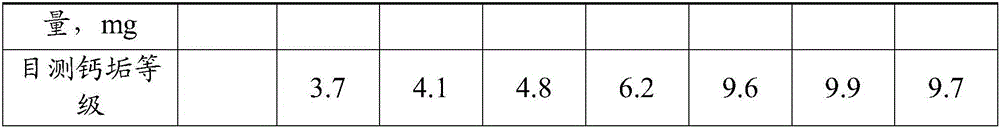

Detergent composition and application thereof

InactiveCN107523428AChelation effectiveEffective combinationInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsNeutral phHydrogen

The invention relates to a detergent composition and application thereof. The pH (potential of Hydrogen) of the detergent composition is 5 to 9; the detergent composition is prepared from the following components in percentage by weight: (i) 0.1 percent to 60 percent of a component A; (ii) 0.1 percent to 10 percent of a component B; (iii) 0.01 percent to 10.00 percent of a surfactant; (iv) 0.01 percent to 40.00 percent of an oxidant; (v) 0.01 percent to 10 percent of an enzyme preparation; (vi) 0 to 50 percent of an additive. The detergent composition provided by the invention has the neutral pH and remarkable water scales are not generated after the detergent composition is used for a dish washing machine for a long period; remarkable damages to the dish washing machine are not caused and the brightness of washed tableware is also not influenced; meanwhile, the detergent composition has strong cleaning power.

Owner:GUANGZHOU LIBY

Liquid detergent composition as well as preparation method and application thereof

InactiveCN107523429AEasy to cleanReduce depositionOrganic detergent compounding agentsSurface-active detergent compositionsHydrogenNeutral ph

The invention relates to a liquid detergent composition as well as a preparation method and application thereof. The pH (potential of Hydrogen) of the liquid detergent composition is 5 to 9; the liquid detergent composition is prepared from the following components in percentage by weight: (i) 0.01 percent to 5 percent of a thickener; (ii) 0.1 percent to 70 percent of a component A; (iii) 0.1 percent to 10 percent of a component B; (iv) 0.01 percent to 10.00 percent of a surfactant; (v) 0.01 percent to 10 percent of an enzymic preparation; (vi) 20 to 99 percent of water. The composition provided by the invention has the neutral pH and remarkable water scales are not generated after the detergent composition is used for a dish washing machine for a long period; remarkable damages to the dish washing machine are not caused and the brightness of washed tableware is also not influenced; meanwhile, the liquid detergent composition has strong cleaning power.

Owner:GUANGZHOU LIBY

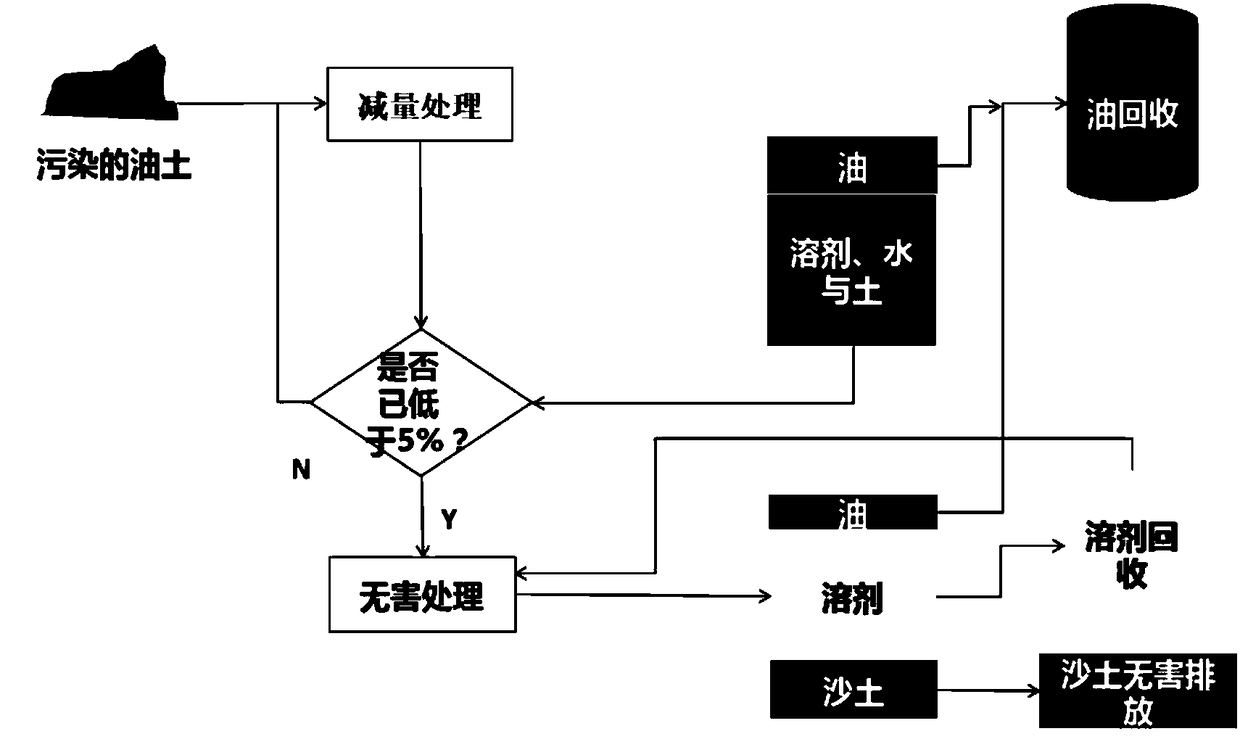

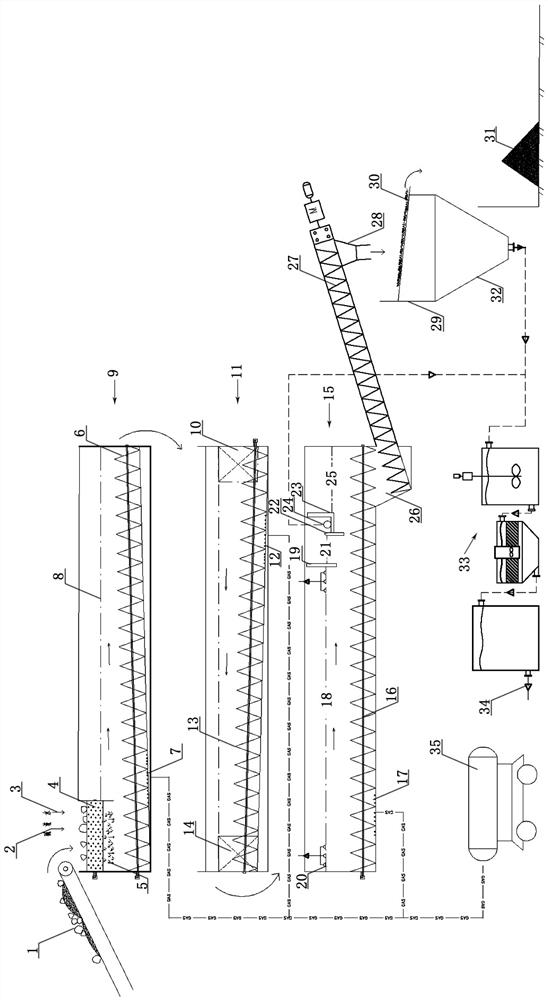

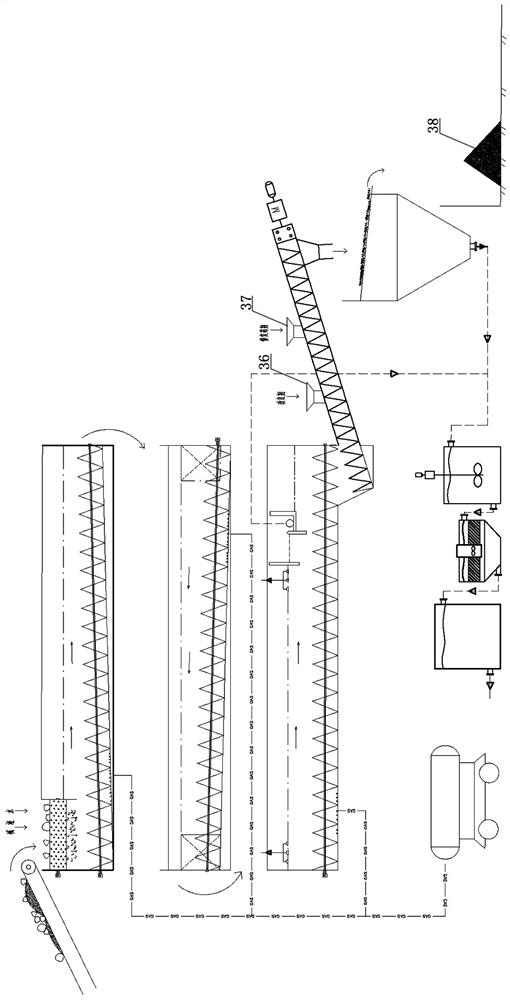

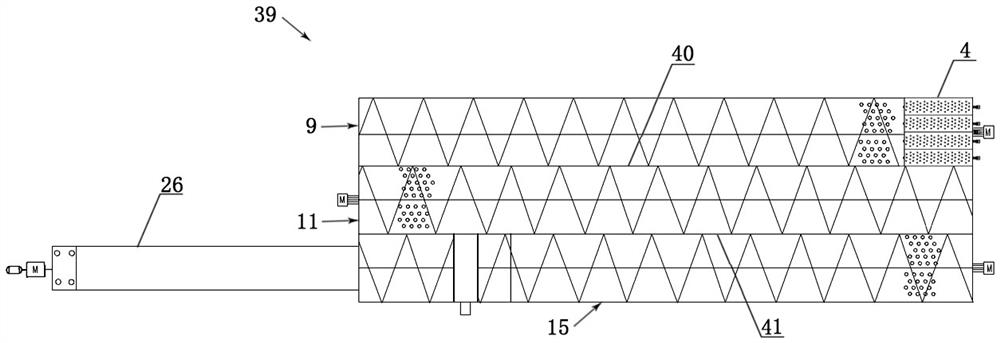

Efficient integrated cleaning system and method for petroleum hydrocarbon organic contaminated soil

ActiveCN112058889ASolve the complex structure of equipmentQuick move and installContaminated soil reclamationGrain treatmentsElectrical controlContaminated soils

The invention discloses an efficient integrated cleaning system and method for petroleum hydrocarbon organic contaminated soil. The system sequentially comprises a contaminated soil feeding unit, a pretreatment crushing unit, a microbubble entrainment cleaning unit, a discharging dehydration unit, a sewage treatment unit and an instrument and electrical control unit, wherein the microbubble entrainment cleaning unit sequentially comprises a first cleaning section and a third cleaning section, the first cleaning section comprises a first spiral scrubbing machine penetrating through the first cleaning section, a first microbubble group generating device located at the front end of the first cleaning section and a first contaminated soil turnover window located at the tail end of the first cleaning section, the third cleaning section comprises a third spiral scrubbing machine penetrating through the third cleaning section and a third microbubble group generating device located at the front end of the third cleaning section, and a material discharging port is formed in the tail end of the third cleaning section and communicated with a discharging dehydration unit. According to the invention, the soil remediation work efficiency is improved, the soil remediation construction and operation cost is reduced, and the system can be widely applied to cleaning treatment of polluted soil.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

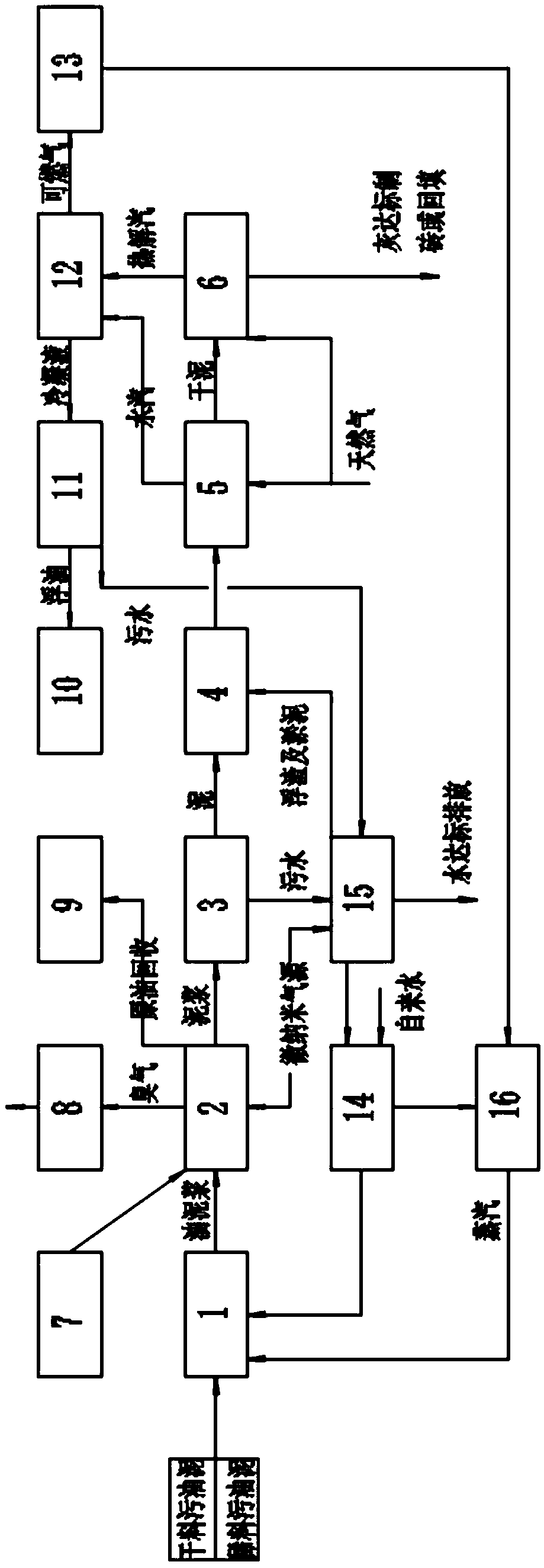

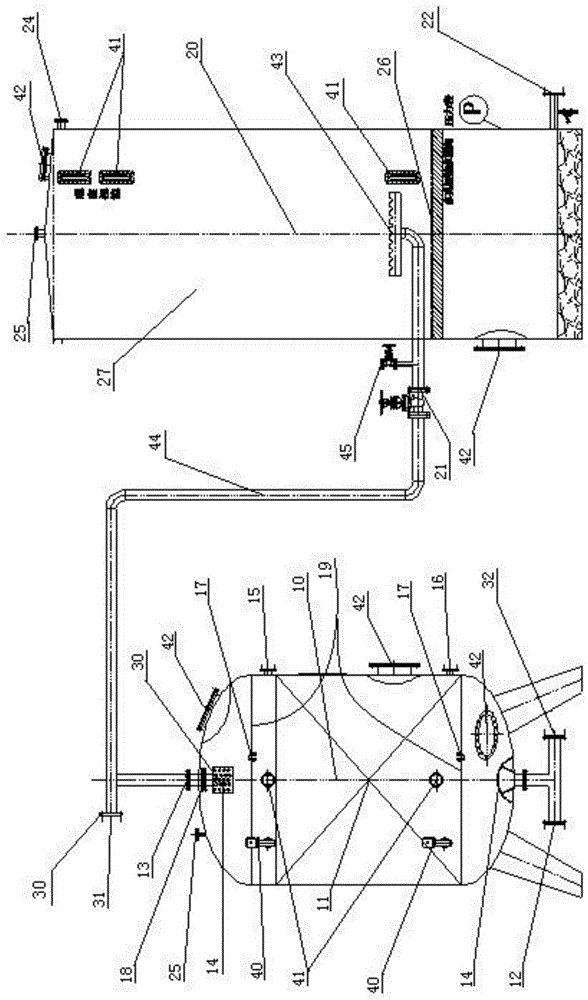

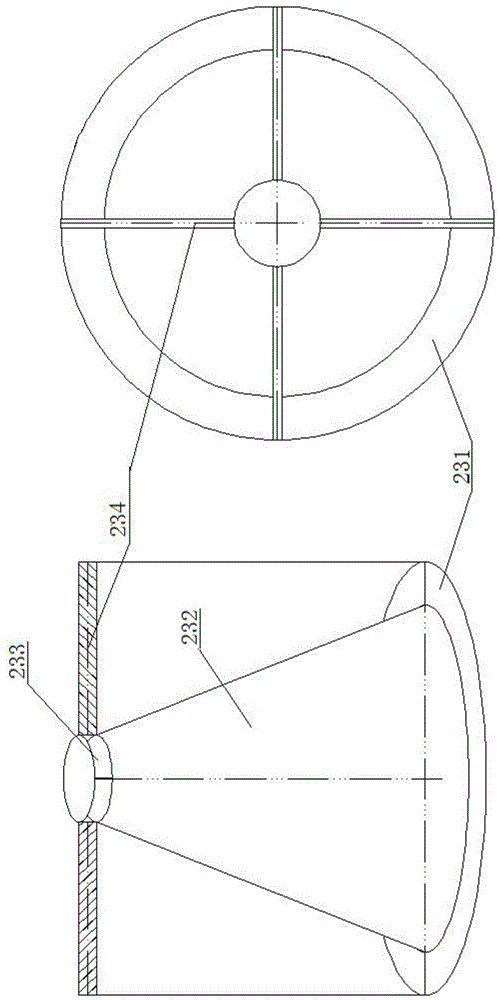

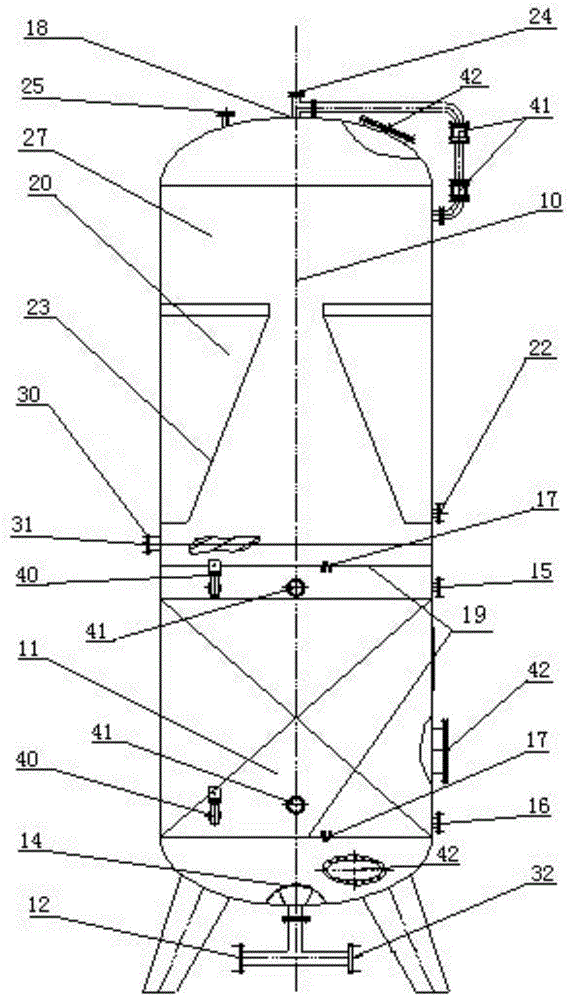

Intelligent dirty oil sludge treatment device and treatment process

ActiveCN108947154ALarge amount of processingAchieving processing powerWaste water treatment from quariesDewatering/demulsification with chemical meansWater sourceSlurry

The invention discloses an intelligent dirty oil sludge treatment device and treatment process. The treatment device comprises an all-in-one machine, an oil removal machine, a separation machine, a mud collecting tank, a dehydration machine, a pyrolysis machine, a medicament tank, a deodorizing tower, a crude oil tank, a light oil tank, a separator, a condenser, a desulfurizing tower, a clear water tank, a sewage station and a steam boiler, wherein an outlet of the all-in-one machine is connected with an inlet of the oil removal machine; the oil removal machine is used for removing crude oil in oil mud slurry; the oil removal machine is used for recycling the crude oil into the crude oil tank, exhausting odor into a deodorizing tower and discharging the mud slurry into the separator; the separator is used for performing solid-liquid separation; the dehydration machine is used for evaporating the water, then feeding into the condenser, and putting dry mud into the pyrolysis machine; thepyrolysis machine is used for feeding pyrolysis steam to the condenser; the condenser is used for draining condensation liquid into the separator; an outlet of the separator respectively leads to thesludge station and the light oil tank; an inlet of the desulfurizing tower is connected with the condenser, and an outlet of the desulfurizing tower is connected with the steam boiler; the clear water tank is used for providing water sources; and the steam boiler is used for supplying heat sources to the all-in-one machine and the oil removal machine.

Owner:PANJIN NINGTAI ENERGY TECH

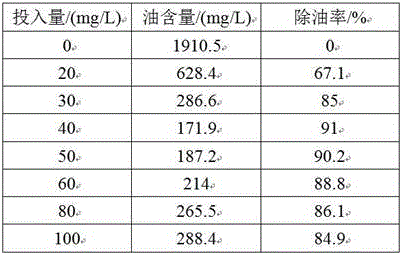

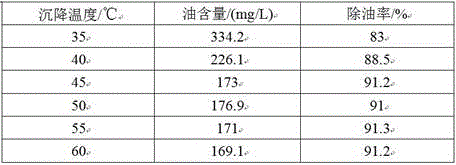

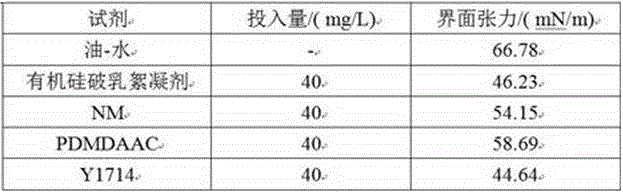

Organosilicone-break-emulsification agent and application thereof

ActiveCN106477700AReduce intensityReduce tensionFatty/oily/floating substances removal devicesNature of treatment waterOil waterSewage

The invention discloses an organosilicone-break-emulsification agent and an application thereof. The water treatment agent of the organosilicone-break-emulsification agent is prepared from cationic demulsifie (NM), flocculant (PDMNAAC)and organosilicone surfactant (Y1714) with a mass concentration ratio of 10: 3: 1. The specific use method aiming at W refining decompression tower top oily sewage is adding the organosilicone-break-emulsification agent of 30-80 mg / L to achieve an oil removal rate of 85% or higher. The effects of demulsification by the demulsifie NM, adsorption bridging and electrical neutralization by the flocculant PDMDAAC, oil-water interface tension decreasing and oil-water interface film tensity reducing by the organosilicone surfactant Y1714 and the like are synthetically developed through the compounding of cationic demulsifie (NM), flocculant (PDMNAAC)and organosilicone surfactant (Y1714). Accordingly, the effect result of oil-water separation is achieved. The organosilicone-break-emulsification agent and the application thereof has the advantages of requiring little water treatment agent dosage, producing little sediment and being high in oil removal rate in the aspect of refining decompression tower top sewage treatment and has certain referential value to refining decompression tower top sewage treatment.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

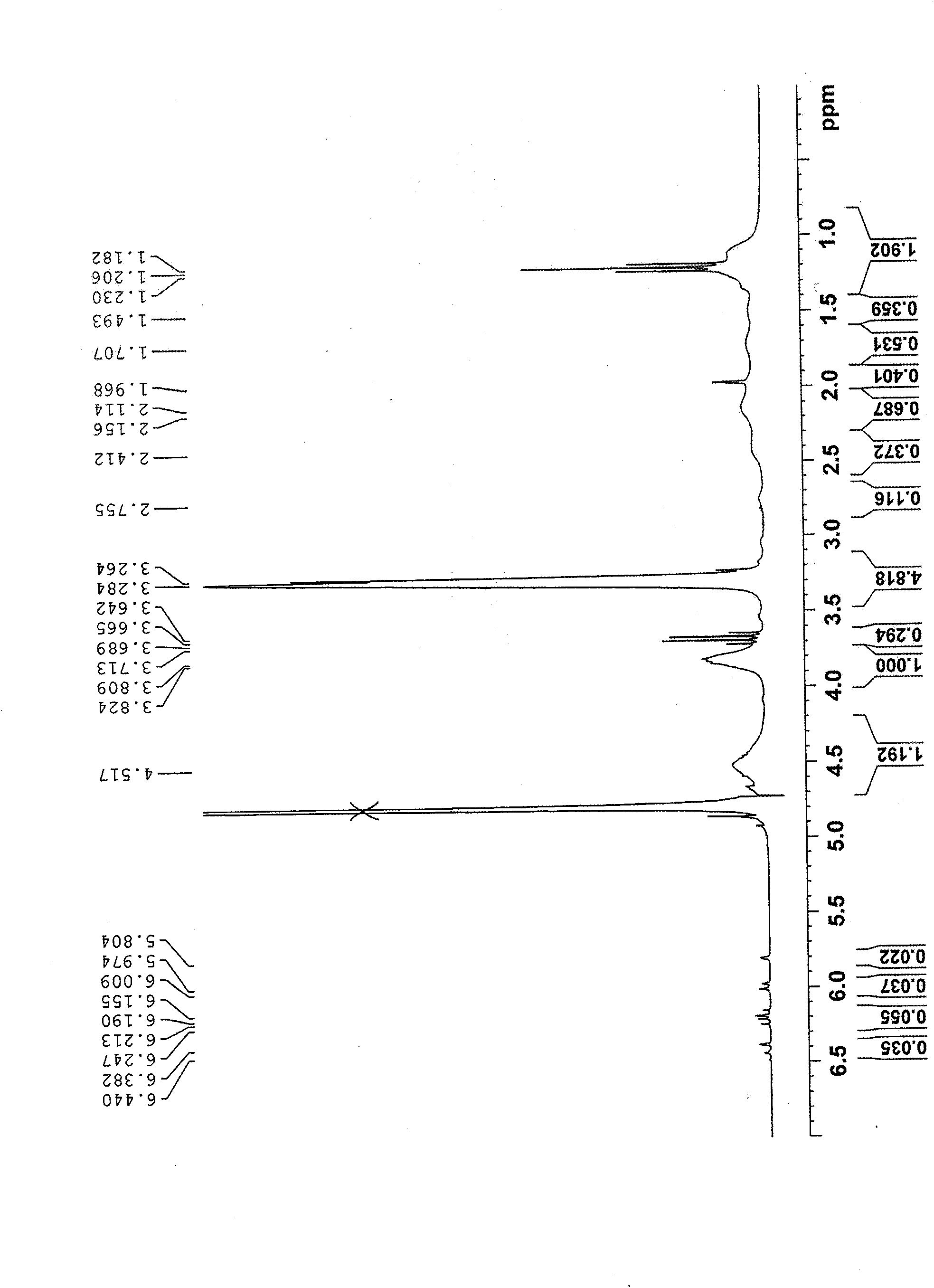

Organic/inorganic hybridized cation reverse demulsifier, preparation method and application thereof

The invention discloses an organic / inorganic hybridized cation reverse demulsifier, a preparation method and an application thereof. The preparation method for the organic / inorganic hybridized cationreverse demulsifier comprises the following steps: 1) adopting a silane coupling agent for modifying the surface hydroxyl group on nanometer SiO2, thereby acquiring modified nanometer SiO2, and then connecting a terminal on the modified nanometer SiO2 surface with a carbon-carbon double bond; 2) trigging ternary polymerization reaction of the modified nanometer SiO2, acrylamide and dimethyl diallyl ammonium chloride, thereby acquiring an end product. According to the invention, the silane coupling agent containing an unsaturated double bond is adopted for modifying nanometer SiO2, so that themodified nanometer SiO2 has a certain hydrophobicity and has an unsaturated carbon-carbon double bond on the terminal; a lyophobic hard-shell hydrophilic soft-shell netted structure can be formed through the ternary polymerization of the modified SiO2, AM and DMDAAC; the structure is capable of effectively increasing electric charge density and is capable of realizing effective demulsification onthe basis of guaranteeing low cation degree; a demulsifier to be matched with the reverse demulsifier is in a nonionic form, so that the formed floc strength is low and the de-oiling rate is high.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Treatment method for tank bottom oil sludge

PendingCN108706843AEasy to separateReduce pollutionSludge treatmentSpecific water treatment objectivesAlkaline waterOil sludge

The invention provides a treatment method for tank bottom oil sludge. The method comprises the following steps: step one, performing water adding and mixing treatment on the oil sludge, enabling the solid content of the oil sludge to reach 4-15%; step two, adding sodium hydroxide solution to adjust a pH value to be 7.5-9; step three, adding a non-ionic surfactant and stirring in a high speed; andstep four, pumping into a clarification tank for precipitation separation. The provided treatment method for the tank bottom oil sludge is simple in reaction condition, convenient in operation, and capable of combining a demulsifying agent, the surfactant and an alkaline water washing technology in a specific reaction sequence and the reaction condition, realizing the rapid separation of the oil sludge, enabling a deoiling rate to reach 95% or more, and reducing the pollution of the oil sludge to the environment.

Owner:中科海创环境科技(大连)有限公司

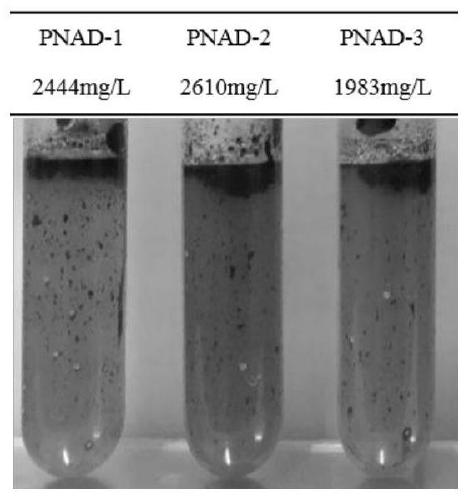

Preparation method of poly (diallyldimethylammonium chloride) as flocculating agent for treating sewage

ActiveCN106986959ALow oil removal rateLow monomer conversionWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationLow speedReaction temperature

The invention discloses a preparation method of poly (diallyldimethylammonium chloride) as flocculating agent for treating sewage. The preparation method comprises the following steps: (1) adding an initiator, a complexing agent and ethylene glycol as a chain transfer agent in an aqueous solution of diallyldimethylammonium chloride, stirring uniformly, and feeding nitrogen to remove air in a reaction container; (2) heating reaction liquid obtained from the step (1) while stirring, and carrying out polymerization reaction; (3) heating to the temperature of 65-85 DEG C, adding the initiator in the reaction liquid again, and adding water in the reaction liquid for reaction; and (4) under protection of the nitrogen, carrying out insulation and curing to obtain the poly (diallyldimethylammonium chloride). The method is simple in process and easy to operate, the reaction temperature is convenient to control, polymerization reaction is stably carried out at low speed, products with medium and low relative molecular mass are easily obtained, and the preparation method is suitable for treatment of oilfield chemical flooding output liquid. The prepared flocculating agent for treating the sewage is high in oil removal rate, high in monomer conversion rate, good in water purification effect, low in viscosity of products and convenient to inject, and has universal applicability.

Owner:中海油(天津)油田化工有限公司 +2

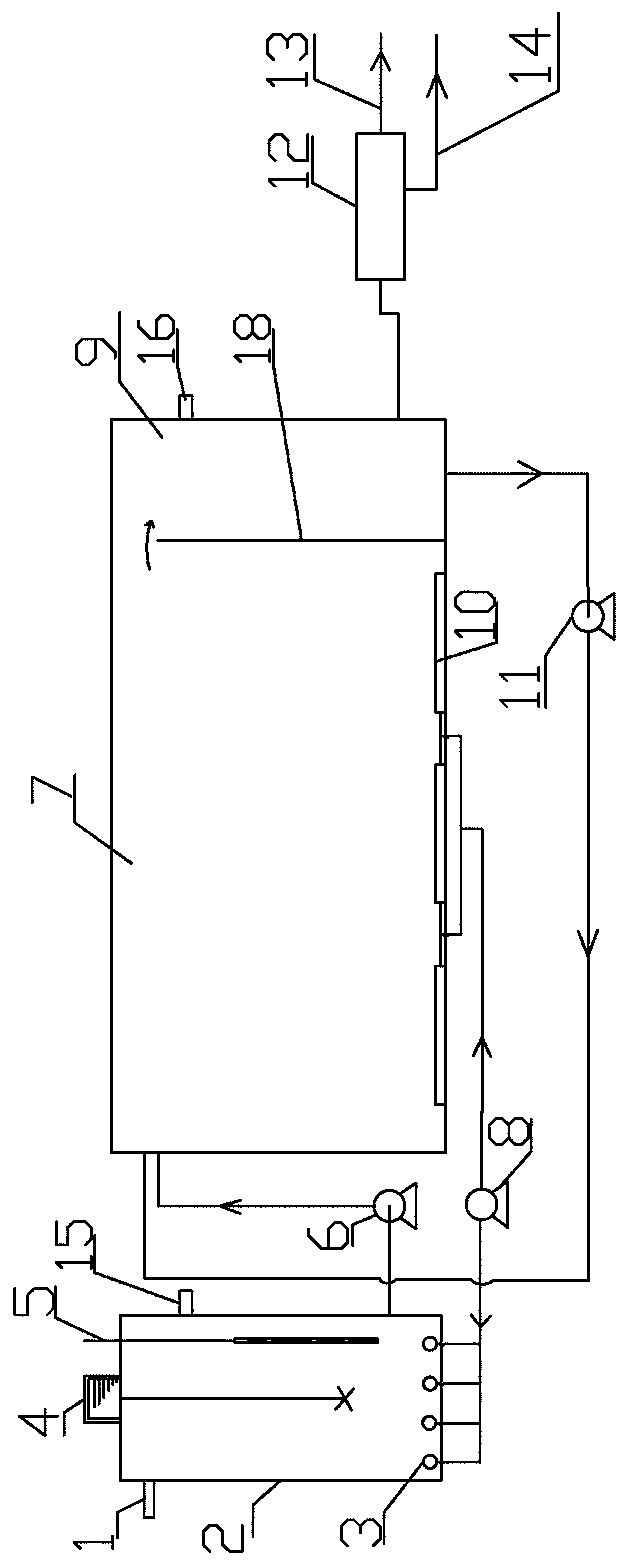

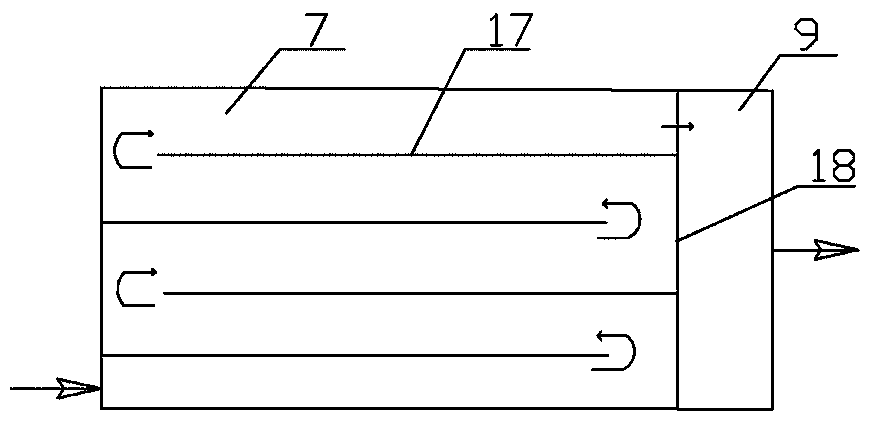

Water-based deoiling treatment method and device for oily sludge in oil field

ActiveCN108996862AReduce oil contentTo achieve the purpose of resource utilizationWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningWater basedMicrobial agent

The invention discloses water-based deoiling treatment method and device for oily sludge in an oil field. The method includes: a) preparing a sludge / water mixture, weight content of oil being 10-20%;b) continuously pumping the sludge / water mixture into a water-based biochemical tank to decompose the mixture with a deoiling composite microbial agent, which contains GWN-1 strain and GWN-2 strain, for 60-84 hours, live bacteria number of the biochemical system being 10<9>-10<11> / ml; c) feeding the degraded sludge / water mixture into a settlement tank for settlement, then feeding a supernatant into a wastewater treatment device and the settlement, in the bottom layer, into a centrifuge, meanwhile, returning a part of liquid to the water-based biochemical tank; d) after the settlement enters the centrifuge, performing solid-liquid separation, and returning the separated wastewater to a sludge regulation tank for reutilization. The invention also discloses the device for achieving the method. The method and the device are high in biochemical degradation speed and efficiency of the oily sludge.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multifunctional treating agent for oilfield sewage

InactiveCN105084435AReduce dosageHigh oil removal rateWaste water treatment from quariesFatty/oily/floating substances removal devicesHigh concentrationFlocculation

The invention relates to a multifunctional treating agent for oilfield sewage, which is composed of the following components in parts by weight: 15-25 parts of demulsifier, 10-20 parts of flocculant, 20-25 parts of corrosion inhibitor, 5-10 parts of surfactant and 5-8 parts of bactericide. The treating agent can simultaneously perform the functions of demulsification, flocculation, bridging, foaming, corrosion and scale inhibition, and sterilization. The composite oily sewage treating agent has the advantages of low consumption, high oil removal rate and obvious corrosion and scale inhibition effects, and is especially suitable for treating high-concentration oilfield sewage.

Owner:张哲夫

Hydrophilic and hydrophobic modified fiber ball filter material for sewage treatment, and preparation method of filter material

InactiveCN109224638AEasy to operateLow equipment requirementsFatty/oily/floating substances removal devicesFiltration separationFiberPolymer science

The invention relates to a hydrophilic and hydrophobic modified fiber ball filter material for sewage treatment, belonging to the field of sewage treatment. A preparation method of the hydrophilic andhydrophobic modified fiber ball filter material for the sewage treatment comprises the following steps: dipping fiber balls in an acetic acid solution with a mass concentration of 25%, and carrying out heat treatment for 1-2 hours; then, washing the treated fiber balls with water, putting into a modifier solution, and dipping for 2-10h under the condition of heating; taking out the modified fiberballs, and carrying out heat treatment on the modified fiber balls for 0.5-1 hour at 100-200 DEG C to obtain the hydrophilic and hydrophobic fiber ball filter material, wherein the modifier solutionis prepared from polyvinyl alcohol, methacrylic acid, sodium perfluorocarboxylate, polydimethyldiallyl ammonium chloride, polyhydroxy fatty acid amide, polyethylene glycol and deionized water. The hydrophilic and hydrophobic modified fiber ball filter material prepared by the method has good oil removing ability and is easy to clean, so that the recycling of the fiber ball filter material is promoted.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Preparation method of nano magnetic particles for sewage treatment

InactiveCN109081394AGood dispersionGraft structure is stableFatty/oily/floating substances removal devicesOther chemical processesSewage treatmentAqueous solution

The invention provides a preparation method of nano magnetic particles for sewage treatment. The method includes the steps of firstly, processing Fe3O4 nano magnetic particles with an alkaline solution; secondly, modifying the nano magnetic particles obtained in the first step with tetramethoxysilane; thirdly, coupling the nano magnetic particles obtained after the second step with PEG polymer with photoreaction groups and aliphatic chains to obtain the nano magnetic particles grafted with the aliphatic chains. The preparation method has the advantages that the prepared nano magnetic particleshave a hydrophilic structure and a hydrophobic structure, can keep good dispersing performance in an aqueous solution, have good affinity to oily pollutants, and are easy to achieve fast oil drop cleaning and high in oil removing rate; meanwhile, the prepared nano magnetic particles are stable in grafting structure and capable of being repeatedly used after recycling and washing, and actual testsshow that the nano magnetic particles can be reused for 15-20 times.

Owner:SUZHOU AIBOMAIER NEW MATERIAL CO LTD

High polymer resin, and apparatus and method for removing oil by using it

ActiveCN104086679ARemove in timeEasy to installFatty/oily/floating substances removal devicesOther chemical processesAutomatic controlDifferential pressure

The invention relates to an oil-containing wastewater oil removal technology, and especially discloses a coalescence material used in a coalescence process oil removal technology, an oil removal method and an oil removal apparatus. The purposes of the invention comprise provision of a polymer resin simple to prepare, provision of an oil removal apparatus using the polymer resin and having a high oil removal rate and obvious energy and water saving benefits, and provision of a high-oil-content wastewater oil removal method using the above synthetic resin and the oil removal apparatus. The polymer resin is highly stable and firm in a subsequently introduced lipophilic group, can be repeatedly used, and is simple to prepare without amination. The oil removal apparatus comprises an aggregation device and an oil-water separating device, and also comprises a differential pressure detection device, and a resin layer is loosened through the automatic control of a pressure inductor in order to reduce the operation differential pressure; and the upper end of the aggregation device is provided with a wash water inlet, and the lower end of the aggregation device is provided with a wash water outlet.

Owner:NINGBO ZHENGGUANG RESIN CO LTD

Degreasing agent and preparation method therefor

InactiveCN105238602AHigh oil removal rateFast cleaningSurface-active non-soap compounds and soap mixture detergentsSolventSURFACTANT BLEND

In order to solve problems that an existing degreasing product in the prior art damages human skin, corrodes cleaned appliances, has a relatively strong irritating odor and is not ideal in degreasing effect, the invention provides a degreasing agent and a preparation method therefor. The degreasing agent provided by the present invention is characterized by comprising the following components in percentage by weight: 0.1-5% of edible essence, 0.2-10% of a solubilizing agent, 10-35% of a surfactant, 0.2-8% of a cosolvent, 0.2-8% of a builder, 0.05-1% of dilute hydrochloric acid and the balance of deionized water. The degreasing agent and the preparation method therefor provided by the present invention have the beneficial technical effects of high degreasing rate and fast cleaning speed, mildness, no irritating odor and no damage to human skin and no corrosion to the cleaned appliances.

Owner:重庆市涣颜环保科技有限公司

Preparation method of reversed-phase demulsification water purifying agent for oil-containing sewage treatment of thickened oil

ActiveCN109628140AEnhance demulsificationHigh speedDewatering/demulsification with chemical meansViscous liquidHalohydrocarbon

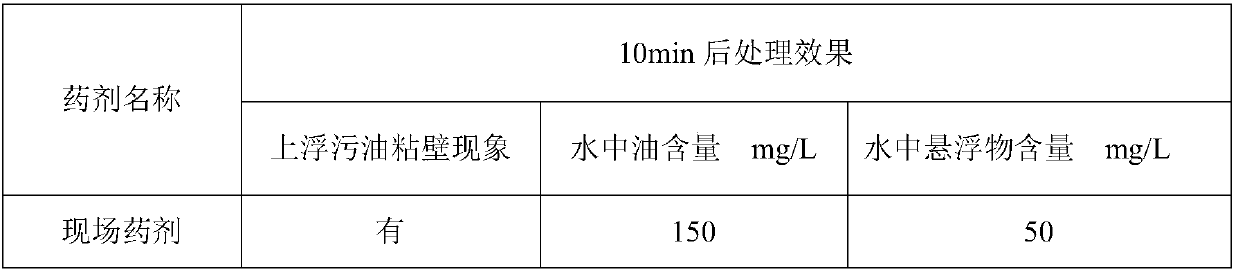

The invention discloses a preparation method of a reversed-phase demulsification water purifying agent for oil-containing sewage treatment of thickened oil. The preparation method comprises the stepsthat N,N-dimethylethanolamine serves as an initiator to react with epoxy propane and ethylene oxide to prepare a precursor, and then the precursor reacts with halohydrocarbon to prepare a brown viscous liquid reversed-phase demulsification water clarifier. The reversed-phase demulsification water purifying agent obtained through the preparation method is a cationic polymer and brown viscous liquid, it is tested that the rotating viscosity is 200-280 CP at the temperature of 25 DEG C and at the rotating speed of 100 r / min, the water purifying agent can increase the demulsification and coalescence speed of emulsified oil drops at high temperature (70-90 DEG C) when used for thickened oil sewage treatment, treated waste oil does not stick to a wall, the separation effect of an inclined plateoil remover is improved, and the operation frequency for cleaning tank and removing dirt is reduced.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

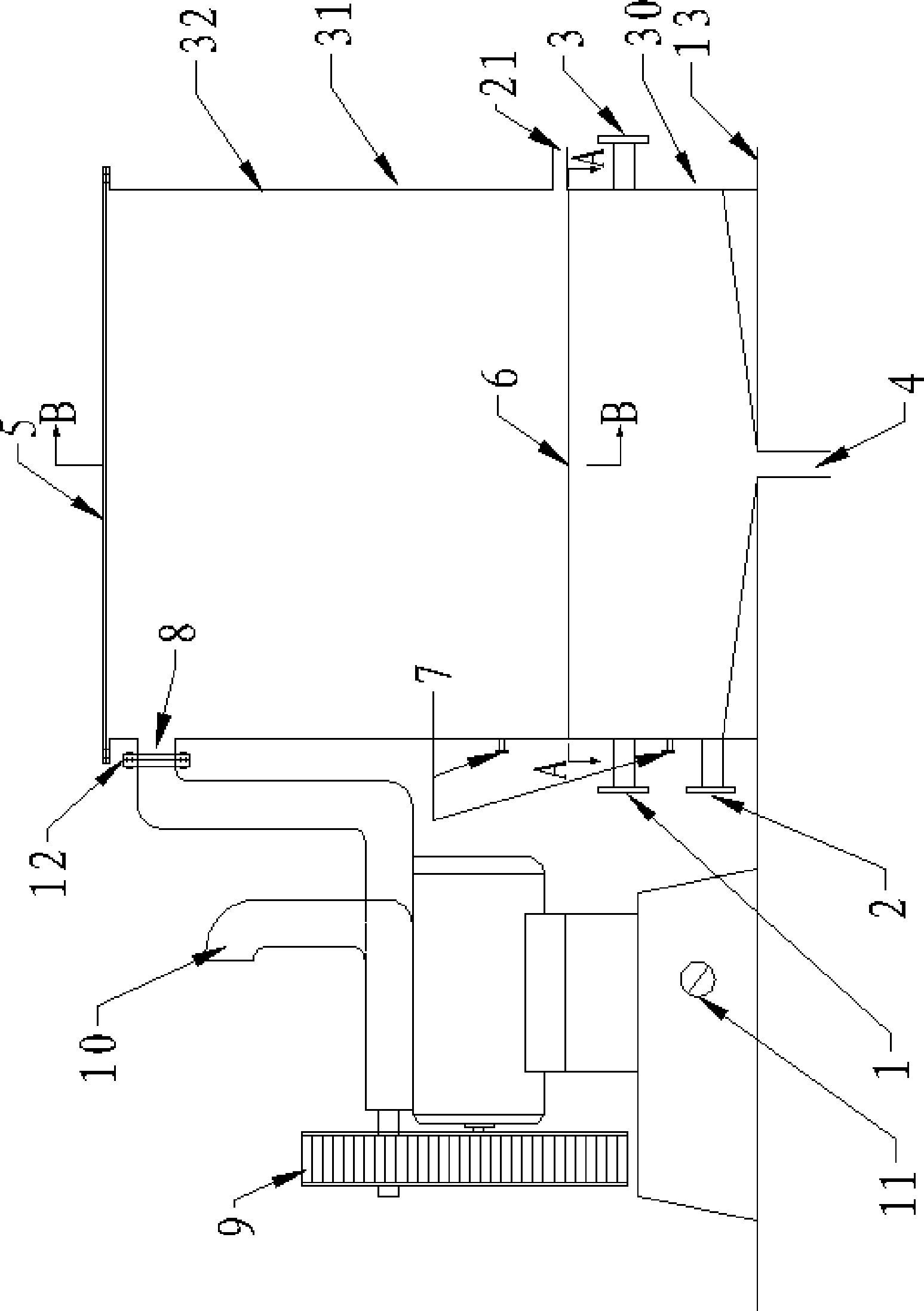

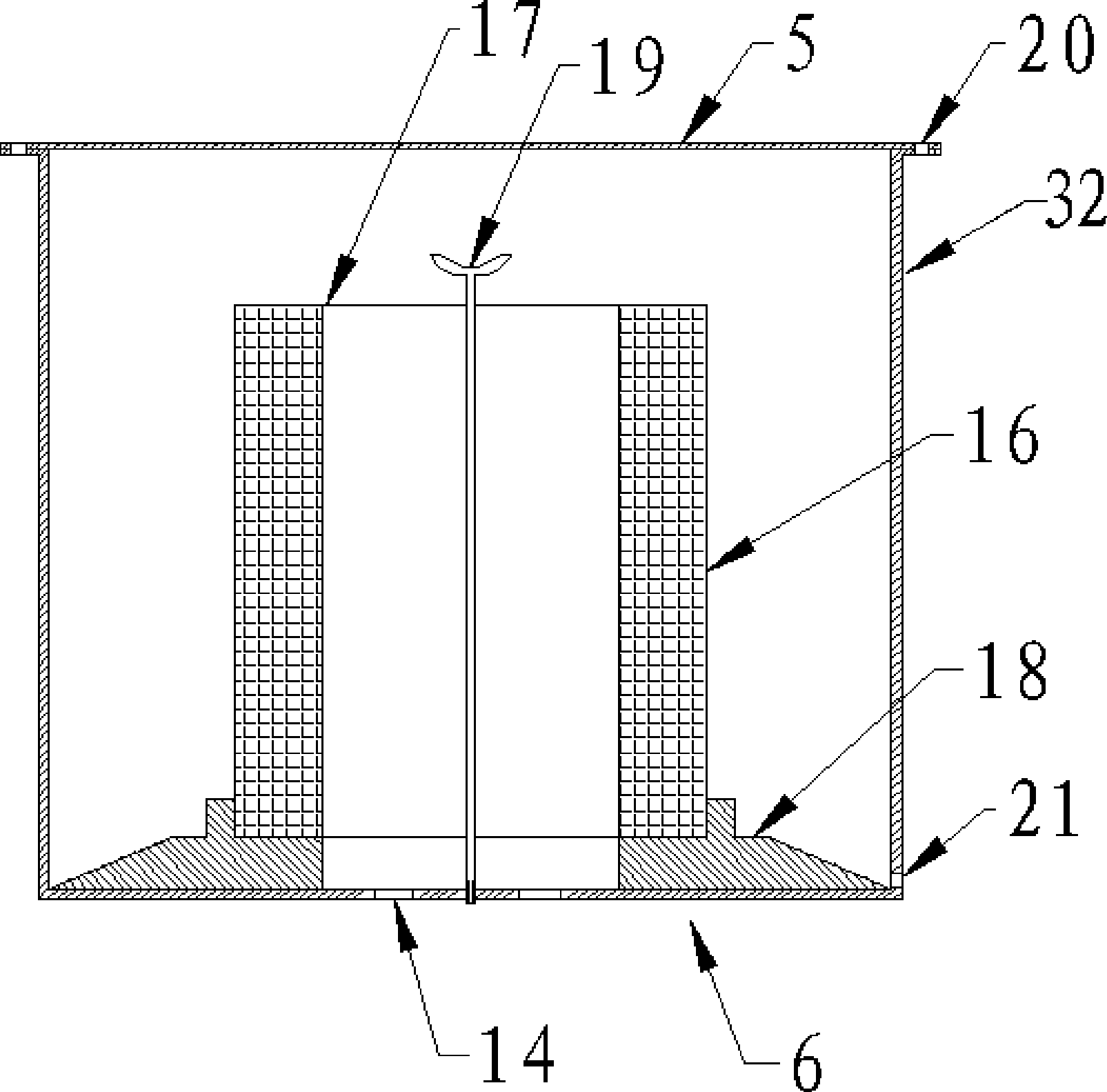

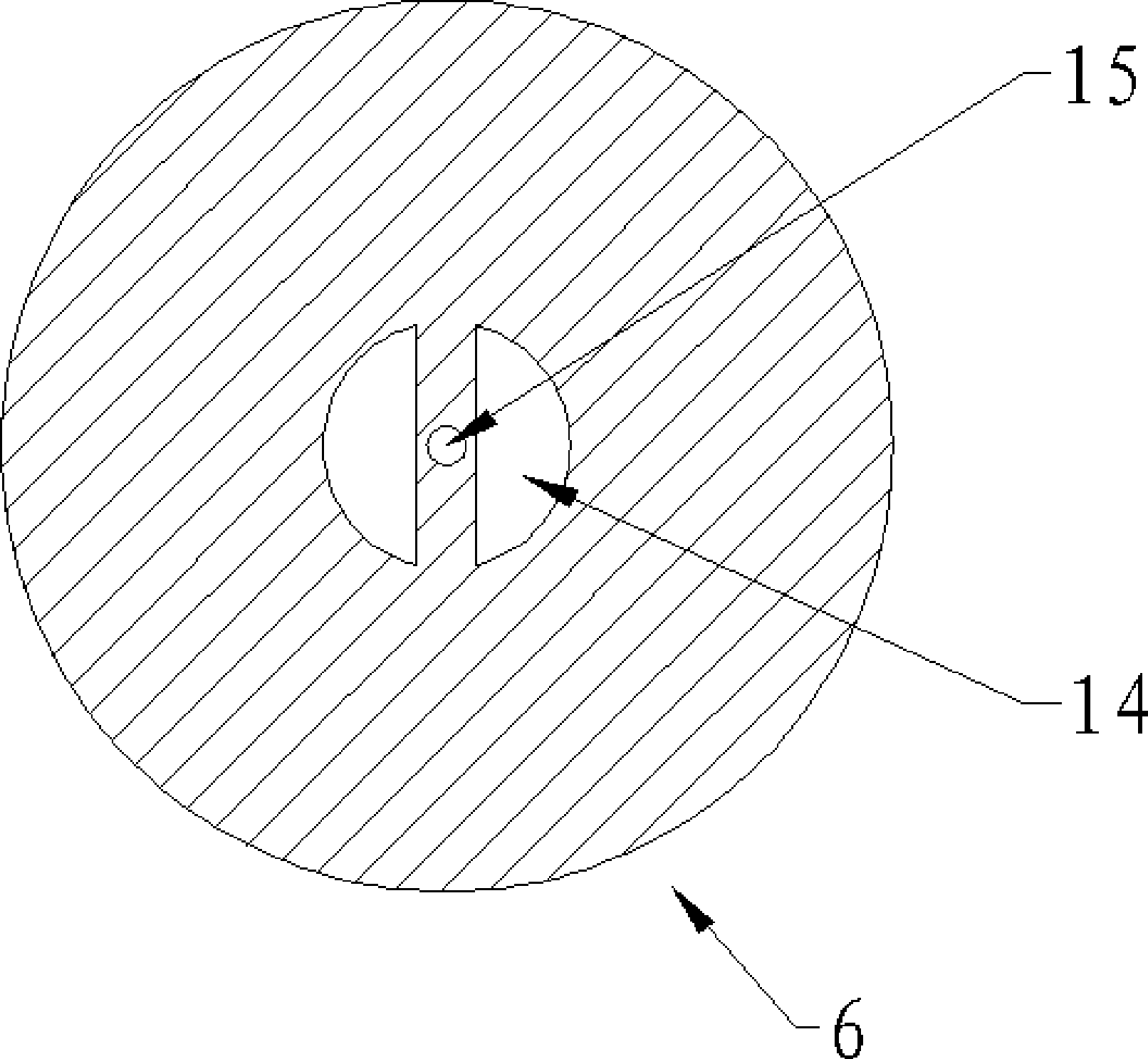

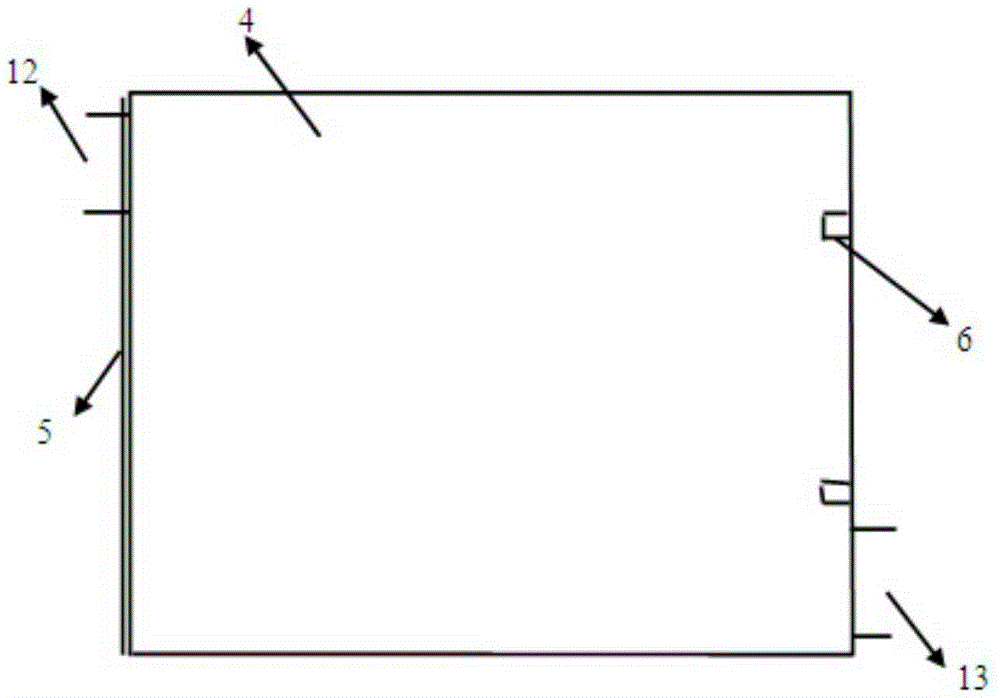

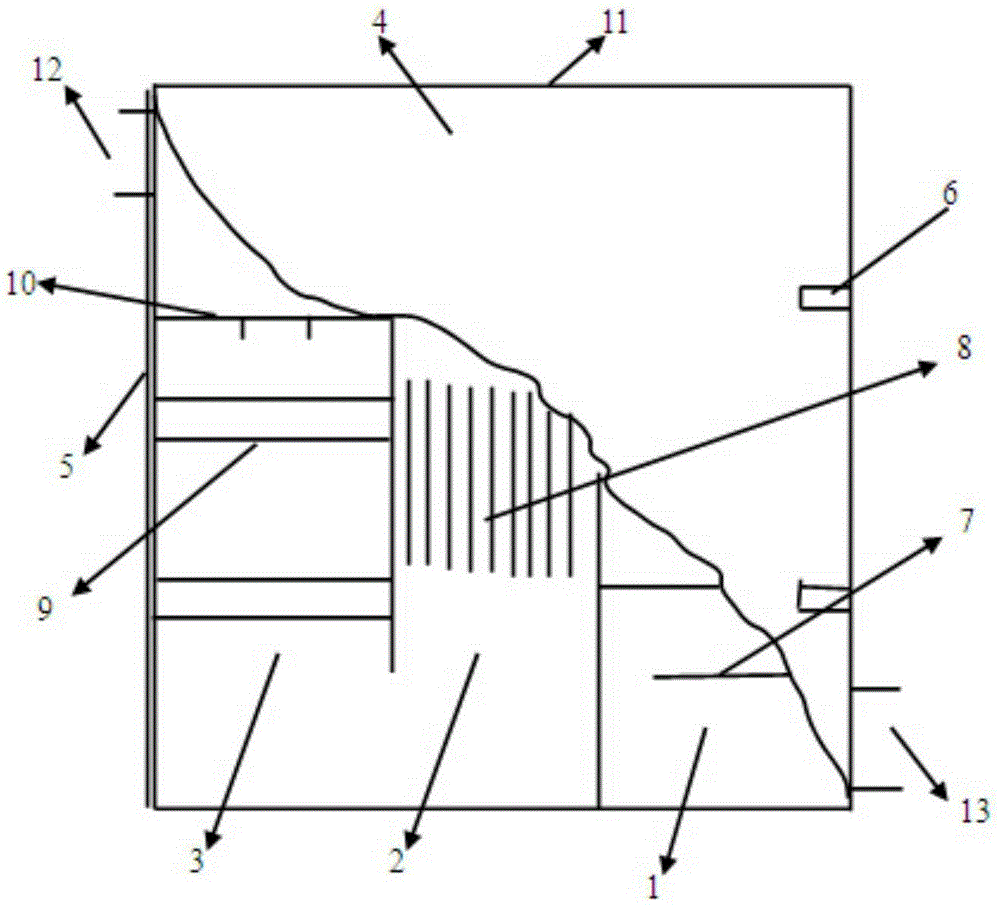

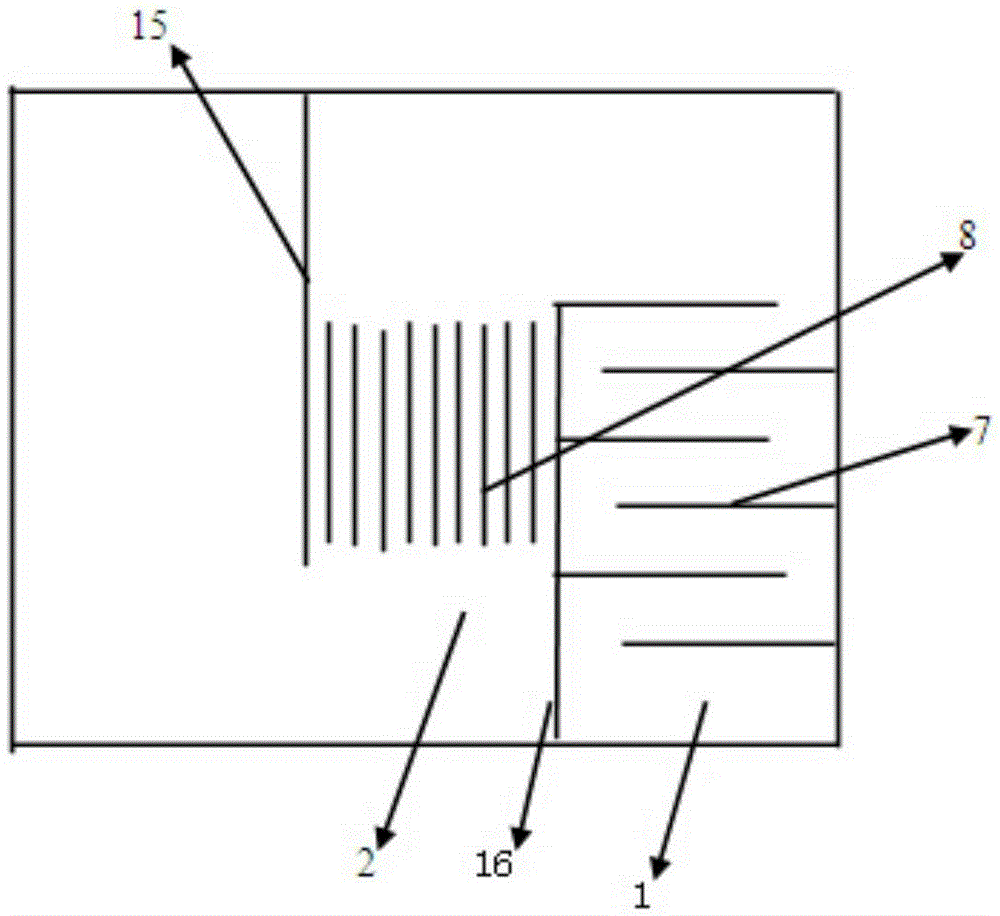

Novel kitchen lampblack purification device

InactiveCN105240893AReduce odorReduce noiseDomestic stoves or rangesLighting and heating apparatusEngineeringNoise reduction

The invention relates to a novel kitchen lampblack purification device. The novel kitchen lampblack purification device comprises a shell (11), a gas outlet (12) is formed above the left end of the shell (11), a gas inlet (13) is formed below the right end of the shell (11), and the gas outlet (12) and the gas inlet (13) are connected with a lampblack pipe through reducing pipes; and a door (4) is installed on the front face of the shell (11), the shell (11) is internally provided with a front section (1), a middle section (2) and a back section (3) from right to left in sequence, a filtering method is adopted in the front section (1) to achieve first-stage oil removing, a static method is adopted in the middle section (2) to achieve second-stage oil and peculiar smell removing, and the back section (3) is a noise reduction section. According to the novel kitchen lampblack purification device, the filtering method is adopted in the front section to achieve first-stage oil removing, the static method is adopted in the middle section to achieve second-stage oil and peculiar smell removing, noise reduction sheets of a micropore opening foam aluminum plate are adopted on the back section to remove airflow noise, and a closed foam aluminum plate is used for isolating the mechanical noise of a draught fan, so that oil removing, noise reduction and peculiar smell removing are integrated, the peculiar smells are removed and the noise is reduced while the better lampblack removing effect of the kitchen lampblack purification device is achieved, and a series of environmental problems caused by lampblack discharging of lampblack discharging units are solved completely.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com