Detergent composition and application thereof

A composition and detergent technology, applied in the directions of detergent compositions, surface active detergent compositions, organic detergent compositions, etc., can solve the problem of short washing time, high washing temperature, low cleaning power and anti-scaling performance, etc. The problem is to reduce the deposition of scale, improve the anti-scaling performance, and achieve the effect of excellent anti-scaling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0094] The preparation method of detergent composition, comprises the following steps:

[0095] 1) First put the filler into the batching pot;

[0096] 2) Under stirring, add component A, component B, and surfactant in turn, and stir evenly;

[0097] 3) Throw in defoamer, oxidizing agent and activator thereof, and stir evenly;

[0098] 4) Put the essence and enzyme preparation into the batching pot and stir evenly;

[0099] 5) Add other additives into the batching pot and stir evenly;

[0100] 6) Continue to fully stir the materials in the batching pot to ensure that there is no crust and agglomeration phenomenon, and sieve the uniformly mixed materials (20-80 mesh), pass the inspection and pack.

[0101] The detergent compositions of the present invention can be processed into any desired form. According to the determination of further components, it can be made into liquid or solid immediately. Liquid compositions can be formulated as liquid dishwashing detergents with ...

Embodiment

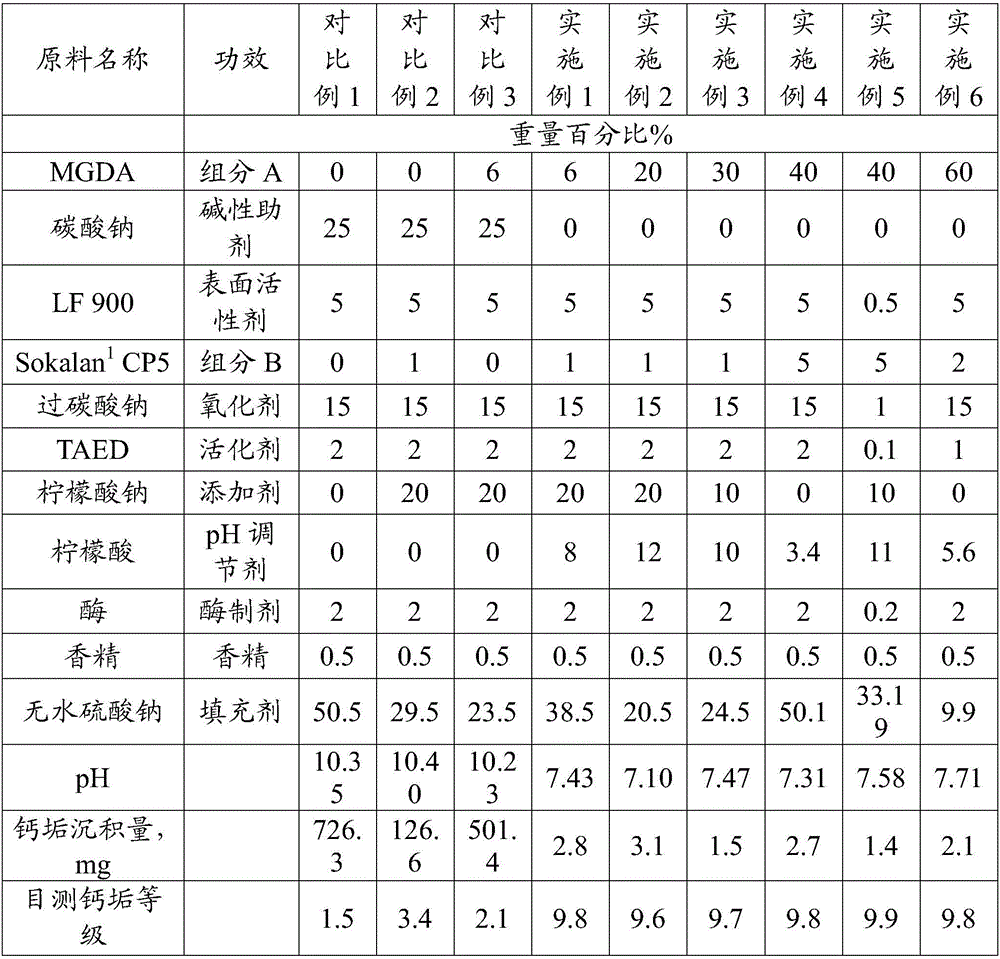

[0136] The detergent compositions of Comparative Examples 1-3 and Examples 1-6 were formulated according to Table 1.

[0137] The automatic dishwasher detergent formula composition of table 1 comparative example 1-3 and embodiment 1-6

[0138]

[0139] 1. Available from BASF.

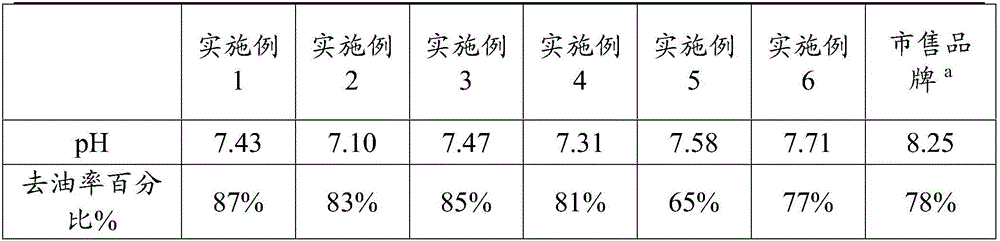

[0140] Table 2 Oil removal rate test results

[0141]

[0142] a, the commercially available brand is weak alkaline dishwashing liquid

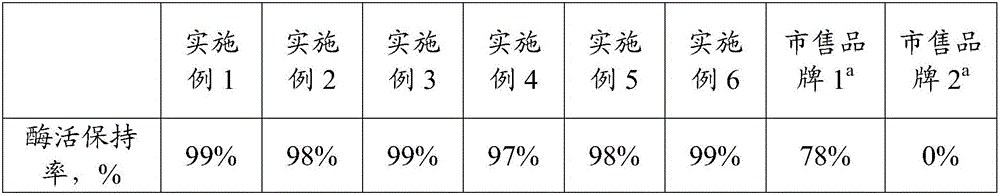

[0143] Table 3 Enzyme stability test

[0144]

[0145] Commercially Available Brands 1 a is an enzyme-containing alkaline dishwashing powder; commercially available brand 2 a Weak alkaline dishwashing liquid containing enzymes

[0146] In Comparative Example 1, Comparative Example 2 and Comparative Example 3 of Table 1, a large amount of sodium carbonate was added, but no pH regulator was added, resulting in a high pH of the composition aqueous solution, all of which were strongly alkaline. This can have a noticeable corrosive effect on the cutlery. Mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com