Method for oil sludge tempering and solidification pelletizing

A sludge, conditioning technology, applied in the methods of granulating raw materials, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult to form solidification, unstable shape, complex components, etc., to improve mutual solubility and adsorption. The effect of improving the compatibility, improving the oil removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

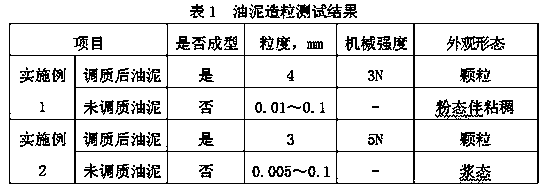

Embodiment 1

[0027] Taking the "three muds" produced in the sewage workshop of an oil refinery in northern Shaanxi and the oil sludge at the bottom of a crude oil settlement tank of an oil production plant combined station in northern Shaanxi mixed at a mass ratio of 1:6 as an example, the initial water content is 65%, and the oil content is 65%. 30% of similar substances and 5% of mud content. The specific tempering and granulation method is as follows:

[0028] 1) Reduction, separation and treatment of oily sludge

[0029] Inject the sludge into the sludge thickening tank with a mud pump, and add cationic polyacrylamide with a weight average molecular weight of 15,000 Daltons of 1% of the oily sludge mass for sedimentation and separation. After standing for 6 hours, separate the oil and water in the upper part of the sludge thickening tank After that, it is reinjected to the sewage treatment plant for treatment, and the lower part of the water-containing oil sludge is mixed with a floccu...

Embodiment 2

[0036] Taking the oil sludge at the bottom of a crude oil settlement tank at an oil production plant union station in northern Shaanxi as an example, the initial water content is 40%, the oily substance content is 30%, and the mud content is 30%. The specific conditioning and granulation methods are as follows:

[0037] Reduction, separation and treatment of oily sludge

[0038] Inject the sludge into the sludge concentration tank with a mud pump, and add 0.1% of the mass of the oily sludge to the zwitterionic polyacrylamide with a weight-average molecular weight of 10,000 Daltons for sedimentation and separation. After standing for 8 hours, remove the oil and water from the upper part of the sludge concentration tank After separation, it is re-injected to the sewage treatment plant for treatment. The lower part of the water-containing oil sludge is mixed with a conditioner and then enters a horizontal screw centrifuge for solid-liquid separation. The flocculant is acrylamide-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com