High polymer resin, and apparatus and method for removing oil by using it

A technology of polymer resin and oil-water separation device, which is applied in the field of coalescing materials, can solve the problems of oil pollution that cannot be removed, the oil content of sewage stock solution is limited, and the preparation process of oil-removing resin is complicated, and achieves simple preparation process and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The following part of this example describes a polymeric resin:

[0041] The polymer resin is made by the following methods:

[0042]Step 1, mixing 10 kg of cross-linked styrene-based gel-type strongly acidic cation exchange resin with a degree of cross-linking of 3 and 10 kg of water, adjusting the pH to 8 with sodium hydroxide;

[0043] Step 2, the product of step 1 is heated up to 60°C;

[0044] Step 3, add cetyltrimethylammonium chloride 50g to the product of step 2, and keep warm for 3 hours;

[0045] Step 4, washing and discharging the product of Step 3, collecting the final product with a particle size of 0.3 mm to 1.25 mm to obtain a polymer resin.

[0046] The following part of this example describes an oil removal device:

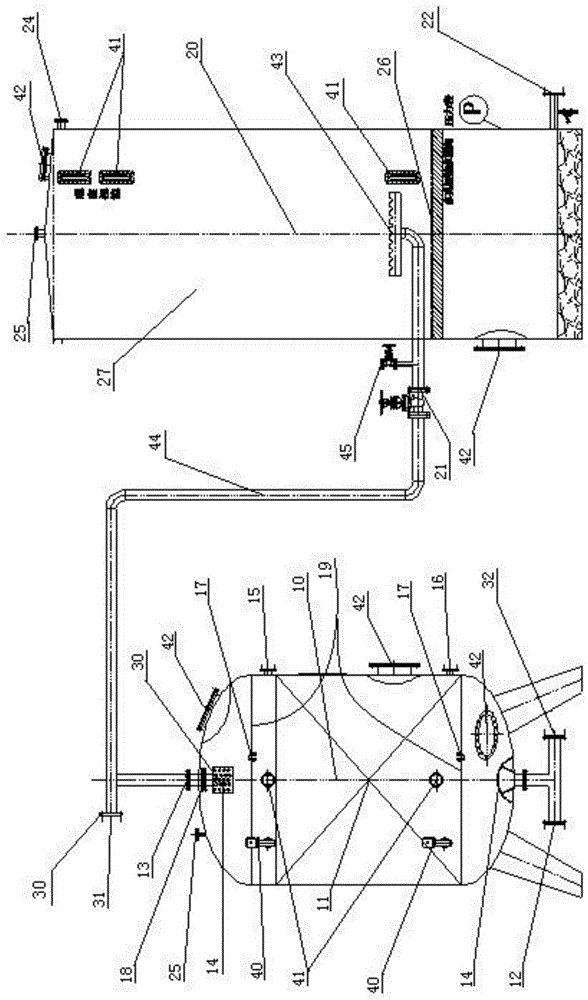

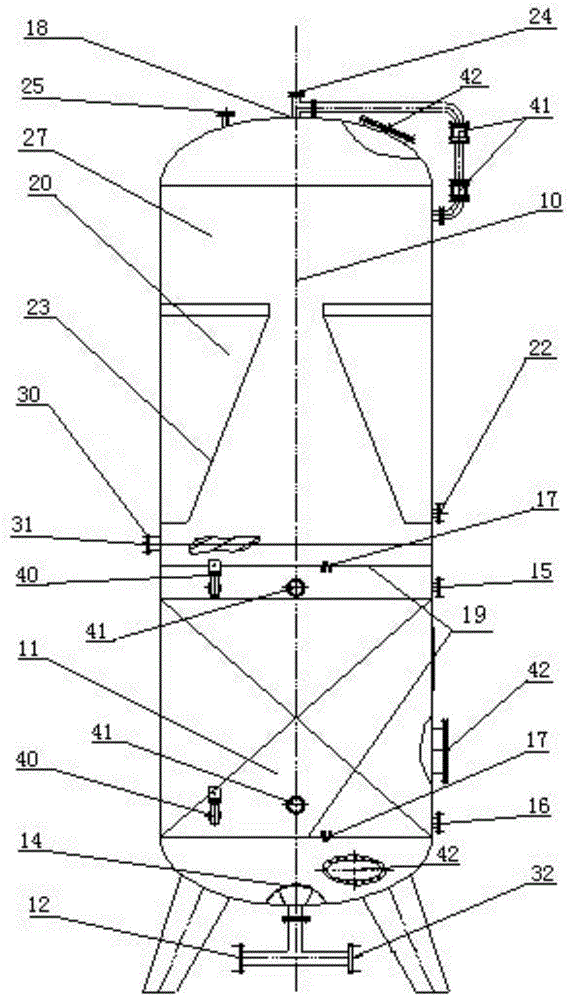

[0047] Such as figure 1 , 3 As shown, the degreasing device is composed of agglomerator 10, resin bed 11, oily sewage inlet 12, oily sewage outlet 13, screen 14, resin loading port 15, resin unloading port 16, water cap 17, crown 18, p...

Embodiment 2

[0063] The degreasing device and degreasing method used in this embodiment are the same as those in Embodiment 1, the difference lies in the structure of the oil-water separation device and the preparation method of the polymer resin.

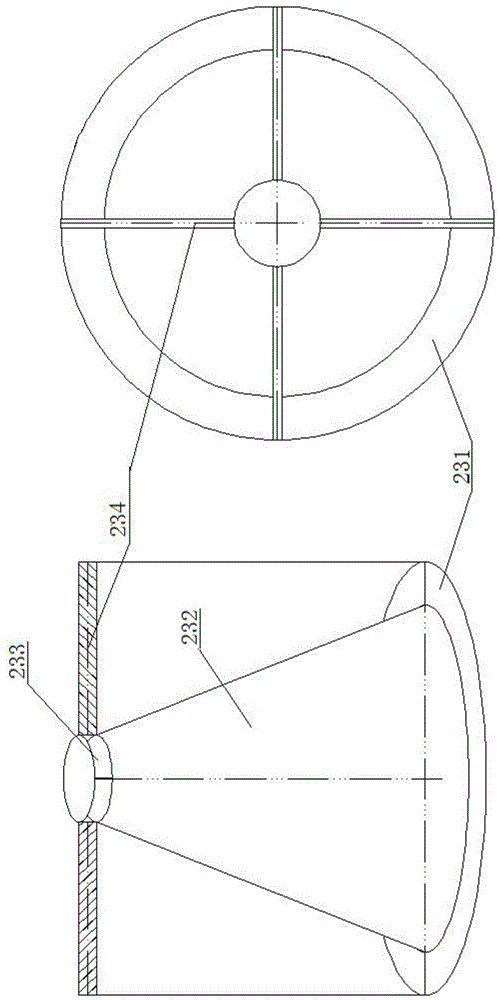

[0064] Such as figure 2 , 4 , 5, the treated water inlet 21 of the oil-water separation device 20 is connected to the oily sewage outlet 13 through the link pipeline 44, the treated water inlet 21 is arranged at the middle and lower part of the oil-water separator 20, and the end of the pipeline of the treated water inlet 21 is provided with a water distributor 43. There is a porous oil-water isolation plate 26 under the water distributor 43. The porous oil-water isolation plate 26 is lined with carbon steel rubber, the thickness of the plate is 20-30 mm, the diameter of the hole is 20 mm, the diameter of the maintenance manhole 42 is 400 mm, and the lower part is supported by 10 channel steel rack to fix. An air inlet pipe 45 is arranged on...

Embodiment 3

[0073] The degreasing device used in this embodiment and the degreasing method are the same as in embodiment 1 or embodiment 2, except that the polymer resin is made by the following method:

[0074]Step 1, mixing 10 kg of cross-linked styrene-based gel-type strongly acidic cation exchange resin with a degree of cross-linking of 5 with 10 kg of water, adjusting the pH to 8 with sodium hydroxide;

[0075] Step 2, the product of step 1 is heated up to 70°C;

[0076] Step 3, add octadecyltrimethylammonium chloride 70g in the product of step 2, keep warm for 5 hours;

[0077] Step 4, washing and discharging the product of Step 3, collecting the final product with a particle size of 0.3 mm to 1.25 mm to obtain a polymer resin.

[0078] Oil removal according to the above method is not limited by oil content and oil type, the maximum oil content can reach 1000mg / L, the oil removal rate is above 99.5%, and the oil recovery rate reaches 96.5%. The resin needs to basically fill the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com