Novel kitchen lampblack purification device

A technology for oil fume purification and kitchen, which is applied in the direction of oil fume removal, household heating, lighting and heating equipment, etc. It can solve the impact on the lives of surrounding residents, affect the normal life of residents, noise pollution and other problems, and achieve convenient cleaning and maintenance. Equipment installation And the effect of easy operation and maintenance, high oil removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

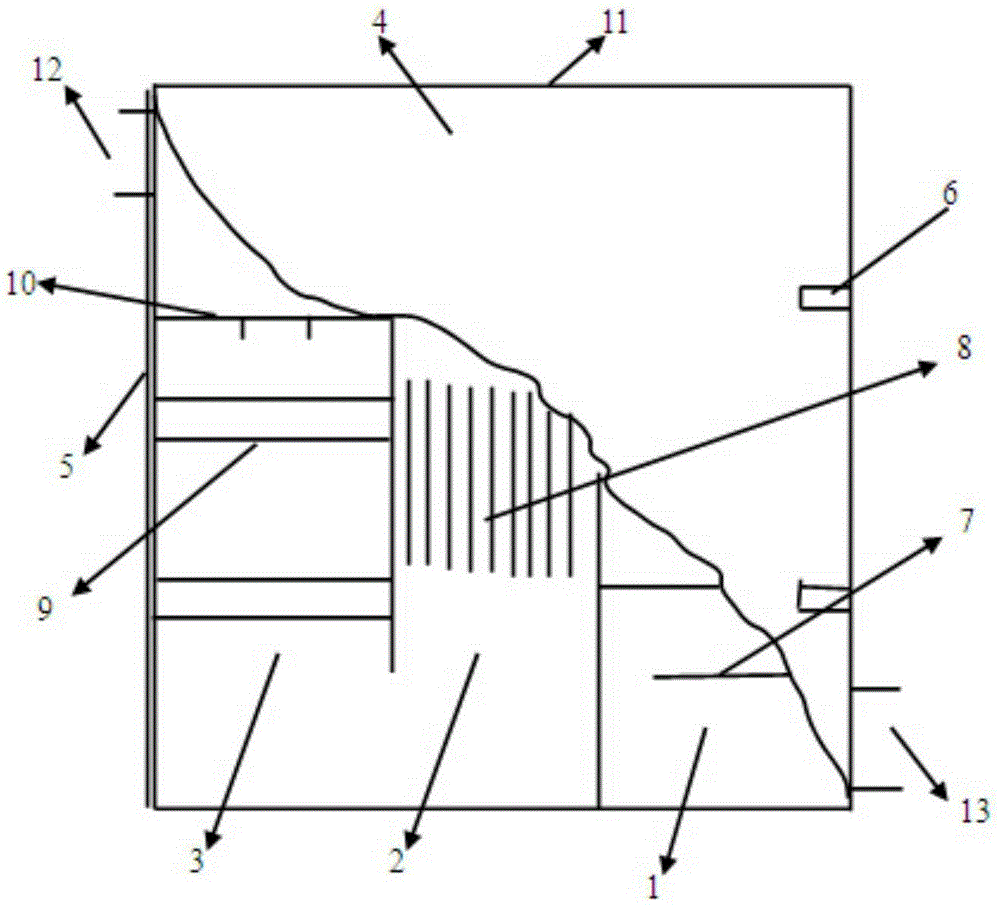

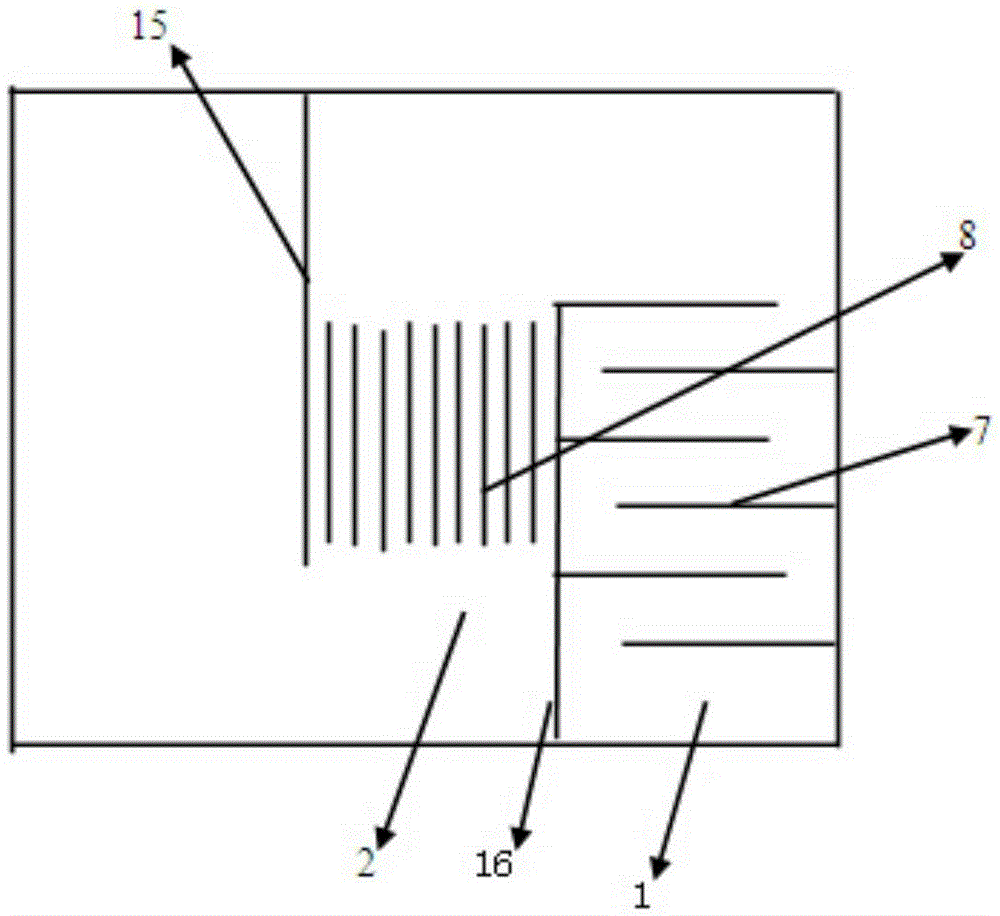

[0026] As shown in the drawings, the present invention includes: a housing 11, an air outlet 12 is opened above the left end of the housing 11, an air inlet 13 is opened below the right end of the housing 11, and the air outlet 12 and the air inlet 13 are all passed through gradually. The shrink tube is connected to the oil fume pipe. There is a door 4 on the front of the housing 11. The housing 11 is in the shape of a cuboid. The left end of the door 4 is connected to the housing 11 through a hinge 5. The right end of the door 4 is equipped with a door buckle 6, which is convenient for filtering materials. , Cleaning and maintenance of the electrostatic precipitator and sound-absorbing sheet; the casing 11 and the door 4 are made of stainless steel or galvanized sheet, the thickness of the casing 11 and the door 4 are both 1.1-2.1mm, and the inside of the casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com