Water treatment agent and preparation method thereof

A technology of water treatment agent and surfactant, applied in the field of water treatment agent and its preparation, can solve the problems of difficulty in meeting discharge standards, high operating costs, incomplete treatment, etc., and achieves high oil removal rate, high activity, and dispersibility. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

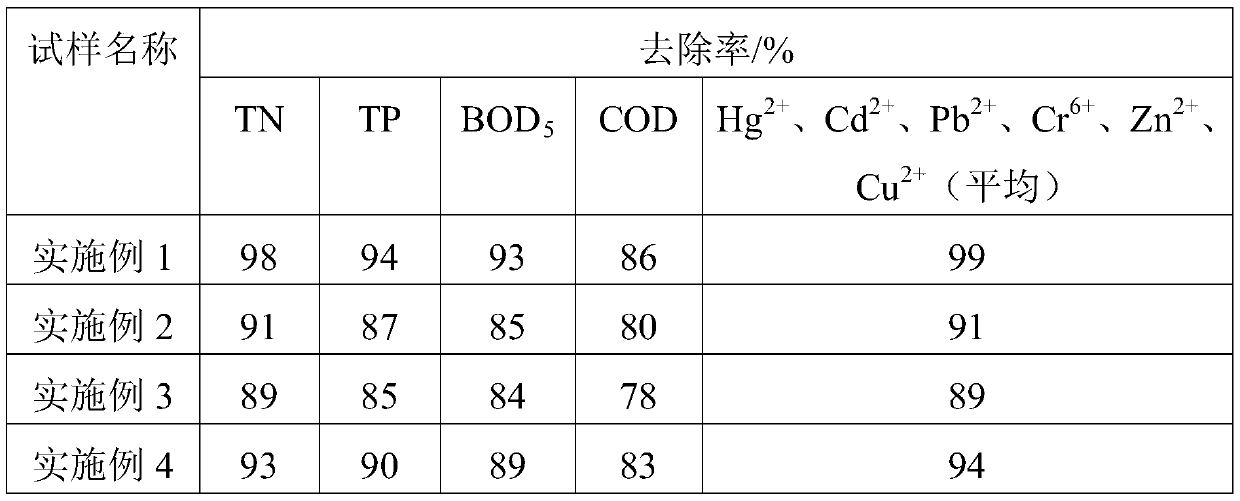

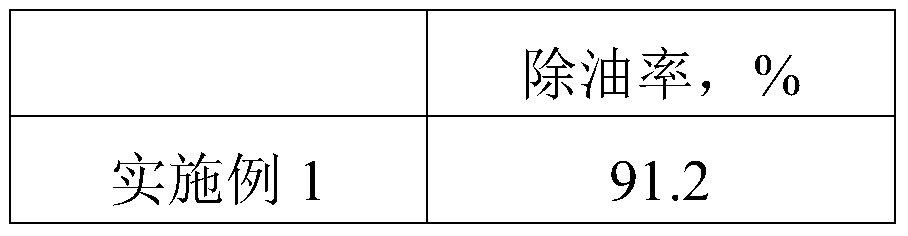

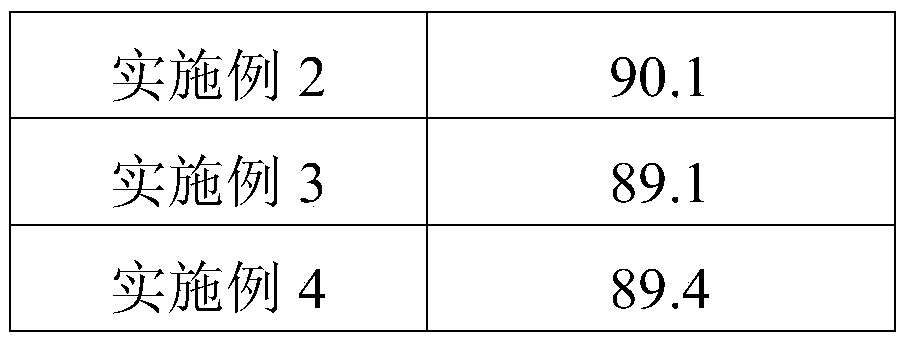

Examples

Embodiment 1

[0027] Water treatment agent raw materials: zeolite 4kg, quartz 1kg, potassium feldspar 1kg, polyacrylamide 0.03kg, polyoxyethylene lauryl ether 0.08kg, surfactant 0.03kg.

[0028] Described tensio-active agent is by 0.01kg tetradecyl dimethyl benzyl ammonium chloride, 0.01kg dodecyl dimethyl benzyl ammonium chloride, 0.01kg dodecyl benzyl trimethyl chloride ammonium mixture.

[0029] Mix the zeolite, quartz, and potassium feldspar in the above parts by weight, activate them at 300°C for 30 minutes (that is, place them in an oven at 300°C for 30 minutes), grind them ultrafinely to a particle size of 5 μm, and mix them with polyacrylamide, The water treatment agent is obtained by mixing polyoxyethylene lauryl ether and a surfactant.

Embodiment 2

[0031] The water treatment agent is prepared by the raw material ratio and method of Example 1, the difference is only: the surfactant is composed of 0.015kg tetradecyl dimethyl benzyl ammonium chloride, 0.015 kg dodecyl dimethyl benzyl ammonium chloride benzyl ammonium chloride mixed.

Embodiment 3

[0033] The water treatment agent is prepared according to the raw material ratio and method of Example 1, the difference is only: the surfactant is composed of 0.015kg tetradecyldimethylbenzyl ammonium chloride, 0.015kg dodecylbenzyltri Mixture of methyl ammonium chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com