Water-based deoiling treatment method and device for oily sludge in oil field

A sludge water-based, oil treatment technology, applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc., can solve the problems of long treatment cycle, slow biochemical degradation, complicated bacterial culture process, etc., to achieve Low operating cost and high oil removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

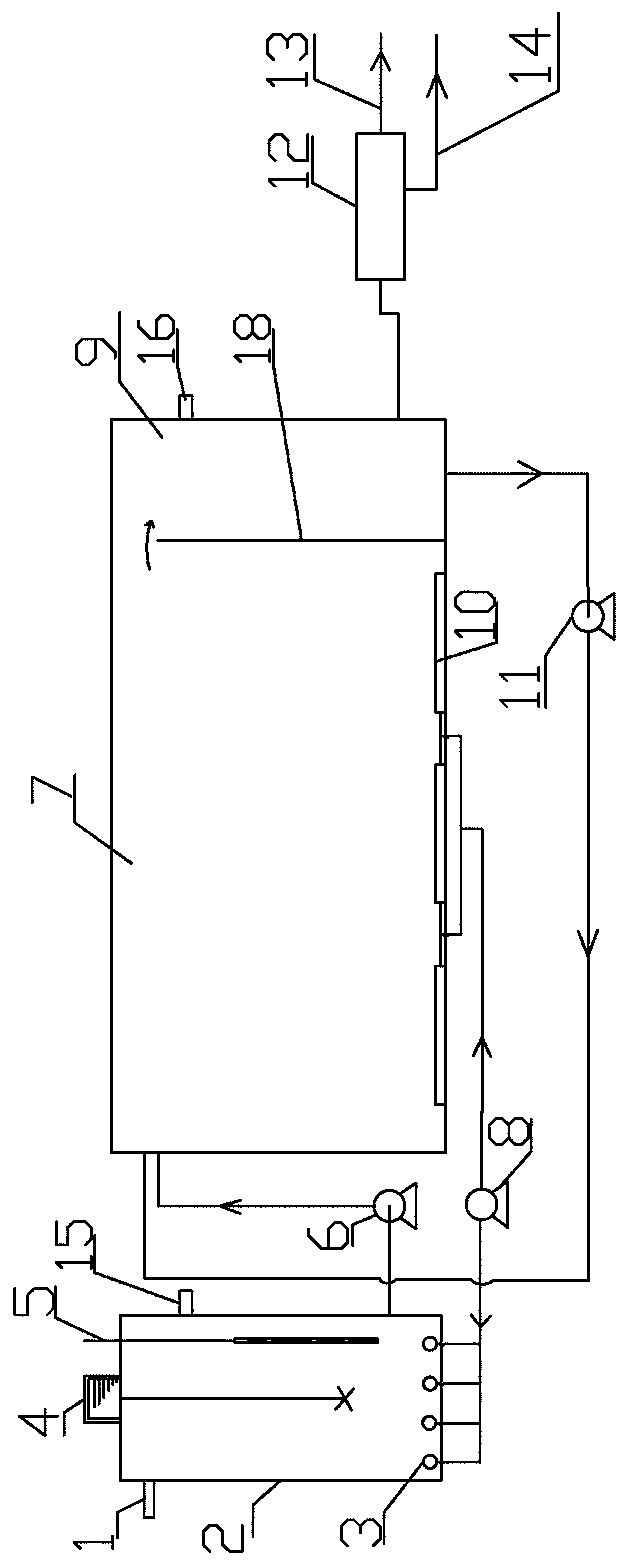

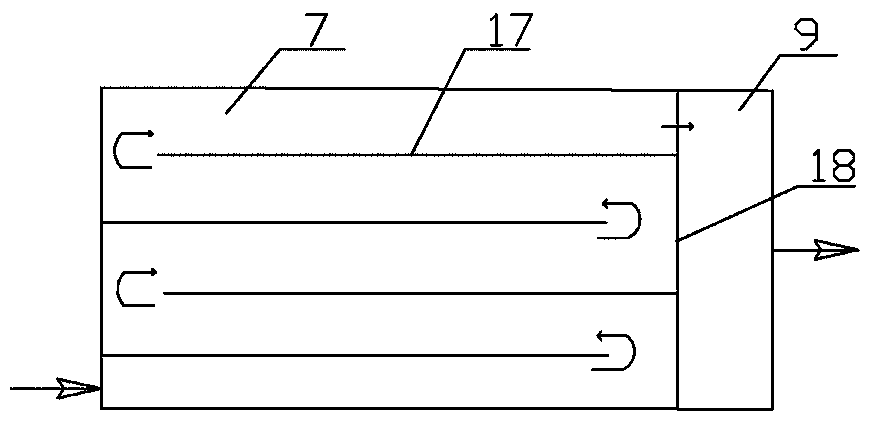

[0034] Such as Figure 1-2 As shown, it is a water-based degreasing treatment device for oily sludge in an oil field, including a sludge conditioning tank 2, a water-based biochemical tank 7, a settling tank 9, and a centrifuge 12. The sludge conditioning tank 2 is equipped with an agitator 4 and heating rod 5, the upper part of the sludge conditioning tank 2 is provided with an oil receiving port 15 and a conditioning water inlet 1, and the sludge conditioning tank 2 is connected to the inlet of the water-based biochemical pool 7 through the liquid inlet pump 6, and the water-based biochemical An aeration pipe 10 is provided at the inner bottom of the tank 7; the settling tank 9 is arranged side by side with the water-based biochemical tank 7 and is separated by a partition 18; an overflow channel is provided on the top of the partition 18; Liquid outlet 16, sludge settling tank 9 is connected to the inlet of water-based biochemical tank 7 through return pump 11; The conditi...

Embodiment 2

[0039] Utilize the device of embodiment 1 to degrade the oily sludge in the oil field. Before the treatment, a biochemical system needs to be established in the water-based biochemical pool 7, which can be processed as follows:

[0040]In step (1), fill the water-based biochemical tank 7 with oilfield produced water, and add 10 mg / L soybean flour and 20 mg / L wheat bran at the same time. According to the COD condition of the water body, COD:N:P=100:5 :1 ratio to add the corresponding inorganic phosphate and inorganic ammonium salt. Add a compound degreasing agent with a mass ratio of 0.1%, and the number of viable bacteria per gram is ≥10 9 indivual. The compound degreasing bacteria agent is composed of 2 strains of degreasing bacteria, which are sourced from the General Microorganism Collection Center (CGMCC) of the China Microbiological Culture Collection Management Committee, and the preservation numbers are: CGMCC No.13903 and CGMCC No.13902. The ratio of the two strains ...

Embodiment 3

[0051] Utilize the device of embodiment 1 and the biochemical system that embodiment 2 establishes to the processing of oilfield oily sludge, it comprises the steps:

[0052] 1) In the sludge conditioning tank 2, configure a mud-water mixture with an oil content of 20% by weight. While stirring, control the temperature of the mud-water mixture at 50°C. After conditioning for 2 hours, remove the surface oil slick; the stirring speed is 100r / min ;

[0053] 2) The remaining mud-water mixture is poured into the water-based biochemical pool 7 continuously, and the biochemical system established by the oil-removing compound bacterial agent decomposes for 60 hours to degrade the petroleum substances in the mixture. During the degradation, the biochemical system in the water-based biochemical pool 7 is kept dissolved The oxygen content is 3.8-4.2mg / L; the compound bacterial agent contains GWN-1 strain and GWN-2 strain, and the number of viable bacteria in the biochemical system is 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com