Technique and device for purifying oil-containing exhaust

A tail gas purification device and technology for tail gas purification, which are applied to the components of pumping devices for elastic fluids, steam condensation, chemical instruments and methods, etc., can solve the problems of poor purification effect of oily tail gas purification process, and achieve recycling lubrication Oil, energy saving, and environmental pollution reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

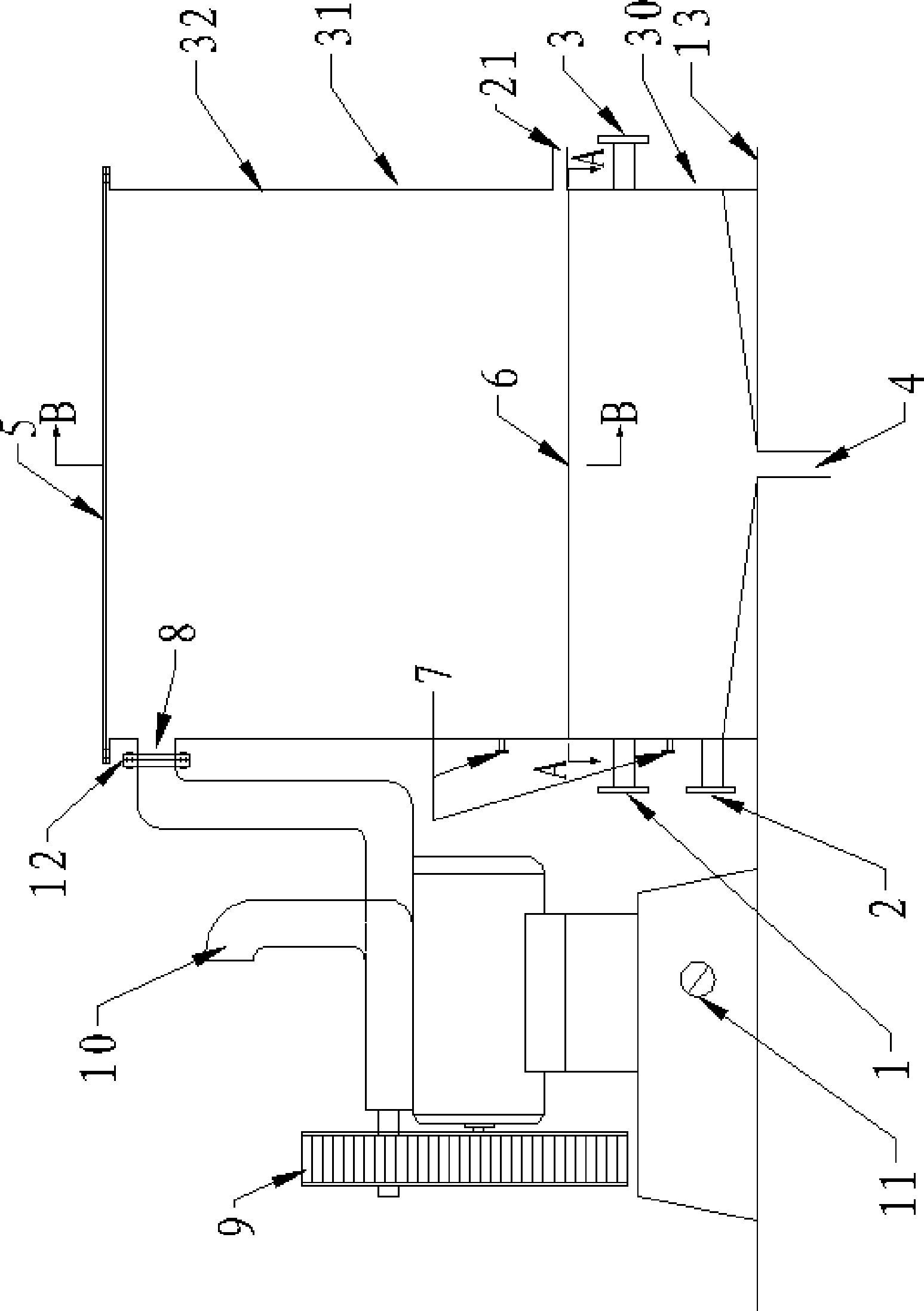

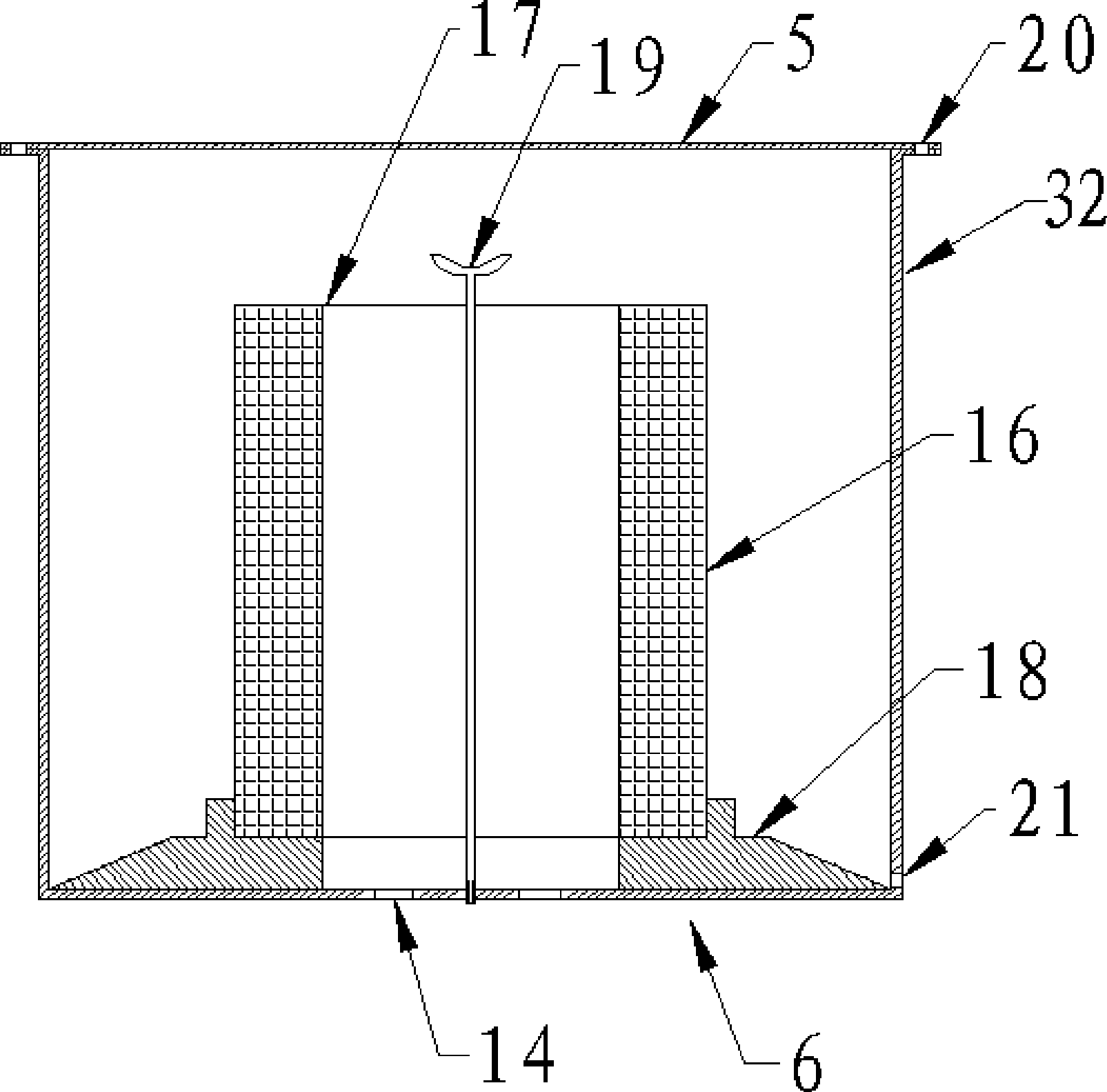

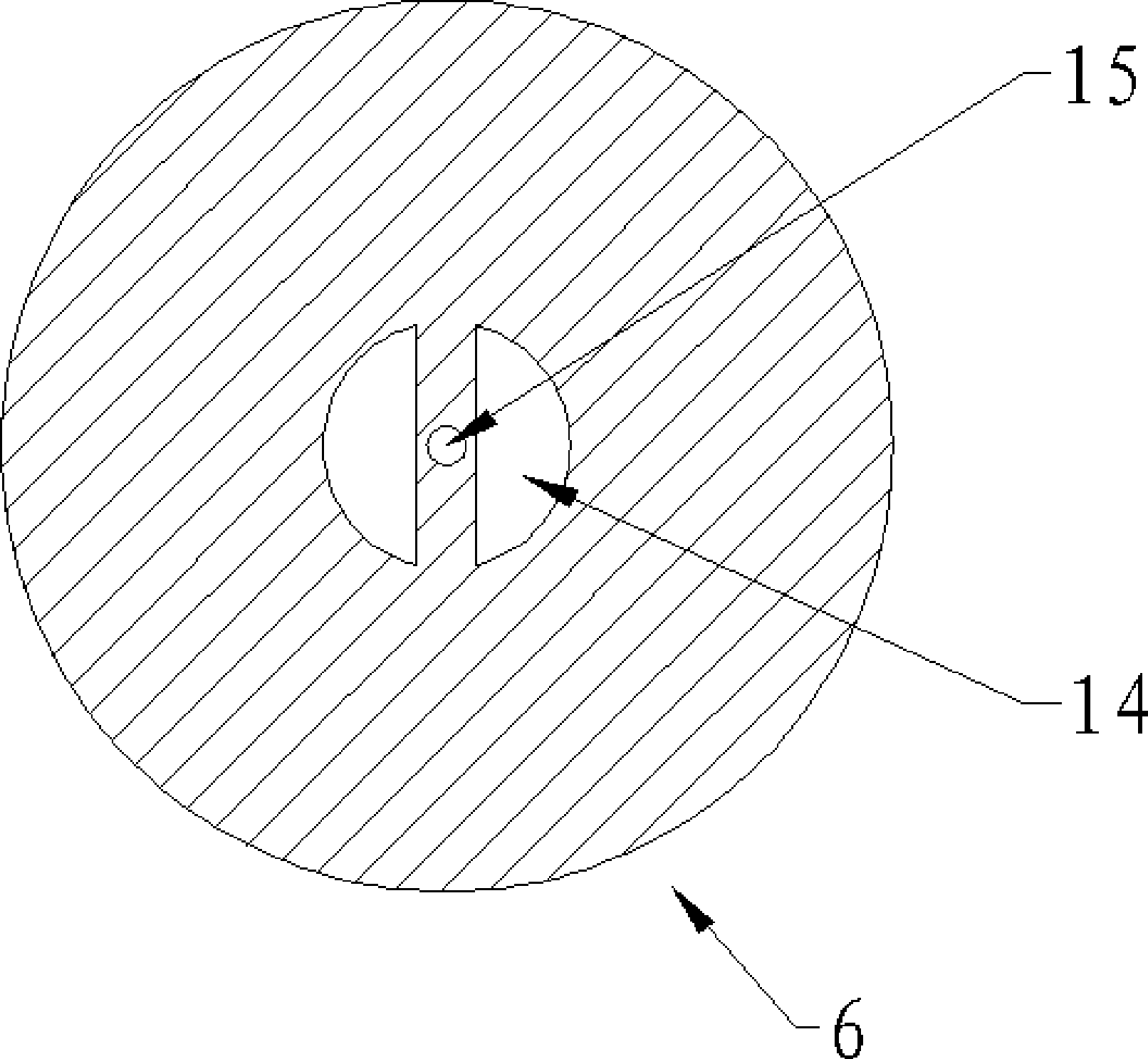

[0042] Such as figure 1 , figure 2 and image 3 As shown, the oily tail gas purification device of the present invention includes an air inlet 1 and an exhaust port 10, and an indirect cooling separation device 30 and a filter 31 are sequentially arranged between the air inlet 1 and the air outlet 10, and the indirect cooling The separation device 30 is set as a spiral tube exhaust gas channel 22 and a refrigerant channel 23, the exhaust gas inlet of the exhaust gas channel 22 is the air inlet 1, and the exhaust gas outlet of the exhaust gas channel 22 is the filter air inlet 14; the refrigerant channel 23 is connected to the refrigerant supply System; the lower end of the exhaust passage 22 is provided with an oil discharge port 4, the filter 31 adopts a cylindrical assembly, including the bottom plate 6, the outer wall 32 around the bottom plate 6 and the sealing cover 5 on the outer wall 32, and the cylindrical composite filter element 16 is installed on the bottom plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com