Intelligent dirty oil sludge treatment device and treatment process

A treatment device and sludge sludge technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve the problems of refinement and low intelligence, and achieve the purpose of increasing sludge Effects of treatment volume, fuel consumption reduction, and usage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

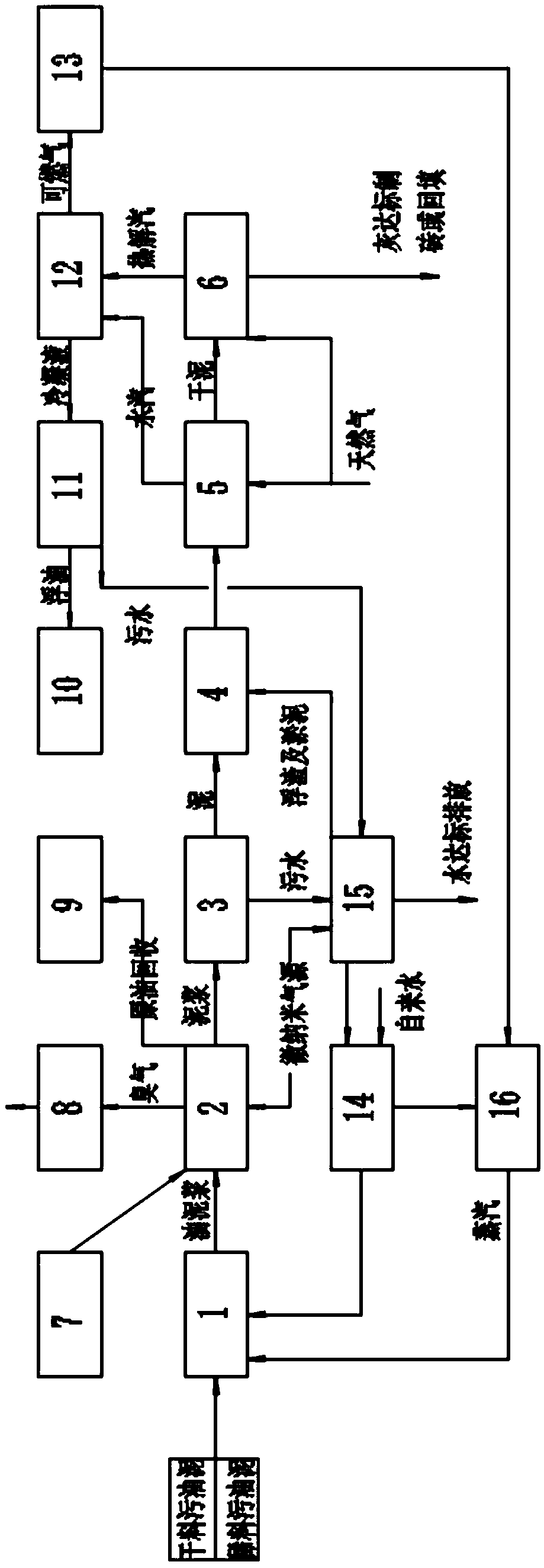

[0035] The intelligent sewage sludge treatment device of the present invention includes an integrated machine 1, an oil remover 2, a separator 3, a sludge collection tank 4, a dehydrator 5, a pyrolysis machine 6, a chemical tank 7, a deodorization tower 8, a crude oil Tank 9, light oil tank 10, separator 11, condenser 12, desulfurization tower 13, clear water tank 14, sewage station 15 and steam boiler 16; the outlet of the integrated machine 1 is connected to the inlet of the deoiler 2; The oil remover 2 is used to remove the crude oil in the oil mud; the oil remover recycles the crude oil to the crude oil tank 9, discharges the odor into the deodorization tower 8, and discharges the mud into the separator 3; the chemical tank 7 and the oil remover The machine 2 is connected; the separator 3 is used for solid-liquid separation operation, the mud is discharged into the mud collection tank 4, and the sewage is discharged into the sewage station 15; the described mud collection t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com