Composite type emulsion breaking flocculant

A composite flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, mining wastewater treatment, etc., can solve the problems of difficult treatment of aging oily sewage, achieve strong flocculation ability, high deoiling rate, and low reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

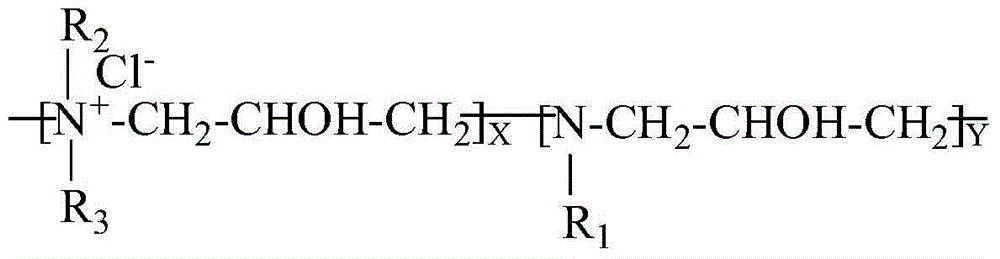

Method used

Image

Examples

Embodiment 1

[0033] The analysis of embodiment 1 aging oily sewage

[0034] Take 50ml of aged oily sewage, extract it repeatedly (7-8 times) with petroleum ether with a boiling range of 30-60°C, remove the oil in the water, put the extracted sewage into a dialysis bag, and use deionized water in a Soxhlet extractor Heated to reflux to obtain microbial flocs, and their properties were measured. The experimental results showed that the Zeta potential of the microbial flocs was -91.556mV, and the average particle size was 1002nm.

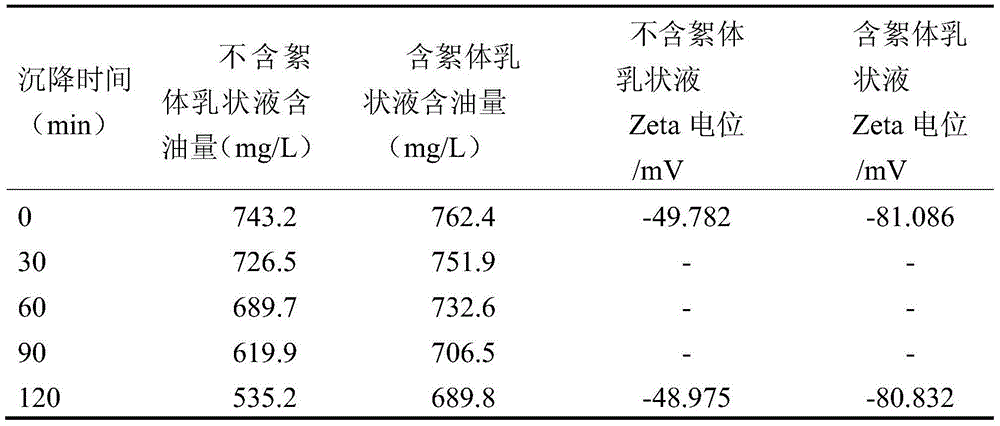

[0035] The effect of the microbial flocs on the stability of the oil-water emulsion was studied. The simulated oil-water emulsion was obtained by shear emulsification. After settling at 10°C for 2 hours, the oil content and Zeta potential in the water are shown in Table 1:

[0036] Table 1

[0037]

[0038] It can be seen from the experimental results that two simulated oil-water emulsions were prepared under the same conditions, and the oil content in the wate...

Embodiment 2

[0039] The screening of embodiment 2 demulsifiers

[0040] Screening of demulsifier According to SY5281-91 crude oil demulsifier performance test-bottle test method, take 50mL water sample in a graduated bottle, add demulsifier 400mg / L, observe at 50°C for 2 hours, and finally test the treated water sample Oil content in water, Zeta potential.

[0041] The screening of demulsifiers is mainly carried out for cationic, anionic, nonionic, amphoteric, biological and industrial demulsifiers. The experimental results are shown in Table 2.

[0042] Table 2

[0043]

[0044]

[0045] Obviously, the cationic demulsifier YL-07 has the best effect among the above-mentioned demulsifiers.

Embodiment 3

[0046] The selection of the compound demulsification flocculant of different proportions of embodiment 3

[0047] Dilute YL-07:PDMDAAC:PAC:W6590 with different mass concentration ratios with water to form a 0.1% demulsification flocculation solution. According to the SY5281-91 bottle test method, take 50mL water sample in a graduated bottle, add 320mg / L demulsification flocculation solution The milk flocculation solution was reacted in a water bath at a temperature of 50°C for 2 hours, and finally the oil content in water of the treated water sample was detected. The experimental results are shown in Table 3 below:

[0048] table 3

[0049]

[0050] Obviously, 60wt%-80wt% of YL-07; 10wt%-20wt% of PDMDAAC; 5wt%-10wt% of PAC; at 90%. Among them, the optimal ratio is: 62.5wt% of YL-07; 18.75wt% of PDMDAAC; 9.375wt% of PAC; and 9.375wt% of W6590, the oil removal rate is as high as 96.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com