Organosilicone-break-emulsification agent and application thereof

A technology of organic silicon and flocculant, which is applied in the direction of flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, liquid separation, etc. It can solve problems such as difficult oil removal effect, polluted oil products, and secondary pollution. , to achieve the effects of weakening the strength of the oil-water interface film, high oil removal rate and fast settlement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

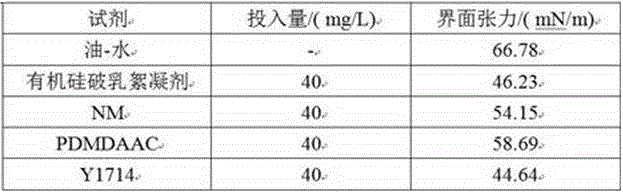

[0016] Take 50 mL of the oily sewage at the top of the decompression tower of the W refinery into a graduated bottle, and add 100 mg / L of water treatment agent (NM:PDMDAAC:different types of silicone surfactant mass concentration ratio is 10:3:1) , settled at 60°C for 2 h, and the oil content in the treated water was measured by UV spectrophotometry. The experimental results are shown in Table 1.

[0017] Table 1

[0018]

[0019] Obviously, when NM, PDMDAAC and silicone surfactant Y1714 or silicone surfactant 559 were compounded, the oil content in the water decreased from 2161.1 mg / L to 2161.1 mg / L after adding 100 mg / L water treatment agent and settling at 60 °C for 2 h. to 311.2 mg / L and 340.3 mg / L, and the oil removal rates reached 85.6 % and 84.3 %, respectively. Among them, NM, PDMDAAC and silicone Y1714 have a better degreasing effect.

Embodiment 2

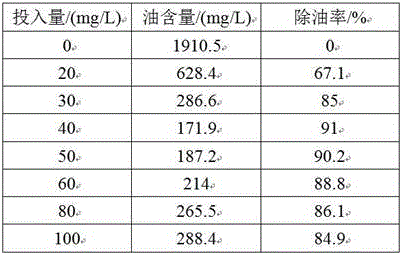

[0021] Take 50 mL of oily sewage from the top of W refining vacuum tower in a graduated bottle, add different concentrations of water treatment agents (NM:PDMDAAC:Y1714 mass concentration ratio is 10:3:1), settle at 60°C for 2h, The oil content in the treated water was measured by UV spectrophotometry. The experimental results are shown in Table 1.

[0022] Table 2

[0023]

[0024] Obviously, when 30-80 mg / L water treatment agent is added, the oil content in the water will drop from 1910.5 mg / L to about 200 mg / L when it settles at 60°C for 2 hours, and the oil removal rate will reach more than 85%.

Embodiment 3

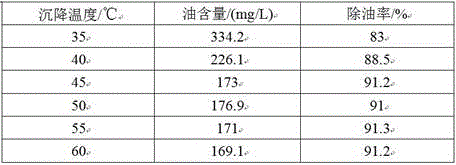

[0026] Take 50 mL of oily sewage from the top of W refinery decompression tower in a graduated bottle, add 40 mg / L of water treatment agent (NM:PDMDAAC:Y1714 mass concentration ratio is 10:3:1), and settle at 60°C At different times, the oil content in the treated water was measured by UV spectrophotometry. The experimental results are shown in Table 3.

[0027] table 3

[0028]

[0029] Obviously, when 40 mg / L water treatment agent is added, the oil removal rate can reach about 91.0% when it settles at 60°C for 30-45 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com