Polymer and its preparation method and application, and processing method for oily sewage

A treatment method and polymer technology, applied in the field of polymers, can solve the problems of high difficulty in treatment, high specificity of emulsion, and the need to improve the oil removal rate, so as to achieve improved oil removal rate, short treatment time and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

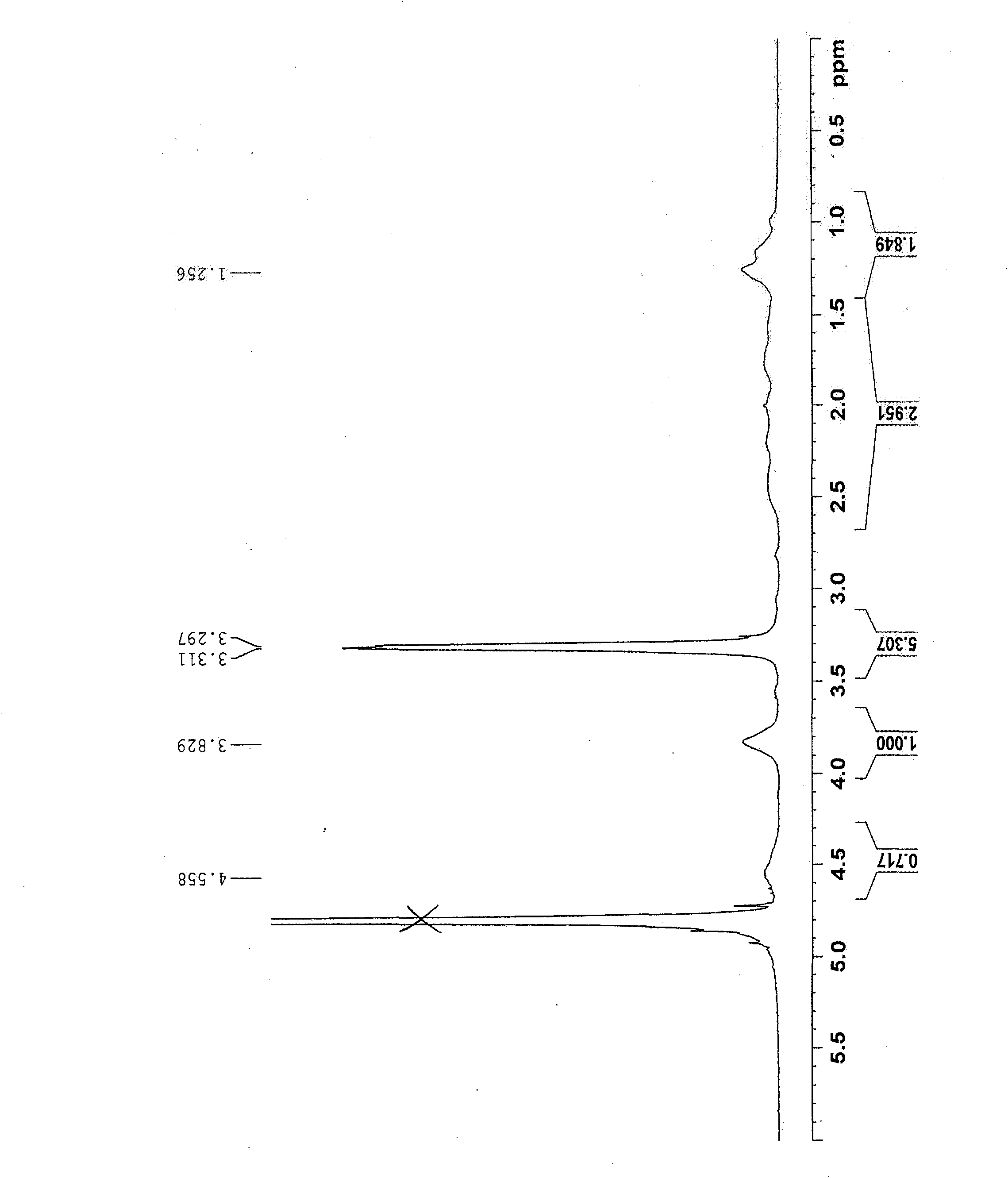

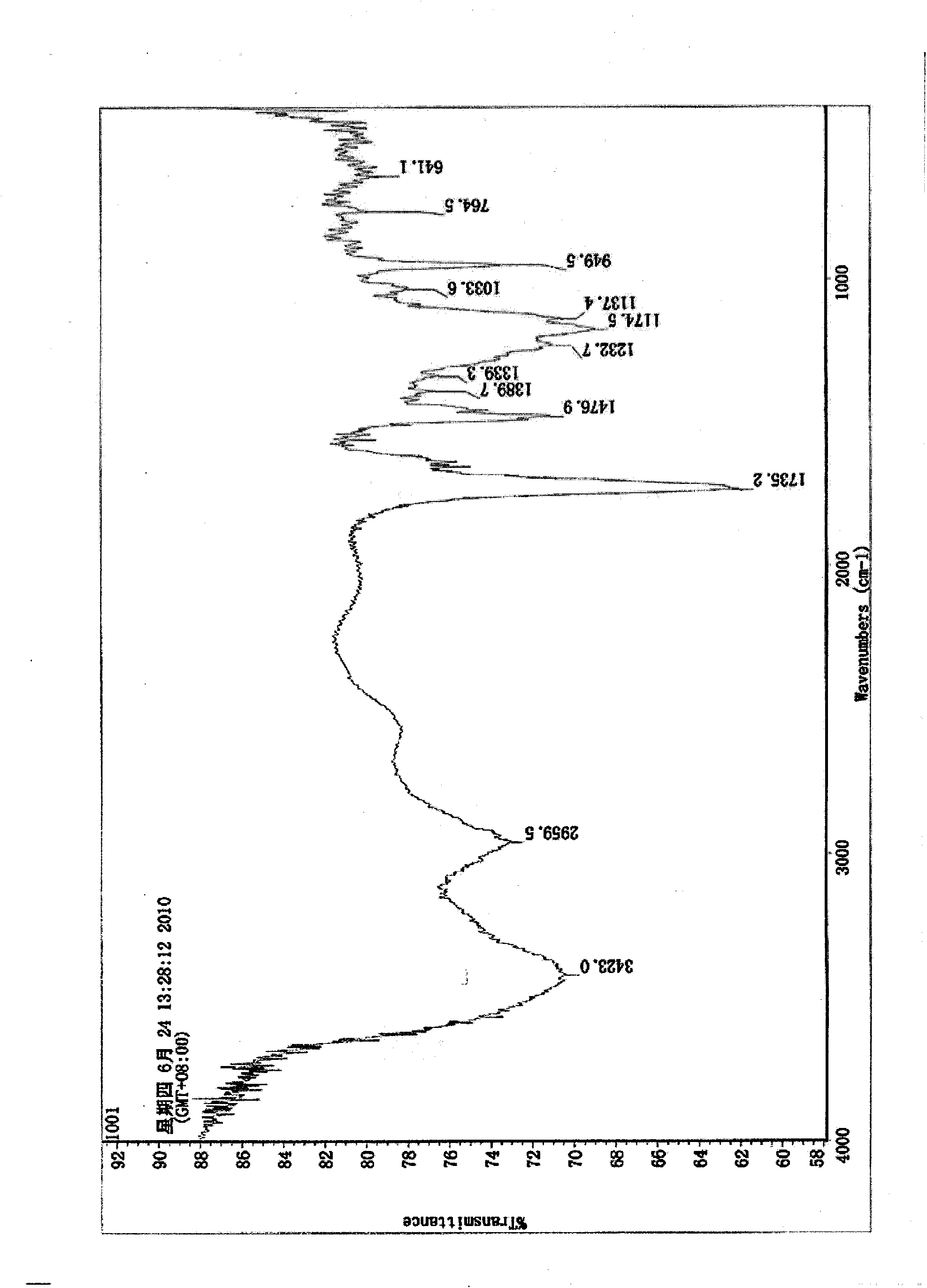

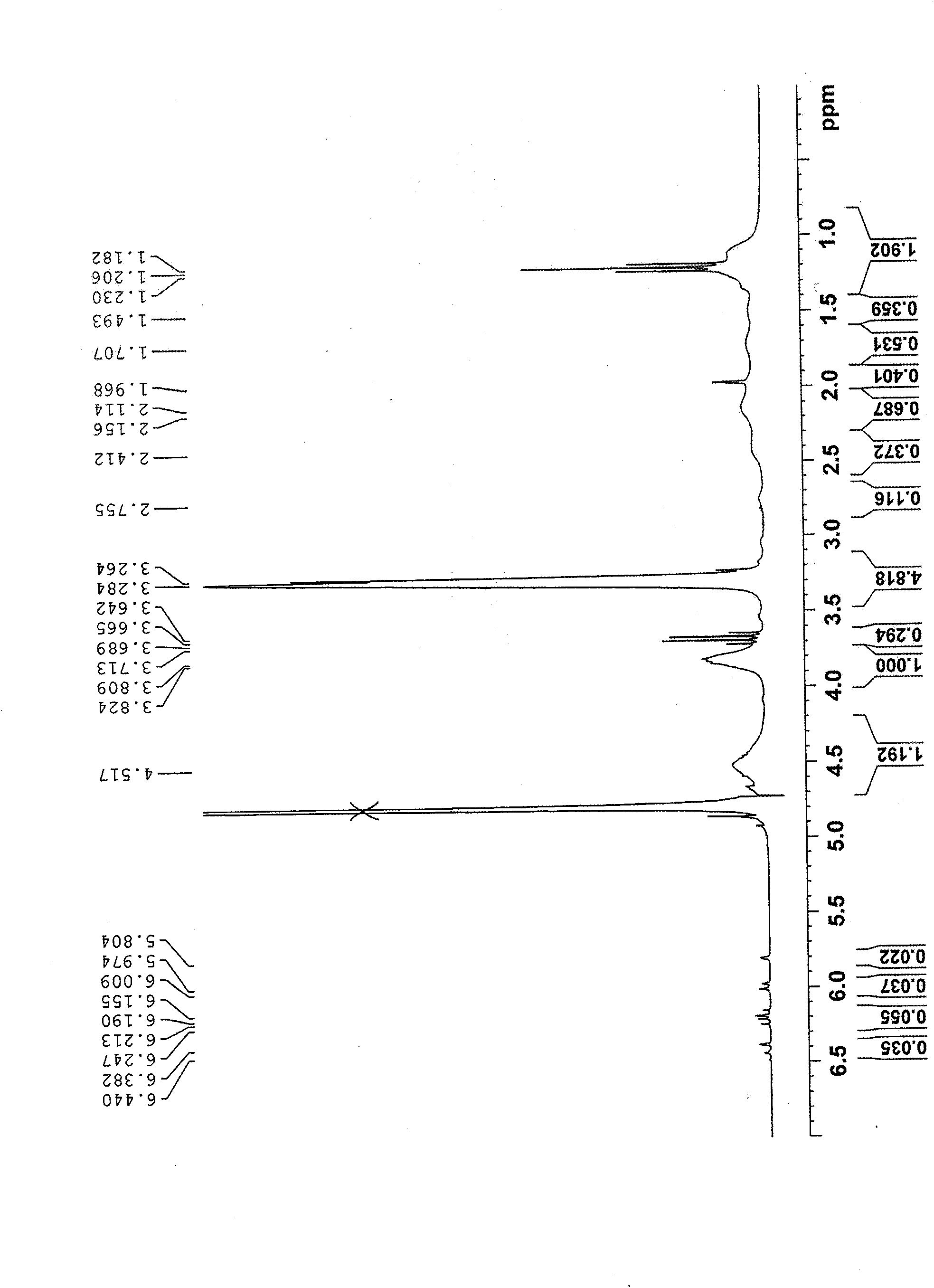

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing a polymer, wherein the method comprises: the method comprises:

[0040]Under polymerization conditions, the acrylic acid ester hydrophobic monomer shown in structural formula (4), methacryloyloxyethyl trimethyl ammonium chloride and structural formula (5) The solution of the solution is contacted in the presence of an initiator, and the degree of contact makes the intrinsic viscosity of the product obtained after contacting be 33-362ml / g;

[0041]

[0042] Among them, R represents H or -(CH 2 ) m -OH, 1≤m≤5, m is a positive integer; 1≤n≤5, n is a positive integer;

[0043] Based on the total amount of the acrylic hydrophilic monomer shown in structural formula (4), methacryloyloxyethyltrimethylammonium chloride and the acrylate hydrophobic monomer shown in structural formula (5), The amount of the acrylic hydrophilic monomer is 50-67% by weight, the amount of methacryloyloxyethyltrimethylammonium chloride ...

Embodiment approach

[0056] According to a preferred embodiment of the present invention, the preparation method of described polymer comprises the following steps:

[0057] Step 1, add part of acrylic acid or hydroxypropyl acrylate, methacryloyloxyethyltrimethylammonium chloride and propyl acrylate, surfactant and solvent into the reactor, stir well until completely dissolved.

[0058] Step 2: install a constant-pressure separatory funnel on the reactor, replace the air in the reactor with nitrogen and feed in nitrogen continuously, heat to raise the temperature, and add an initiator under the condition of 30-60°C to start the reaction. During the reaction, the remaining acrylic acid or hydroxypropyl acrylate is added dropwise, and the addition is completed within 0.5 to 1 hour. The reaction time is not less than 4h.

[0059] Step 3: Cool down to 10-20°C, precipitate with absolute ethanol or acetone, and dry to obtain a white or light yellow solid; or directly discharge as a solution product to ...

Embodiment 1

[0071] Steps:

[0072] Step 1, weigh 1 gram of butyl acrylate, 0.648 grams of cetyltrimethylammonium bromide, 9 grams of methacryloyloxyethyltrimethylammonium chloride, 5 grams of acrylic acid and 80 grams of deionized water and add Into the reactor, stir well until completely dissolved.

[0073] Step 2, install a constant pressure separatory funnel on the reactor, replace the air in the reactor with nitrogen and feed nitrogen continuously, heat up to 30°C, add 0.0486 gram of sodium thiosulfate, potassium persulfate and azo (2- Amidinopropane) dihydride (the weight ratio of the three is 1:2:1) to start the reaction. Add 40 g of deionized water and 15 g of acrylic acid into a constant pressure separatory funnel, add dropwise at a constant speed and complete the dropwise addition within 0.5 to 1 hour. Total reaction 4h.

[0074] Step 3, cooling down, precipitating with absolute ethanol, and drying to obtain a white solid.

[0075] The polymer had an intrinsic viscosity of 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com