Horizontal spiral discharge sedimentation filtration centrifuge and secondary separation process thereof

A horizontal screw and centrifuge technology, which is applied in the field of centrifuges, can solve problems such as bottlenecks, oil yields that cannot be improved, and drum residue deterioration, etc., to achieve high liquid yields and complete dehydration of secondary fabrics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

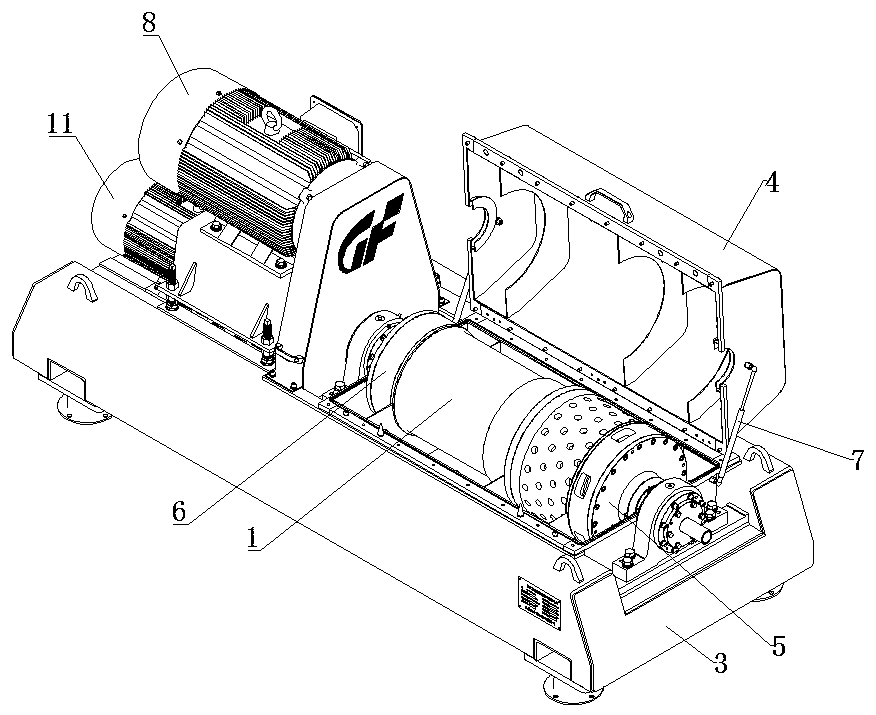

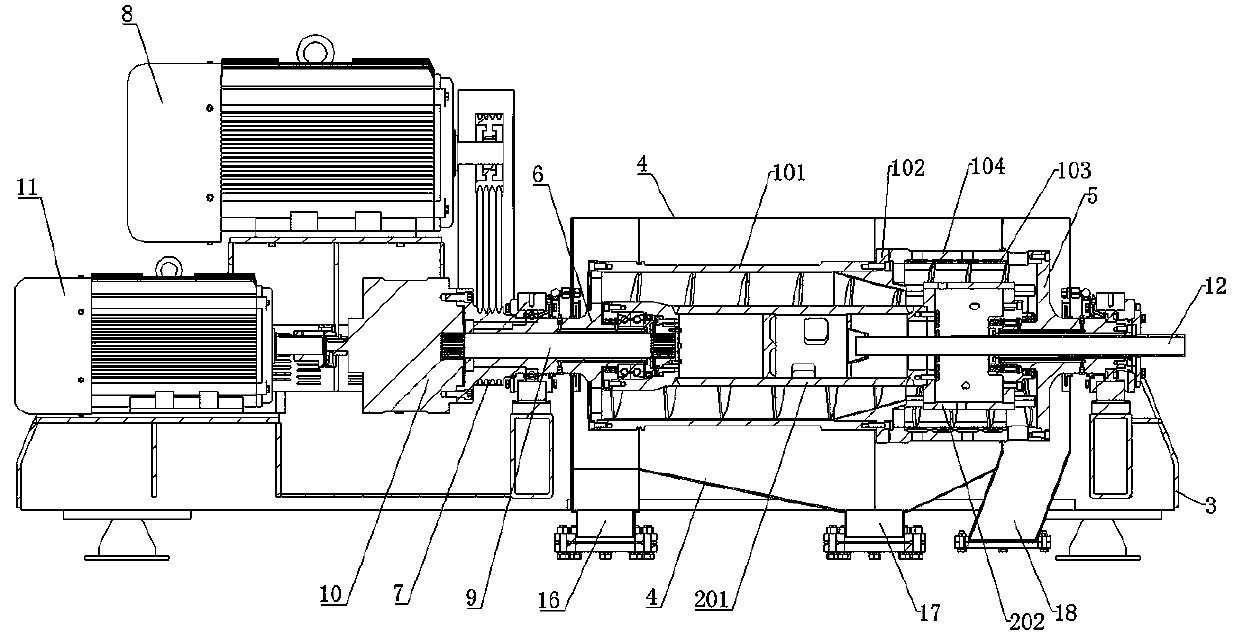

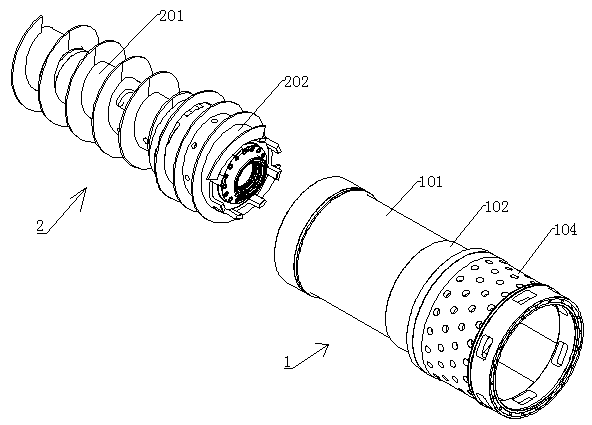

[0047] Such as Figure 1~Figure 10 As shown, a horizontal screw discharge sedimentation filter centrifuge includes a machine base 3 and a casing 4 . The casing 4 is arranged on the machine base 3 , the drum part 1 is arranged in the casing 4 , and the screw pusher 2 is arranged in the drum part 1 .

[0048] In this solution, the casing 4 is divided into two parts, an upper casing and a lower casing, one side of which is hinged and the other side can be opened. The opening and closing of the upper casing and the lower casing is realized through a pneumatic strut 13 . In order to achieve good sealing, a rectangular groove is formed on the end surface of the lower casing at the contact surface of the upper casing and the lower casing, and a rectangular sealing strip 14 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com