Efficient continuous vacuum fryer

A vacuum fryer, high-efficiency technology, used in oil/fat roasting, baking, food science, etc., can solve problems such as poor sealing of sealing rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

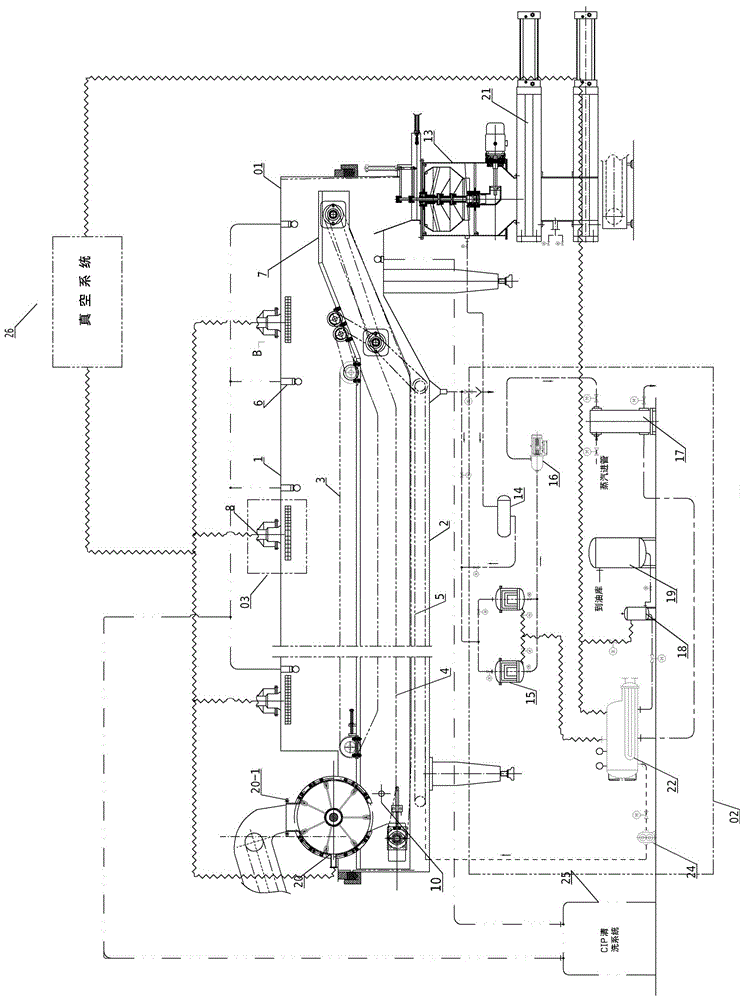

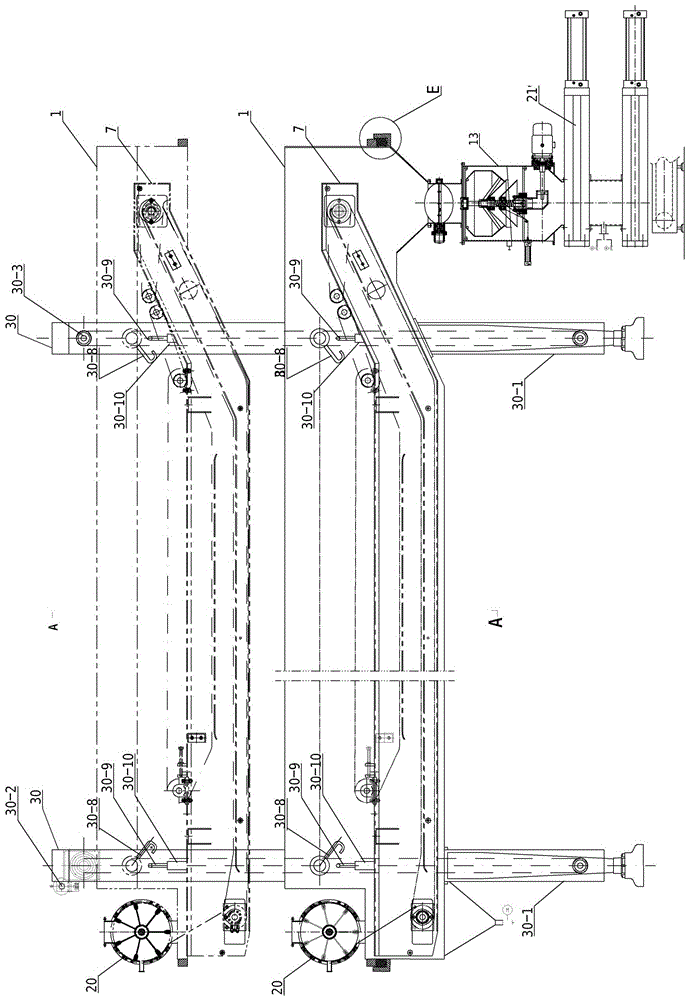

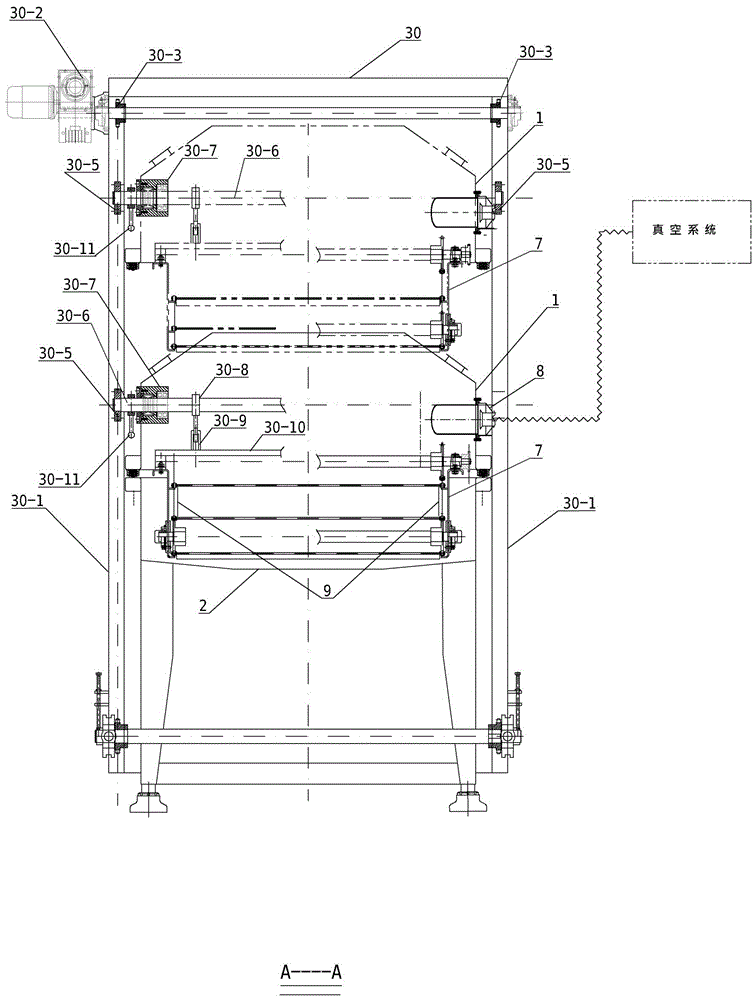

[0028] Such as figure 1 In the shown embodiment: the frying cabin 01 is composed of the frying cabin upper cabin 1, the frying cabin lower cabin 2, the frying cabin sealing strip 11, the mesh belt frame 7, and the slag scraping device 5, and the frying cabin lower cabin 2 is provided with a mesh belt frame 7, a conveying mesh belt 4, a pressing mesh belt 3 and a slag scraping device 5, the conveying mesh belt 4 and the pressing mesh belt 3 are placed on the mesh belt frame 7, and the conveying mesh belt 4 The baffle plate 9 is set on both sides of the space between the pressing mesh belt 3 to prevent material leakage and reduce the amount of oil residue. The scraping device 5 is arranged at the bottom of the mesh belt frame 7, which can be designed as a chain type or a reciprocating type. The viewing mirror is set on the cabin 1 to facilitate the observation of the processing status of the internal materials. The number and position of the viewing mirrors are determined accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com