Natural composite polyaluminium chloride water treatment agent and preparation method thereof

A polyaluminum chloride, water treatment technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of secondary pollution of residual substances, poor adsorption capacity, etc., and achieve beneficial degradation performance , the effect of reducing usage and improving bridging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

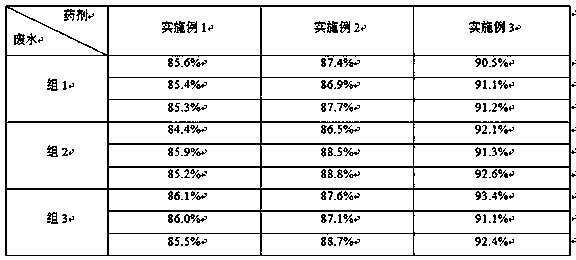

Embodiment 1

[0030] A natural composite polyaluminum chloride water treatment agent includes the following components: polyaluminum chloride, polyacrylamide modified starch, etherified modified chitosan, and glacial acetic acid.

[0031] The preparation method of the natural composite aluminum chloride water treatment agent includes the following steps:

[0032] (1) In terms of parts by weight, dissolve 35 parts of modified starch in 35 parts of distilled water, stir and disperse, and then add modified chitosan according to the mass ratio of modified starch to modified chitosan at 1:1 , Add 0.5mL / g modified starch glacial acetic acid after heating to 60°C, and stop the reaction with cold water after 1.5h reaction to obtain mixed liquid a;

[0033] (2) In 25 parts of polyaluminum chloride solution, add 5% by mass of the mixed solution a under stirring conditions, and rapidly stir the reaction for 2 hours to completely dissolve, to obtain a composite aluminum chloride water treatment agent.

[0034]...

Embodiment 2

[0044] A natural composite polyaluminum chloride water treatment agent includes the following components: polyaluminum chloride, polyacrylamide modified starch, etherified modified chitosan, and glacial acetic acid.

[0045] The preparation method of the natural composite aluminum chloride water treatment agent includes the following steps:

[0046] (1) In terms of parts by weight, dissolve 50 parts of modified starch in 40 parts of distilled water, stir and disperse, then add modified chitosan according to the mass ratio of modified starch to modified chitosan of 6:1 After heating to 80°C, adding 1mL / g of glacial acetic acid of modified starch, reacting for 2h and then terminating the reaction with cold water to obtain mixed liquid a;

[0047] (2) In 30 parts of polyaluminum chloride solution, add 15% of the mass of mixed solution a under stirring conditions, and quickly stir and react for 3 hours to completely dissolve to obtain a composite aluminum chloride water treatment agent. ...

Embodiment 3

[0058] A natural composite polyaluminum chloride water treatment agent includes the following components: polyaluminum chloride, polyacrylamide modified starch, etherified modified chitosan, and glacial acetic acid.

[0059] The preparation method of the natural composite aluminum chloride water treatment agent includes the following steps:

[0060] (1) According to the weight ratio, dissolve 40 parts of modified starch in 40 parts of distilled water, stir and disperse, then add modified chitosan according to the mass ratio of modified starch to modified chitosan 4:1 , After heating to 70℃, adding 0.8mL / g of modified starch glacial acetic acid, reacting for 2h and then terminating the reaction with cold water to obtain mixed liquid a;

[0061] (2) In 28 parts of polyaluminum chloride solution, add 10% of the mass of mixed solution a under stirring conditions, and quickly stir for 3 hours to completely dissolve to obtain a composite aluminum chloride water treatment agent.

[0062] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com