Aquaculture tail water treatment agent as well as preparation process and preparation device thereof

An aquaculture and preparation device technology, applied in water/sewage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. The preparation equipment is complex, and it is difficult to meet the requirements of tail water treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

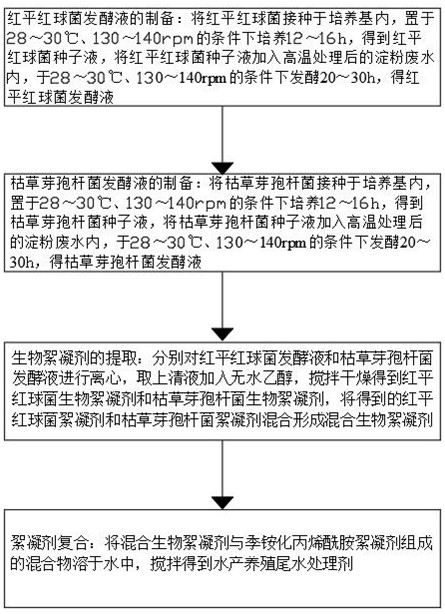

[0048] Such as figure 1 As shown, an aquaculture tail water treatment agent, the aquaculture tail water treatment agent is composed of the following components by weight: 30 to 40 parts of Rhodococcus erythroflatus flocculant, 20 to 30 parts of Bacillus subtilis flocculant and 10 ~20 parts of quaternized acrylamide flocculant.

[0049] A preparation process of an aquaculture tail water treatment agent, the specific steps are as follows:

[0050] Step 1. Preparation of Rhodococcus erythropolis fermentation broth: Inoculate Rhodococcus erythrococcus in the culture medium and culture it at 28-30°C and 130-140rpm for 12-16 hours to obtain Rhodococcus erythropolis seed liquid. Rhodococcus erythroflates seed liquid is added to the high-temperature-treated starch wastewater, and fermented at 28-30°C and 130-140rpm for 20-30 hours to obtain Rhodococcus erythroflates fermentation liquid;

[0051] Step 2, preparation of Bacillus subtilis fermentation liquid: inoculate Bacillus subtili...

Embodiment 2

[0057] Embodiment 2 is a further improvement to Embodiment 1.

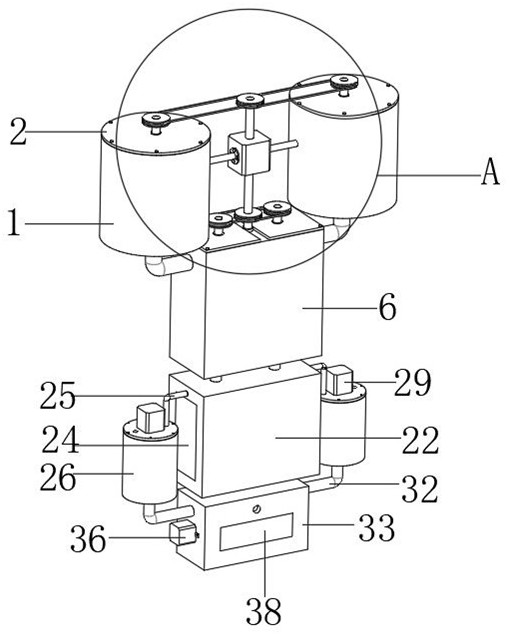

[0058] Such as figure 2 , 4 , 5, 6, 7, 8, 9, 10, and 11 show a preparation device for aquaculture tail water treatment agent, comprising two groups of fermentation broth preparation components, flocculant extraction components and composite mixing components, characterized in that: Fermentation broth preparation components include strain tube 1, tube cover 2, No. 1 electric heating ring 3, No. 1 temperature sensor 4, L-connecting tube 5, double-chamber fermentation box 6, closing cover 7, and No. 2 electric heating ring 8. The No. 2 temperature sensor 9 and the liquid discharge pipe 10; the cylinder cover 2 is threadedly connected to the top of the strain liquid cylinder 1, the No. 1 electric heating ring 3 is embedded on the inner wall of the strain liquid cylinder 1, and the No. 1 temperature sensor 4 Installed on the inner wall of the spawn liquid cylinder 1, the No. 1 electric heating ring 3 is equidistantl...

Embodiment 3

[0062] Embodiment 3 is a further improvement to Embodiment 2.

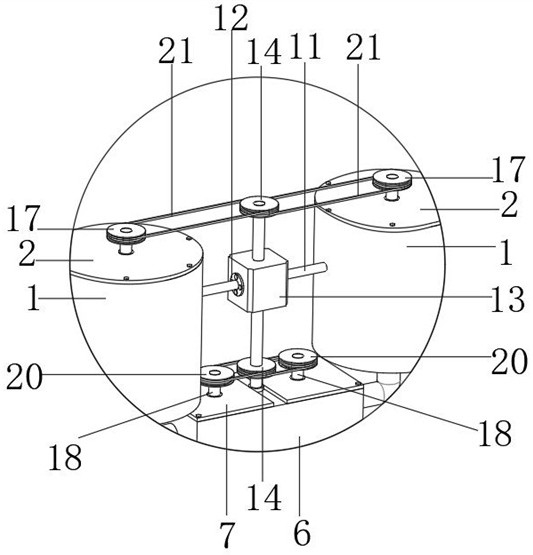

[0063] Such as figure 2 , 3 , 4, 5, and 6, also includes linkage stirring components,

[0064] The linkage stirring assembly includes a connecting rod 11, a connecting plate 12, a double-axis motor 13, a driving pulley 14, a stirring rod 15 for the strain liquid, a stirring rod 16 for the strain liquid, a driving pulley 17, a stirring rod 18 for the fermentation liquid, and a fermentation liquid stirring rod 18. Liquid stirring sub-rod 19, No. 2 transmission pulley 20 and transmission belt 21, connecting rod 11 is welded and fixed on the side wall of strain liquid cylinder 1, connecting plate 12 is arranged on the end of connecting rod 11, and biaxial motor 13 is screwed on the connecting plate 12, the driving pulley 14 is installed on the two output shafts of the biaxial motor 13, the spawn liquid stirring rod 15 rotates and runs through the center of the cylinder cover 2, and the spawn liquid stirring rod 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com