Patents

Literature

53results about How to "Reduce resin viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

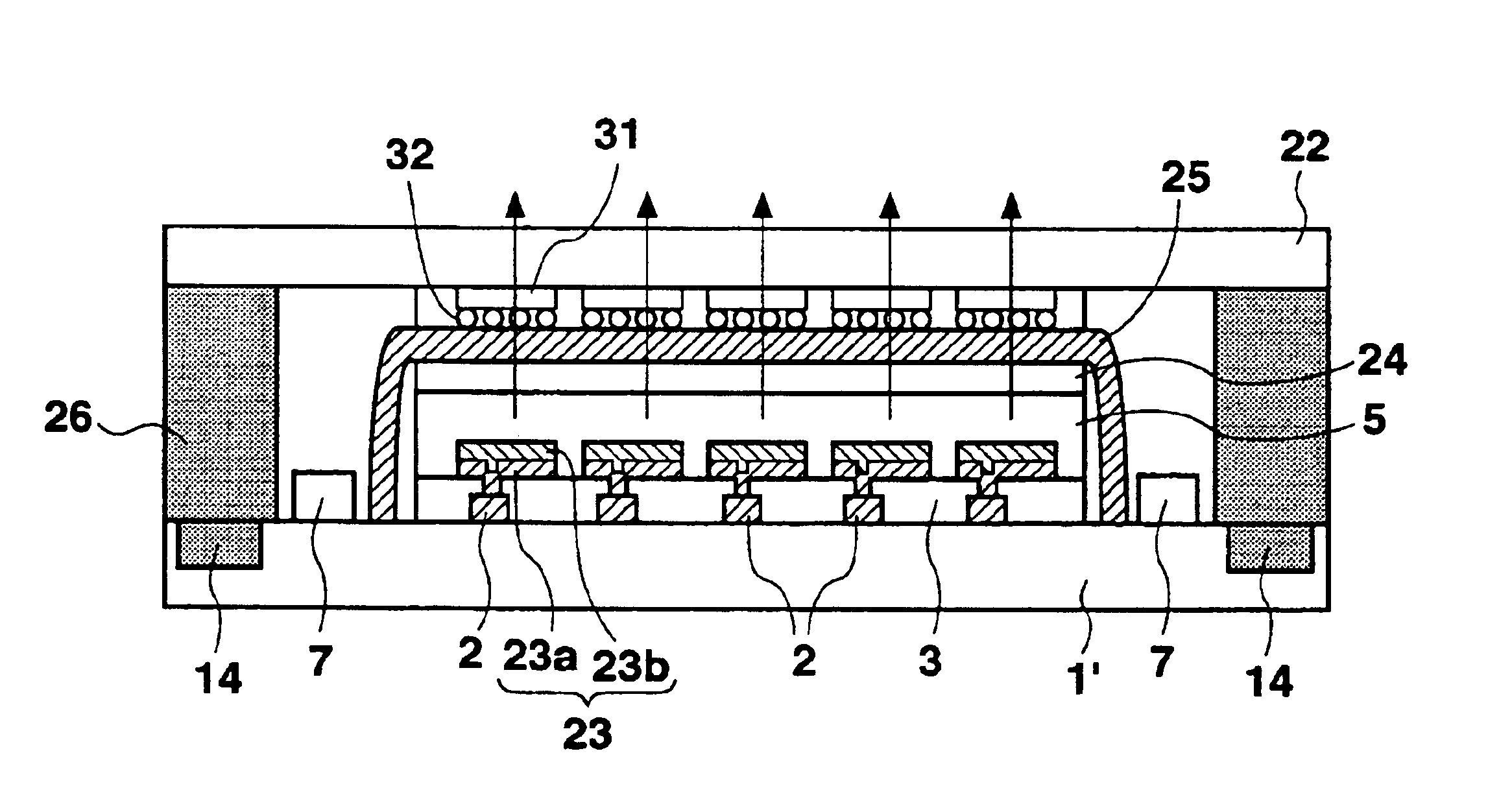

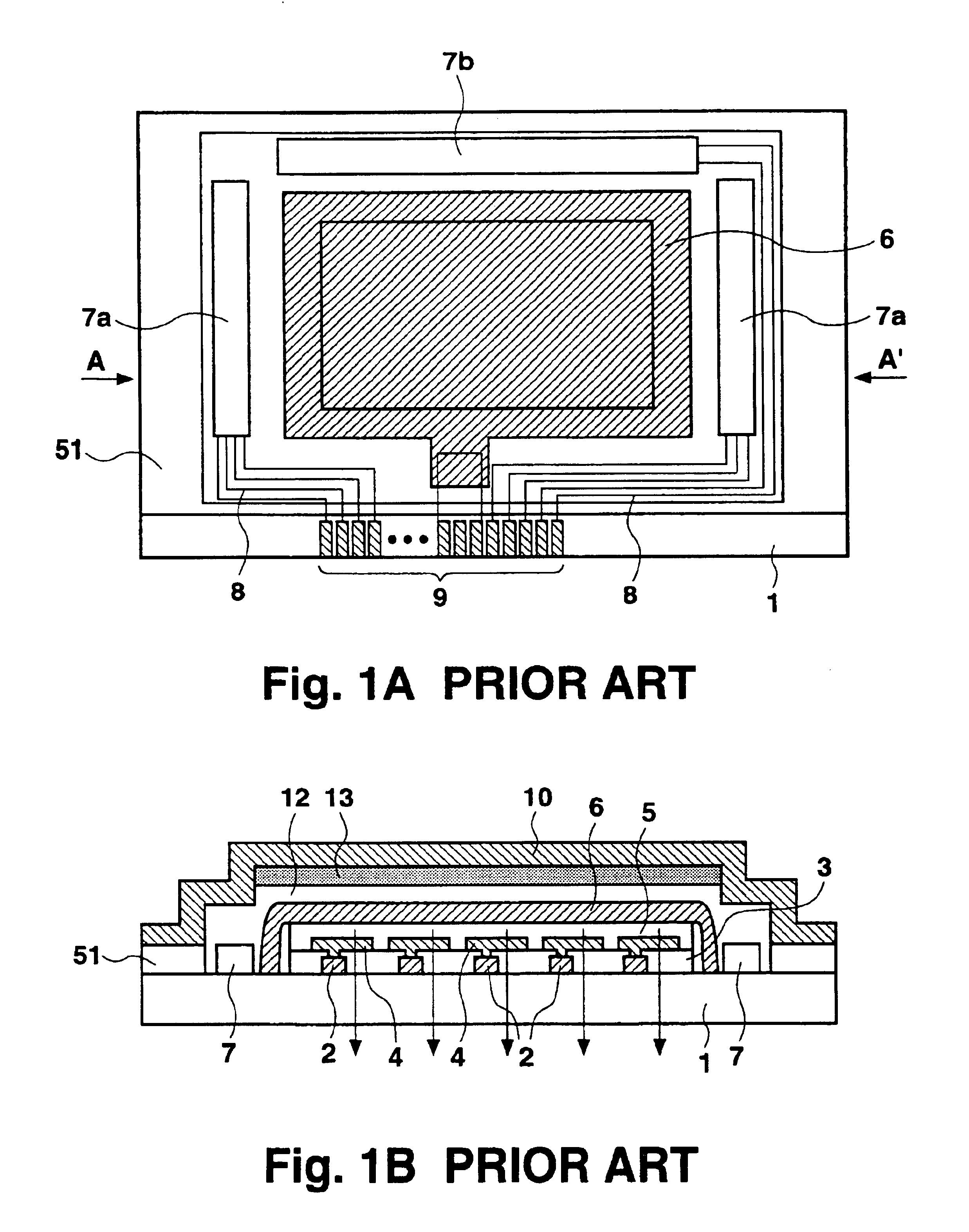

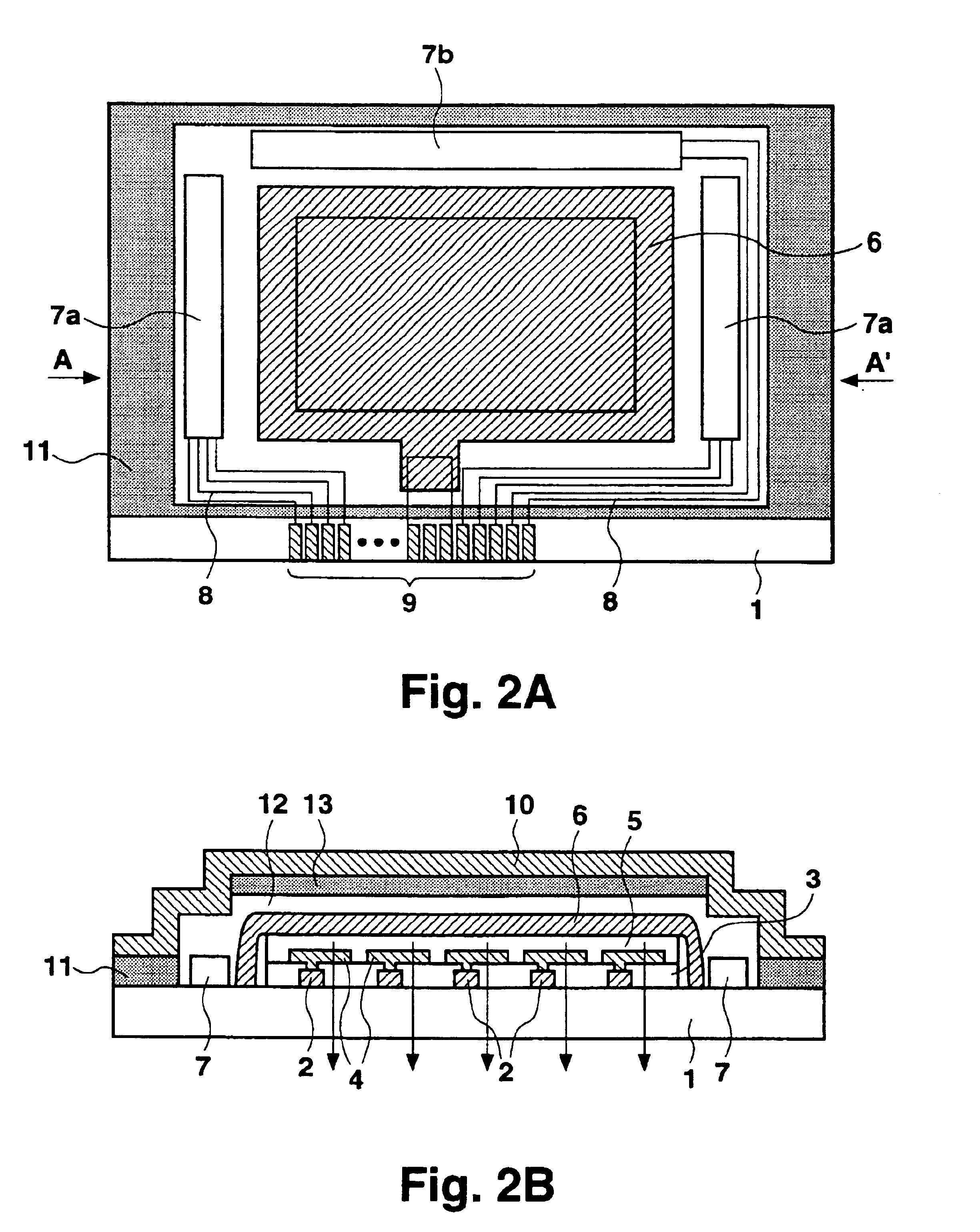

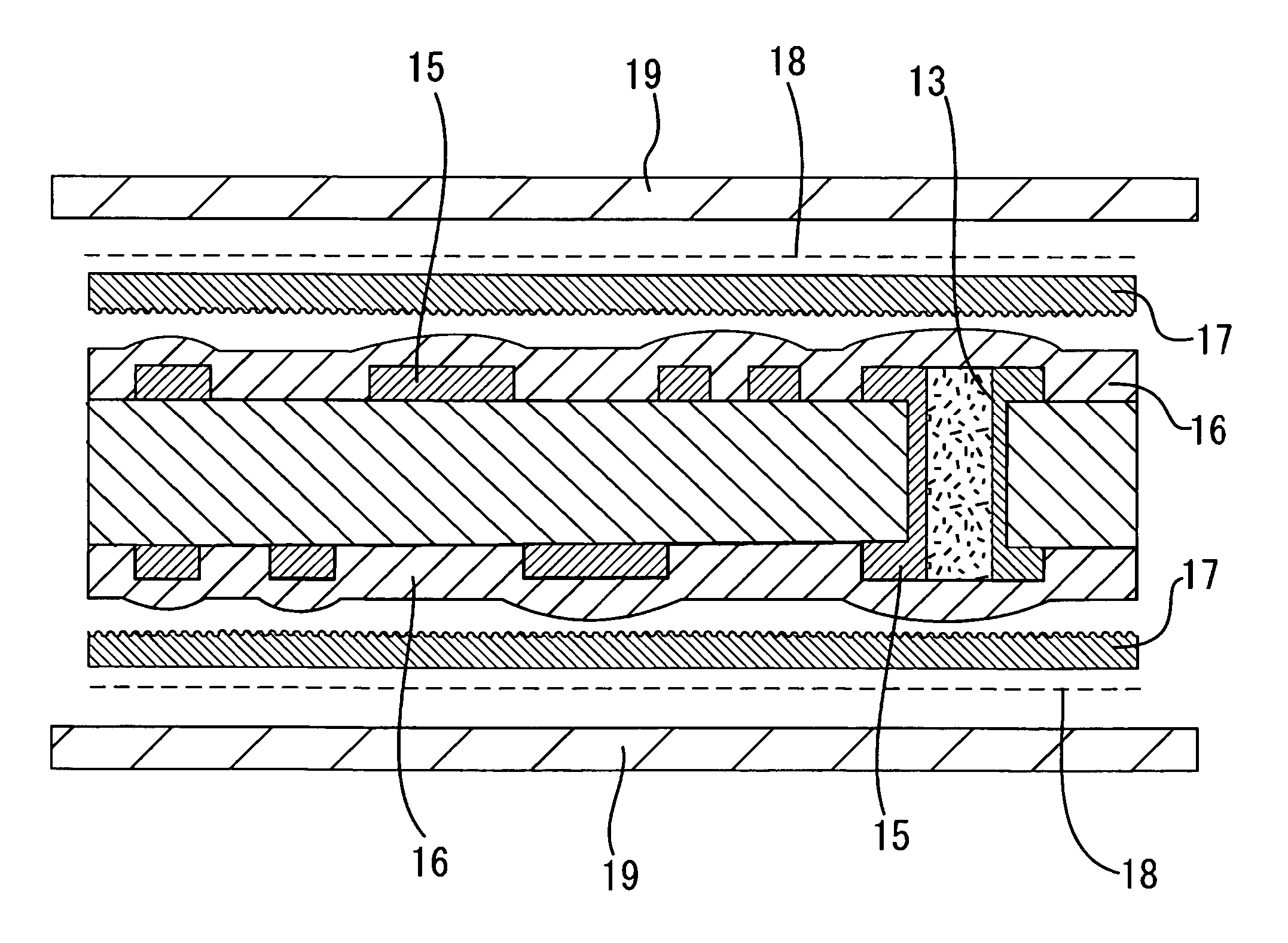

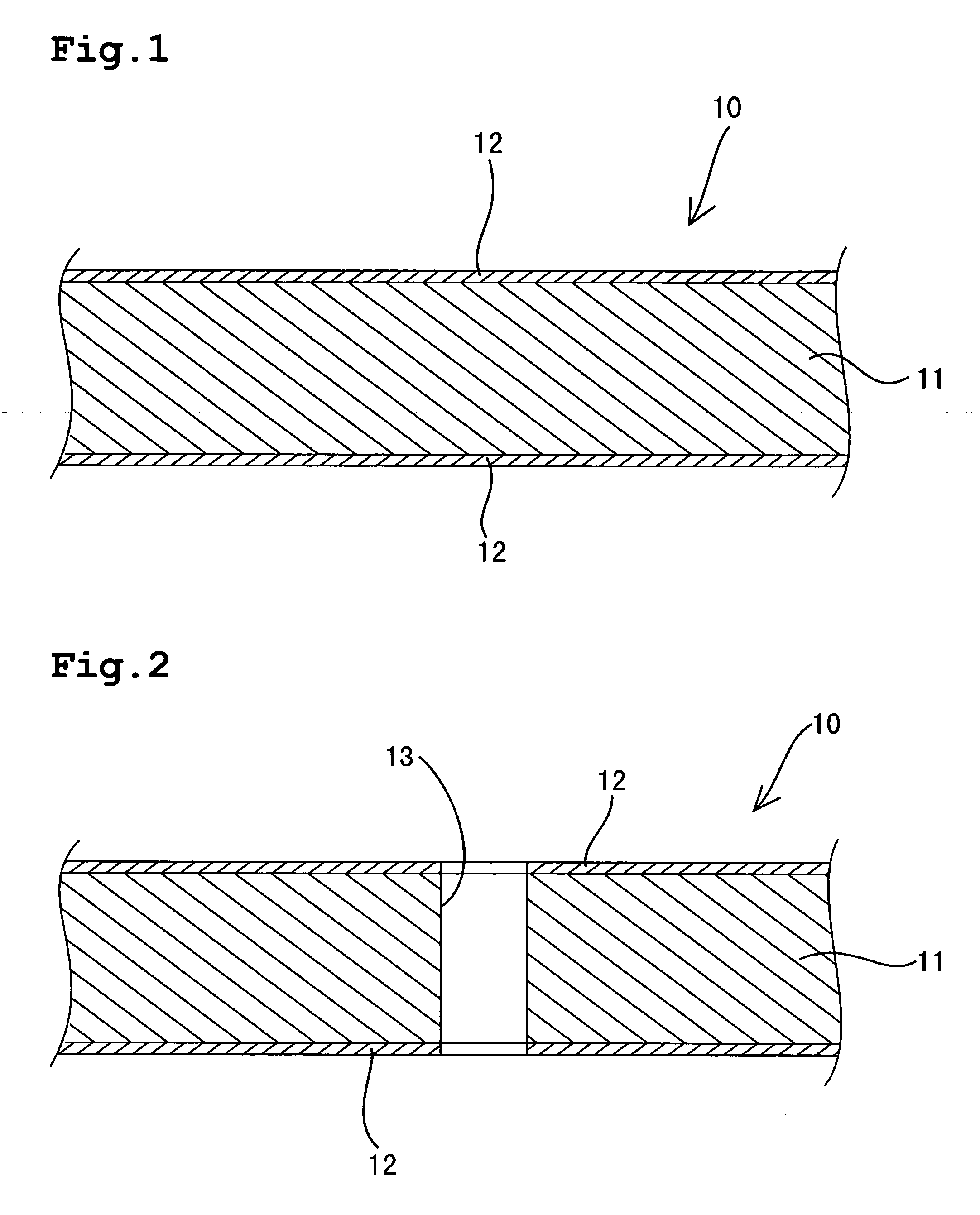

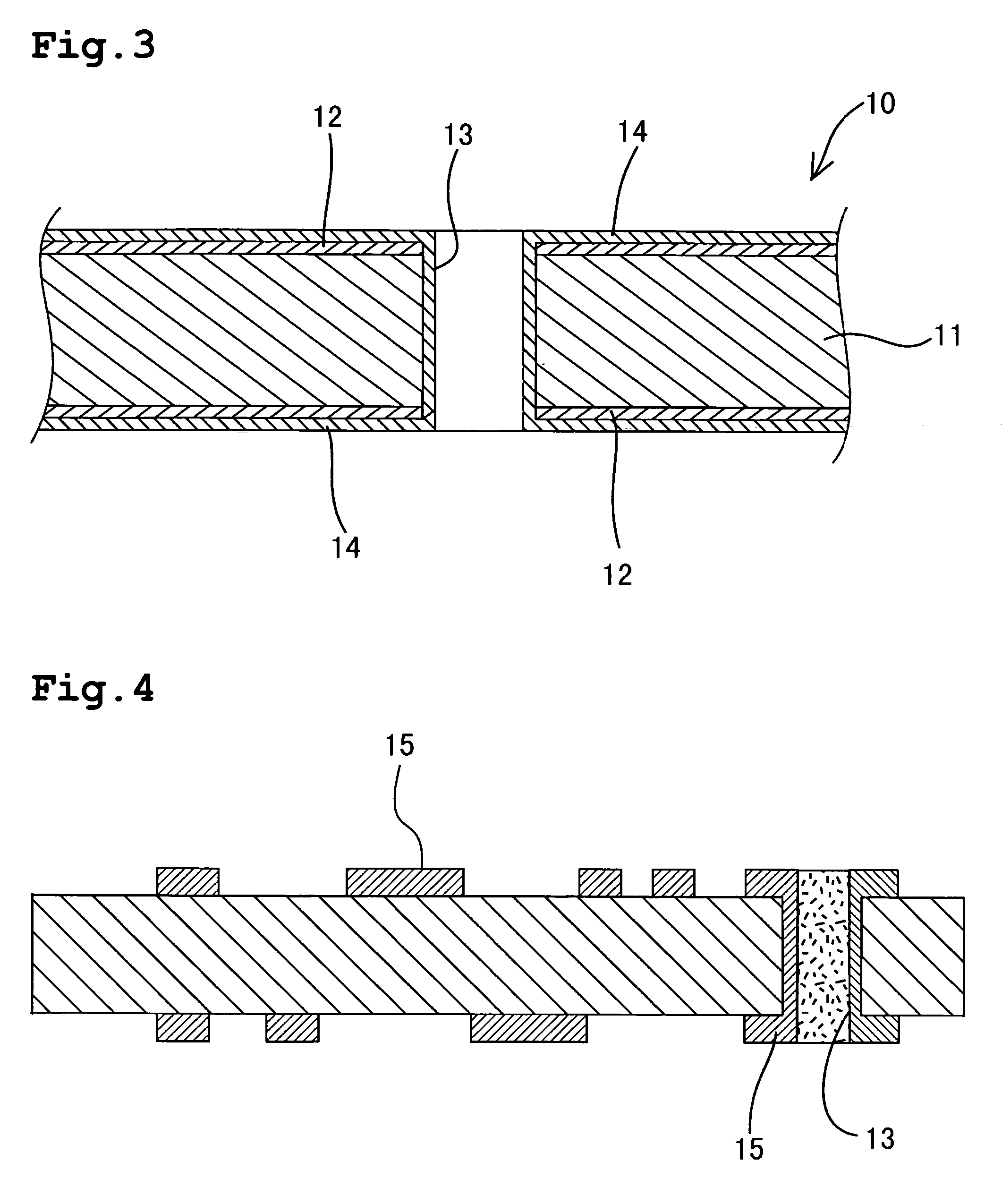

Electroluminescence display device having a desiccant

InactiveUS6833668B1Increase the aperture ratioReliable sealing structureDischarge tube luminescnet screensElectroluminescent light sourcesDesiccantDisplay device

Powder desiccant is mixed into a seal which adheres a first substrate to a second substrate, thereby sealing a display region. Almost no moisture permeates through the outer surfaces of the substrates sandwiching the display region, while moisture permeating through the seal is adsorbed by the desiccant. An emissive layer is thereby prevented from deterioration due to moisture. By covering the display region with a resin sealing layer composed of resin having desiccant mixed therein, the display region can reliably be protected from moisture. By forming a groove in the substrate and placing a desiccant therein, moisture can be further reliably adsorbed.

Owner:SANYO ELECTRIC CO LTD

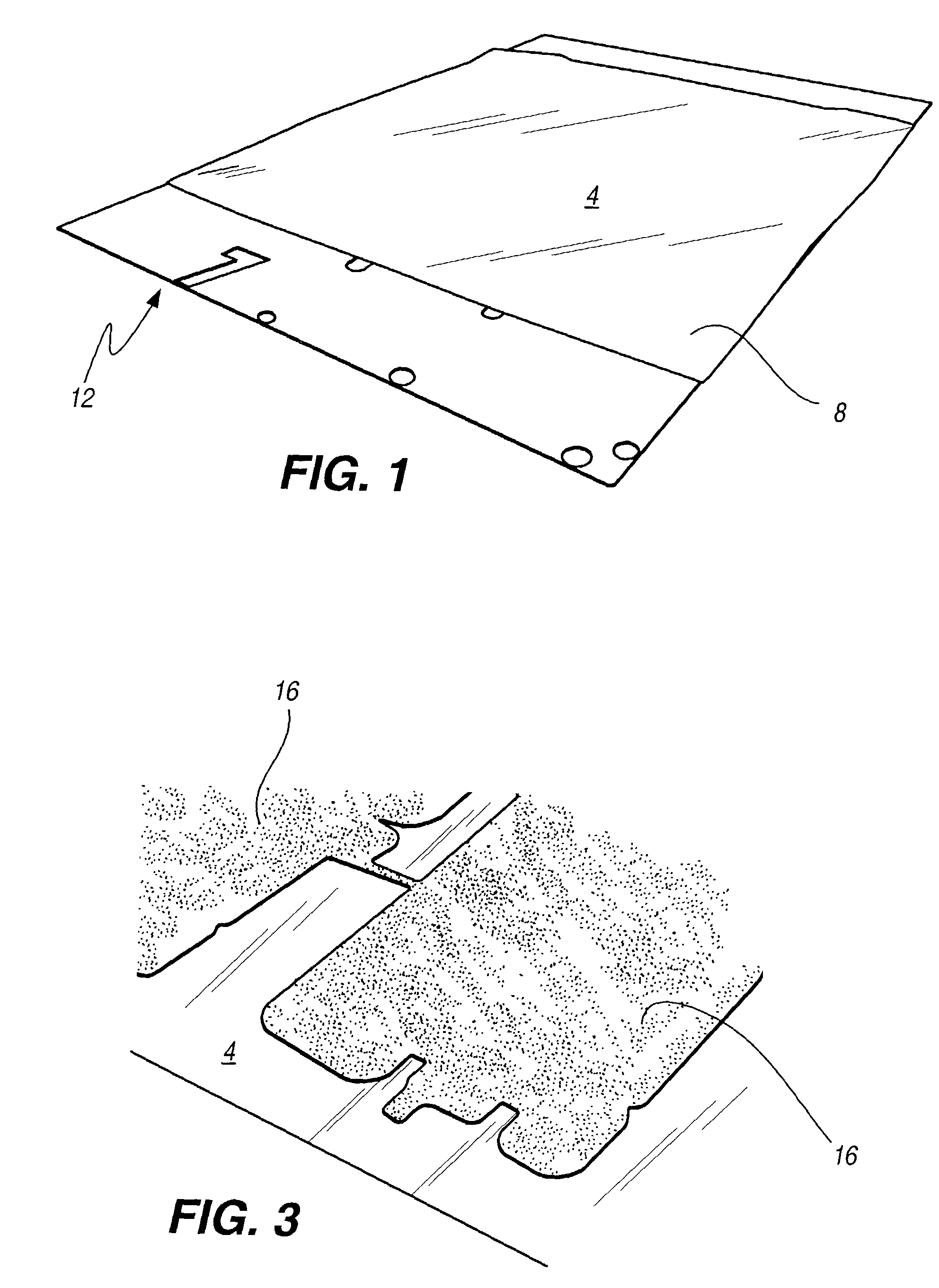

Screen printed resin film applique or transfer made from liquid plastic dispersion

InactiveUS6977023B2Increases viscosity and thicknessPrevent discolorationRadiation applicationsDecorative surface effectsScreen printingFree form

The present invention is directed to the use of a resin dispersion to form a variety of decorative transfers. The transfers can include a decorative medium such as flock. Primary and secondary carriers are used in some embodiments of the invention. The resin dispersion, when gelled and fused, can provide a free-form design article that can be readily applied to any desirable substrate, such as a textile.

Owner:HIGH VOLTAGE GRAPHICS

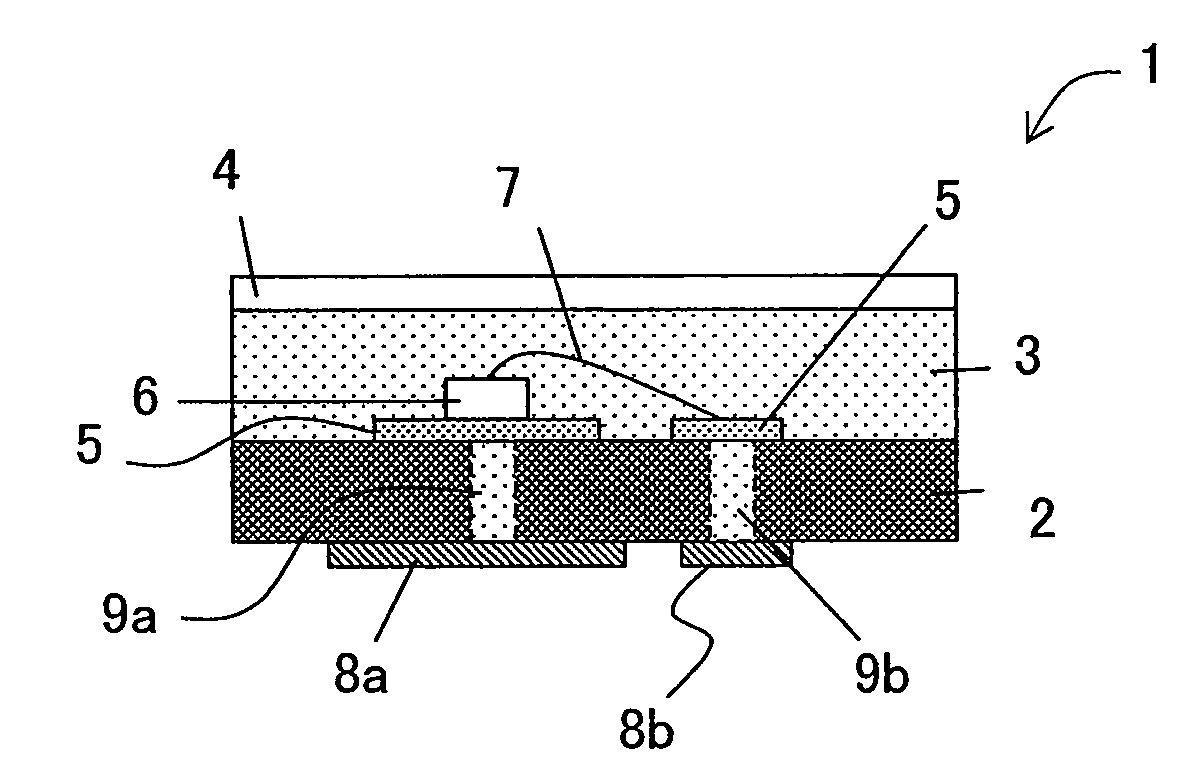

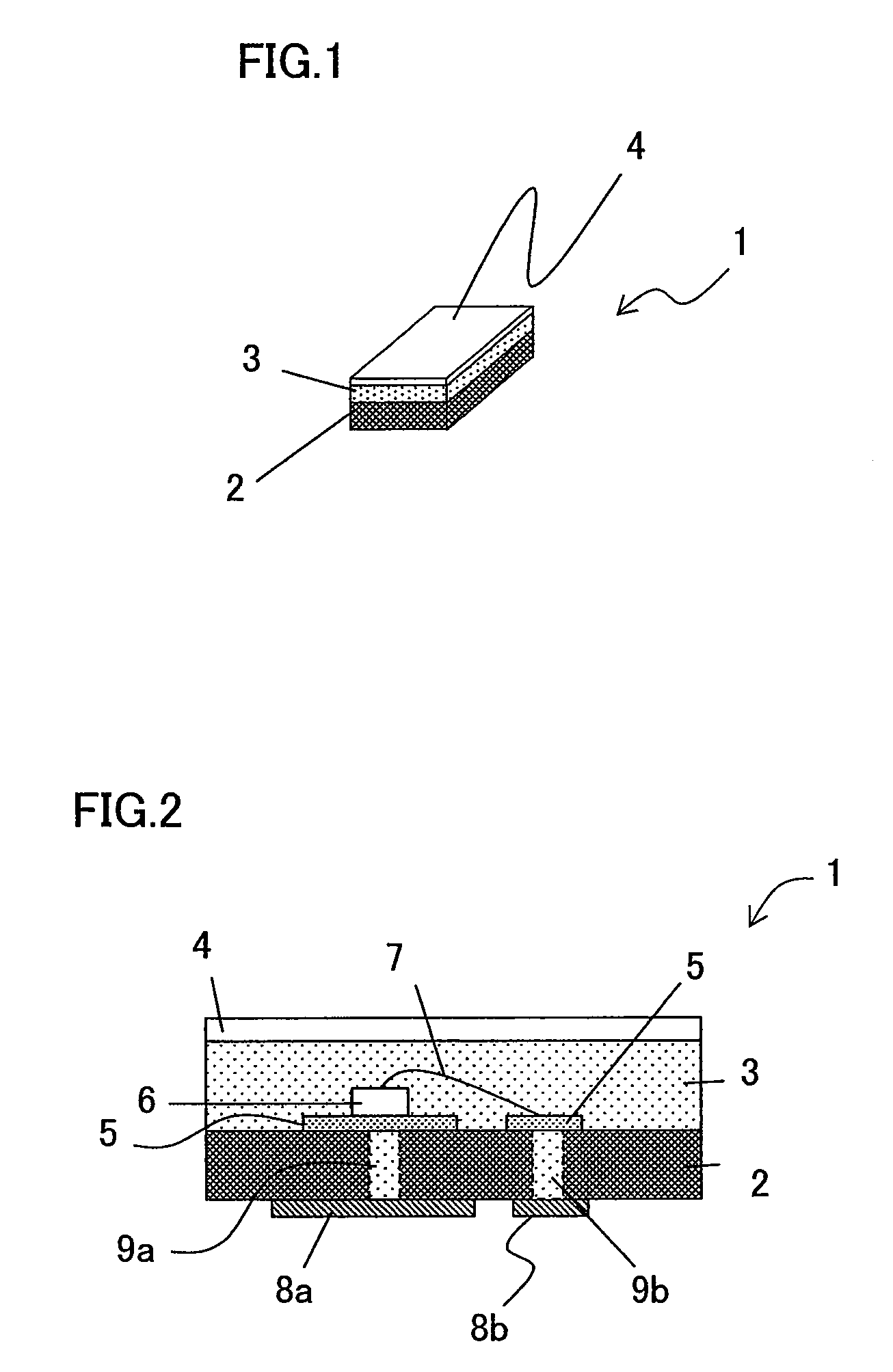

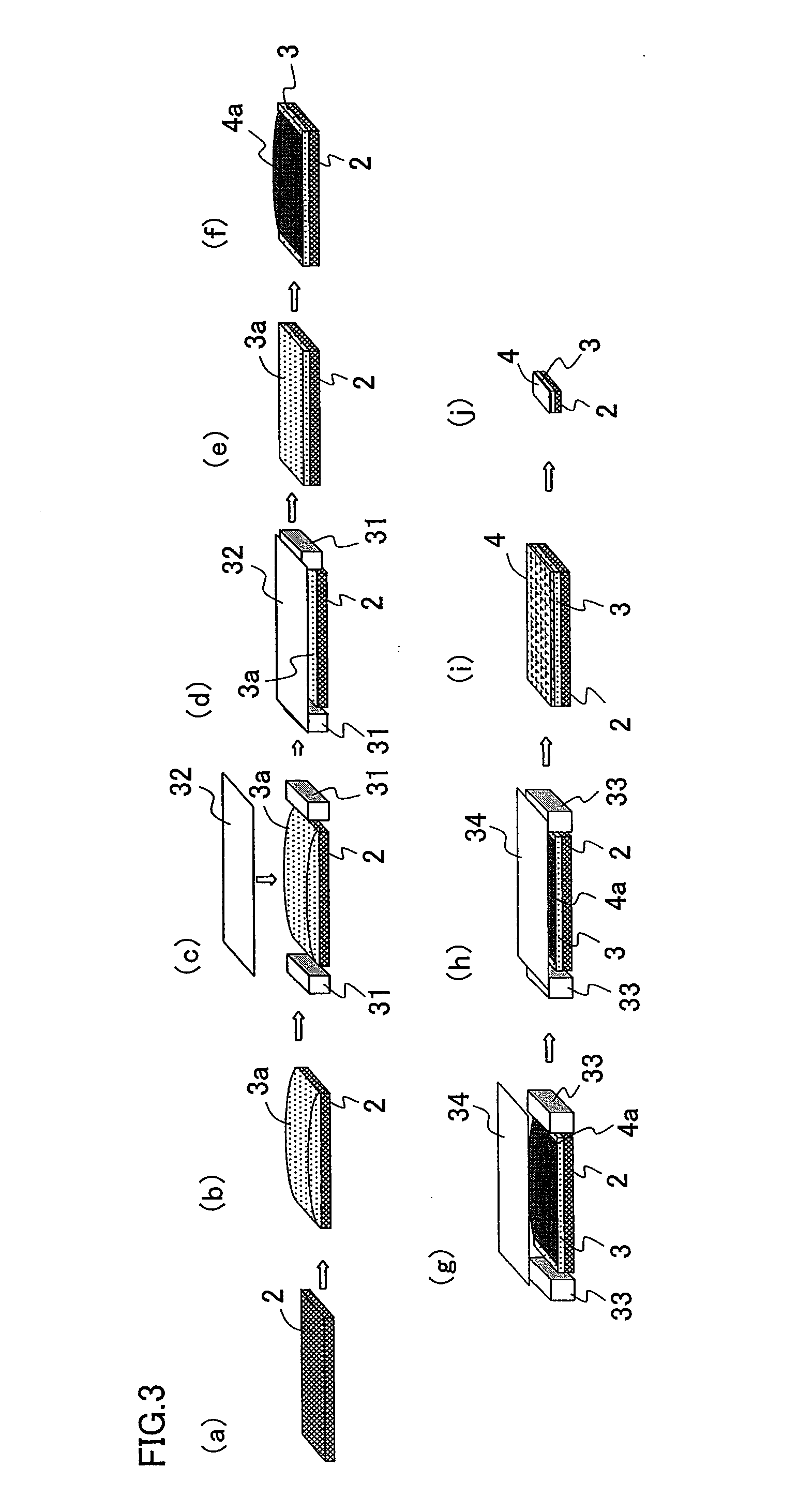

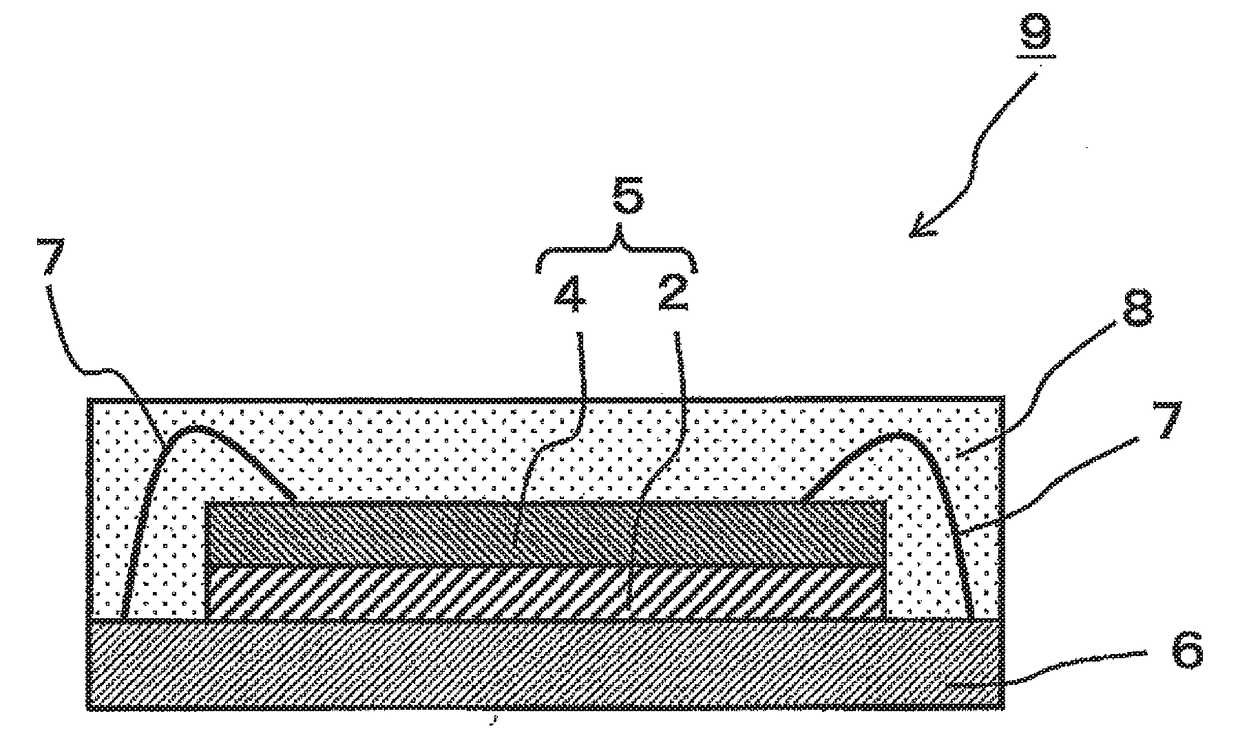

Light emitting apparatus, method for manufacturing the light emitting apparatus, electronic device and cell phone device

ActiveUS20080303411A1Reduce resin viscosityProportionally largeDischarge tube luminescnet screensLamp detailsPhosphorEngineering

A light emitting apparatus is provided, and the light emitting apparatus has a light emitting device mounted on a substrate or a resin package where a substrate surface or the resin package is resin-encapsulated by an encapsulating resin section added with a phosphor in such a manner to cover the light emitting device. A surface resin layer of a different color from that of the encapsulating resin section is provided on a surface side of the encapsulating resin section.

Owner:SHARP KK

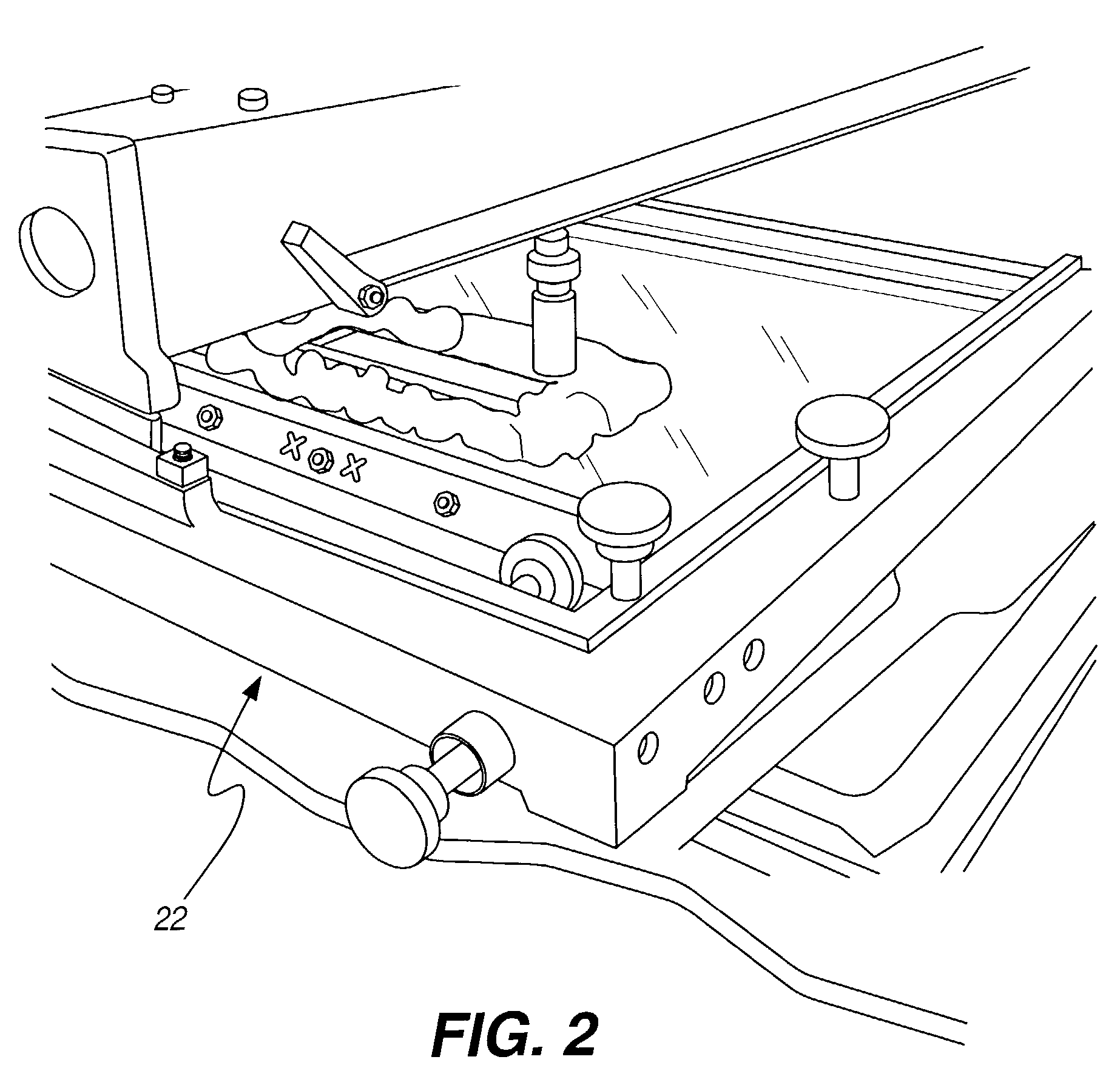

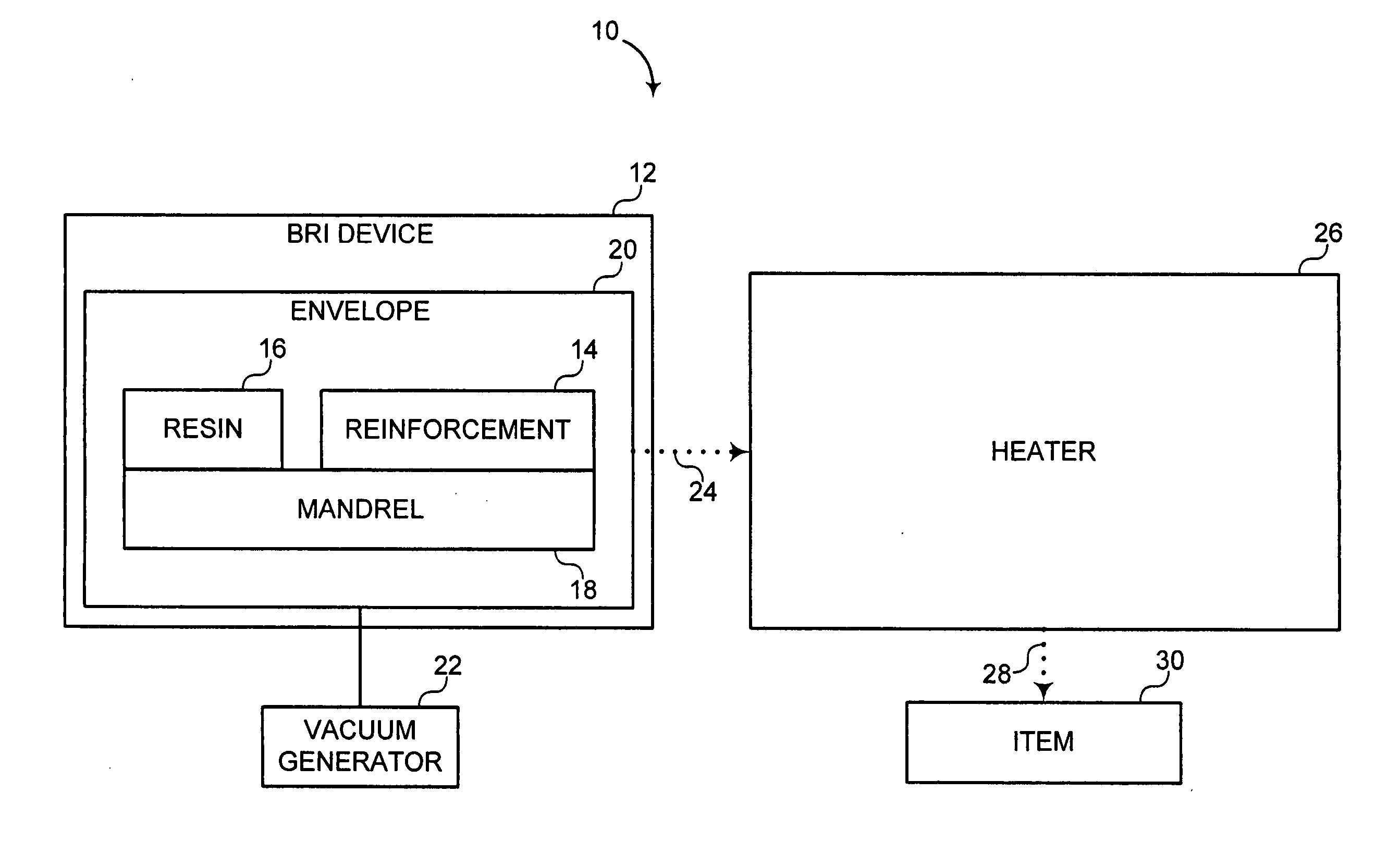

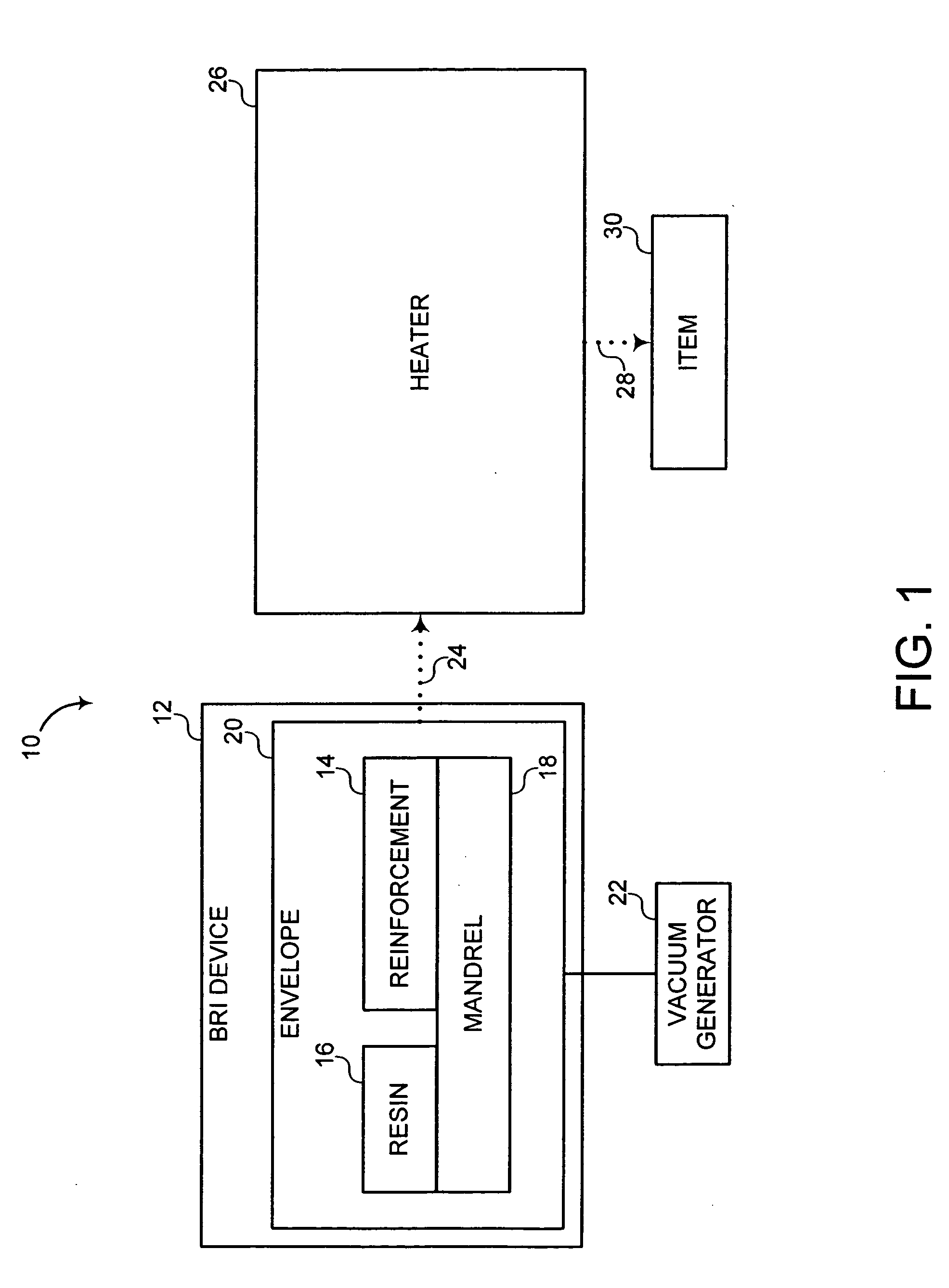

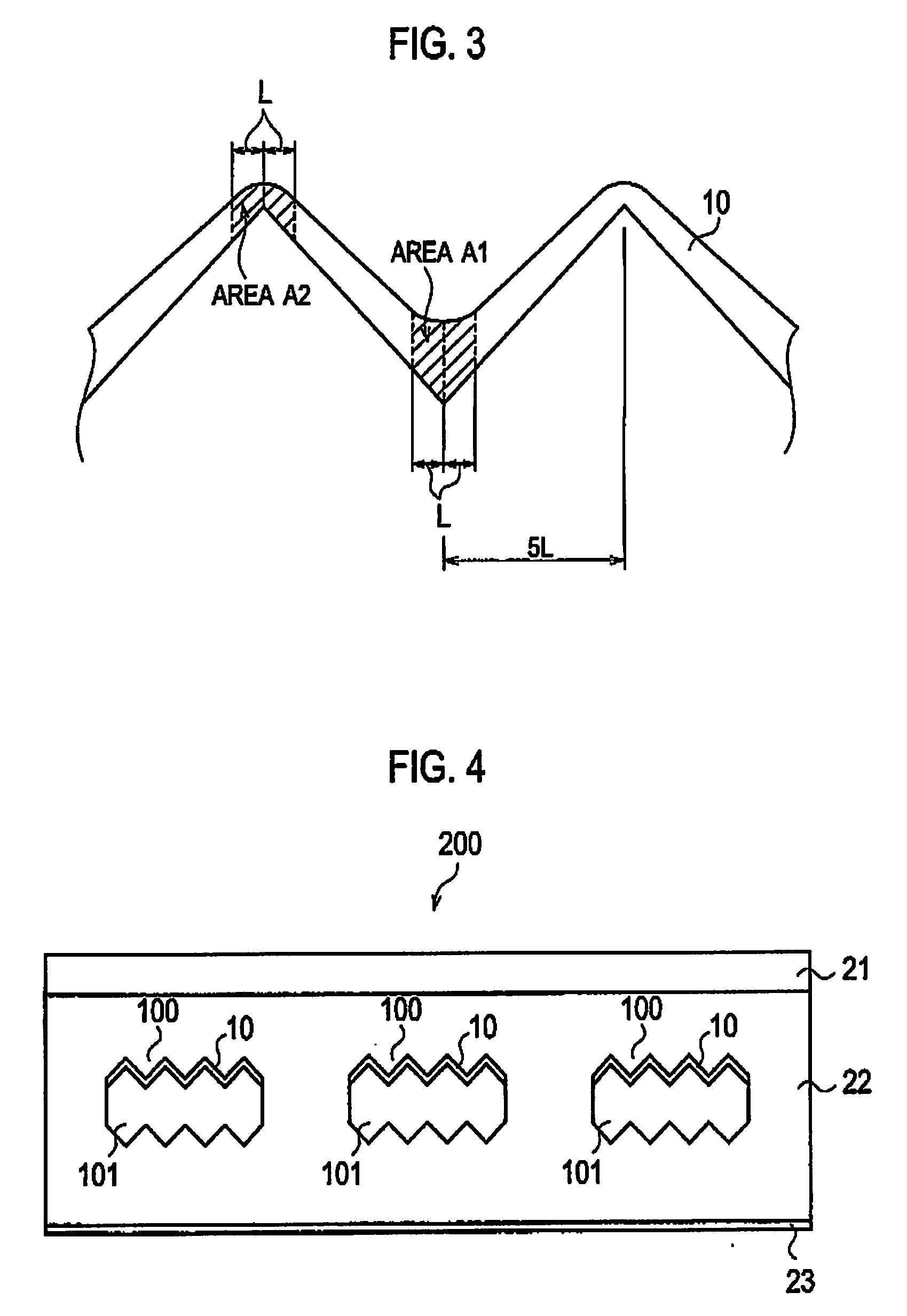

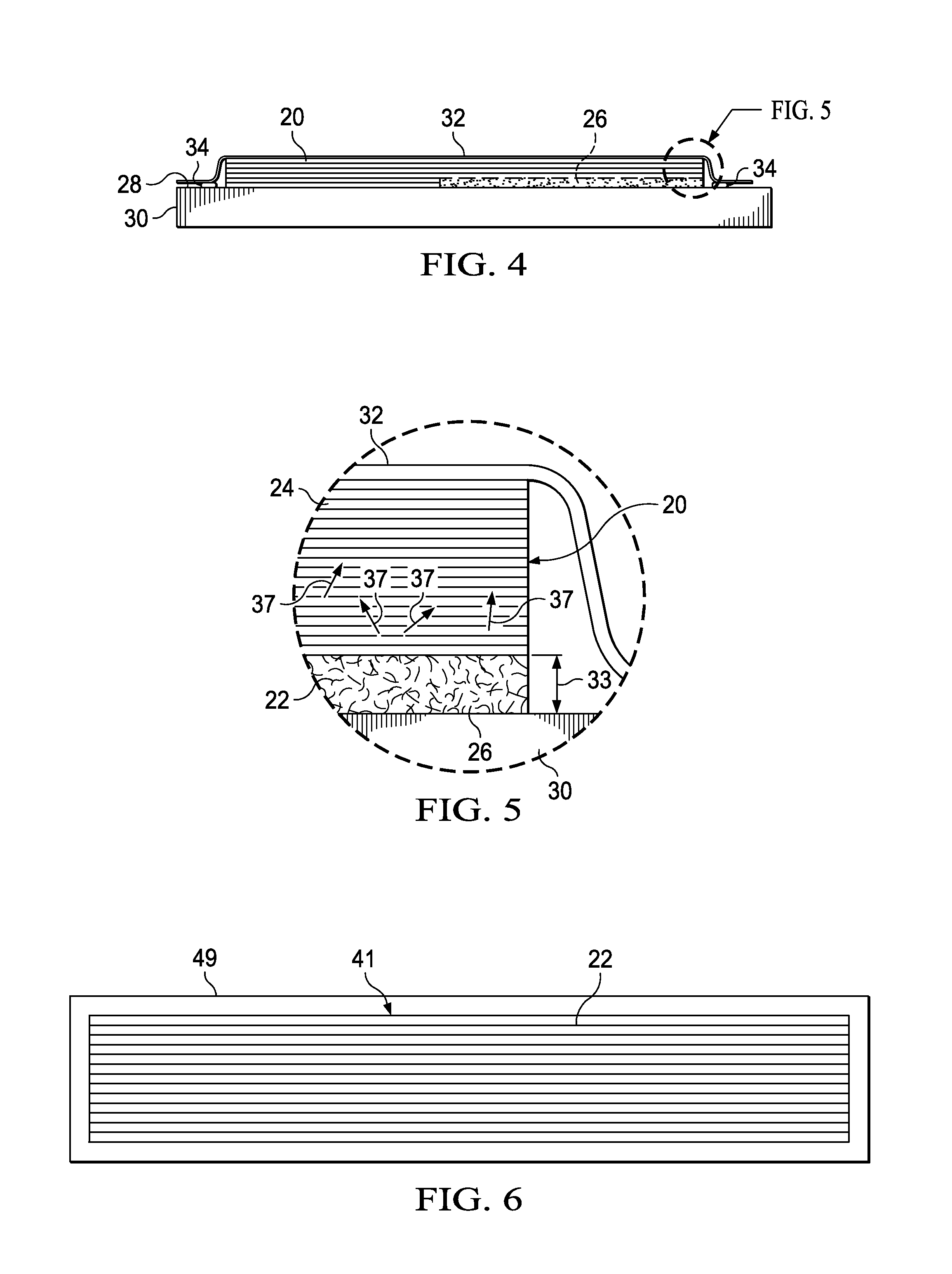

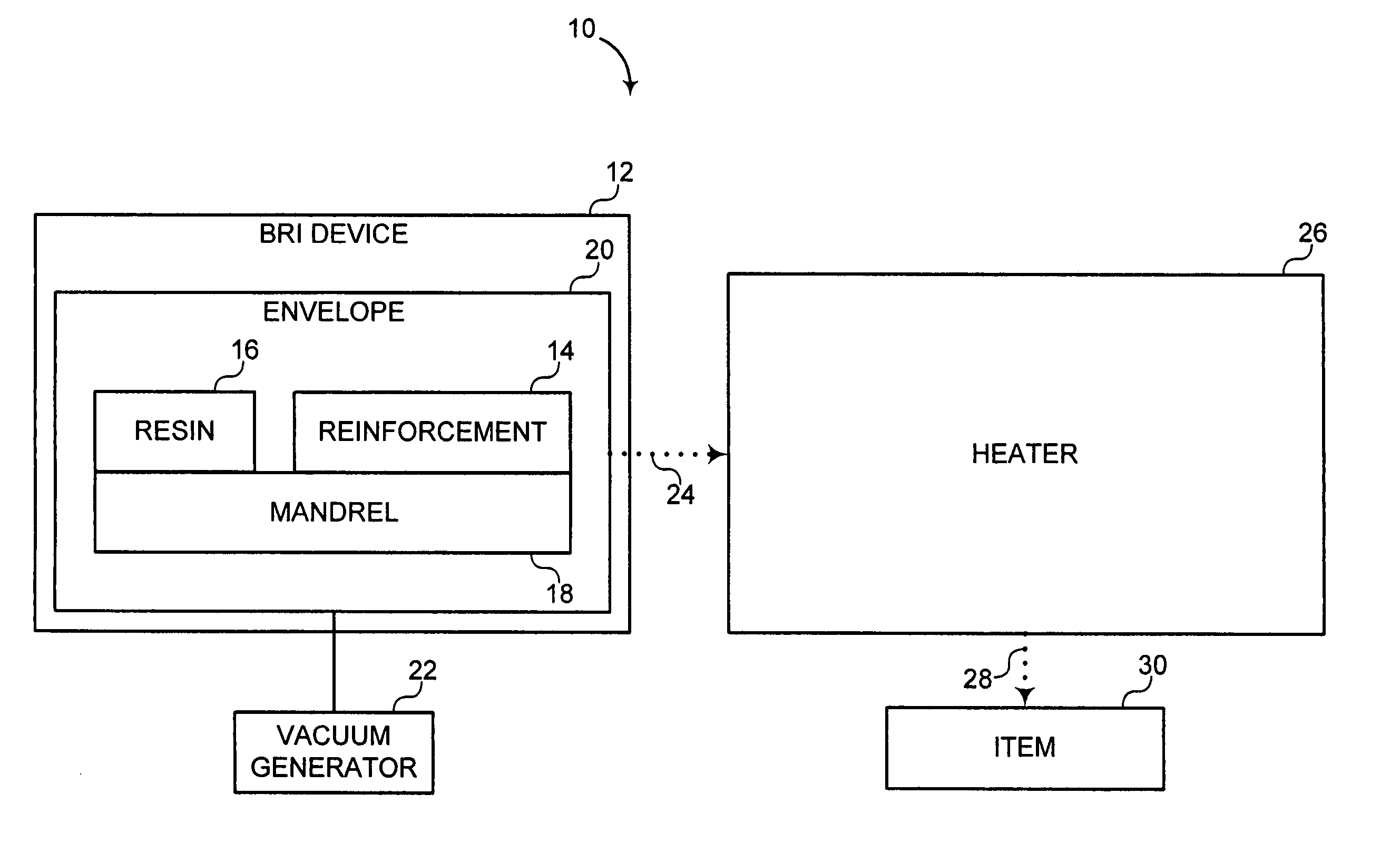

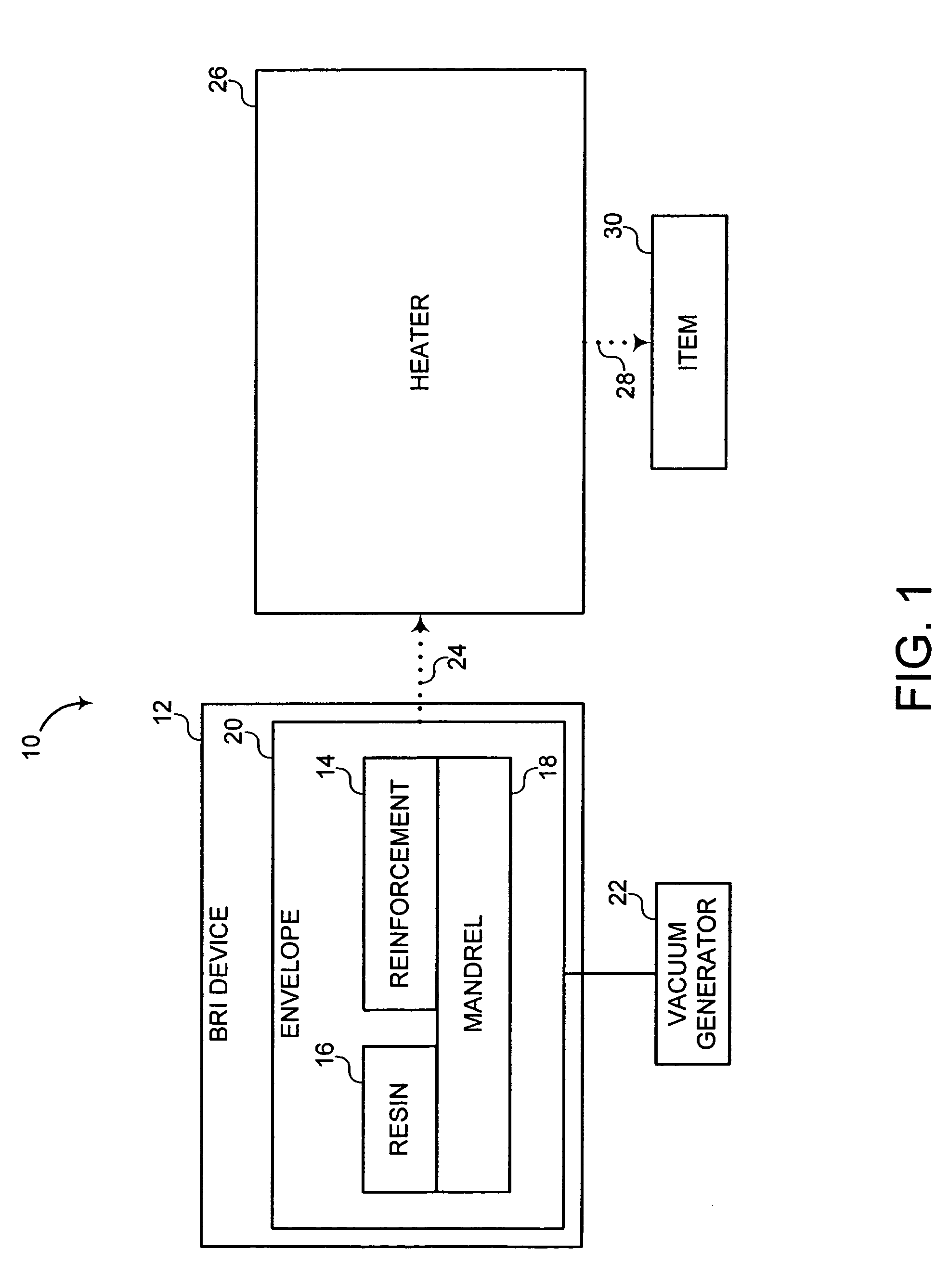

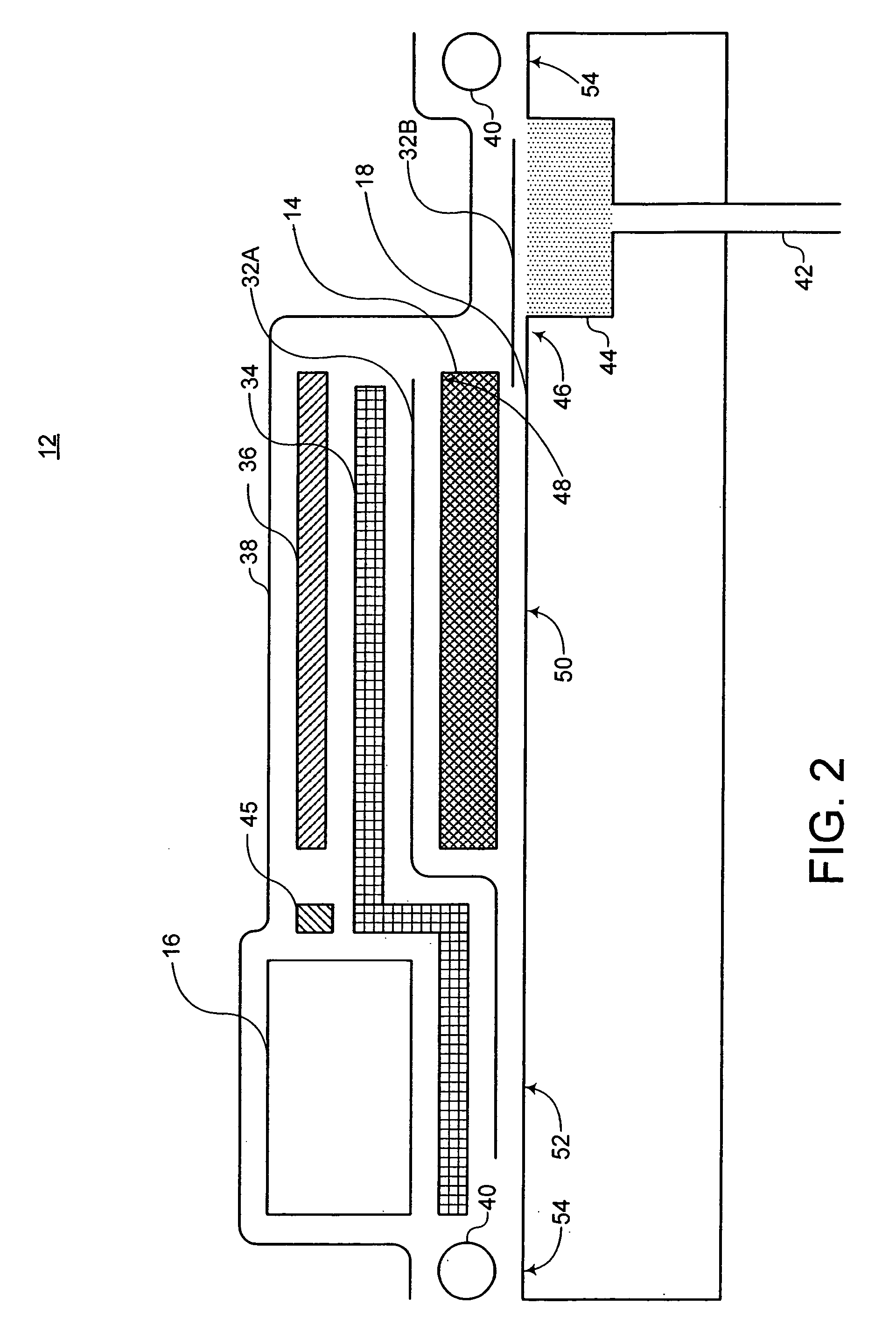

Bulk resin infusion system apparatus and method

ActiveUS20070108665A1Convenient infusionReduce resin viscosityElectric discharge heatingWood working apparatusMaterials scienceComposite material

A composite item is fabricated in system that includes a layer of preform, supply of resin, mandrel, and bagging film. The layer of preform corresponds to the composite item. The supply of resin is sufficient to infuse the preform. The mandrel includes a preform receiving zone to receive the layer of preform and a resin receiving zone to receive the supply of resin. The resin receiving zone is adjacent to the preform receiving zone. The bagging film is operable to generate an envelope surrounding the preform receiving zone and the resin receiving zone.

Owner:THE BOEING CO

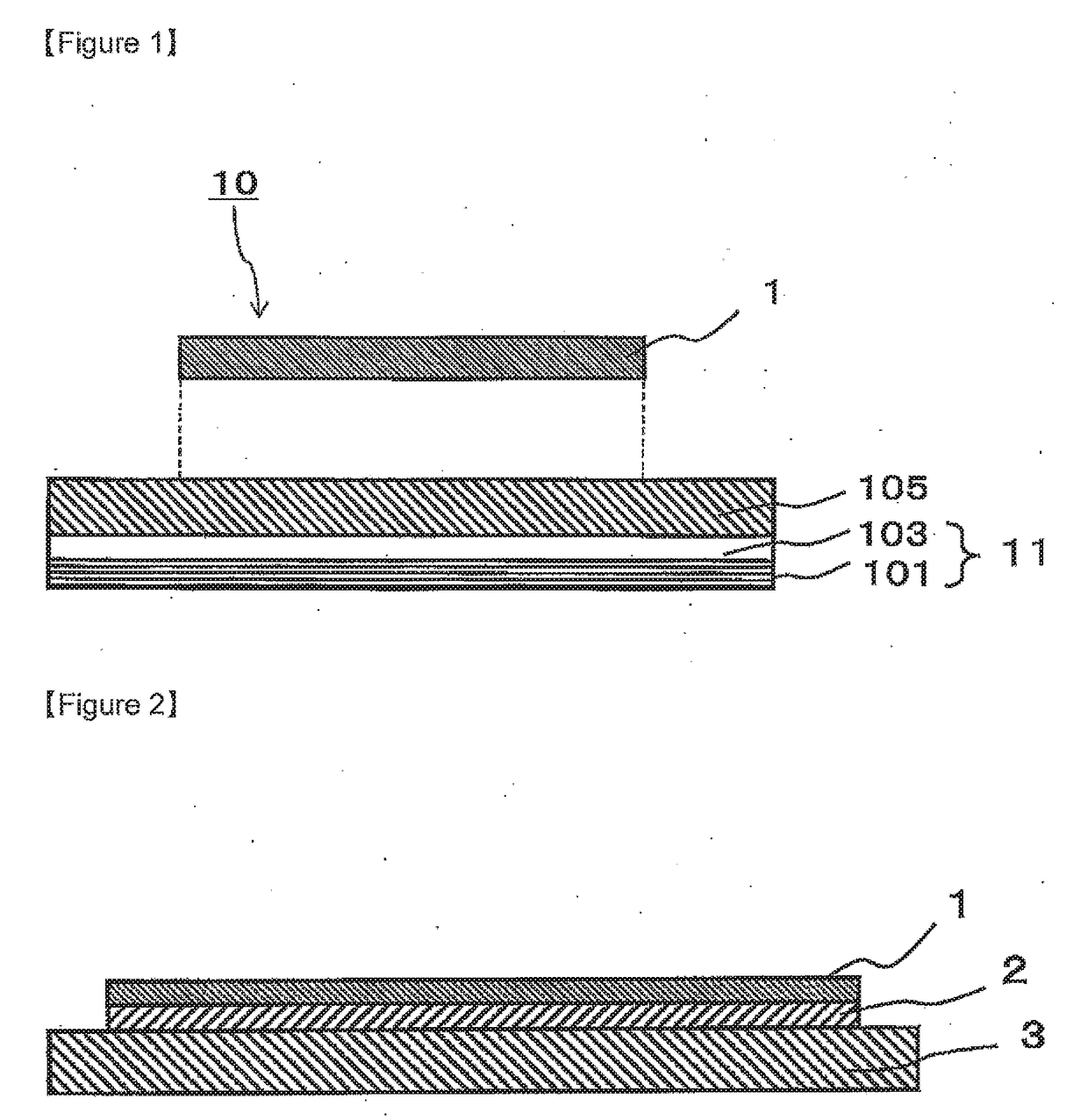

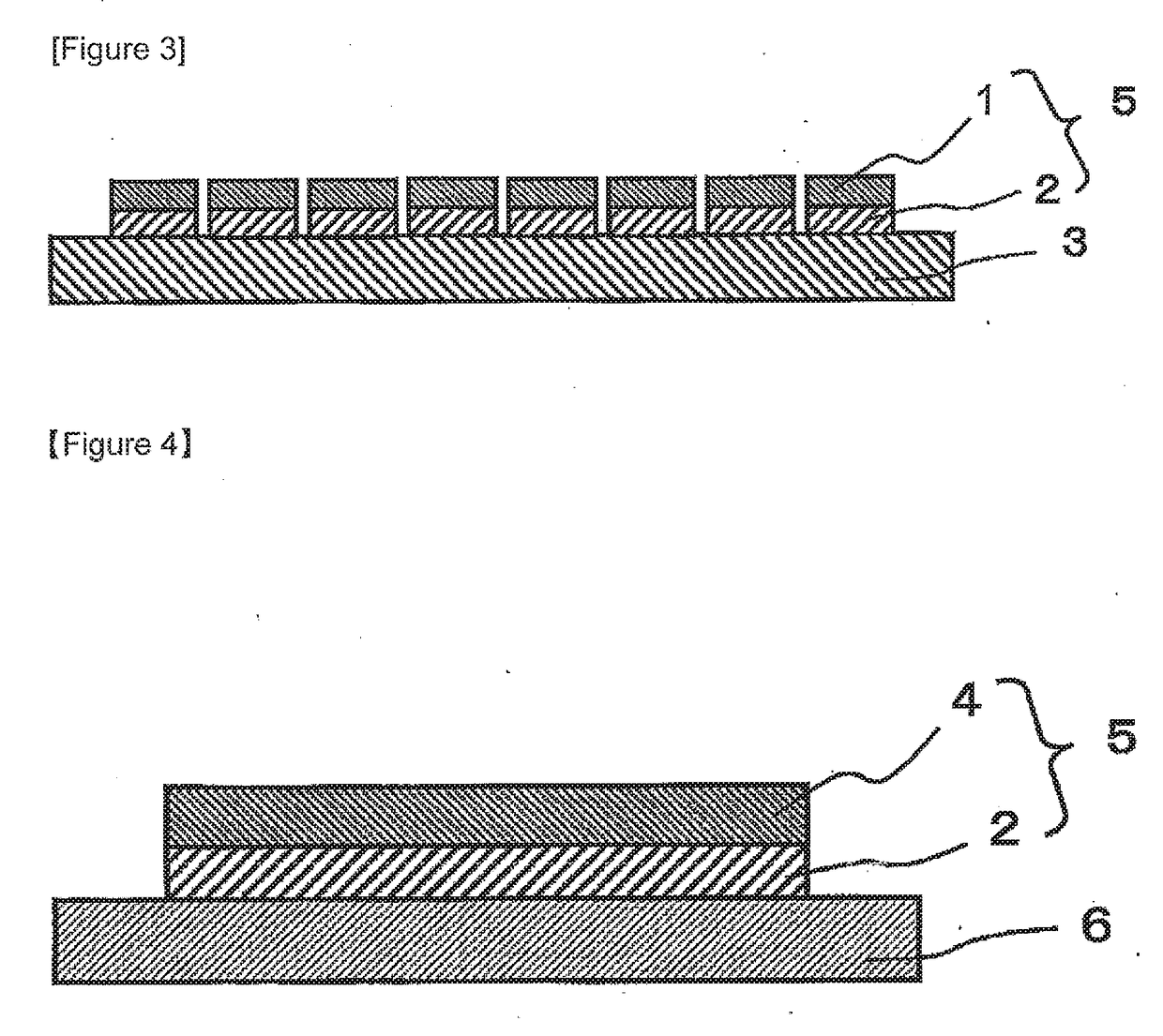

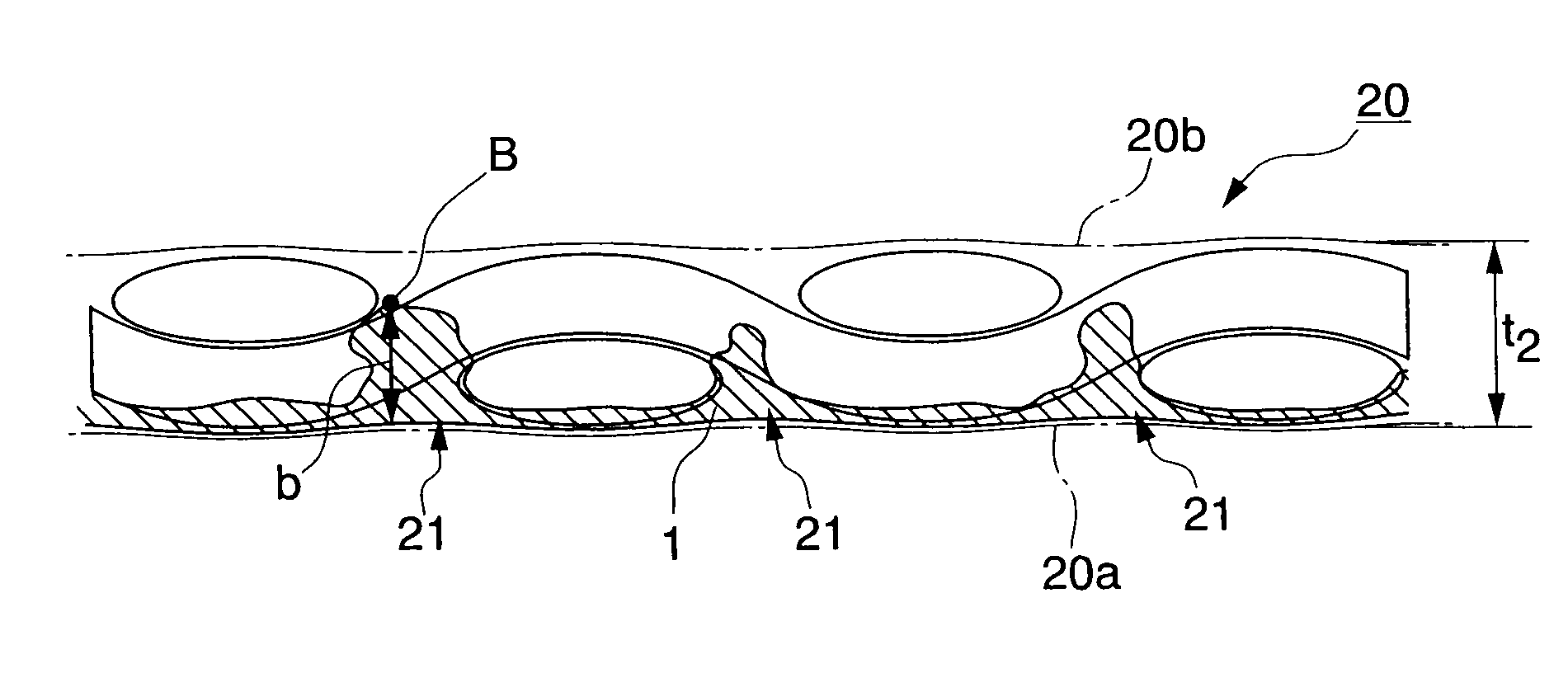

Solar cell module

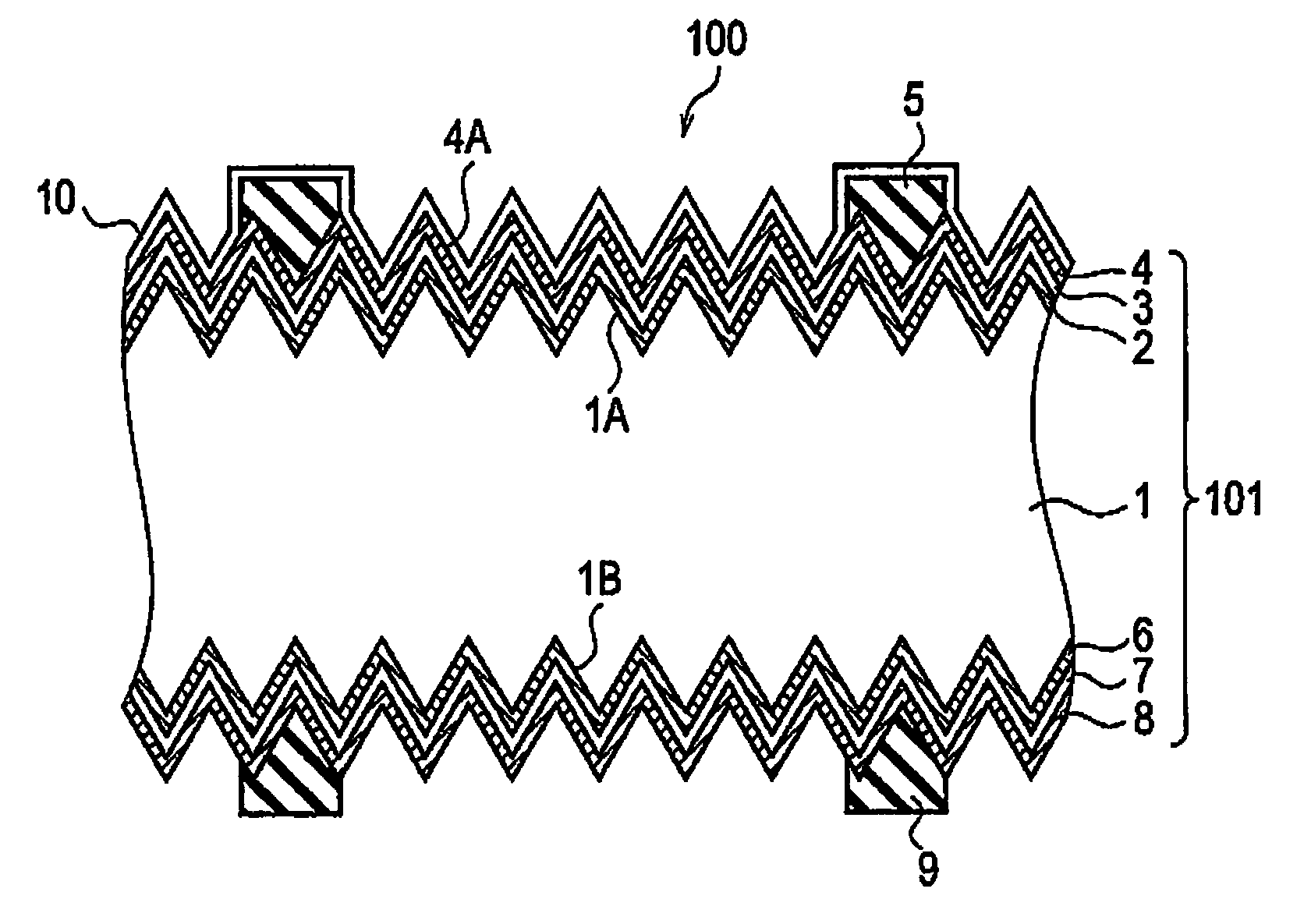

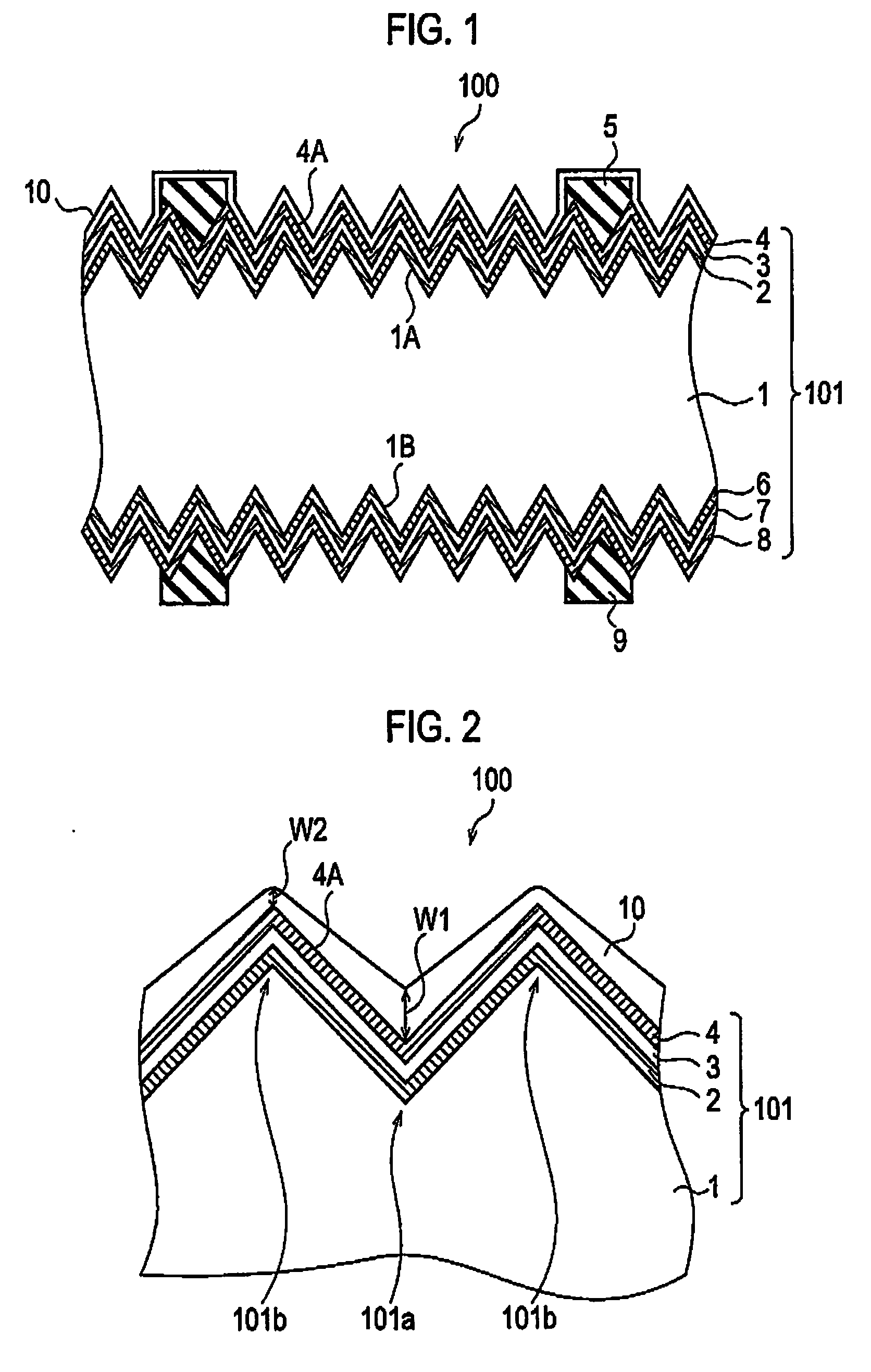

InactiveUS20100006147A1Relieve pressureReduce warpagePhotovoltaic energy generationSemiconductor devicesPhotoelectric conversionEngineering

A solar cell module includes: a photoelectric conversion body 101 having an uneven surface on a light-entering surface; and a protection layer 10 made of a resin and provided to cover the uneven surface. In a cross section of the protection layer 10 taken in parallel to a light-entering direction, a thickness W2 of a projected portion on the uneven surface is smaller than a thickness W1 of a recessed portion on the uneven surface.

Owner:SANYO ELECTRIC CO LTD

Unsaturated polyester resin composition

InactiveUS6808821B2Excellent gloss retention and yellowing resistanceReduce resin viscositySynthetic resin layered productsThin material handlingPolymer sciencePolyester resin

Disclosed is an unsaturated polyester resin composition comprising an unsaturated polyester (A) and a polymerizable unsaturated monomer (B), wherein the "shrinkage stress upon cooling" of a cured article thereof is 17 MPa or less and the ratio of the "shrinkage stress upon cooling / elastic limit" is 1 or less. The cured article has excellent gloss retention and yellowing resistance.

Owner:DAINIPPON INK & CHEM INC

Methods of preventing the production of sand with well fluids

InactiveUS6213209B1Reduce resin viscosityPromote formationFluid removalDrilling compositionSoil scienceOpen cell

Methods of preventing the production of sand with fluids produced from a subterranean formation penetrated by a well bore are provided. The methods basically comprise the steps of preparing a resin composition which delayedly forms a hardened open cell foam capable of allowing the passage of well fluids therethrough while screening and preventing the passage of formation sand and then placing the resin composition adjacent to the formation by way of the well bore.

Owner:HALLIBURTON ENERGY SERVICES INC

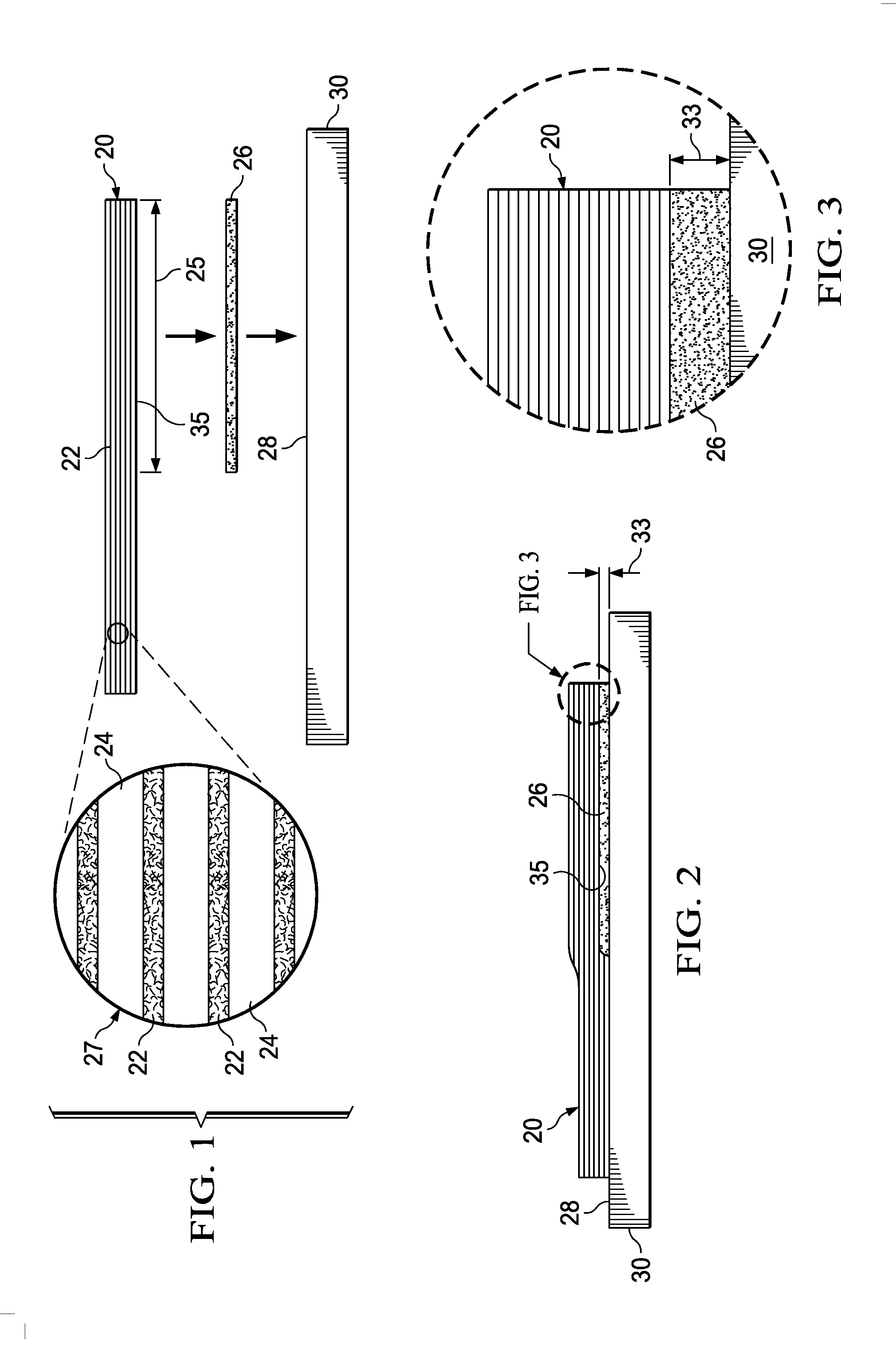

Exposing Fibers in Composite Laminates

ActiveUS20140119813A1High strengthImprove crack resistanceAdhesive processesWood working apparatusFiberComposite laminates

Owner:THE BOEING CO

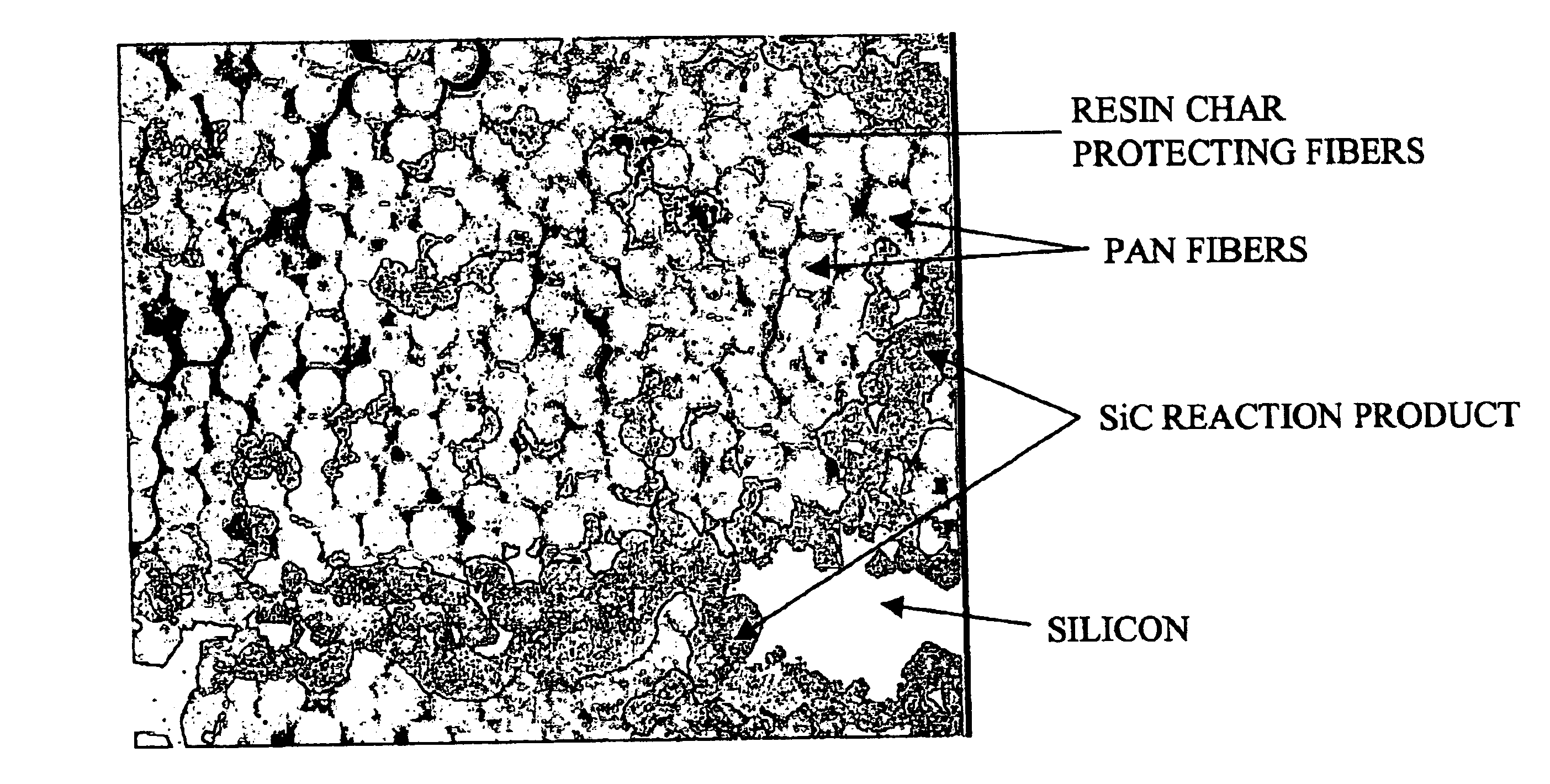

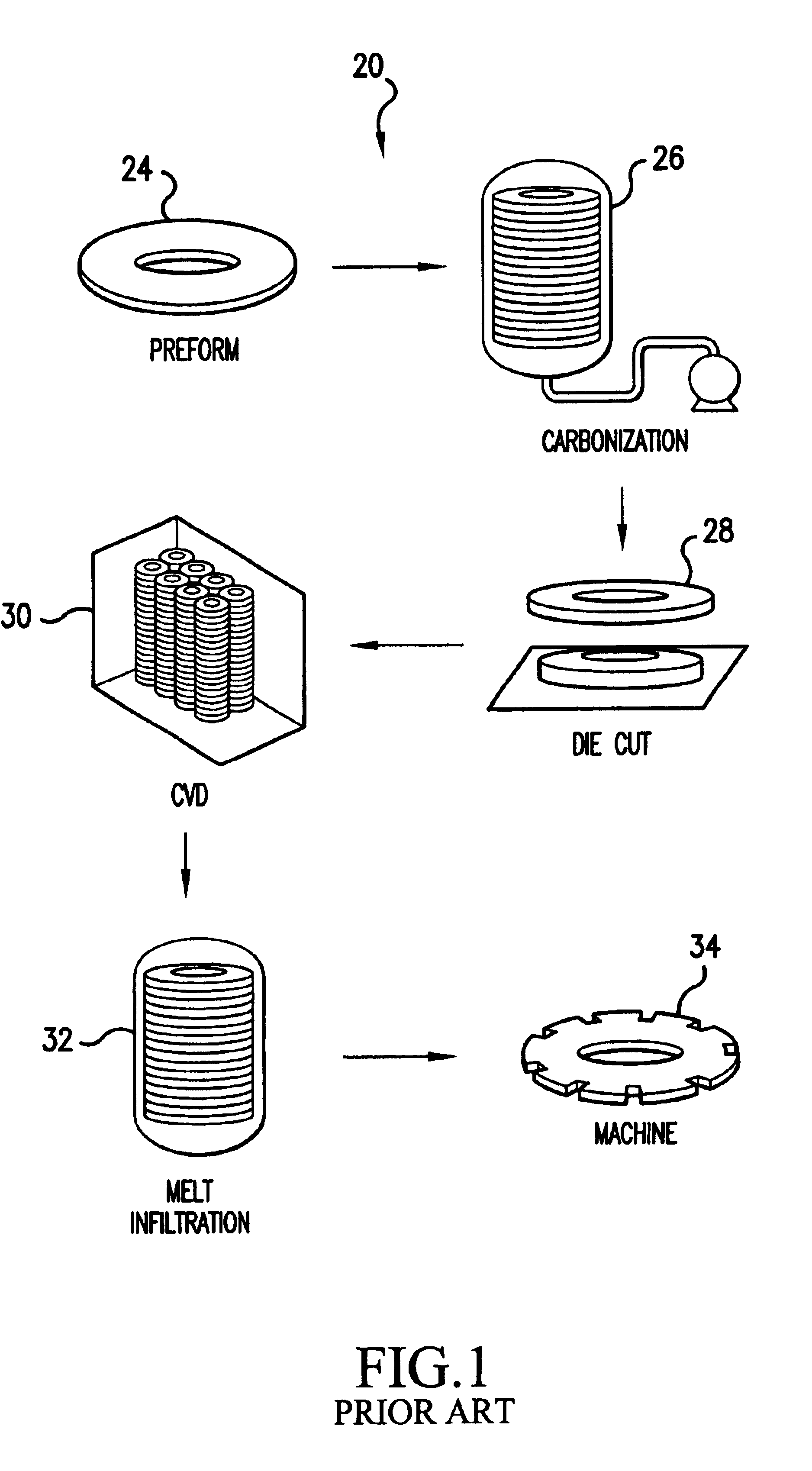

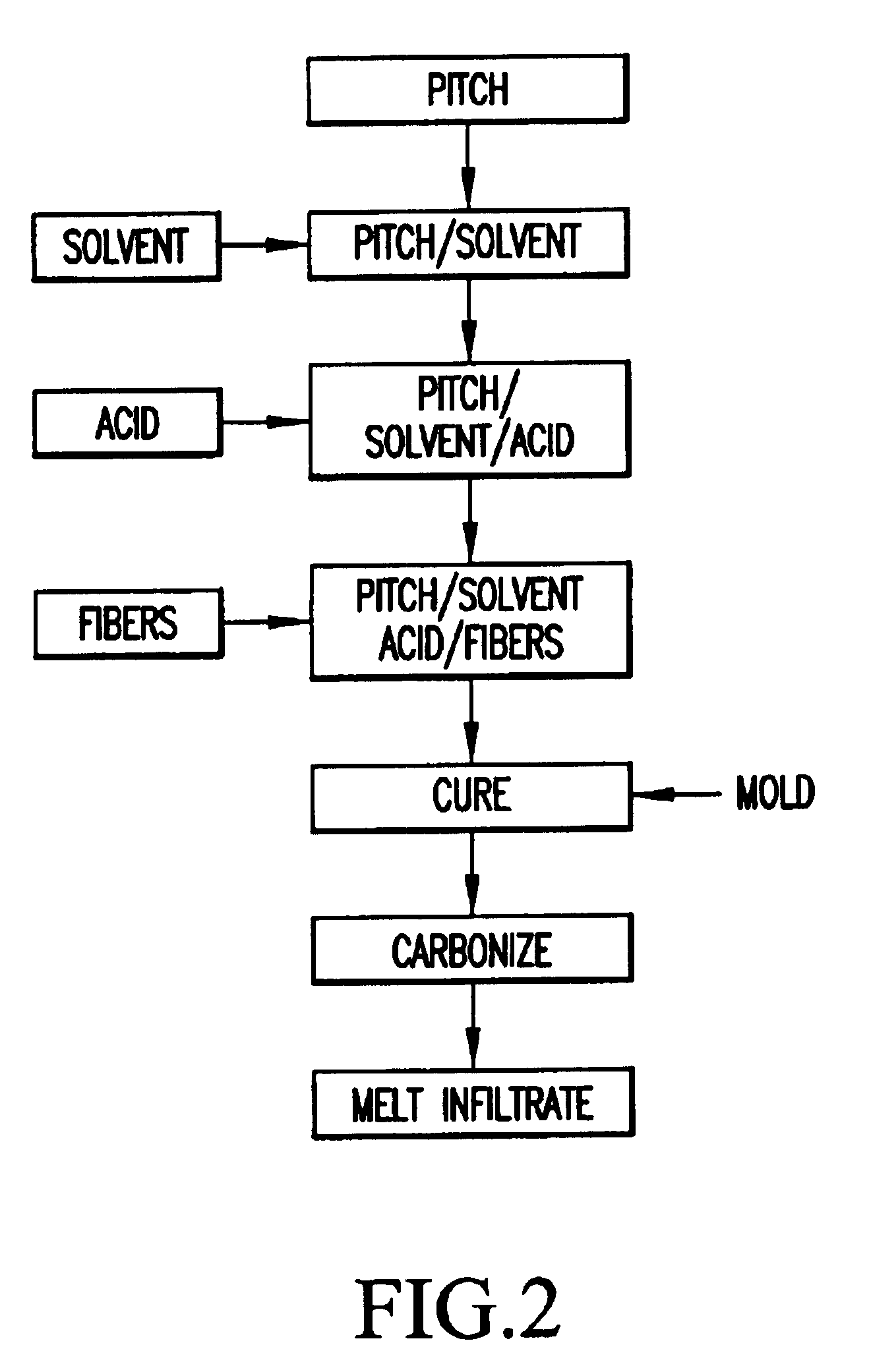

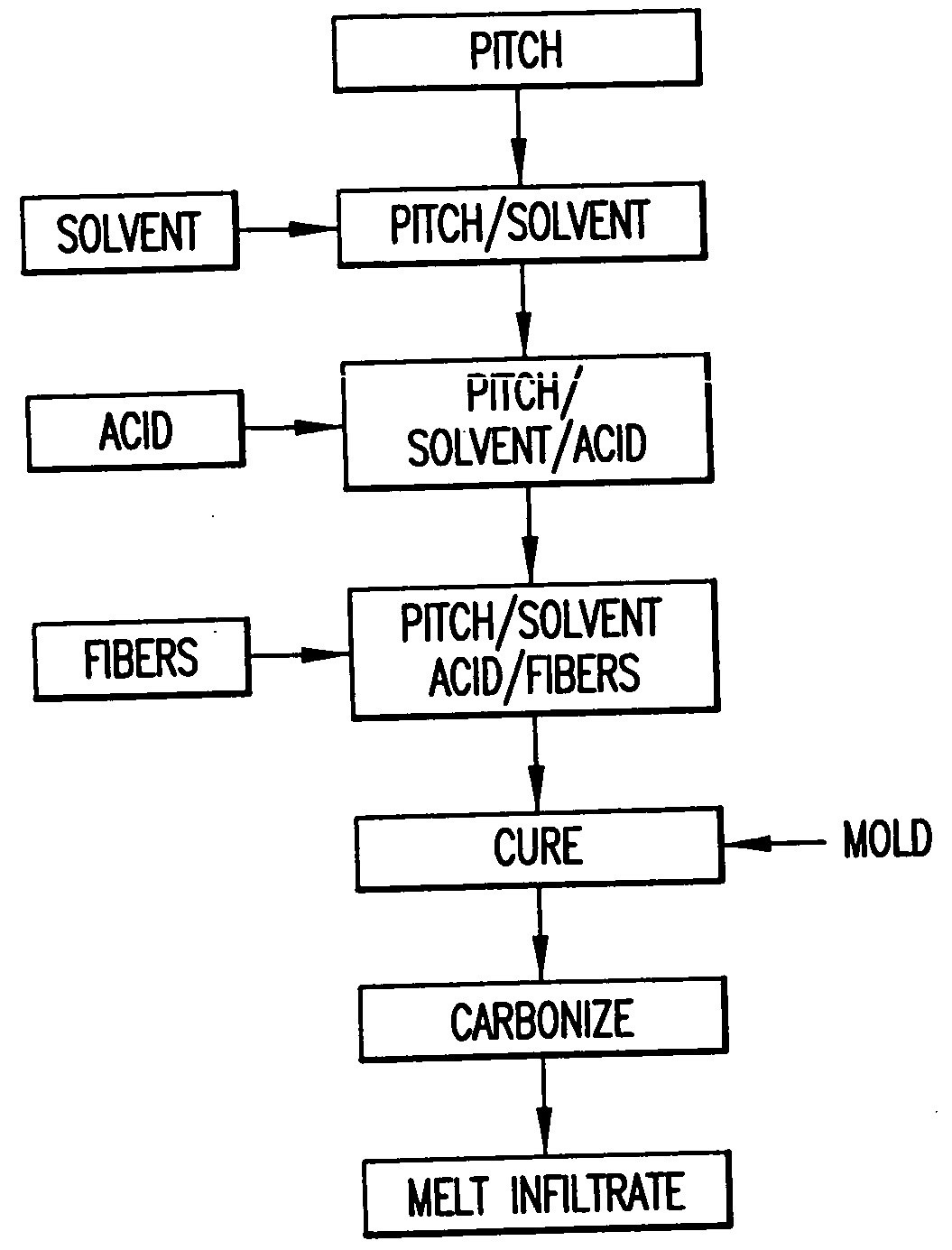

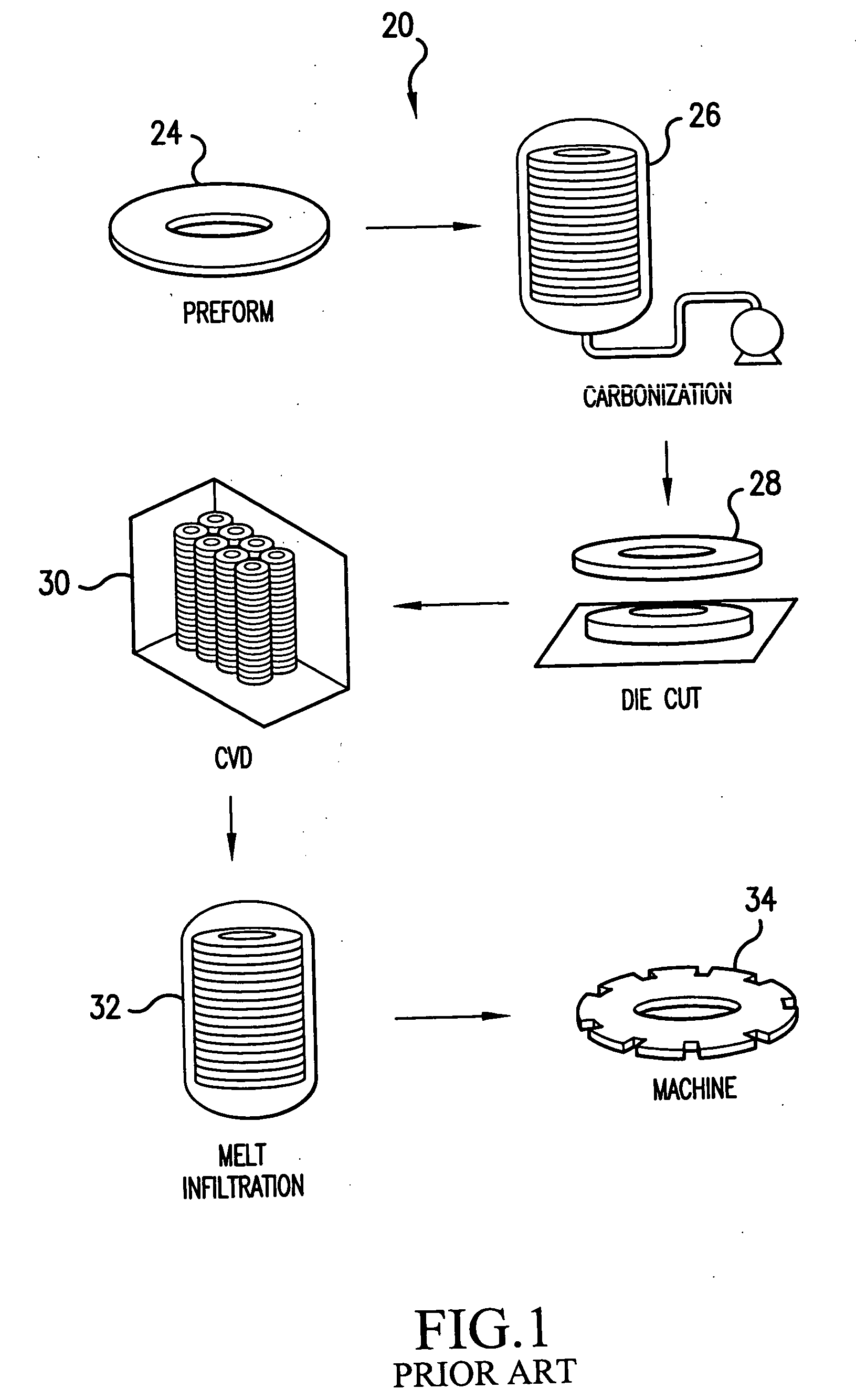

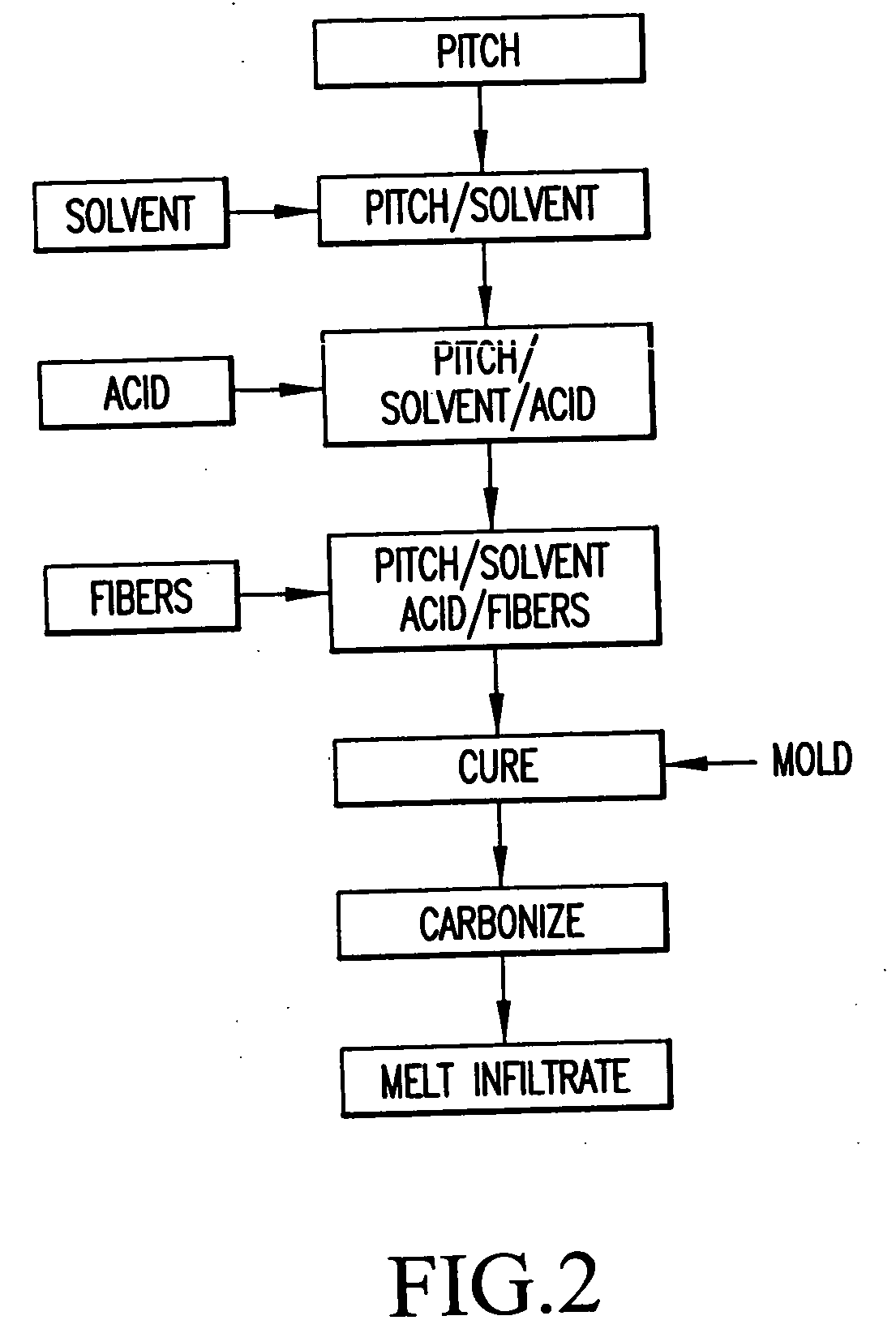

Melt-infiltrated pitch-pan preforms

InactiveUS6749937B2Omission of costly CVD stepGood adhesionBraking discsCeramic layered productsPorosityCarbon fibers

Carbon-silicon carbide brake preforms are manufactured by carbonizing a blend of carbon (e.g., polyacrylonitrile) fibers and thermosetting pitch resin, optionally along with a lubricant such as graphite, to provide an intermediate product having open porosity and subsequently filling the pores of the intermediate product with silicon by a melt infiltration process. Molded articles that consist principally of carbon, that have relatively high strength and resistance to decomposition by frictional heat, and that are suitable for melt infiltration with silicon, are produced by, e.g.: coating randomly oriented polyacrylonitrile-derived carbon fibers, optionally mixed with finely divided carbon powder, with a thermosetting blend of (a) pitch and (b) an organic medium, at an elevated temperature to form a viscous molding compound; molding the compound at a low pressure and elevated temperature so that a solid compact is obtained; stripping a molded article made of said compound from the mold; optionally heating the molded article at gradually increasing temperatures to insure complete condensation within the article; and carbonizing the condensed molded article in an inert atmosphere at gradually increasing temperatures to produce a molded C / C intermediate article suitable for melt-infiltration with silicon. The preforms may be configured in the form of a disc brake rotor or a disc brake pad.

Owner:HONEYWELL INT INC

Unsaturated polyester resin composition

InactiveUS20040024140A1Excellent gloss retention and yellowing resistanceReduce resin viscosityThin material handlingPolyester coatingsPolymer chemistryUnsaturated monomer

Disclosed is an unsaturated polyester resin composition comprising an unsaturated polyester (A) and a polymerizable unsaturated monomer (B), wherein the "shrinkage stress upon cooling" of a cured article thereof is 17 MPa or less and the ratio of the "shrinkage stress upon cooling / elastic limit" is 1 or less. The cured article has excellent gloss retention and yellowing resistance.

Owner:DAINIPPON INK & CHEM INC

Resin composition for coating and coating composition for curing

InactiveUS6713551B2High hardnessGood flexibilityPolyurea/polyurethane coatingsPolyether coatingsPolyolHardness

The present inventors provides polyol-containing resin compositions for coatings which can give cured coating films having high hardness and at the same time high solid compositions to meet the recent resources saving and / or environmental protection requirements, and curable coating compositions having high reactivity at curing, giving the coating film with good appearance and the coatings with prolonged pot life.The invention is directed to a resin composition for coatings comprising a polyol (A1) or (A2), a polyether polyol (B) and a solvent (C),wherein the polyol (A1) comprises a hydroxyl-containing polymerizable unsaturated monomer and a ring structure-containing polymerizable unsaturated monomer as essential componentsand the polyol (A2) comprises a hydroxyl-containing polymerizable unsaturated monomer and a linear branched structure-containing polymerizable unsaturated monomer as essential components.

Owner:NIPPON SHOKUBAI CO LTD

Melt-infiltrated pitch-pan preforms

InactiveUS20040202896A1Omission of costly CVD stepGood adhesionBraking discsCeramic shaping apparatusPorosityCarbon fibers

Carbon-silicon carbide brake preforms are manufactured by carbonizing a blend of carbon (e.g., polyacrylonitrile) fibers and thermosetting pitch resin, optionally along with a lubricant such as graphite,.to provide an intermediate product having open porosity and subsequently filling the pores of the intermediate product with silicon by a melt infiltration process. Molded articles that consist principally of carbon, that have relatively high strength and resistance to decomposition by frictional heat, and that are suitable for melt infiltration with silicon, are produced by, e.g.: coating randomly oriented polyacrylonitrile-derived carbon fibers, optionally mixed with finely divided carbon powder, with a thermosetting blend of (a) pitch and (b) an organic medium, at an elevated temperature to form a viscous molding compound; molding the compound at a low pressure and elevated temperature so that a solid compact is obtained; stripping a molded article made of said compound from the mold; optionally heating the molded article at gradually increasing temperatures to insure complete condensation within the article; and carbonizing the condensed molded article in an inert atmosphere at gradually increasing temperatures to produce a molded C / C intermediate article suitable for melt-infiltration with silicon. The preforms may be configured in the form of a disc brake rotor or a disc brake pad.

Owner:HONEYWELL INT INC

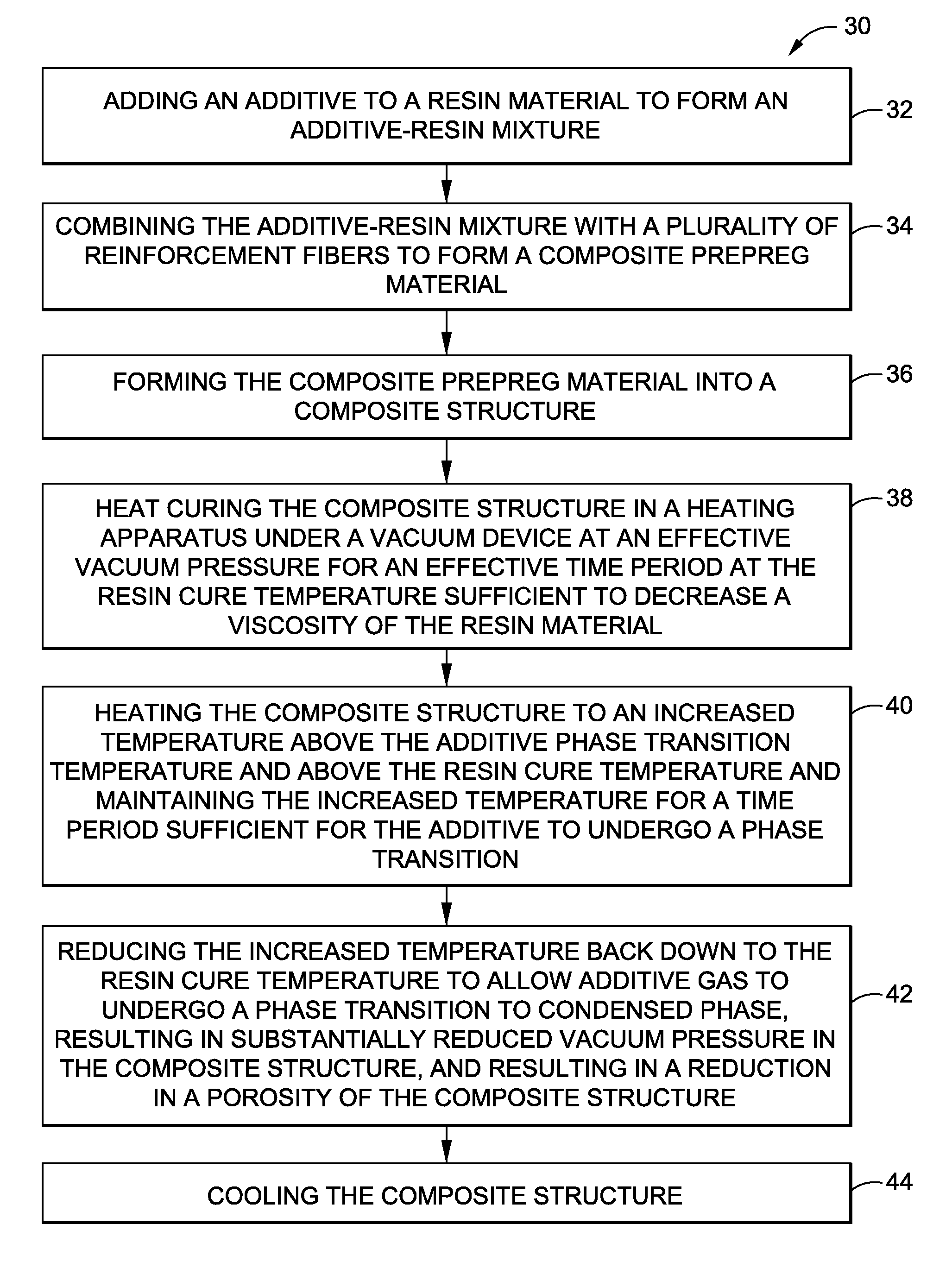

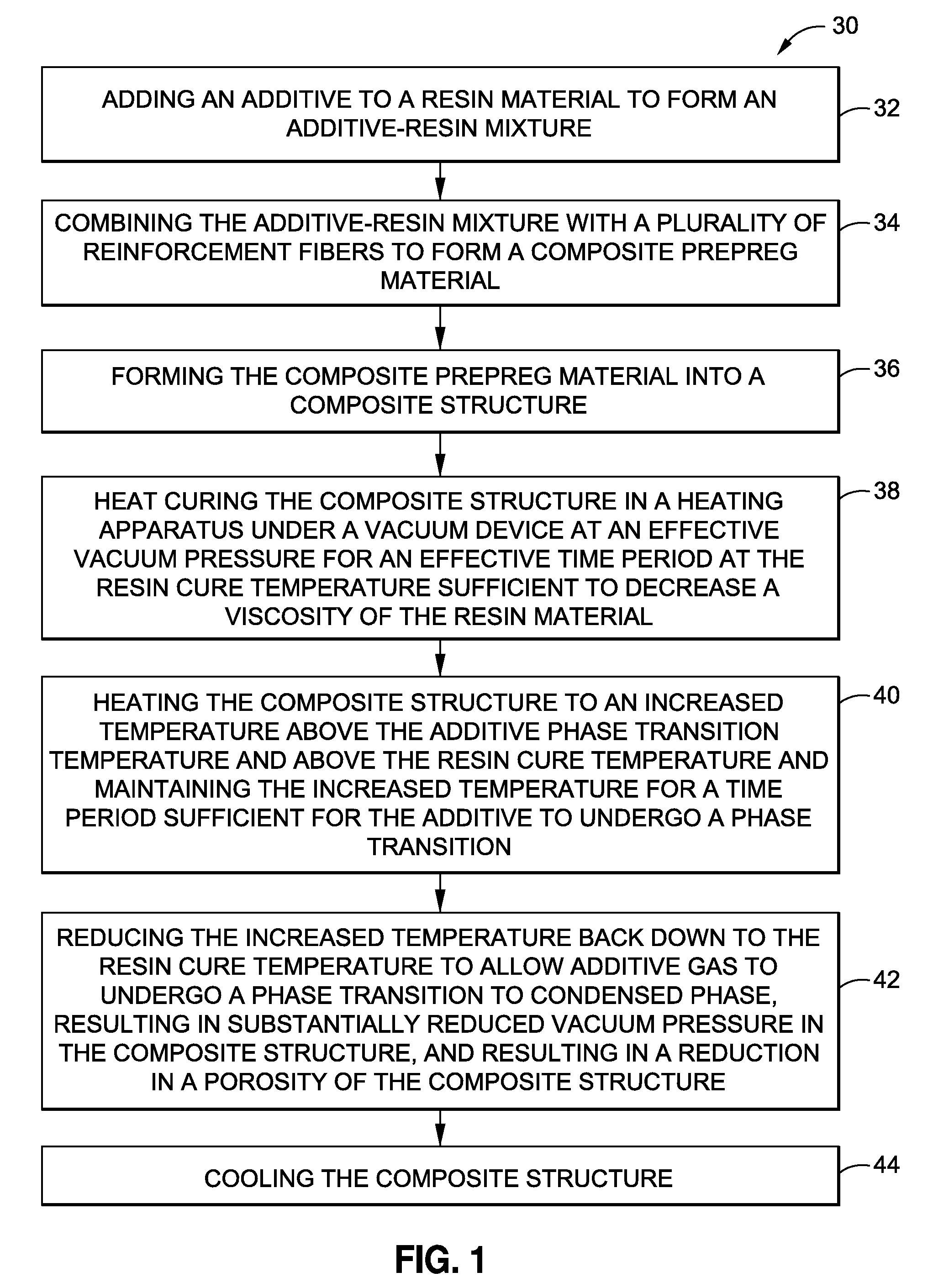

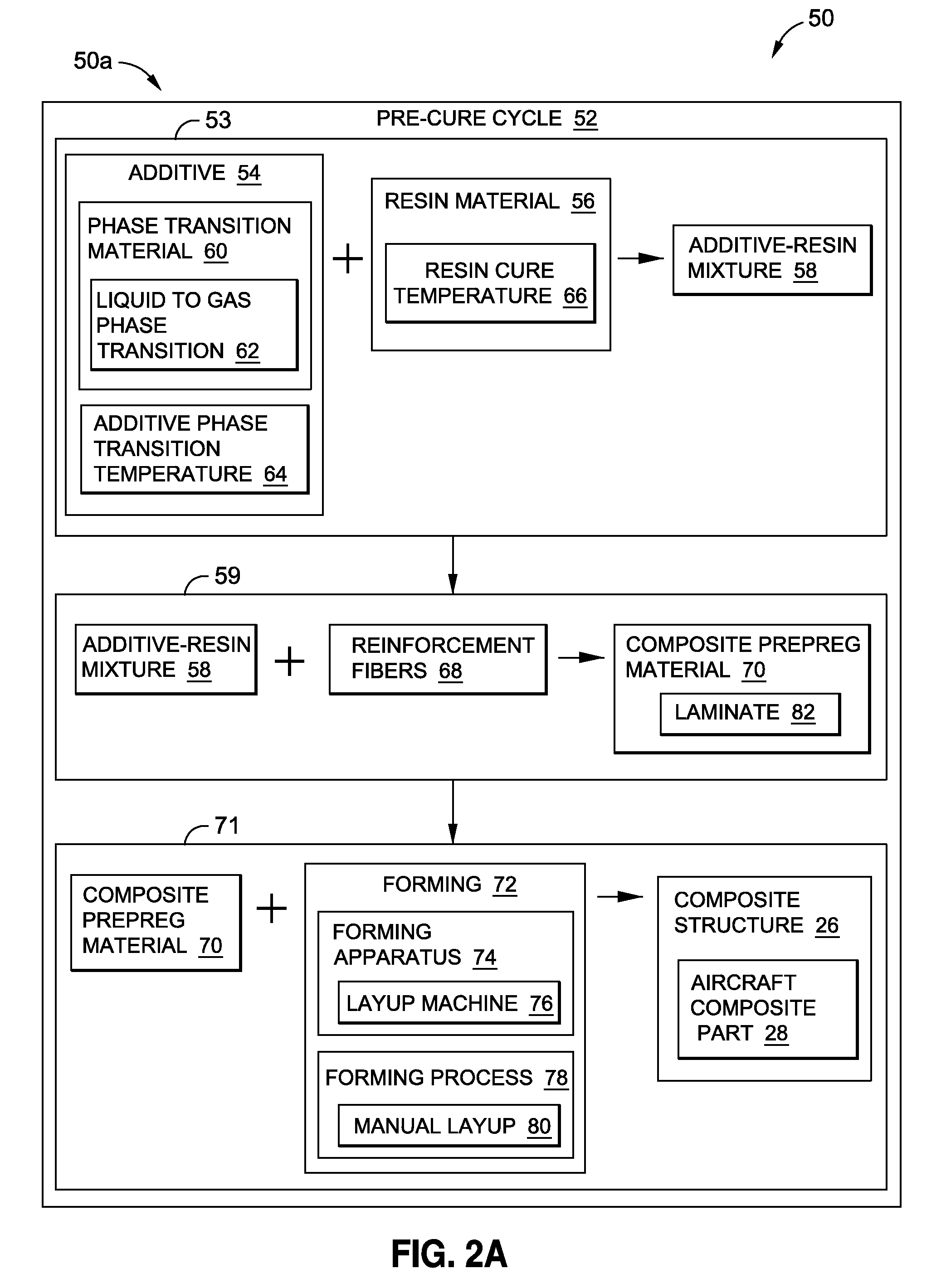

Method and system to reduce porosity in composite structures

InactiveUS8647548B1Reduce porosityMeet actual needsLaminationEfficient propulsion technologiesPorosityFiber

In an embodiment of the disclosure, there is provided a method to reduce porosity in a composite structure. The method adds an additive to a resin material to form an additive-resin mixture. The method combines the additive-resin mixture with reinforcement fibers to form a composite prepreg material, and in turn, a composite structure. The method heat cures the composite structure in a heating apparatus under a vacuum device at the resin cure temperature, heats the composite structure to an increased temperature above the additive phase transition temperature, and maintains the increased temperature for a time period sufficient. The method reduces the increased temperature back down to the resin cure temperature to allow the additive gas to undergo a phase transition to a condense phase, resulting in a substantially reduced vacuum pressure, resulting in a reduction in a porosity of the composite structure.

Owner:THE BOEING CO

Bulk resin infusion system apparatus and method

ActiveUS7633040B2Convenient infusionReduce resin viscosityWood working apparatusFlat articlesComposite material

A composite item is fabricated in system that includes a layer of preform, supply of resin, mandrel, and bagging film. The layer of preform corresponds to the composite item. The supply of resin is sufficient to infuse the preform. The mandrel includes a preform receiving zone to receive the layer of preform and a resin receiving zone to receive the supply of resin. The resin receiving zone is adjacent to the preform receiving zone. The bagging film is operable to generate an envelope surrounding the preform receiving zone and the resin receiving zone.

Owner:THE BOEING CO

Resin composition for coating and coating composition for curing

InactiveUS20020040094A1High hardnessGood flexibilityPolyurea/polyurethane coatingsPolyether coatingsPolyolHardness

The present inventors provides polyol-containing resin compositions for coatings which can give cured coating films having high hardness and at the same time high solid compositions to meet the recent resources saving and / or environmental protection requirements, and curable coating compositions having high reactivity at curing, giving the coating film with good appearance and the coatings with prolonged pot life. The invention is directed to a resin composition for coatings comprising a polyol (A1) or (A2), a polyether polyol (B) and a solvent (C), wherein the polyol (A1) comprises a hydroxyl-containing polymerizable unsaturated monomer and a ring structure-containing polymerizable unsaturated monomer as essential components and the polyol (A2) comprises a hydroxyl-containing a polymerizable unsaturated monomer and a linear branched structure-containing polymerizable unsaturated monomer as essential components.

Owner:NIPPON SHOKUBAI CO LTD

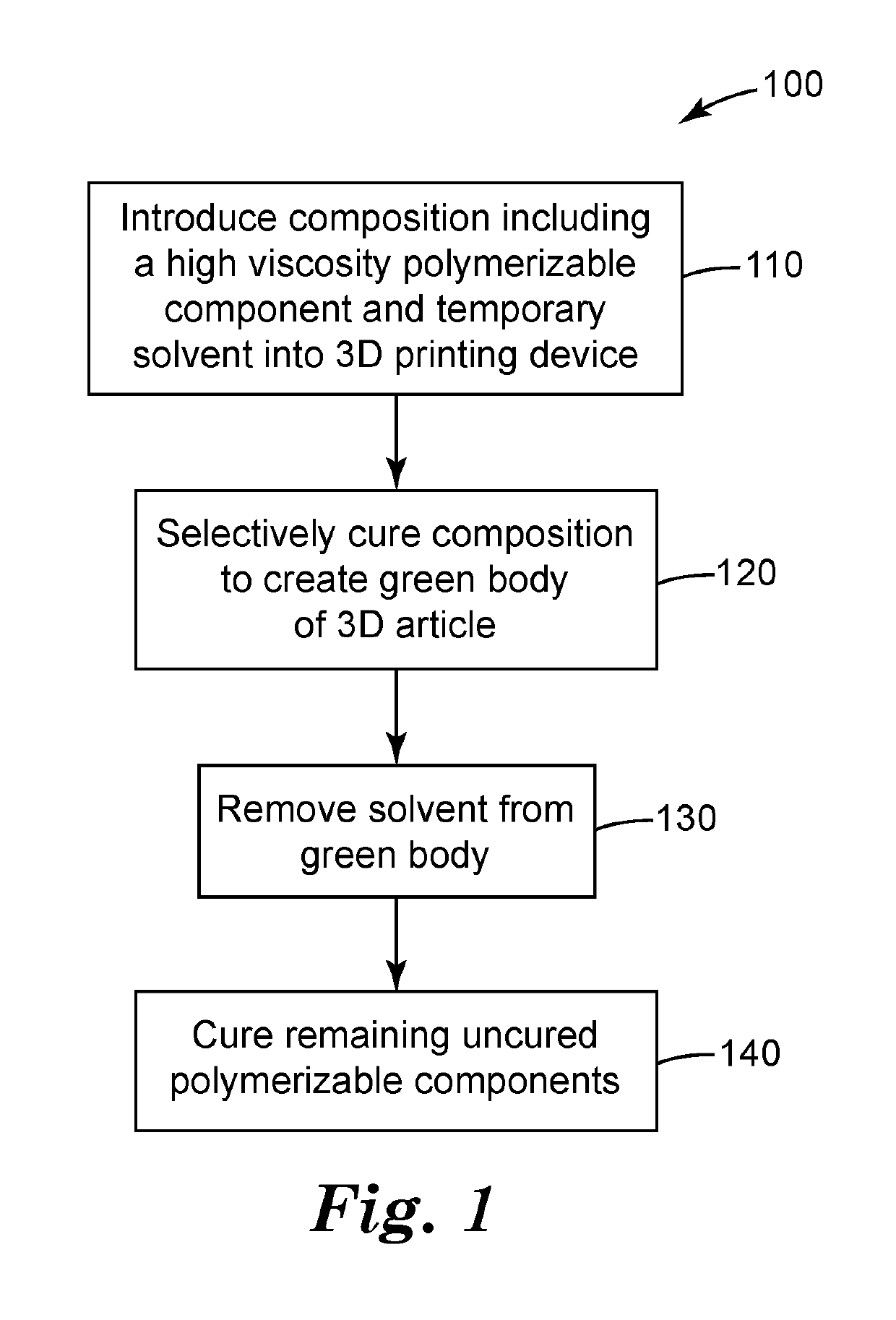

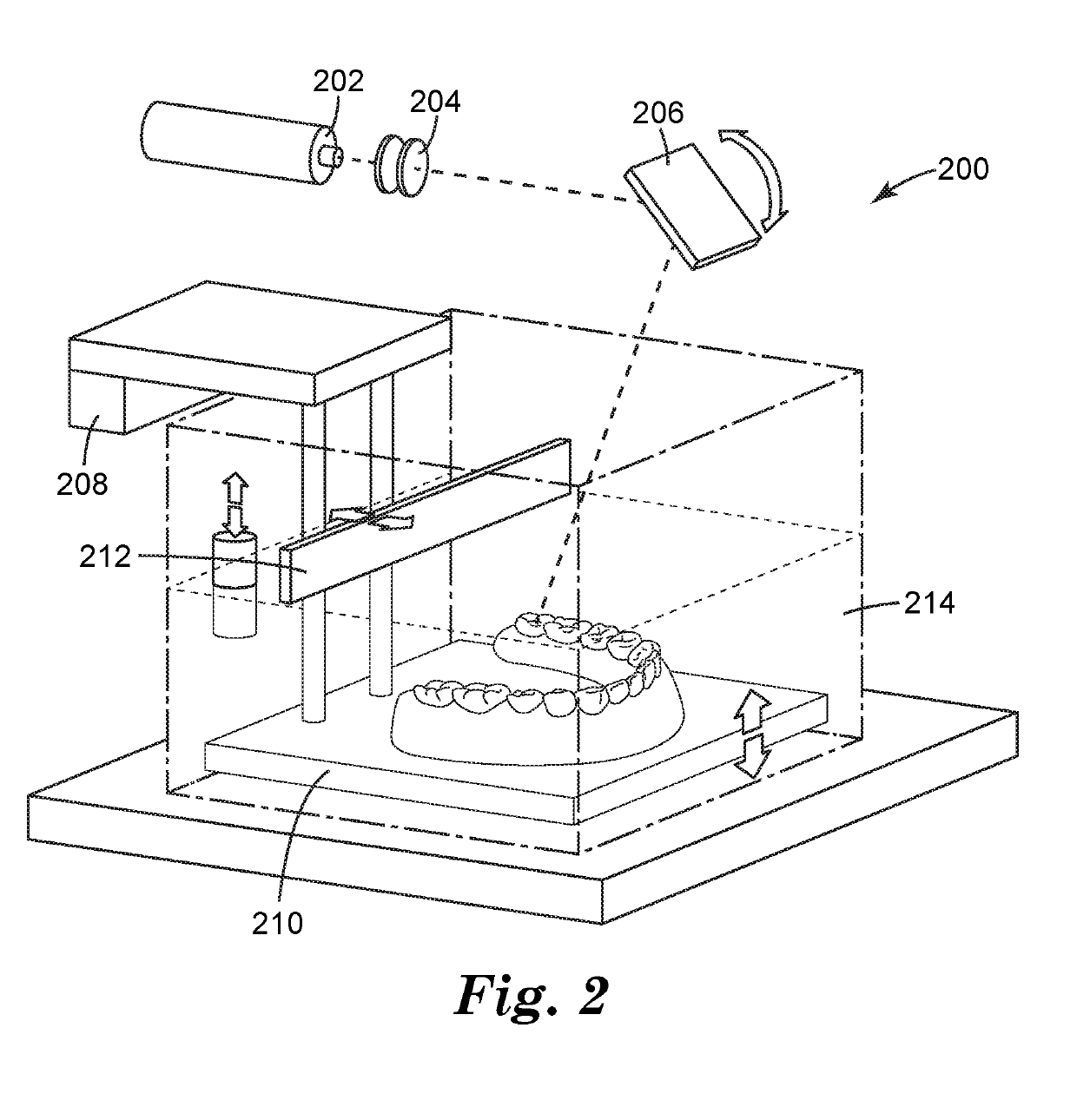

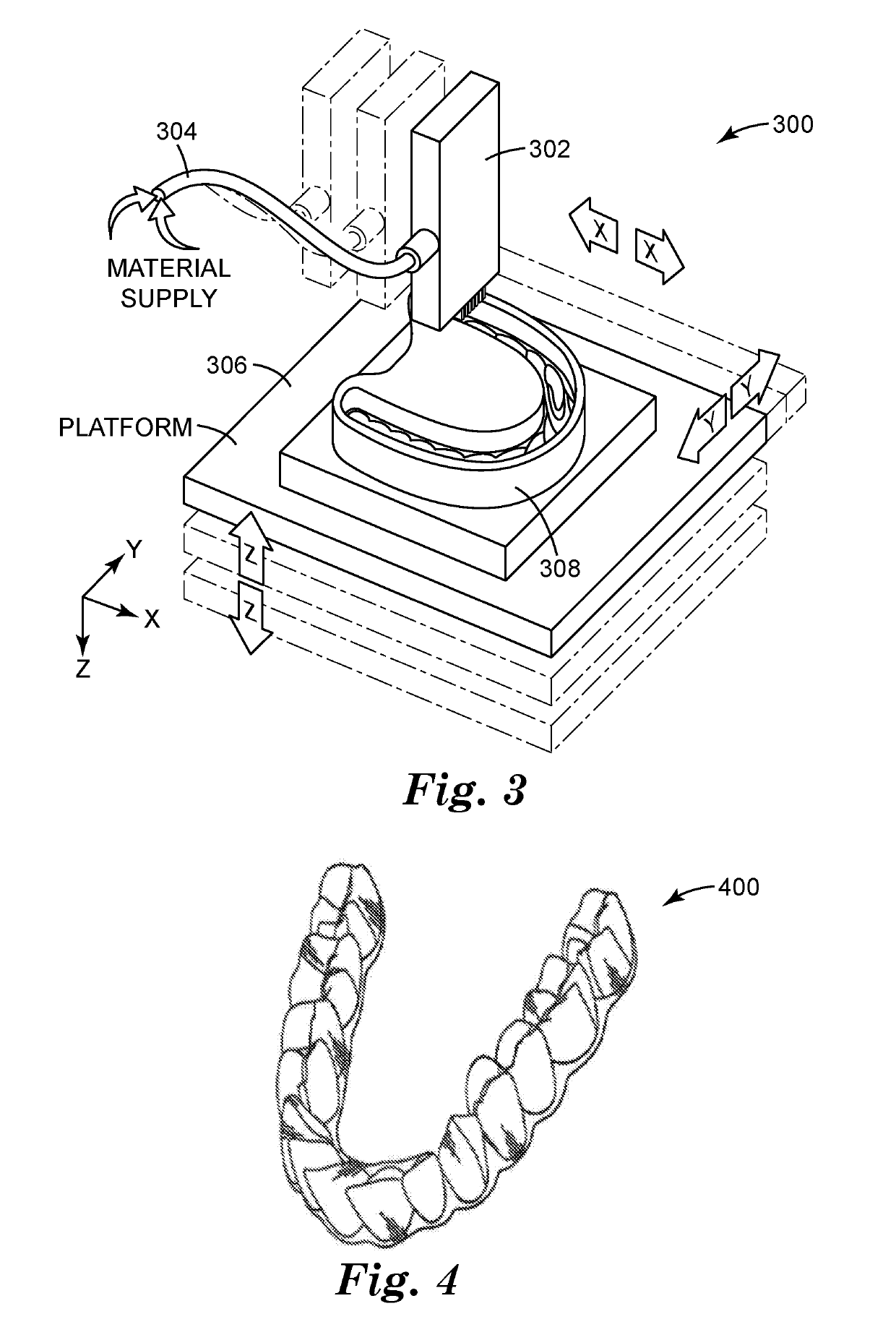

Printable compositions including highly viscous components and methods of creating 3D articles therefrom

ActiveUS20190163060A1Low viscosityProper curing rateAdditive manufacturing apparatusAdditive manufacturing with liquidsMethacrylatePolymer science

The present disclosure provides a method for building a three-dimensional object using a printable composition including high viscosity polymerizable components. The method includes the steps of a) providing a printable composition comprising a high viscosity polymerizable component and a temporary solvent; b) selectively curing the printable composition to form an article representing the shape of the three-dimensional object; and c) removing a substantial amount of the temporary solvent from the article. The method is particularly well suited to making an orthodontic clear tray aligner. Also disclosed are a variety of printable compositions including high viscosity polymerizable components, such as polyurethane methacrylates, and temporary solvents.

Owner:3M INNOVATIVE PROPERTIES CO

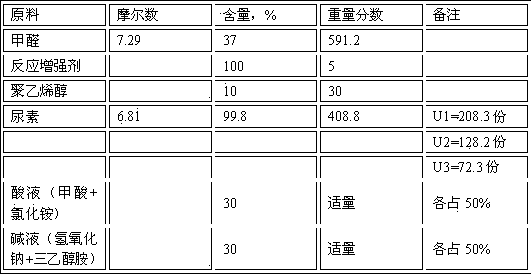

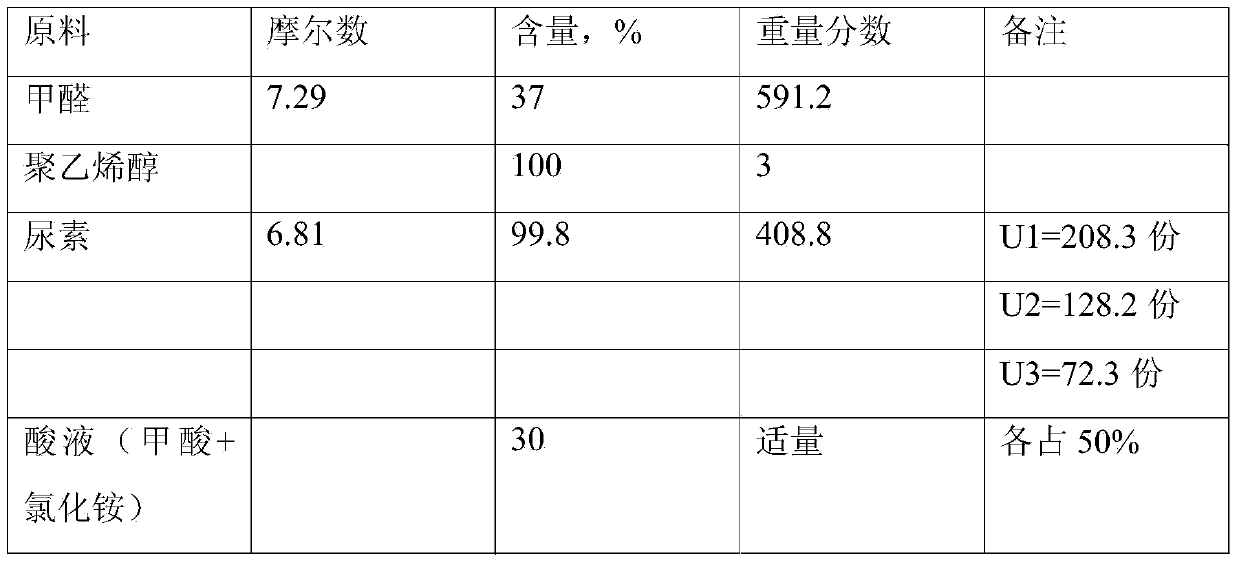

Grafted nano ambary fiber crystal whisker modified urea formaldehyde resin adhesive and preparation method thereof

ActiveCN104194695AReduce resin viscosityLong storage periodAldehyde/ketone condensation polymer adhesivesMacromolecular adhesive additivesHemp fiberPolymer chemistry

The invention discloses a grafted nano ambary fiber crystal whisker modified urea formaldehyde resin adhesive and a preparation method thereof. The grafted nano ambary fiber crystal whisker modified urea formaldehyde resin adhesive is prepared from formaldehyde, urea, polyvinyl alcohol and a reaction enhancer, wherein the mole ratio of the formaldehyde to the urea is (1.1-0.95):1, and the addition amount of the polyvinyl alcohol is 0.1-0.8% of the total weight. The addition amount of the reaction enhancer is 0.1-3.0% of the total weight. The preparation method comprises the following steps: adding the reaction enhancer, adding the first batch of urea according to a mole ratio of (2.0-2.2):1, adding the second batch of urea according to the mole ratio of (1.4-1.2):1, and finally, adding the third batch of urea according to the mole ratio of (0.95-1.1):1. By using the formaldehyde and urea in a low mole ratio as the raw materials, the self-made acrylic acid grafted nano ambary fiber crystal whisker is added to increase the molecule branching degree and molecular weight of the resin, so that the low-mole-ratio urea formaldehyde resin has the advantages of low formaldehyde content, high adhesion strength and low cost.

Owner:BEIJING FORESTRY UNIVERSITY

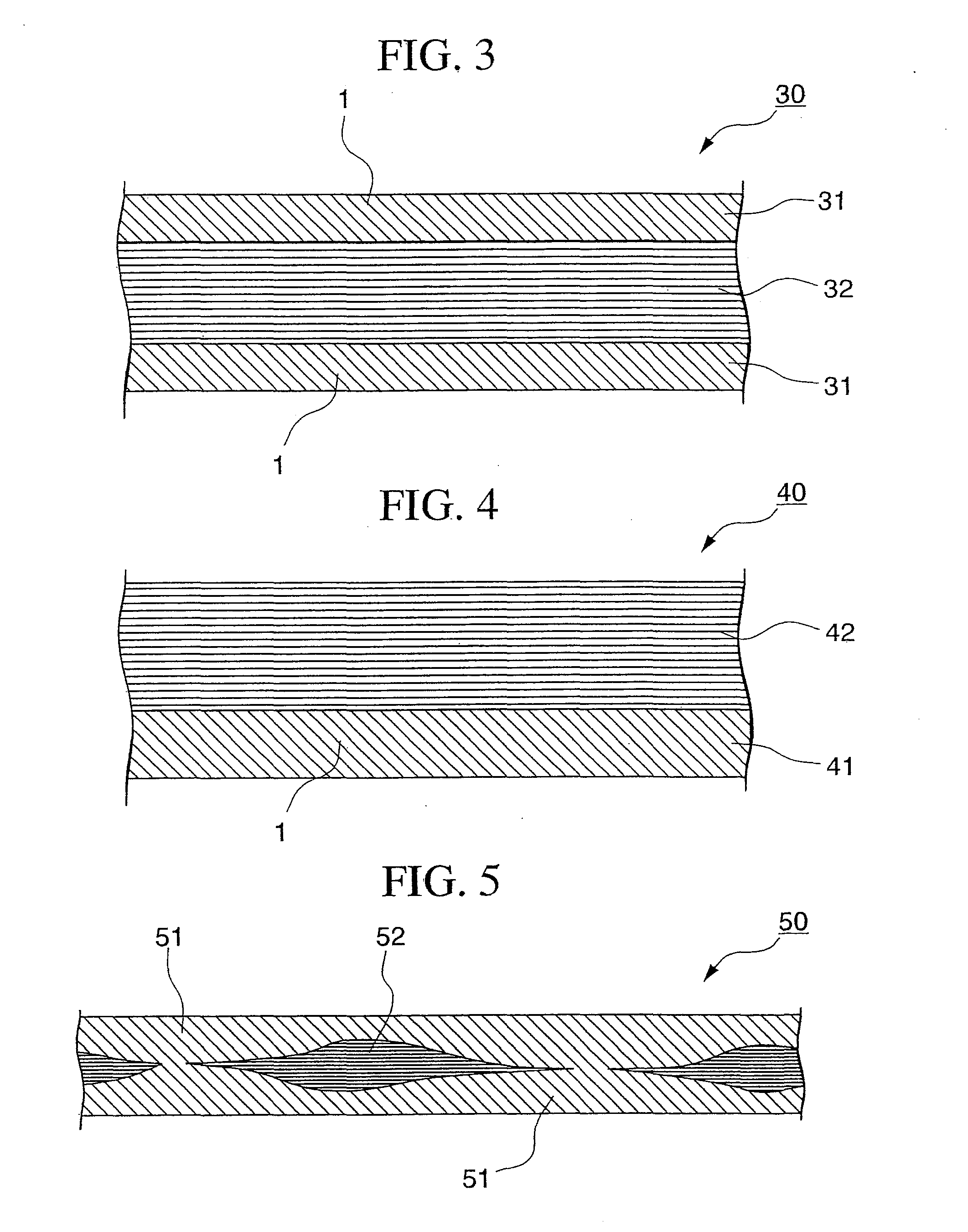

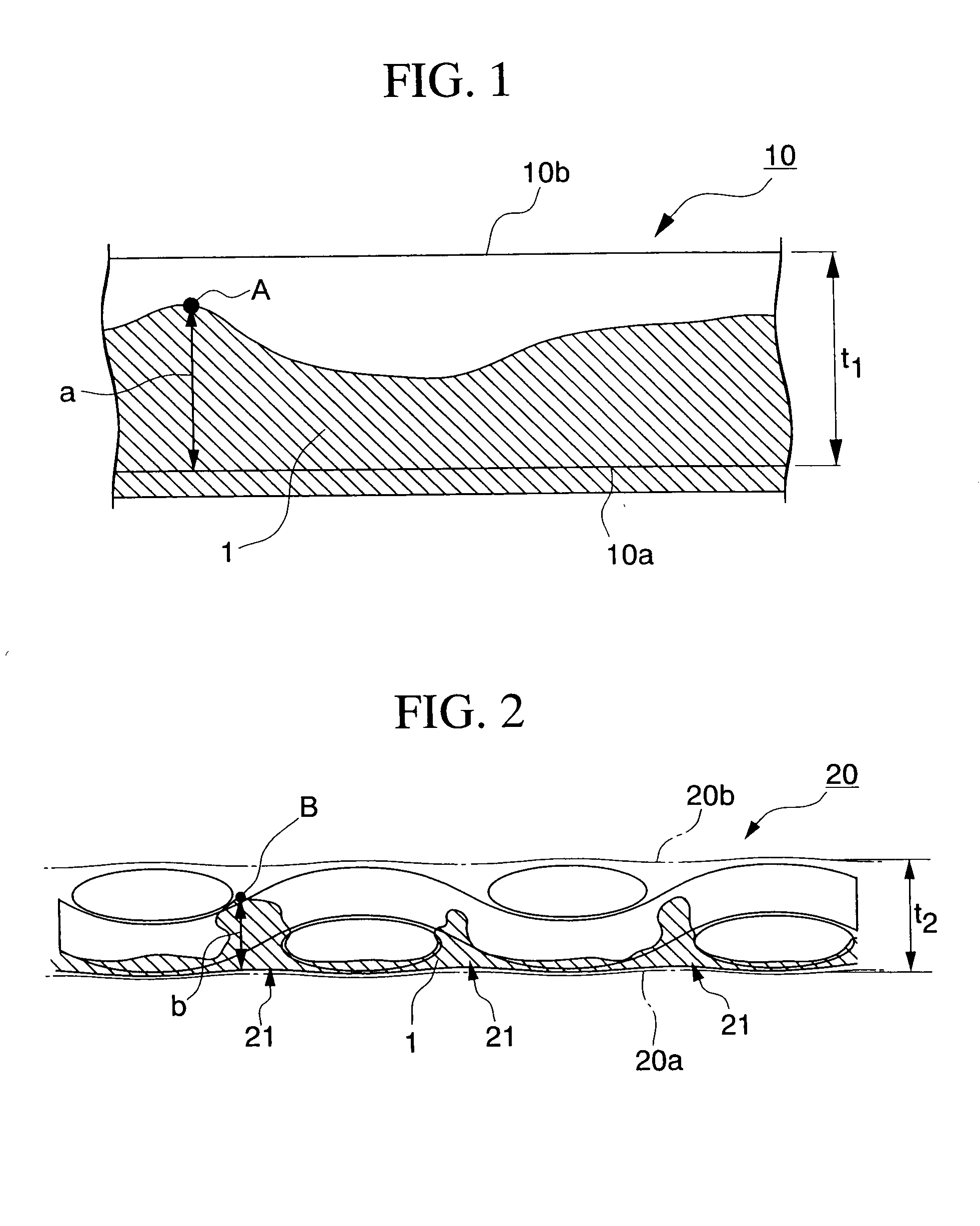

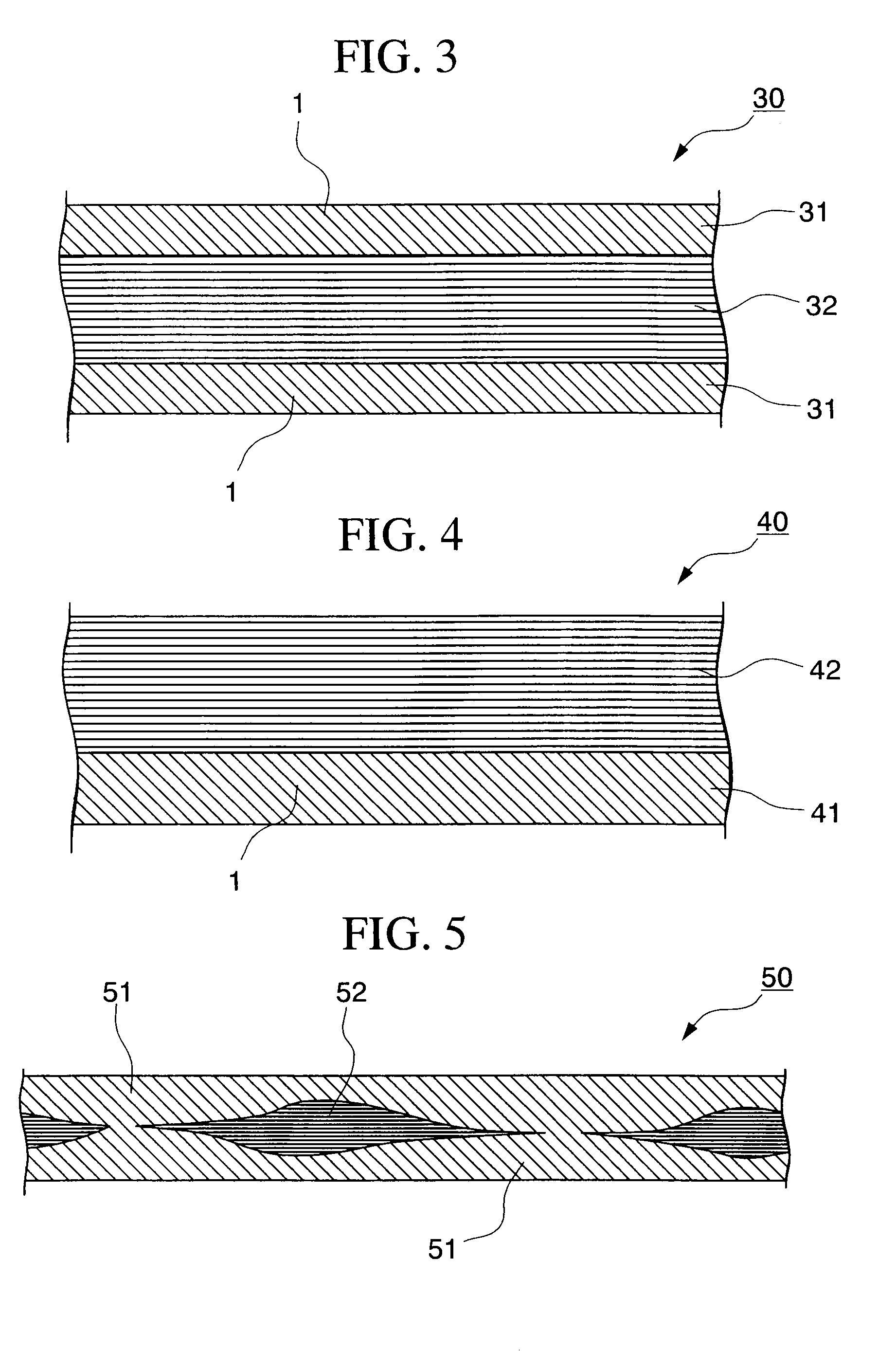

Prepreg, intermediate material for forming frp, and method for production thereof and method for production of fiber-reinforced composite material

InactiveUS20110151206A1Easy to peelReduce resin viscosityFibre treatmentSynthetic resin layered productsVacuum pressureCoverage ratio

An FRP is produced using a prepreg comprising reinforcing fiber, a sheet-like reinforcing fiber substrate containing reinforcing fiber, and a matrix resin, wherein the matrix resin is impregnated into the sheet-like reinforcing fiber substrate and also covers one surface of the sheet-like reinforcing fiber substrate, and the matrix resin impregnation ratio is within a range of 35% to 95%; a prepreg comprising reinforcing fiber, a sheet-like reinforcing fiber substrate containing reinforcing fiber, and a matrix resin, wherein the matrix resin exists on both surfaces of the sheet-like reinforcing fiber substrate, and the portion inside the sheet-like reinforcing fiber substrate into which the matrix resin has not been impregnated is continuous; or a prepreg comprising reinforcing fiber, a sheet-like reinforcing fiber substrate containing reinforcing fiber, and a matrix resin, wherein at least one surface exhibits a sea-and-island-type pattern comprising resin-impregnated portions (island portions) where the matrix resin is present at the surface and fiber portions (sea portions) where the matrix resin is not present at the surface, the surface coverage ratio of the matrix resin on those surfaces with said a sea-and-island-type pattern is within a range of 3% to 80%, and the weave intersection coverage ratio for the island portions, represented by a formula (1) shown below, is at least 40%, displays excellent external appearance, with no internal voids or surface pinholes, even when molded is conducted using only vacuum pressure.Island portions weave intersection coverage ratio (%)=(T / Y)×100 (1)(wherein, T represents a number of island portions that cover weave intersections, and Y represents a number of weave intersections within said reinforcing fiber woven fabric on said surface with said sea-and-island-type pattern).

Owner:MITSUBISHI RAYON CO LTD

Resin-filled ferrite carrier for electrophotographic developer, production method thereof and electrophotographic developer using the ferrite carrier

Employed are a resin-filled ferrite carrier for an electrophotographic developer filled with a resin in voids of a porous ferrite core material, wherein the resin filled in the voids is a silicone resin which has a softening point of 40° C. or above and is cured at or above such softening point, and the filled amount is 7 to 30 parts by weight based on 100 parts by weight of the core material, a method for producing thereof band an electrophotographic developer using this ferrite carrier.

Owner:POWDERTECH

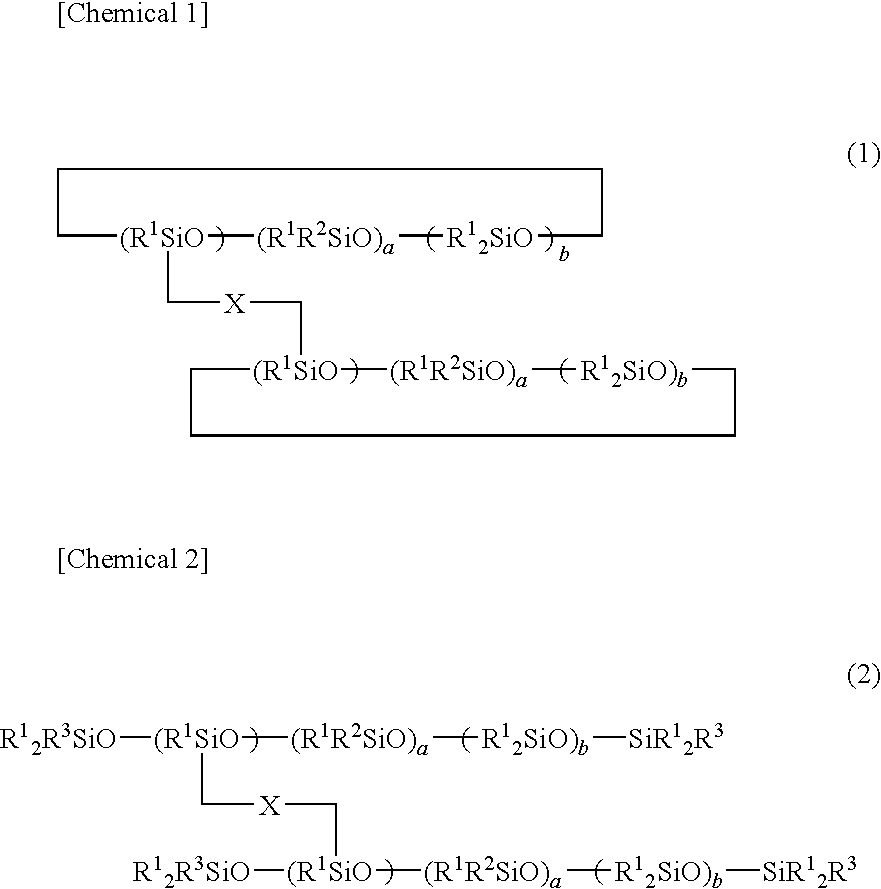

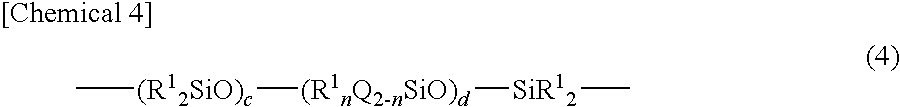

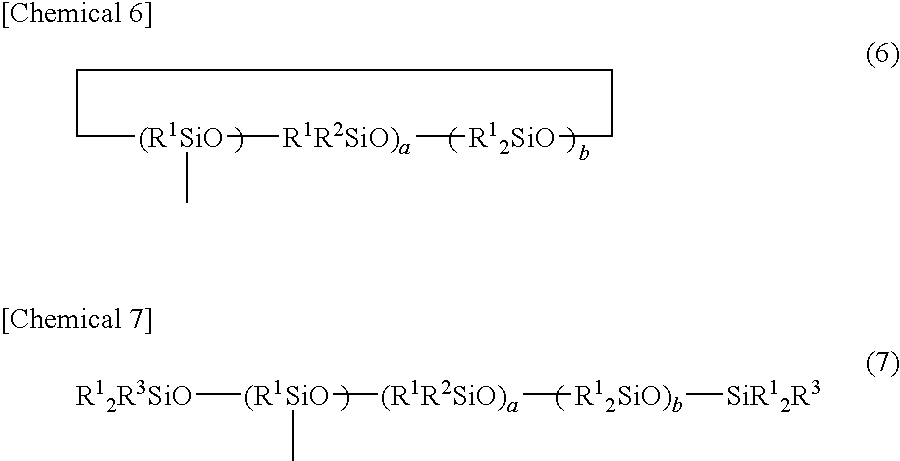

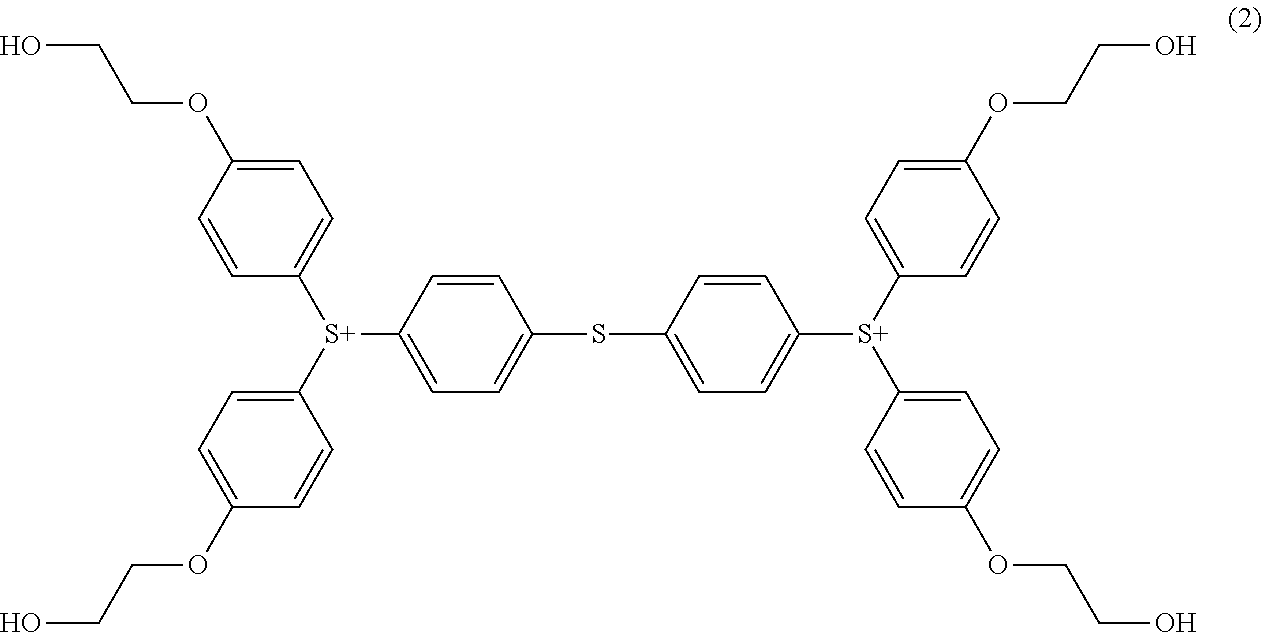

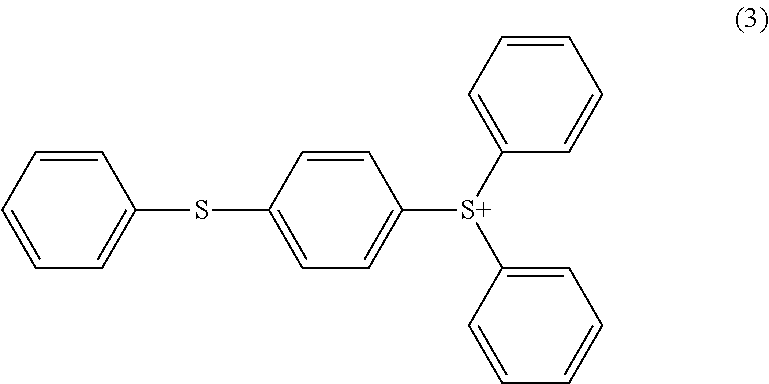

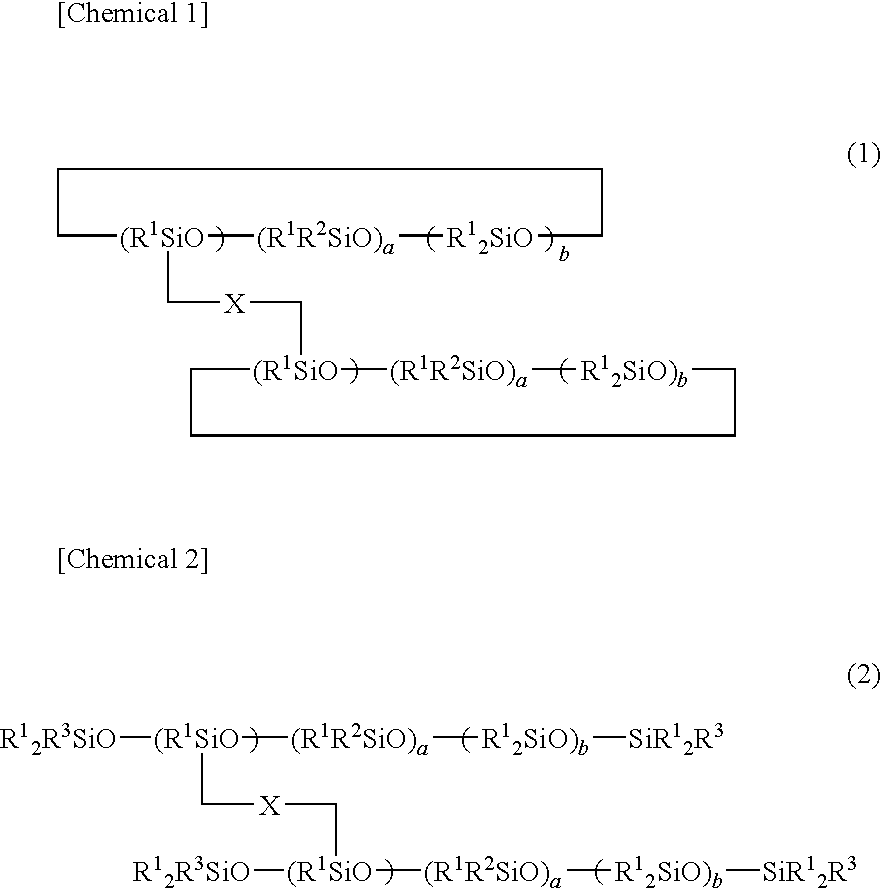

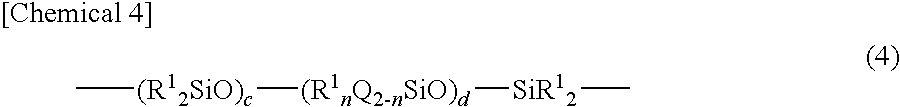

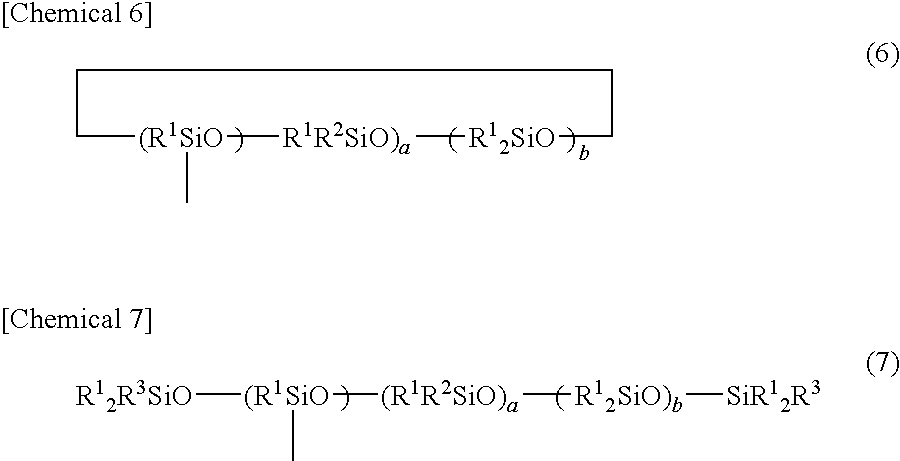

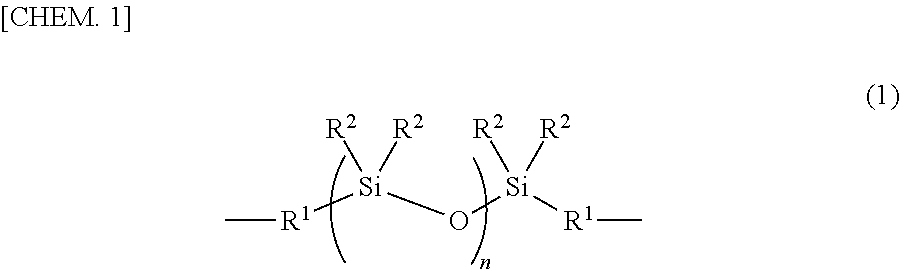

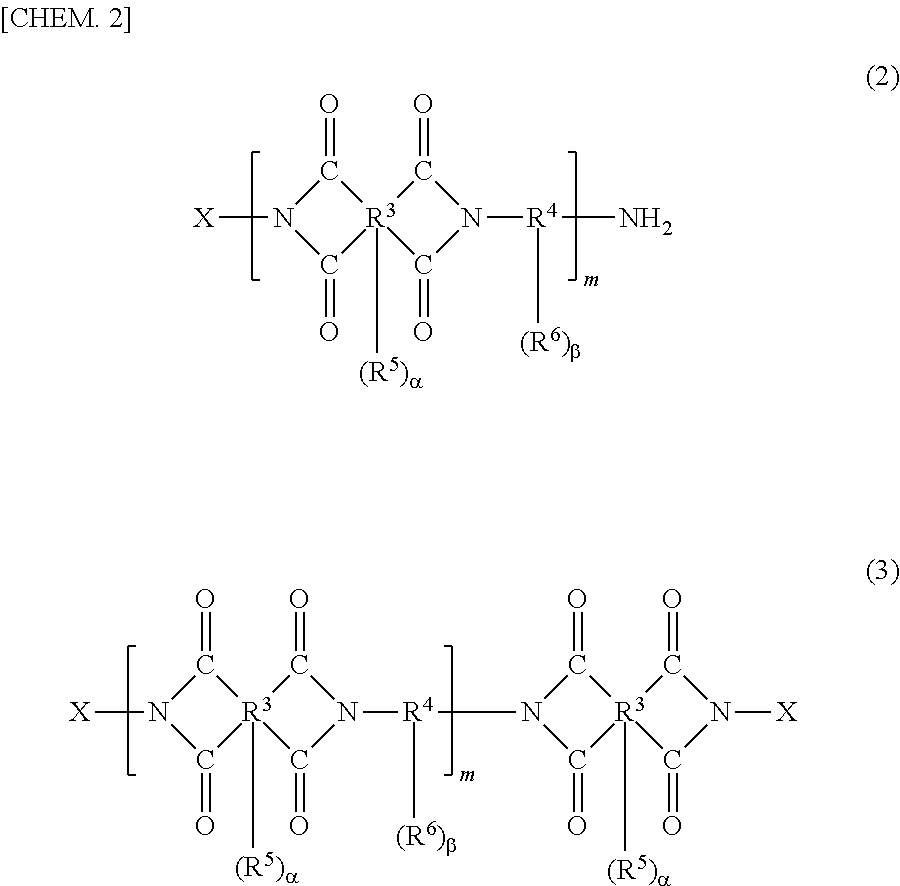

Thermosetting resin composition and semiconductor sealing medium

ActiveUS7932319B2Reduce resin viscosityImprove toughnessSemiconductor/solid-state device detailsSolid-state devicesCarbon numberOrganic group

A thermosetting resin compositing having an essential component (A) organopolysiloxane containing a compound represented by following general formula (1) or (2) and optical semiconductor peripheral material using the composition. [Herein, in the formulas, R1 independently represents a substituted or non-substituted monovalent hydrocarbon radical with the carbon number of 1 to 10, R2 represents an epoxy group-containing organic group, R3 represents R1 or R2, a independently represents an integer of 2 or more, b independently represents an integer of 0 or more, X represents general formula (3), Y represents -o- or a bivalent hydrocarbon radical with the carbon number of 1 to 6, Z represents following formula (4), R1 in the formula independently represents a substituted or non-substituted monovalent hydrocarbon radical with the carbon number of 1 to 10, and c represents an integer of 0 or more.]

Owner:ASAHI KASEI CHEM CORP

Adhesive film and semiconductor package using adhesive film

ActiveUS20170152408A1Improve yieldImprove reliabilityNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsPolymer scienceMeth-

An adhesive film that can solve the problem of pickup defect and improve the yield rate of semiconductor packages. The adhesive film includes: (A) a bismaleimide resin; (B) a radical initiator; and (C) a coupling agent that contains a (meth)acrylic group. Further, an adhesive film with dicing tape, which includes such an adhesive film laminated onto a dicing tape, is provided. Furthermore, a semiconductor package that includes such an adhesive film with dicing tape is provided.

Owner:FURUKAWA ELECTRIC CO LTD

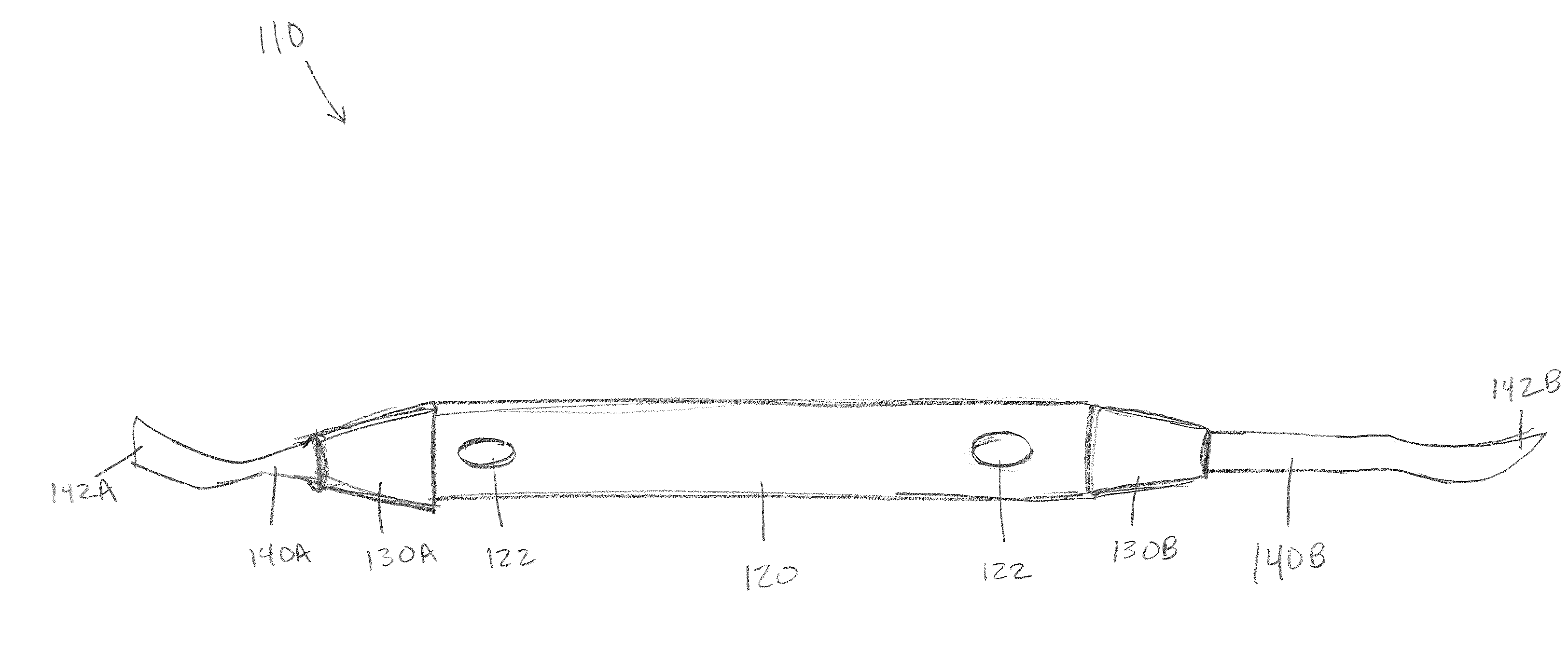

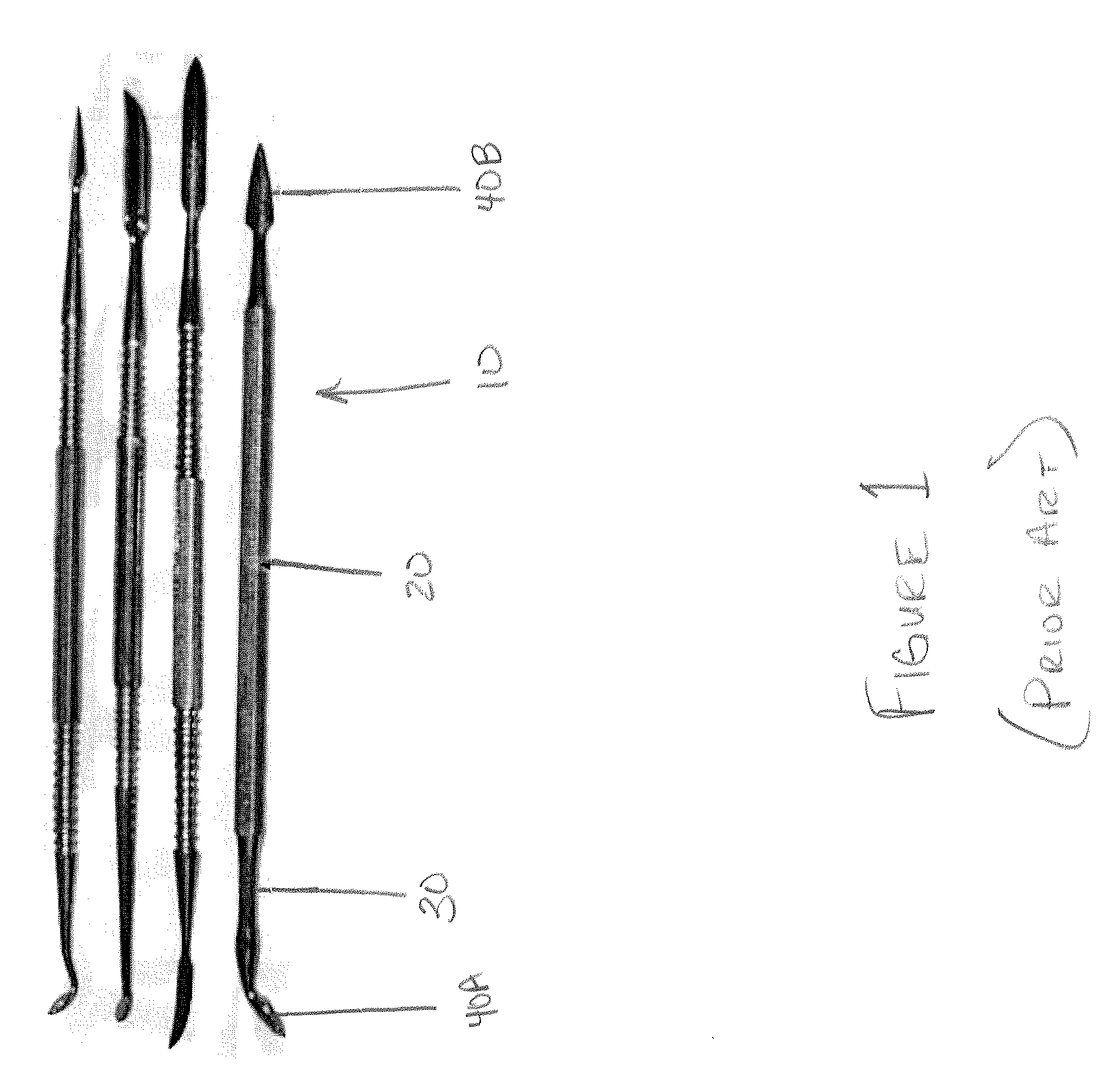

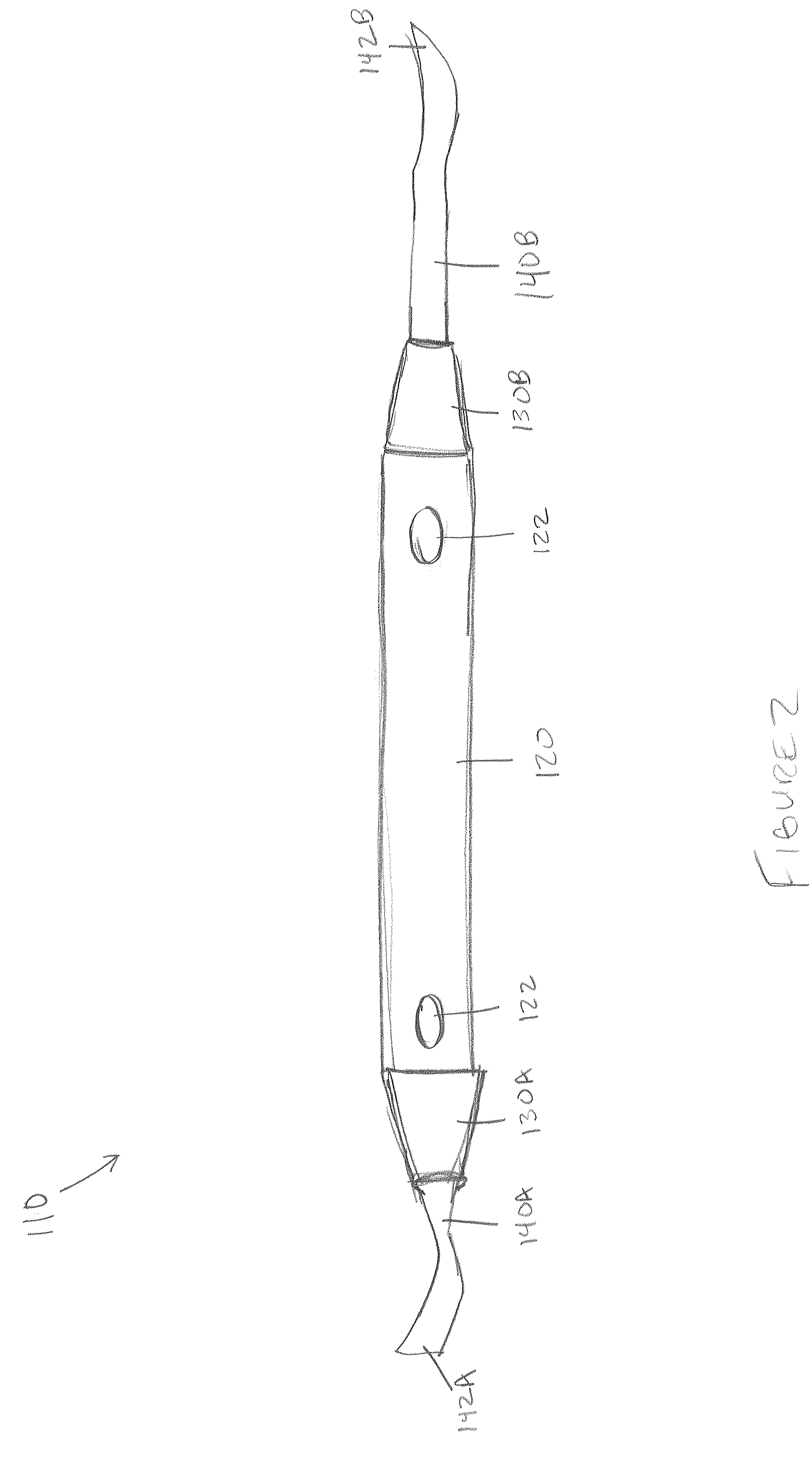

Heated dental placement and carving instrument

InactiveUS20070212660A1Lower viscosityViscosity of resin be lowerDental toolsBoring toolsDental instrumentsDental composite resin

A dental instrument for working with composite resin includes an elongate handle and at least one tool attached at an end of the elongate handle. The tool is heated and / or vibrationally driven, and used to engage and work dental composite resin.

Owner:MEDICAL COLLEGE OF GEORGIA RES INST

Photo-curable resin composition for optical component, optical component produced by employing the resin composition, and optical component production method

InactiveUS20160083505A1High transparencyReduce resin viscosityOptical articlesOptical elementsEpoxyPolymer science

A photo-curable resin composition for an optical component is provided, the photo-curable resin composition including: (A) an epoxy resin having a refractive index of not less than 1.57; (B) an alicyclic epoxy resin; (C) an oxetane resin having at least one oxetane ring in its molecule; and (D) a photoacid generator; wherein the resin (A) is present in a proportion of 20 to 75 wt % based on the amount of an overall resin component of the resin composition; wherein the component (D) is present in a proportion of 0.5 to 2.5 parts by weight based on 100 parts by weight of the overall resin component; the resin composition being free from a solvent component and having a viscosity of 0.5 to 25 Pa·s in a 25° C. environment.

Owner:NITTO DENKO CORP

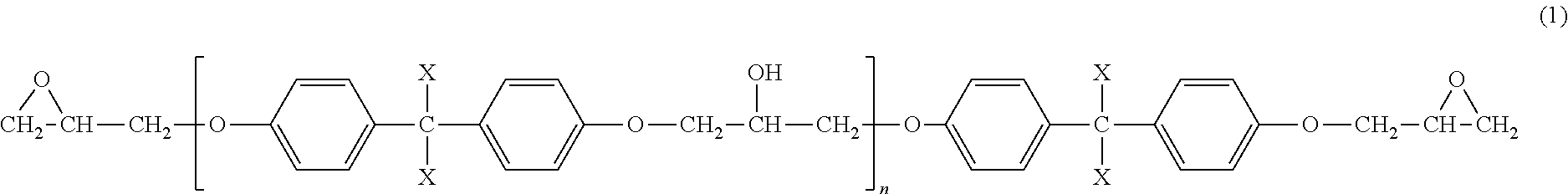

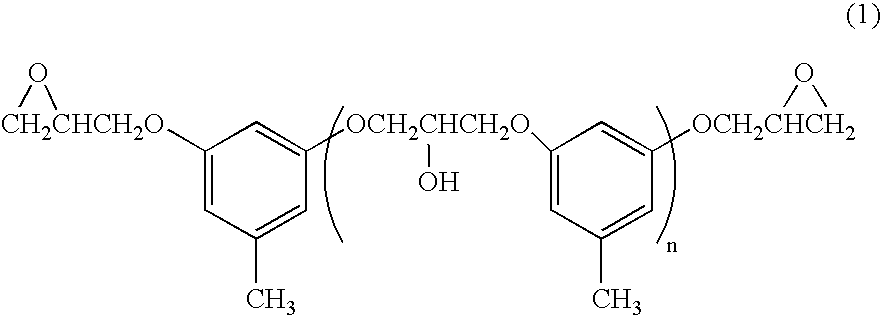

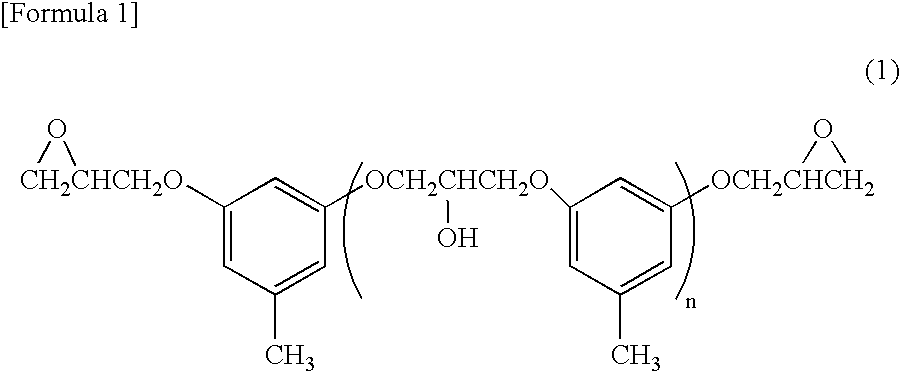

Liquid crystal sealant, liquid crystal display device using the same and method for producing the device

InactiveUS20050181145A1Low viscosityIncrease stickinessLiquid crystal compositionsLamination ancillary operationsCrystallographyEpoxy

A liquid crystal sealant comprising an epoxy resin represented by the following formula (1): [Formula 1](in the formula, n denotes an average polymerization degree and is a positive number of 0-5) as a resin component, a curing agent, a curing accelerator and an inorganic filler is excellent in screen printability as a liquid crystal sealant in making a liquid crystal display device and can provide excellent reliability in moisture resistance for the liquid crystal display device obtained).

Owner:NIPPON KAYAKU CO LTD +1

Prepreg, intermediate material for forming frp, and method for production thereof and method for production of fiber-reinforced composite material

InactiveUS20090123717A1Easy to peelReduce resin viscosityFibre treatmentSynthetic resin layered productsFiber-reinforced compositeWoven fabric

An FRP is produced using a prepreg comprising reinforcing fiber, a sheet-like reinforcing fiber substrate containing reinforcing fiber, and a matrix resin, wherein the matrix resin is impregnated into the sheet-like reinforcing fiber substrate and also covers one surface of the sheet-like reinforcing fiber substrate, and the matrix resin impregnation ratio is within a range of 35% to 95%; a prepreg comprising reinforcing fiber, a sheet-like reinforcing fiber substrate containing reinforcing fiber, and a matrix resin, wherein the matrix resin exists on both surfaces of the sheet-like reinforcing fiber substrate, and the portion inside the sheet-like reinforcing fiber substrate into which the matrix resin has not been impregnated is continuous; or a prepreg comprising reinforcing fiber, a sheet-like reinforcing fiber substrate containing reinforcing fiber, and a matrix resin, wherein at least one surface exhibits a sea-and-island-type pattern comprising resin-impregnated portions (island portions) where the matrix resin is present at the surface and fiber portions (sea portions) where the matrix resin is not present at the surface, the surface coverage ratio of the matrix resin on those surfaces with said a sea-and-island-type pattern is within a range of 3% to 80%, and the weave intersection coverage ratio for the island portions, represented by a formula (1) shown below, is at least 40%, displays excellent external appearance, with no internal voids or surface pinholes, even when molded is conducted using only vacuum pressure.Island portions weave intersection coverage ratio (%)=(T / Y)×100 (1)(wherein, T represents a number of island portions that cover weave intersections, and Y represents a number of weave intersections within said reinforcing fiber woven fabric on said surface with said sea-and-island-type pattern).

Owner:MITSUBISHI RAYON CO LTD

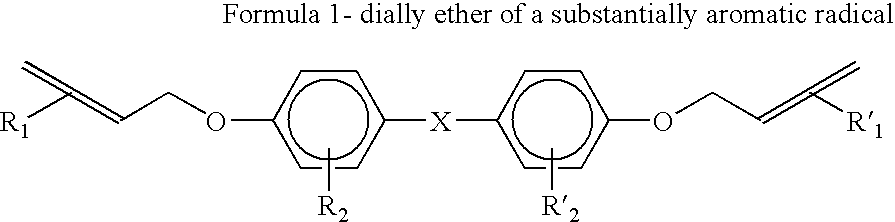

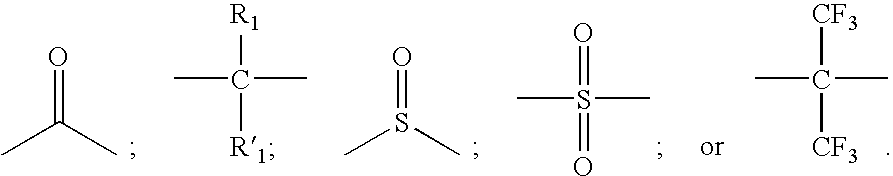

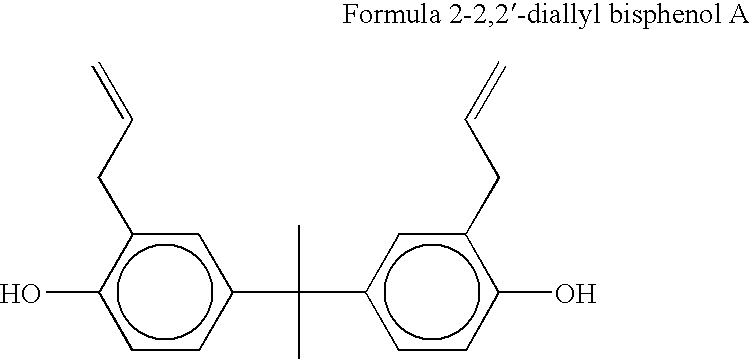

Bismaleimide resin system with improved manufacturing properties

The present invention is a thermosetting bismaleimide resin system comprising a liquid phase and a solid phase where the non-crystallizing liquid phase contains the curing agents diallyl ether of a substantially aromatic radical and a bis(alkenylphenoxy) ether of a substantially aromatic radical along with a substantially aromatic bismaleimide as a particle slurry and optionally a free radical inhibitor.The curing agents are non-crystallizing compositions for use in bismaleimide resin formulations to increase the thermal durability of a cured resin composite as shown by reduced microcracking as measured by reduced weight loss after thermal aging. The present invention resists microcracking over bismaleimide resin systems which incorporate other curing agents or combinations of curing agents.The present invention further provides a bismaleimide resin formulation suitable to make prepregs with reduced crystallization for reduced viscosity supporting improved manufacturing properties and improved tack.

Owner:CYTEC TECH CORP

Thermosetting Resin Composition and Semiconductor Sealing Medium

ActiveUS20090258992A1Low resin viscosityHigh toughnessSemiconductor/solid-state device detailsSolid-state devicesComposite materialResin composite

A thermosetting resin compositing having an essential component (A) organopolysiloxane containing a compound represented by following general formula (1) or (2) and optical semiconductor peripheral material using the composition. [Herein, in the formulas, R1 independently represents a substituted or non-substituted monovalent hydrocarbon radical with the carbon number of 1 to 10, R2 represents an epoxy group-containing organic group, R3 represents R1 or R2, a independently represents an integer of 2 or more, b independently represents an integer of 0 or more, X represents general formula (3) , Y represents a bivalent hydrocarbon radical with the carbon number of 1 to 6, Z represents following formula (4), R1 in the formula independently represents a substituted or non-substituted monovalent hydrocarbon radical with the carbon number of 1 to 10, and c represents an integer of 0 or more.]

Owner:ASAHI KASEI CHEM CORP

Method for manufacturing printed wiring board

ActiveUS20060115582A1Easy to disassembleNot to damagePretreated surfacesSurface layering apparatusEngineering

A method for manufacturing a printed wiring board, including the steps of: forming a thermosetting resin layer so as to fill the spaces between circuit patterns formed on the printed wiring board; heating and curing the resin layer in a reduced pressure chamber in which the pressure is reduced while a smoothing plate is pressed against the resin layer; and then polishing the cured resin layer covering the circuit patterns, thereby exposing the circuit patterns. The step of heating and curing the resin layer in the reduced pressure chamber comprises the following successively performed steps: step 1: maintaining the resin layer at a non-curable temperature to prevent the resin layer from curing, in a state where the resin layer is pressed via the smoothing plate in the reduced pressure chamber; step 2: heating the resin layer in the pressed state to a curing temperature at which the resin layer is cured; step 3: introducing outside air into the reduced pressure chamber with the pressed state and the curing temperature maintained; step 4: reducing the pressure applied to the smoothing plate with the curing temperature maintained; and step 5: cooling the resin layer.

Owner:NODA SCREEN

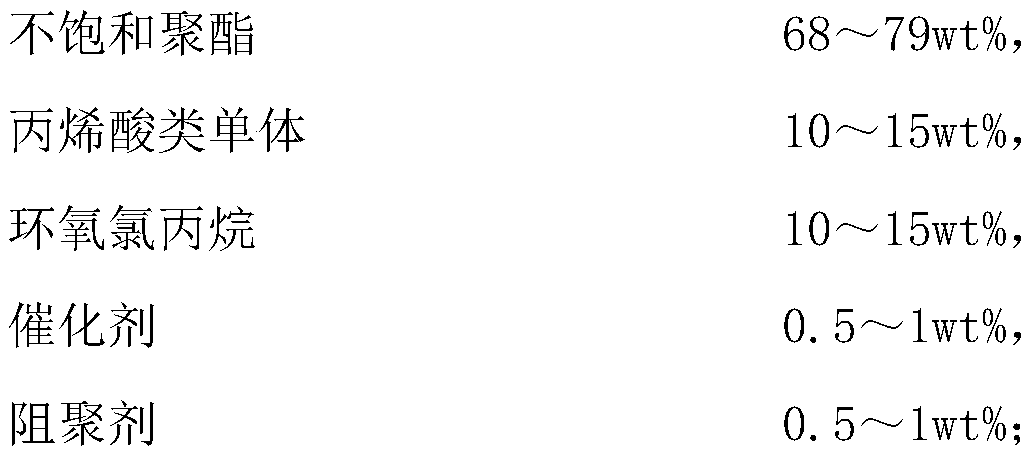

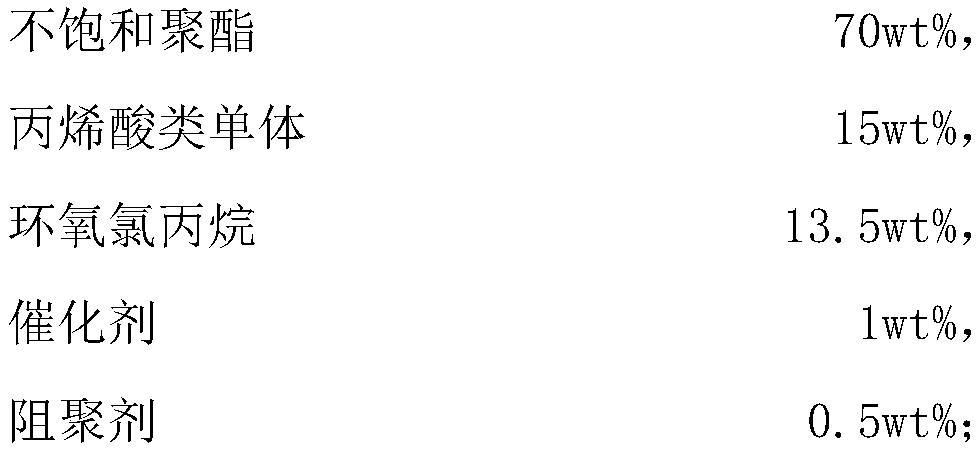

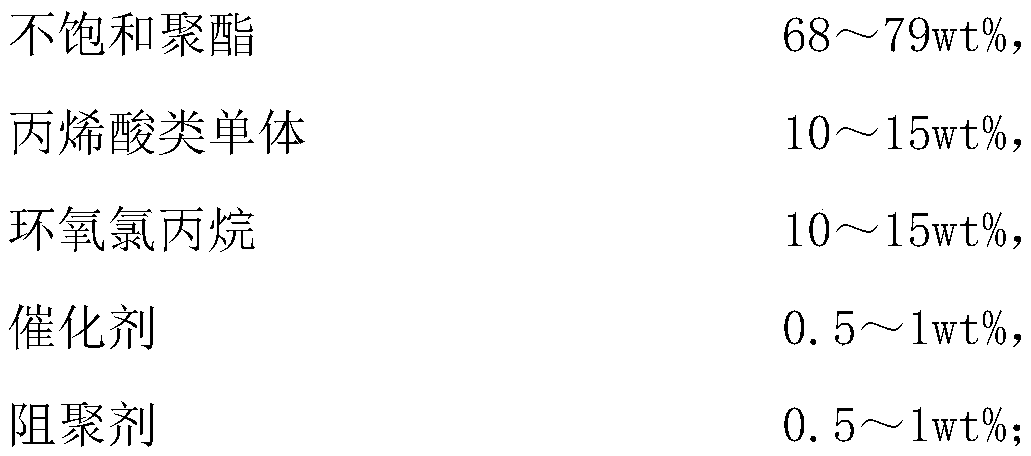

Low-viscosity fast curing UV polyester acrylate and preparation technology thereof

ActiveCN110105851AReduce resin viscosityFast curingPolyester coatingsPhosphinic AcidsMaleic anhydride

The invention relates to the technical field of fine chemical preparation, and discloses a low-viscosity fast curing UV polyester acrylate and a preparation technology thereof. The low-viscosity fastcuring UV polyester acrylate is prepared from 68-79 wt% of unsaturated polyester, 10-15 wt% of an acrylic monomer, 10-15 wt% of epichlorohydrin, 0.5-1 wt% of a catalyst and 0.5-1 wt% of a polymerization inhibitor; and the unsaturated polyester comprises, by weight, 20 parts of maleic anhydride, 10.1 parts of phthalic anhydride, 5.8 parts of deionized water, 0.1 part of hypophosphorous acid, 30 parts of dicyclopentadiene, 20 parts of diethylene glycol, 14.4 parts of pentaerythritol, 8 parts of fumaric acid and 1.5 parts of toluene. The UV polyester acrylate of the invention has the advantagesof low viscosity, fastness in curing, high reaction activity, good economical property, and facilitation of large-scale preparation and promotion of UV paints; and the preparation technology is simple, and is convenient to operate.

Owner:YINGDE YAJIA PAINT

Resin composition, resin composition sheet, semiconductor device and production method therefor

InactiveUS20140291870A1Reduce melt viscosityImprove connection reliabilityOther chemical processesSemiconductor/solid-state device detailsPolymer scienceInorganic particle

A resin composition excellent in both characteristics of preservation stability and connection reliability is provided by a resin composition that contains (a) an epoxy compound, (b) a microcapsule type hardening acceleration agent, and (c) an inorganic particle whose surface is modified with a compound that has an unsaturated double bond.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com