Grafted nano ambary fiber crystal whisker modified urea formaldehyde resin adhesive and preparation method thereof

A technology of kenaf fiber and urea-formaldehyde resin, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of poor water resistance, reduced bonding strength, increased product cost, etc., to reduce The amount of formaldehyde released, the effect of increasing the content of the crystalline region, and reducing the viscosity of the resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

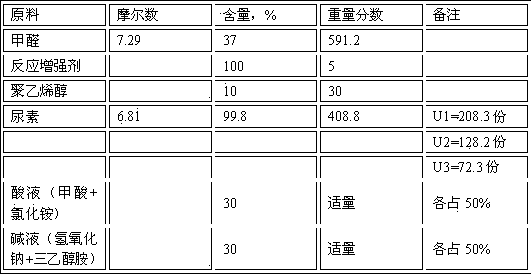

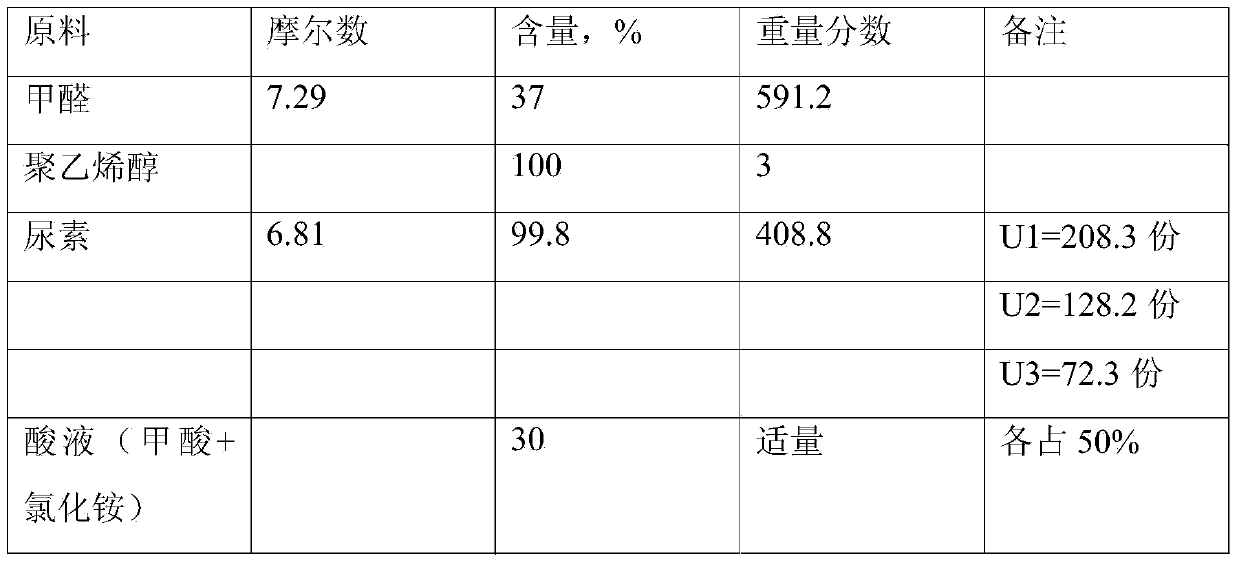

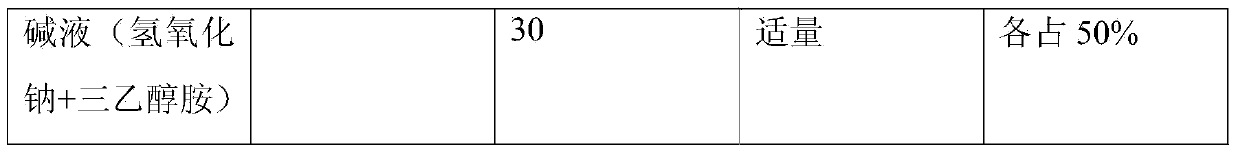

[0026] A grafted nano kenaf fiber whisker modified urea-formaldehyde resin adhesive, prepared from formaldehyde, urea, polyvinyl alcohol and a reaction enhancer, wherein the molar ratio of formaldehyde to urea is 1.07: 1, each raw material See Table 1 below:

[0027] Table 1 The molar ratio of formaldehyde to urea is 1.07︰1 Raw material ratio of urea-formaldehyde resin

[0028]

[0029] Wherein, the reaction enhancer (i.e. cross-linking enhancer) is acrylic acid grafted nano kenaf fiber whiskers;

[0030] The solid content of the reaction enhancer is 100%.

[0031] A kind of preparation method of above-mentioned grafted nanometer kenaf fiber whisker modified urea-formaldehyde resin adhesive, comprises the following steps:

[0032] 1) Put 591.2 parts by weight of 37% industrial formaldehyde into the reaction kettle, adjust the pH value to 7.0 with lye, add 5 parts by weight of reaction enhancer, heat up to 50°C, add 30 parts by weight of polyvinyl alcohol solution, and kee...

Embodiment 2

[0051] A grafted nano kenaf fiber whisker modified urea-formaldehyde resin adhesive is prepared from formaldehyde, urea, polyvinyl alcohol and a reaction enhancer, wherein the mol ratio of the formaldehyde to urea is 1:0.98, each raw material See Table 3 below:

[0052] raw material moles content,% weight fraction Remark formaldehyde 7.12 37 569.8 response enhancer 100 10 polyvinyl alcohol 10 50 urea 7.04 99.8 430.2 U1=210.8 copies U2=140.5 parts U3=78.9 parts Acid solution (formic acid + ammonium chloride) 30 Appropriate amount 50% each Lye (sodium hydroxide + triethanolamine) 30 Appropriate amount 50% each

[0053] It is 1:0.98 to prepare raw materials by formaldehyde and urea molar ratio, and reaction step comprises:

[0054] 1) Put 569.8 parts by weight of 37% industrial formaldehyde into the reaction kettle, adjust the pH value to 7.0 with lye, ...

experiment example

[0069] Add 0.5% ammonium chloride and 0.3% citric acid to the urea-formaldehyde resins of Example 1-2 and Comparative Example 1-2 respectively, and then add 30% flour to make three-layer plywood of 400×400mm.

[0070] Poplar veneer: dry to 6-10% moisture content; thickness 1.5mm;

[0071] The veneer adhesive used the product of Example 1-2 of the present invention and the product of Comparative Example 1-2.

[0072] Plywood is prepared according to the normal process as follows:

[0073] (1) Glue sizing: Glue is applied on both sides of the core board, and the amount of glue applied is 320-360g / m 2 ;

[0074] (2) Aging method and time: closed aging, 20-30 minutes;

[0075] (3) Pre-compression pressure and time: pre-compression for 40 minutes, pressure 0.9MPa;

[0076] (4) Hot pressing pressure: 1.0MPa, hot pressing temperature is 120-130oC, hot pressing time is high pressure 90s / mm.

[0077] According to the test method of GB / T17657-1999 "Physical and Chemical Properties ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com