Low-viscosity fast curing UV polyester acrylate and preparation technology thereof

A polyester acrylate, fast curing technology, applied in the direction of polyester coatings, coatings, etc., can solve the problems of slow curing and high viscosity, and achieve the effect of fast curing, low viscosity and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Put 20 parts of maleic anhydride, 10.1 parts of phthalic anhydride, 5.8 parts of deionized water and 0.1 part of hypophosphorous acid in the reaction kettle in sequence, and react at 110-120 ° C for 0.5 hours;

[0029] (2) Add 30 parts of dicyclopentadiene dropwise for 1.5 hours to react, and keep the temperature at 120° C. for 2.5 hours after dropping;

[0030] (3) Add 20 parts of diethylene glycol, 14.4 parts of pentaerythritol, 8 parts of fumaric acid and 1.5 parts of toluene, raise the temperature to 200°C, keep the system at 200°C, measure the acid value of the reaction system until the acid value of the reaction system is less than 30mgKOH / g;

[0031] (4) Keep the vacuum degree not less than negative 0.085MPa, and continue to cool down to 90°C after vacuuming out the toluene to obtain unsaturated polyester;

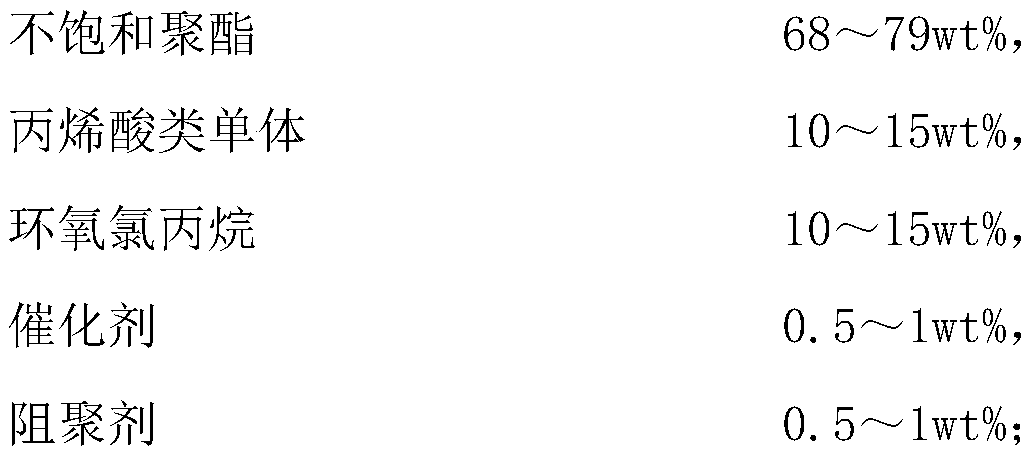

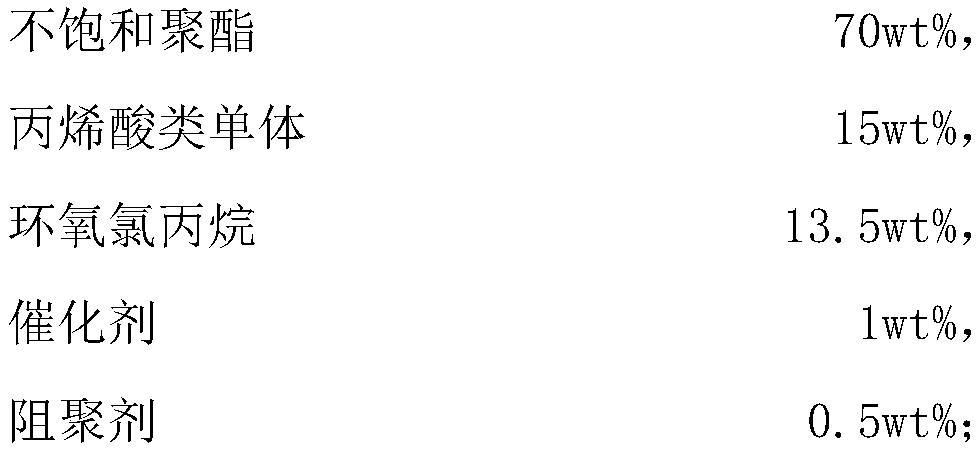

[0032] (5) By weight percentage, that is, unsaturated polyester is 70wt%, acrylic acid monomer is 15wt%, epichlorohydrin is 13.5wt%, catalyst is 1wt%, ...

Embodiment 2

[0036] (1) Put 20 parts of maleic anhydride, 10.1 parts of phthalic anhydride, 5.8 parts of deionized water and 0.1 part of hypophosphorous acid in the reaction kettle in sequence, and react at 110-120 ° C for 0.5 hours;

[0037] (2) Add 30 parts of dicyclopentadiene dropwise for 1.5 hours to react, and keep the temperature at 120° C. for 2.5 hours after dropping;

[0038] (3) Add 20 parts of diethylene glycol, 14.4 parts of pentaerythritol, 8 parts of fumaric acid and 1.5 parts of toluene, raise the temperature to 200°C, keep the system at 200°C, measure the acid value of the reaction system until the acid value of the reaction system is less than 30mgKOH / g;

[0039] (4) Keep the vacuum degree not less than negative 0.085MPa, and continue to cool down to 90°C after vacuuming out the toluene to obtain unsaturated polyester;

[0040] (5) By weight percentage, that is, unsaturated polyester is 72wt%, acrylic acid monomer is 15wt%, epichlorohydrin is 12wt%, catalyst is 0.5wt%, ...

Embodiment 3

[0044] (1) Put 20 parts of maleic anhydride, 10.1 parts of phthalic anhydride, 5.8 parts of deionized water and 0.1 part of hypophosphorous acid in the reaction kettle in sequence, and react at 110-120 ° C for 0.5 hours;

[0045] (2) Add 30 parts of dicyclopentadiene dropwise for 1.5 hours to react, and keep the temperature at 120° C. for 2.5 hours after dropping;

[0046] (3) Add 20 parts of diethylene glycol, 14.4 parts of pentaerythritol, 8 parts of fumaric acid and 1.5 parts of toluene, raise the temperature to 200°C, keep the system at 200°C, measure the acid value of the reaction system until the acid value of the reaction system is less than 30mgKOH / g;

[0047] (4) Keep the vacuum degree not less than negative 0.085MPa, and continue to cool down to 90°C after vacuuming out the toluene to obtain unsaturated polyester;

[0048] (5) By weight percentage, that is, unsaturated polyester is 70wt%, acrylic acid monomer is 15wt%, epichlorohydrin is 13.5wt%, catalyst is 1wt%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com