Prepreg, intermediate material for forming frp, and method for production thereof and method for production of fiber-reinforced composite material

a technology of intermediate materials and composite materials, which is applied in the direction of synthetic resin layered products, weaving, transportation and packaging, etc., can solve the problems of ineffective inability to produce larger products, limited size of molded products, and high cost of autoclave facilities, so as to improve the specific strength and inelasticity, reduce the viscosity of resin, and improve the effect of cost performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

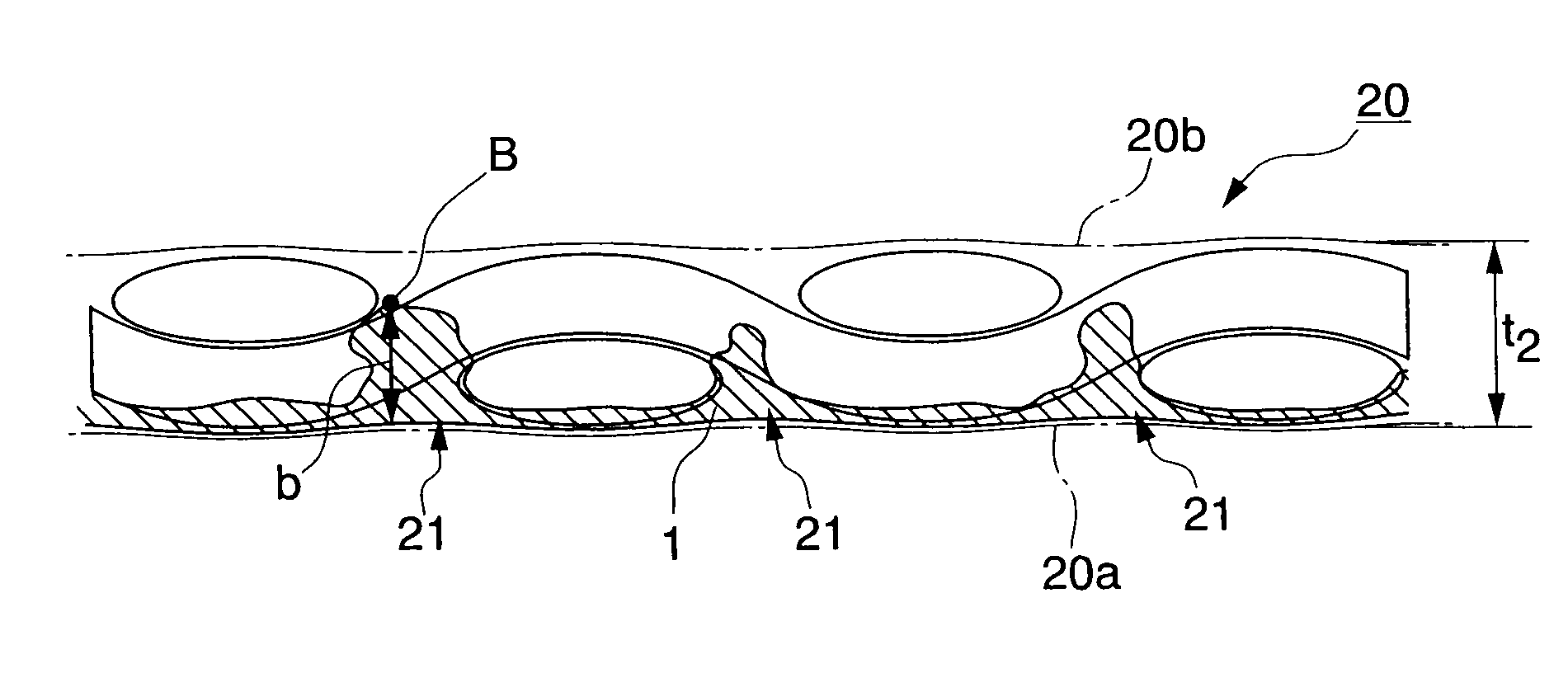

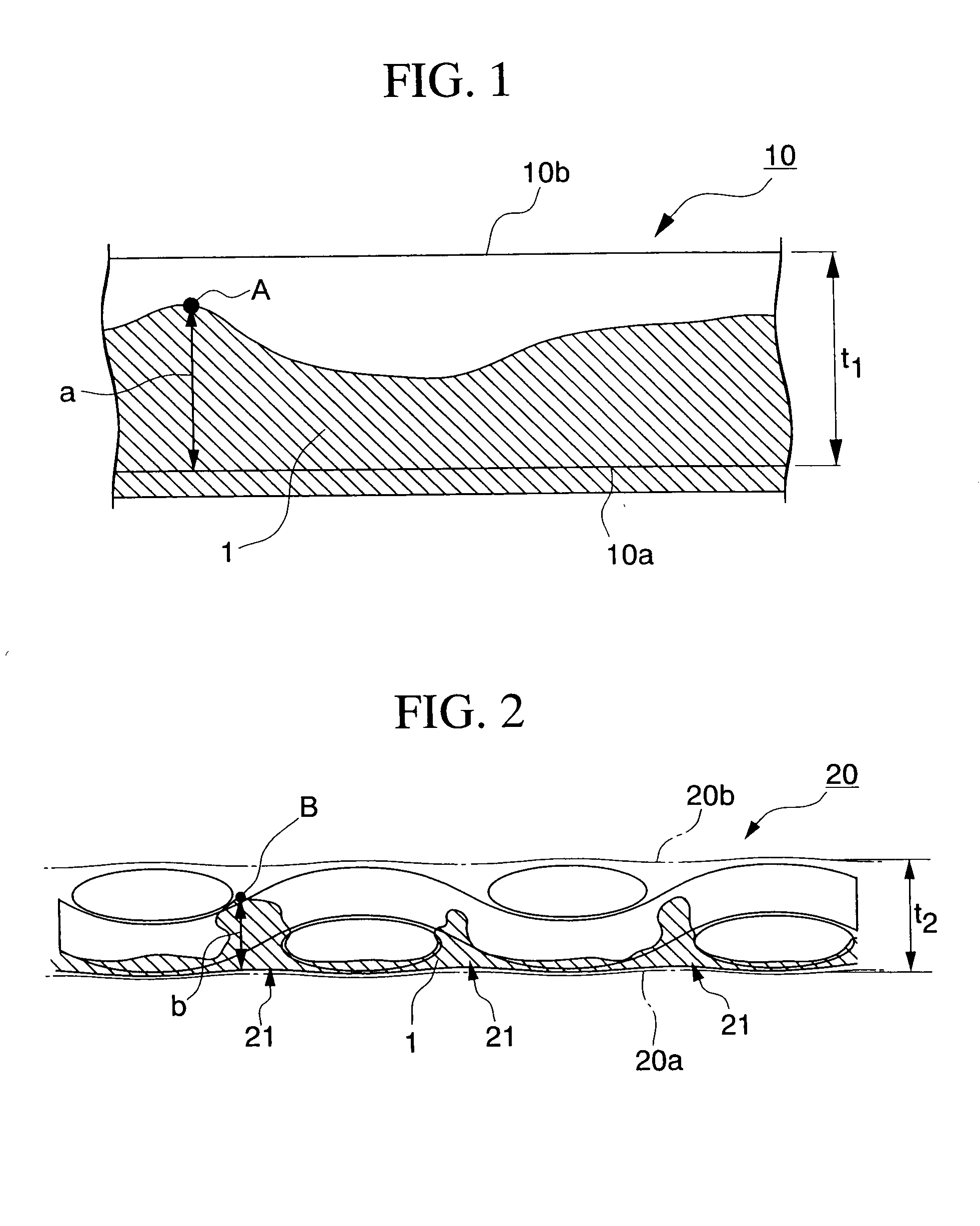

[0136]The matrix resin was applied uniformly to a release sheet at a resin weight of 430 g / m2, thus forming a resin film. This resin film was supplied to a piece of carbon fiber cloth TRK510, manufactured by Mitsubishi Rayon Co., Ltd. (fiber weight 646 g / m2, 2 / 2 twill) from the bottom surface of the cloth, thus impregnating the carbon fiber cloth with the resin. The temperature during impregnation vas 60° C., and the pressure was adjusted to complete the preparation of a prepreg. When the resin impregnation ratio of the thus produced prepreg was measured, the result was 90%, thus confirming the prepreg as conforming to the present invention.

[0137]Next, using the release sheet side of the thus produced prepreg of the present invention as the tool side (a stainless steel plate), a 4-ply laminate was formed at 0° C. The layers from the second layer up were arranged so that the release sheet side of the prepreg faced the opposite side of the previous layer. Vacuum bag molding was conduc...

example 4

[0146]An epoxy resin composition #830 manufactured by Mitsubishi Rayon Co., Ltd. was used as the matrix resin. Using this resin, a resin film was prepared in the same manner as the example 1, and this was then impregnated into a TRK510. The impregnation temperature was set to 50° C. When the resin impregnation ratio of the thus obtained prepreg was measured, the result was (60%, thus confirming the prepreg as conforming to the present invention. Using this prepreg, a molded product was molded. A wooden female mold was used as the molding die. An 8-ply laminate was formed using an alignment pattern of [0° / 45° / 90° / −45° / −45° / 90° / 45° / 0°], with the release sheet side of the prepreg facing the tool surface, and subsequently prepregs arranged so that the release sheet side faced the opposite side of the previous layer. The operation of laminating the prepregs presented absolutely no problems.

[0147]Under the molding conditions used, the temperature was raised from room temperature to 45° C....

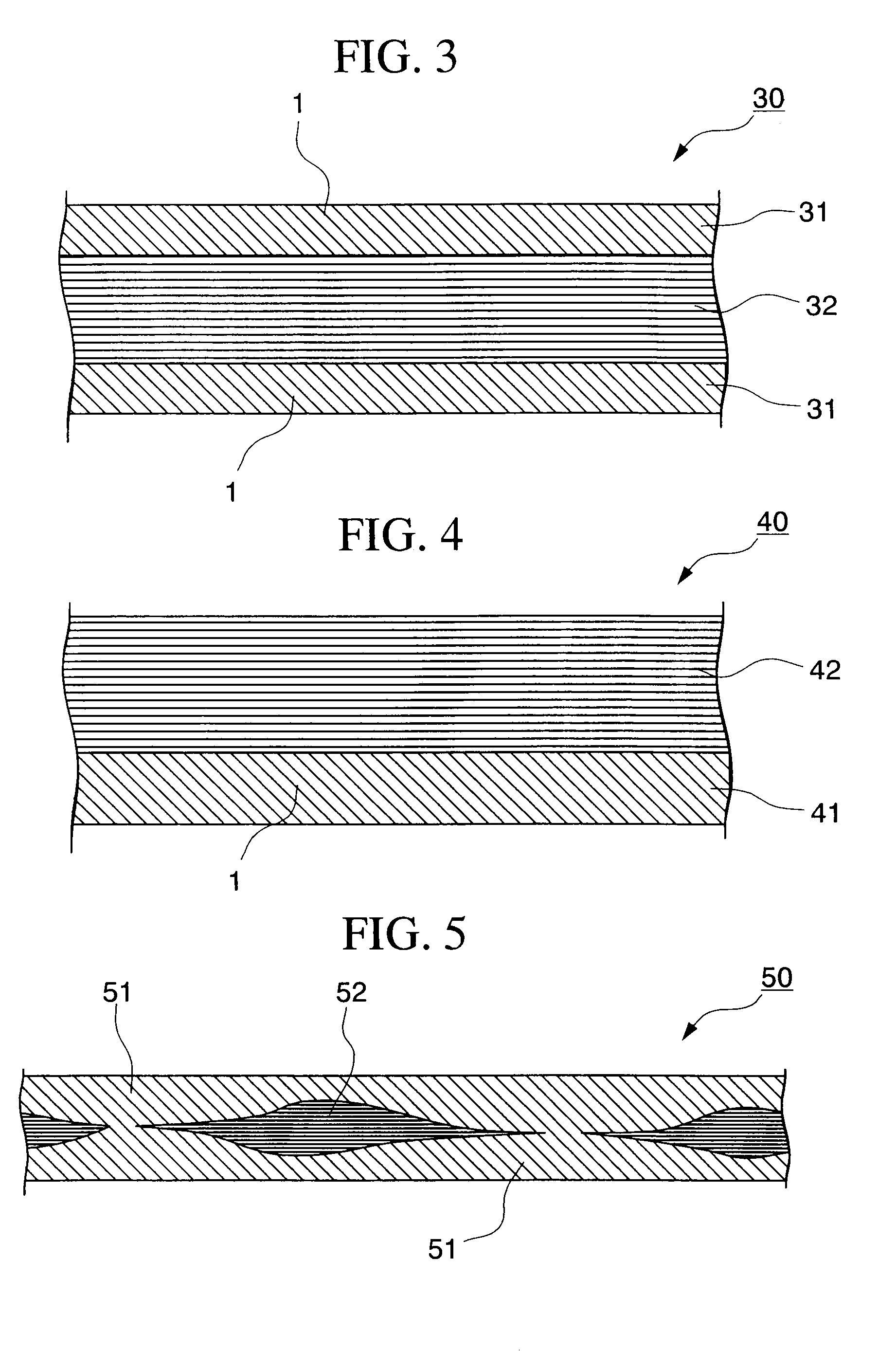

example 5

[0149]Using the resin used in the example 1, and using a non-crimped fabric Quadraxial-Carbon-Gelege (+45°: Carbon 267 g / m2, 0°: Carbon 268 g / m2, −45°: Carbon 267 g / m2, 90°: Carbon 268 g / m2, stitching: PES 6 g·m2, weight 1076 g / m2) manufactured by Saertex Co., Ltd. as a sheet-like reinforcing fiber substrate, a prepreg was prepared in the same manner as the example 1. However, the resin weighting was 717 g / m2. When the resin impregnation ratio was measured, the result was 75%, thus confirming the prepreg as conforming to the present invention. A 2-ply laminate was prepared with the prepreg surfaces facing in the same direction, and a FRP was then molded. The molding was conducted under the same molding conditions as the example 1. The thus obtained molded product displayed no internal voids and no surface pinholes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com