Impregnating agent for high-strength industrial glass fibre spun yarns and preparation method thereof

A glass fiber, high-strength technology, applied in the field of sizing of high-strength industrial glass fiber spun yarn, can solve the problems of poor resin bonding, low tensile strength, poor textile performance, etc., and achieve improved bonding performance, high yarn strength, The effect of good wear resistance of yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

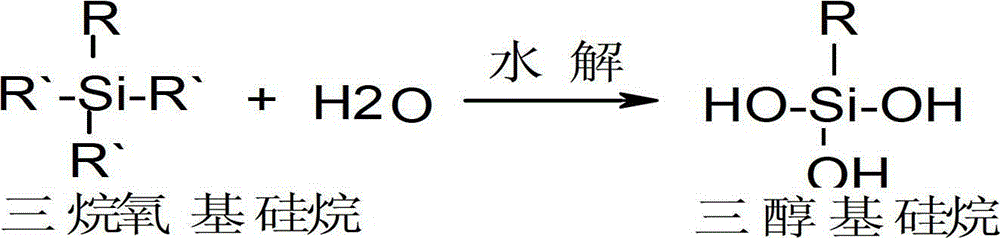

Method used

Image

Examples

Embodiment 1

[0047] The concrete ratio of each component of the wetting agent of the present invention is: modified starch 4Kg, hydrogenated vegetable oil 0.2Kg, vegetable oil emulsifier 0.72Kg, water-based epoxy resin 0.4Kg, softener 0.1Kg, polyethylene glycol 2.0Kg, glacial acetic acid 0.03 Kg, silane coupling agent 0.4Kg, balance is water.

[0048] The preparation method is as follows:

[0049] a. Starch gelatinization:

[0050] Add 50kg of water into the preparation tank and start stirring; after adding 4kg of starch, stir for 5min at a speed of 150rpm; then rinse the starch on the tank wall with water into the tank, adjust the speed and stir at 100rpm; The highest setting is 96°C. After heating with steam for 40-50 minutes, the temperature in the tank reaches 96°C, and the temperature is kept constant for more than 30 minutes;

[0051] b. Vegetable oil emulsification:

[0052] Put the vegetable oil and emulsifier in the warm water tank for preheating in advance; adjust the temperat...

Embodiment 2

[0060] The concrete ratio of each component of the wetting agent of the present invention is: modified starch 5Kg, vegetable oil 0.3Kg, vegetable oil emulsifier 1.02Kg, water-based epoxy resin 0.5Kg, softener 0.2Kg, polyethylene glycol 2.5Kg, glacial acetic acid 0.05Kg 1. Silane coupling agent 0.6Kg, the balance is water.

[0061] The preparation method is as follows:

[0062] a. Starch gelatinization:

[0063] Add 50kg of water into the preparation tank and start stirring; after adding 5kg of starch, stir for 5min at a speed of 150rpm; rinse the starch on the tank wall with water into the tank, and adjust the stirring speed to the normal speed of 100rpm; set the temperature to the highest Set it to 96°C, turn on the steam and heat for 40min-50min, then the temperature in the tank will reach 96°C, and keep the temperature constant for more than 30min;

[0064] b. Vegetable oil emulsification:

[0065] Put the vegetable oil and emulsifier in the warm water tank for preheatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com