Throat-tube type cold-wind-drafted and melt micro-fibre spinning device

A spinning device and microfiber technology, which is applied in the field of a throat-type cold-air drafting molten microfiber spinning device, can solve the problems of high energy consumption, difficult to eliminate fiber thermal stress, low fiber tensile strength, etc. The effect of low power consumption, thermal stress relief, and carbon emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

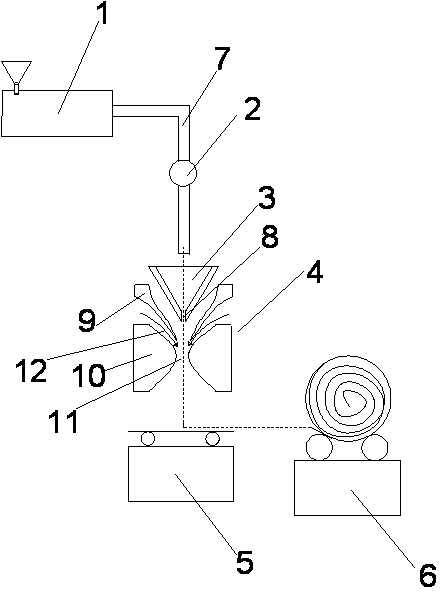

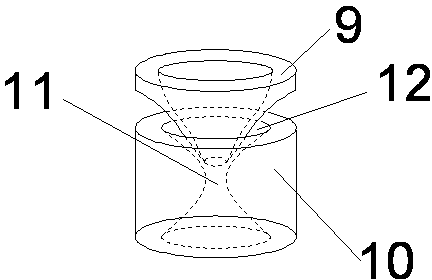

[0016] Such as figure 1 As shown in the present invention, a throat-type cold-air drafting molten microfiber spinning device disclosed in the present invention is mainly used for producing molten microfibers, and specifically includes an extruder 1, a metering pump 2, a spinneret 3, and a throat-type The air drafter 4, the receiving device 5 and the winding device 6, the extruder 1 is connected to the spinneret 3 through the delivery pipe 7 through the metering pump 2, and the spinneret 3 is placed in the throat type air draft The upper end of the stretcher 4, and the interval is greater than 3mm, the receiving device 5 is located directly below the throat type air drafter 4, and the winding device 6 is located on the side of the receiving device 5.

[0017] Specifically, the spinner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com