Spinning oil for terylene staple and preparation method thereof

A polyester staple fiber spinning technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of inability to effectively suppress roller winding and white powder phenomenon, bunching, poor drafting performance, and temperature and humidity spinnability Larger problems, etc., to achieve good carding passability, good smoothness, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

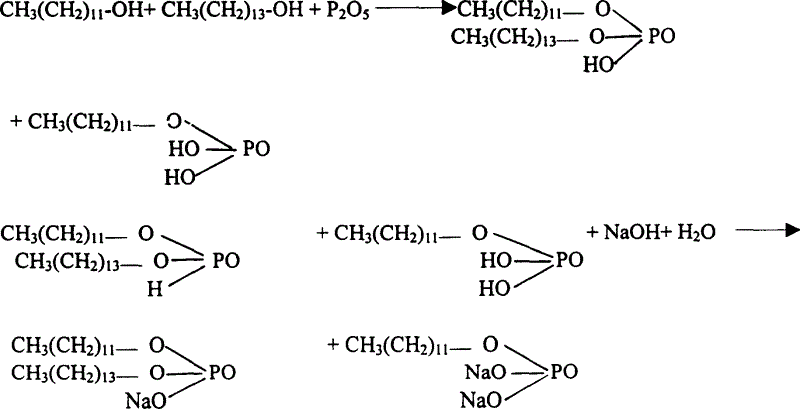

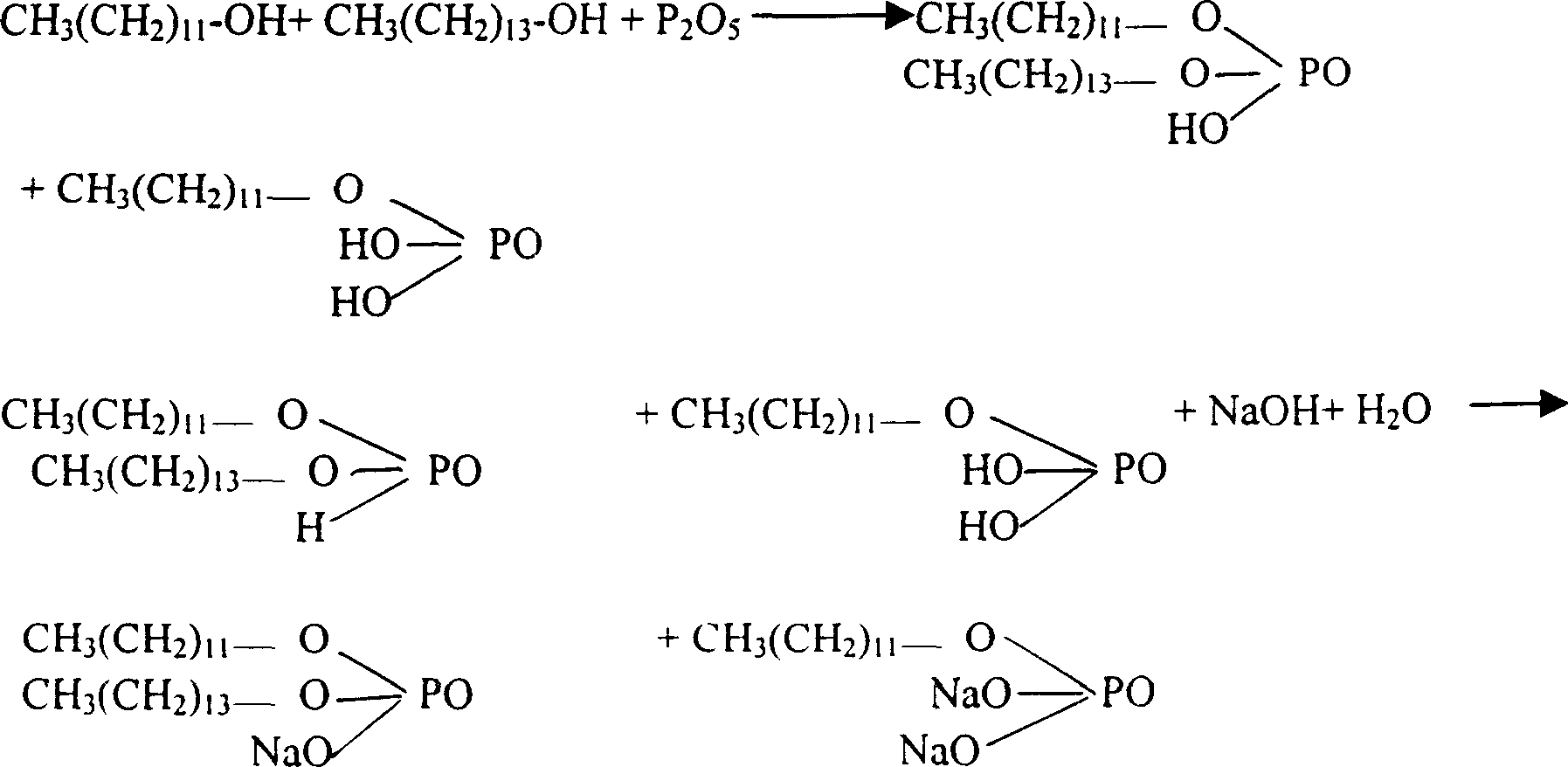

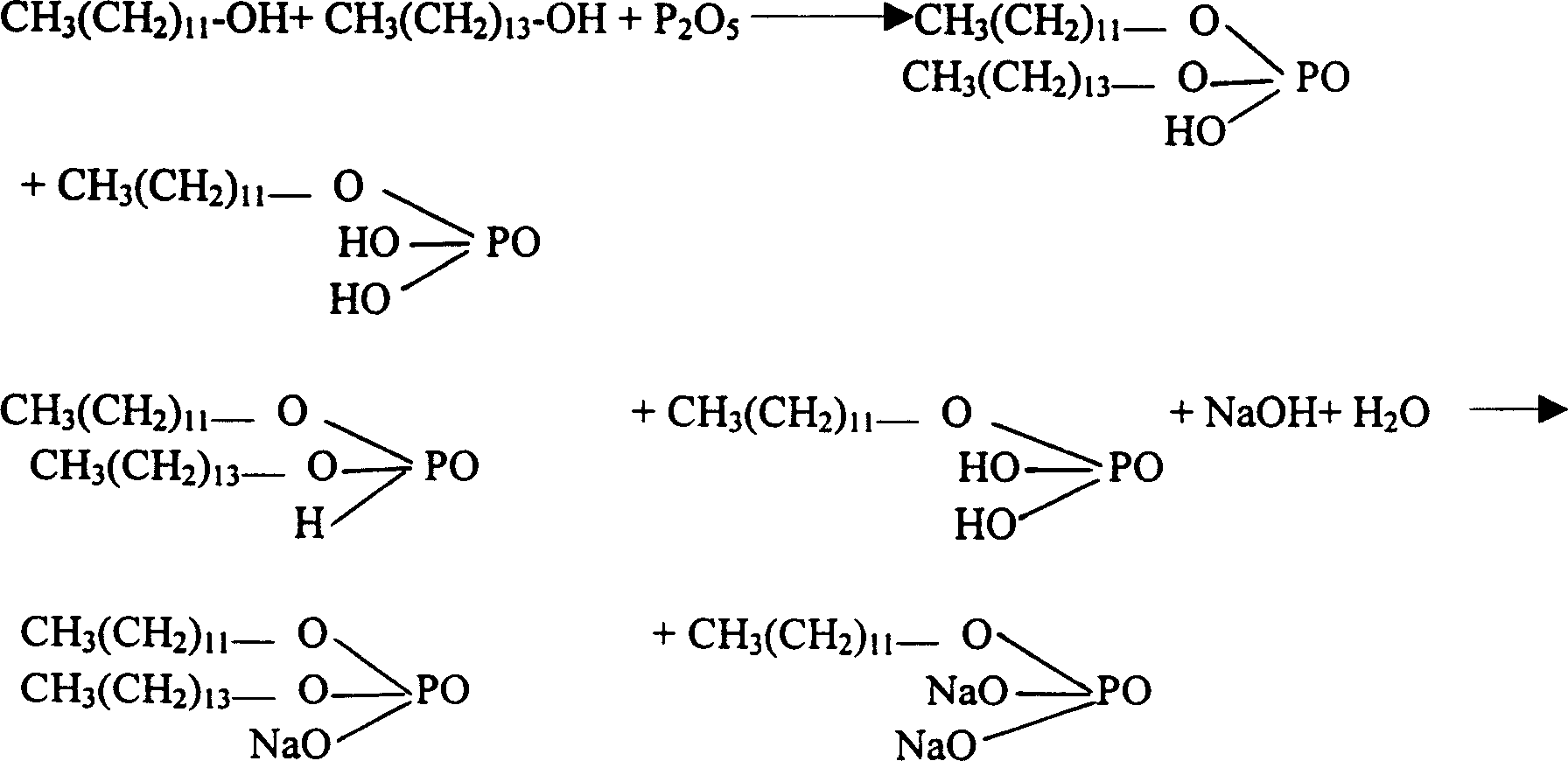

[0037] Group A takes 80g of dodecyl and tetradecandyl alcohol in a ratio of 2:1, P 2 o 5 60g is placed in the reaction vessel and reacts to generate mixed alcohol phosphate, then add 50% NaOH 125g and H 2 O 735g reacted to generate mixed alcohol phosphate sodium salt; Component B: Take 1 part of fatty alcohol polyoxyethylene ether ammonium sulfate and 1 part of coconut oil diethanolamide and mix evenly.

[0038] According to the proportioning ratio of 4: 1, the above-mentioned components A and B are mixed evenly to make the polyester staple fiber oil of the present invention.

example 2

[0040] Component A Take dodecanol 100g, P 2 o 5 58g, 50% NaOH 120g and H 2 O 722g and the remaining 1 are the same as Example 1; Component B Take 2 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, and 1 part of coconut oil diethanolamide and mix well.

[0041] According to the proportioning ratio of 5: 1, the above-mentioned components A and B are uniformly mixed to prepare the polyester staple fiber oil of the present invention.

example 3

[0043] Component A Take 110g of dodecanol and tetradecandyl alcohol in a ratio of 3:1, P 2 o 5 63g, 50% NaOH 128g and H 2 O 700g, the rest are the same as in Example 1; Component B Take 1 part of fatty alcohol polyoxyethylene ether ammonium sulfate, 1.5 parts of coconut oil diethanolamide and mix well.

[0044] According to the ratio of 6:1, mix the above-mentioned components A and B evenly to make polyester staple fiber oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com