Device and method for controlling leno fabric warp on a loom

A leno fabric and warp yarn technology, applied in the field of weaving equipment, can solve problems such as unsuitability for high-speed weaving, yarn wear, and weaving defects, and achieve the effects of not being easy to break, reducing the risk of weaving defects, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

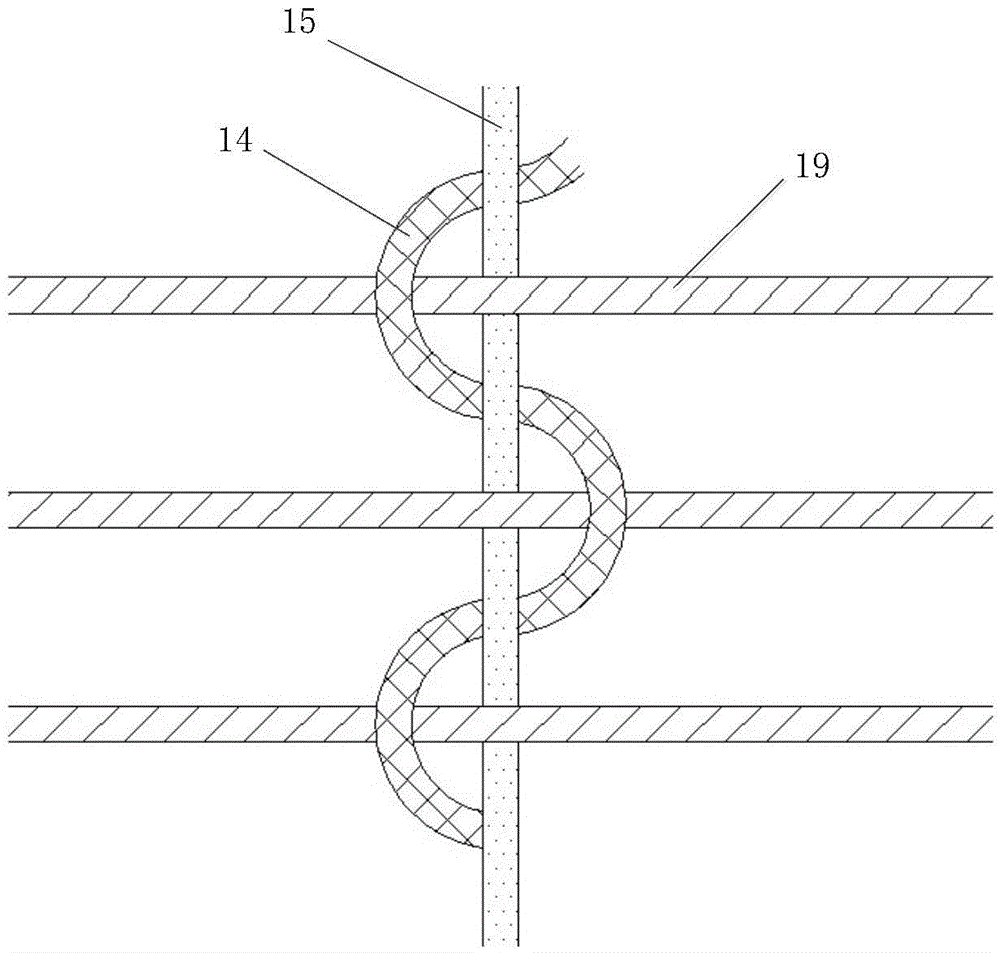

[0024] The characteristics of leno fabrics are produced from the different structures of interweaving points and weaving characteristics. The interweaving of yarns can be realized by twisting two kinds of warp yarns, so that there is no need to interweave weft yarns and warp yarns; in each weaving cycle, the warp yarn groups are One warp yarn is on the top and one warp yarn is on the bottom. The warp yarns do not interweave by exchanging their upper and lower positions, but by twisting each other to produce interweaving. Therefore, the warp yarns are generally divided into two groups, including a stationary warp yarn group 15 and a rotating warp yarn group 14 (as figure 1 shown), through a special warp control mechanism to make them produce left and right alternate twisting motion.

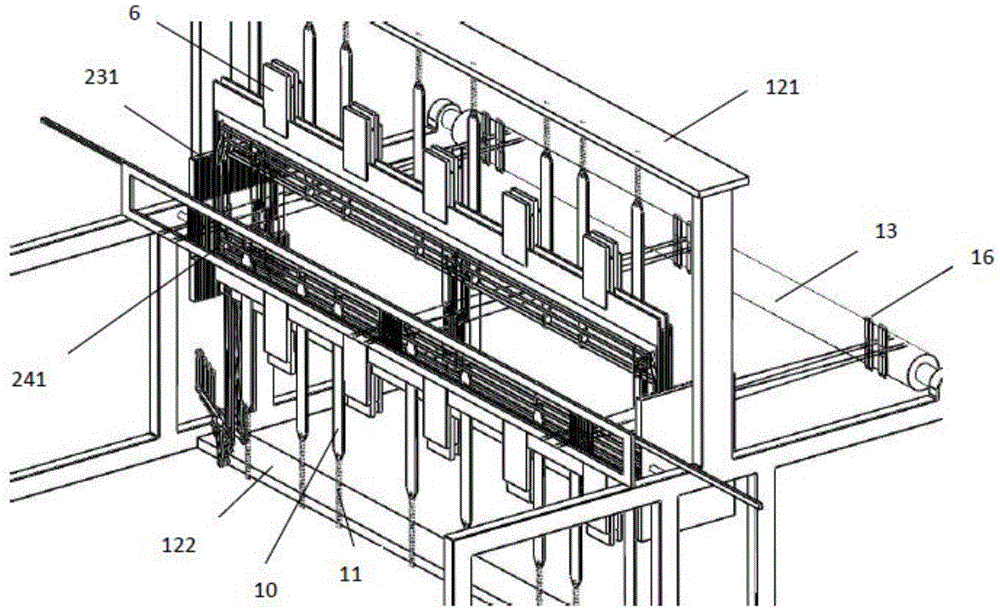

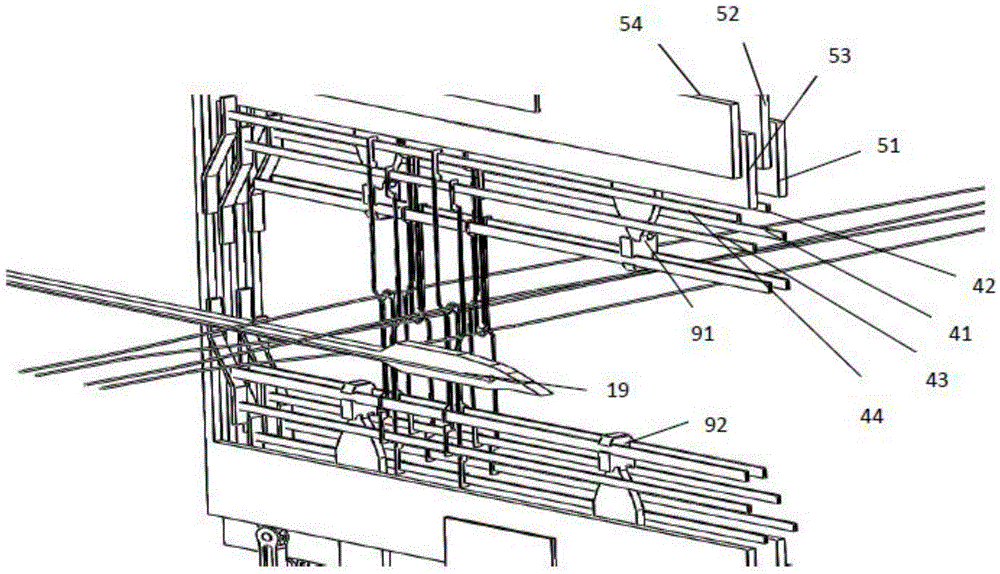

[0025] The warp control device used in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com