Reactive alkali-soluble resin, photosensitive resin composition containing same and application of photosensitive resin composition

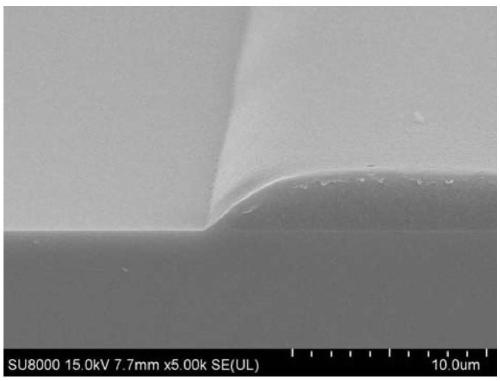

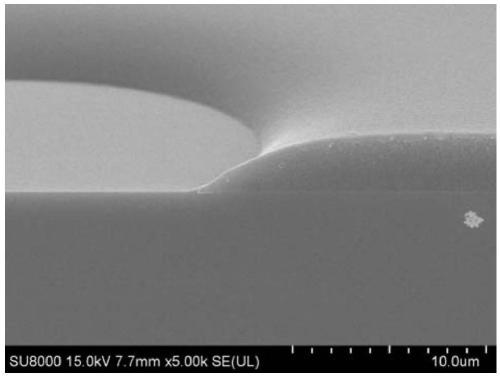

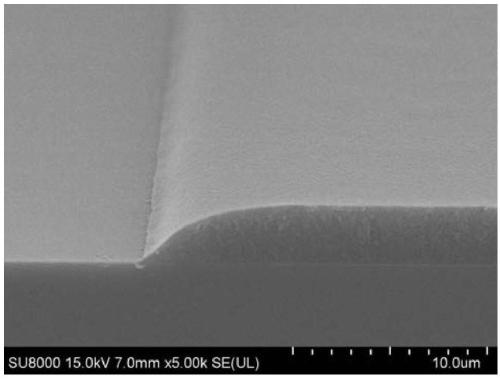

A technology of alkali-soluble resin and photosensitive resin, which is applied in the field of light curing, can solve problems such as edge uniformity, low resolution, color photoresist pixels are not resistant to development, and pattern pixel edges are not neat, etc., to achieve good developability, light Good curing performance and alkali solubility, clear pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0083] Synthetic reactive alkali-soluble resin A1 solution:

[0084] (1) In a 1 L flask equipped with a reflux condenser, a dropping funnel, and a stirrer, nitrogen gas was flowed at 0.02 L / min to form a nitrogen atmosphere, 200 g of propylene glycol monomethyl ether acetate was introduced, and the temperature was raised to 100° C., Add methacrylic acid 3.01g (0.035mol), styrene 3.64g (0.035mol), pentaerythritol diacrylate (PET4A) 8.68 g (0.035 mol) was stirred and reacted for 3 hours, and the temperature was lowered to room temperature to obtain a reactive alkali-soluble resin A1 solution.

[0085] (2) After removing part of the solvent, the reaction type alkali-soluble resin A1 solution with a solid content of 38.1% is obtained. The weight average molecular weight of polystyrene conversion measured by GPC is 11500, and the acid value is 102KOH mg / g. The calculated double bond The equivalent weight is 400 g / mol.

preparation example 2

[0087] Synthetic reactive alkali-soluble resin A2 solution:

[0088] (1) The difference with Preparation Example 1 is that pentaerythritol diacrylate Replaced with pentaerythritol triacrylate (PETA) The amount added was 10.43 g (0.035 mol).

[0089] (2) After removing part of the solvent, the reaction type alkali-soluble resin A2 solution with a solid content of 38.5% is obtained, and the weight-average molecular weight converted from polystyrene measured by GPC is 15800, the acid value is 102KOH mg / g, and the calculated double bond equivalent is 500g / mol.

preparation example 3

[0091] Synthetic reaction type alkali-soluble resin solution A3 liquid:

[0092] (1) The difference with Preparation Example 1 is that pentaerythritol diacrylate Replaced with pentaerythritol tetraacrylate (PEDA) The amount added was 12.32 g (0.035 mol).

[0093] (2) After removing part of the solvent, the reaction type alkali-soluble resin A3 solution with a solid content of 38.7% was obtained, and the weight-average molecular weight converted from polystyrene measured by GPC was 19800, the acid value was 101KOH mg / g, and the calculated double bond equivalent is 600g / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com