Photoresist resin monomer synthesized from carboxylic acid compound and synthesis method thereof

A technology of carboxylic acid compound and resin monomer, applied in the field of photoresist resin monomer and its synthesis, can solve the problem of low resolution of photolithography pattern, and achieve improved resolution, increased etching resistance, and increased solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

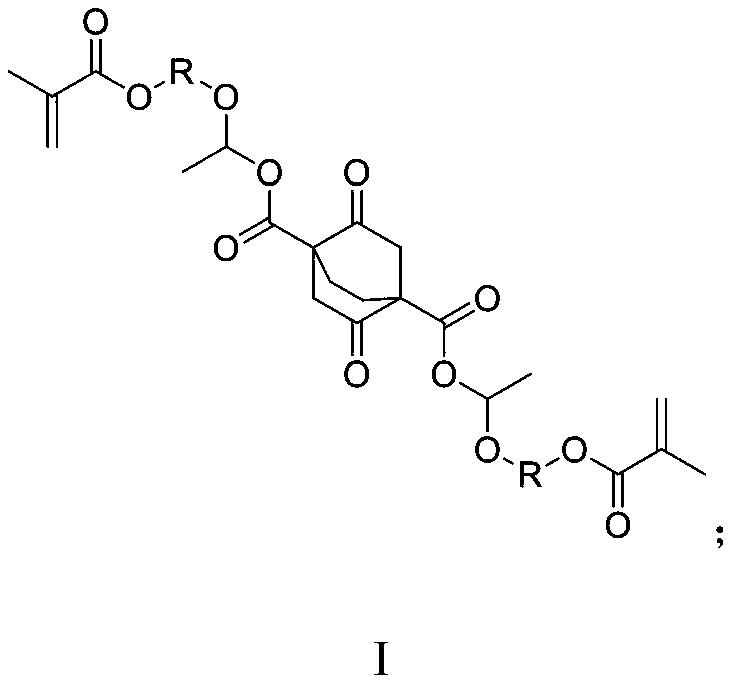

[0034] This embodiment provides a kind of photoresist resin monomer synthesized by carboxylic acid compound, the reaction scheme of the synthetic method of this resin monomer is as follows:

[0035]

[0036] It specifically includes the following steps:

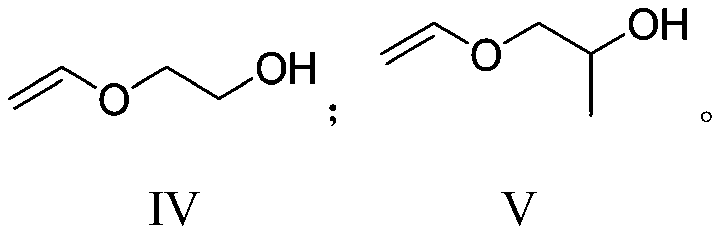

[0037] S1. Dissolve vinyl glycol ether (Formula 1-1, 9.3g, 105.5mmol) and triethylamine (10.7g, 105.7mmol) in dichloromethane (200g) to obtain a mixed solution; Acryloyl chloride (10 g, 95.7 mmol) was added dropwise to the above mixture, stirred at 0° C. for 30 minutes under nitrogen protection, and continued stirring at room temperature for 4 hours after the reaction was completed. Filtrate and concentrate the filtrate to obtain a crude product, which was purified by column chromatography to obtain a colorless liquid intermediate (Formula 1-2, 12 g, 76.8 mmol, yield 80.3%).

[0038] S2, intermediate (12g, 76.8mmol), 2,5-dioxobicyclo[2.2.2]octane-1,4-dicarboxylic acid (8.6g, 38.0mmol) and p-tert-butylcatechol ( 0.5g, 3.0...

Embodiment 2

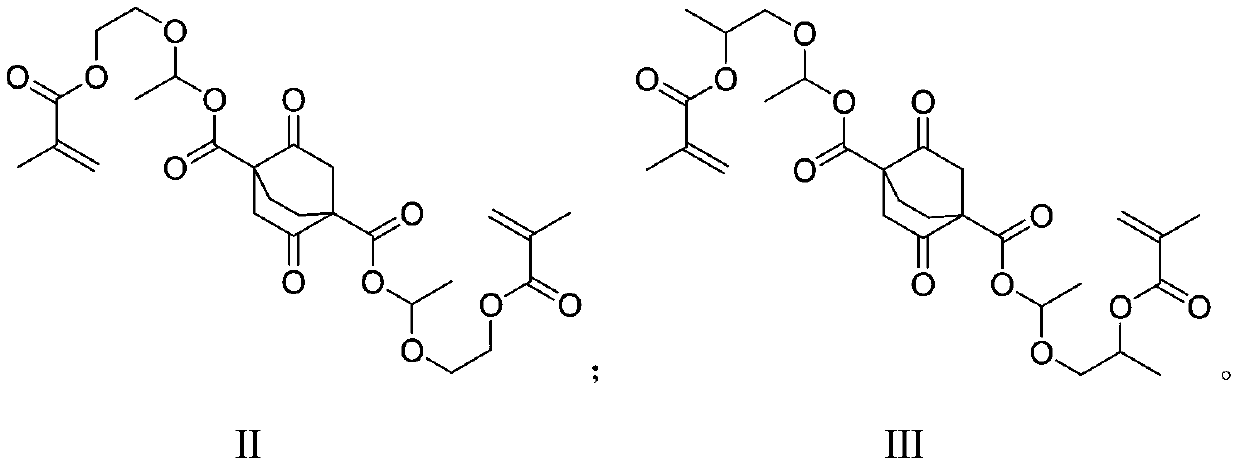

[0040] This embodiment provides a kind of photoresist resin monomer synthesized by carboxylic acid compound, the reaction scheme of the synthetic method of this resin monomer is as follows:

[0041]

[0042] It specifically includes the following steps:

[0043] S1. Dissolve 1-vinyloxy-propan-2-ol (Formula 2-1, 10.8g, 105.7mmol) and triethylamine (10.7g, 105.7mmol) in dichloromethane (200g) to obtain a mixed solution ; Next, methacryloyl chloride (10g, 95.7mmol) was added dropwise to the above mixture, stirred at 0°C for 30 minutes under nitrogen protection, and continued to stir for 4 hours at room temperature after the reaction was completed. Filtrate and concentrate the filtrate to obtain a crude product, which was purified by column chromatography to obtain a colorless liquid intermediate (Formula 2-2, 13.5 g, 79.3 mmol, yield 82.9%).

[0044] S2, intermediate (13.5g, 79.3mmol), 2,5-dioxobicyclo[2.2.2]octane-1,4-dicarboxylic acid (8.8g, 38.9mmol) and p-tert-butylcatech...

Embodiment 3

[0046] This embodiment provides a photoresist resin monomer synthesized by a carboxylic acid compound, and the synthesis method of the resin monomer specifically includes the following steps:

[0047] S1, 1-vinyloxy-propan-2-ol (105.7mmol) and triethylamine (105.7mmol) were dissolved in dichloromethane (200g) to obtain a mixed solution; then, methacryloyl chloride (84.56mmol ) was added dropwise to the above mixture, stirred at 0° C. under nitrogen protection for 30 minutes, and continued to stir for 4 hours at room temperature after the reaction was completed. Filtrate and concentrate the filtrate to obtain a crude product, which is purified by column chromatography to obtain a colorless liquid intermediate.

[0048] S2. After mixing the intermediate (70.2mmol), 2,5-dioxobicyclo[2.2.2]octane-1,4-dicarboxylic acid (39mmol) and p-tert-butylcatechol (3.0mmol) , and placed under the condition of 75° C. and stirred for 1.5 hours, and then distilled under reduced pressure to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com