Patents

Literature

75results about How to "Good alkali solubility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

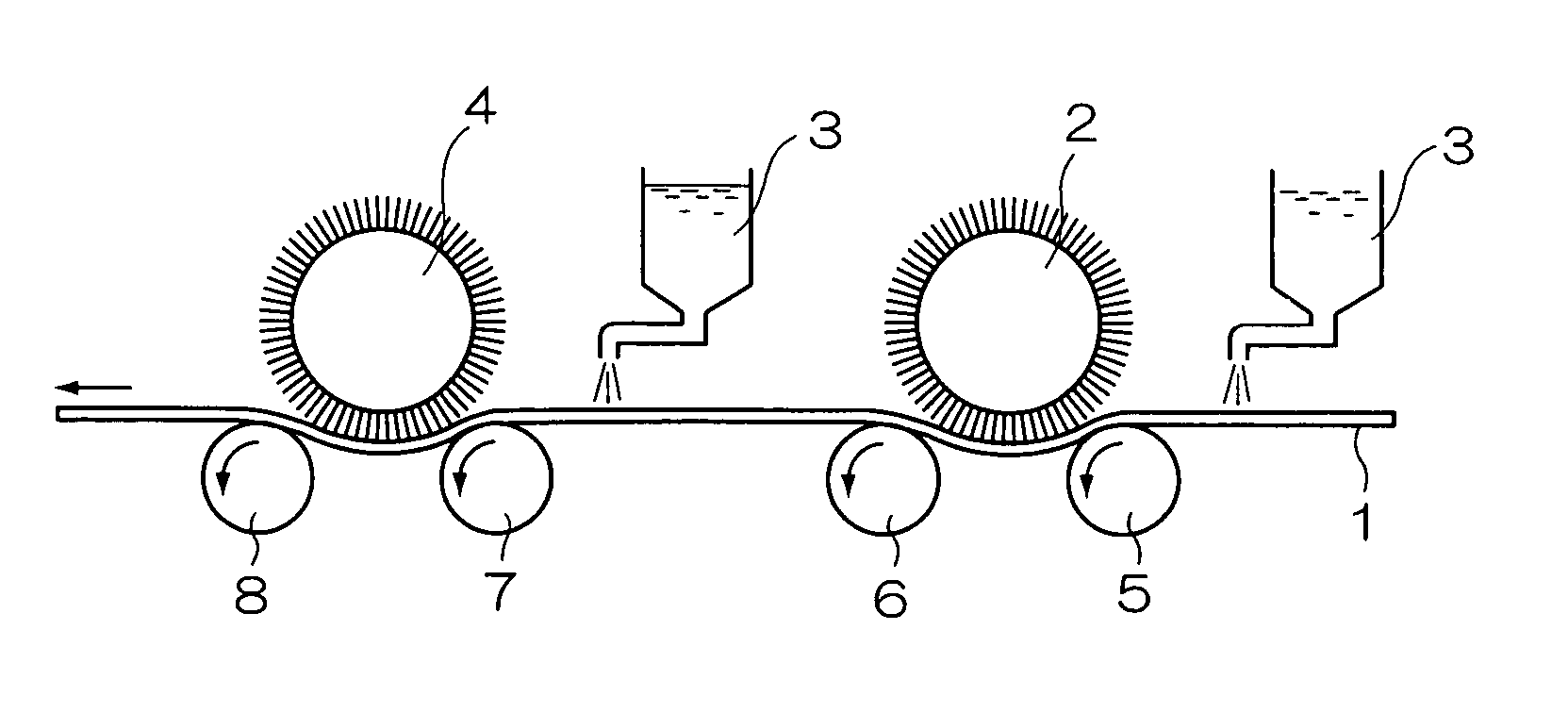

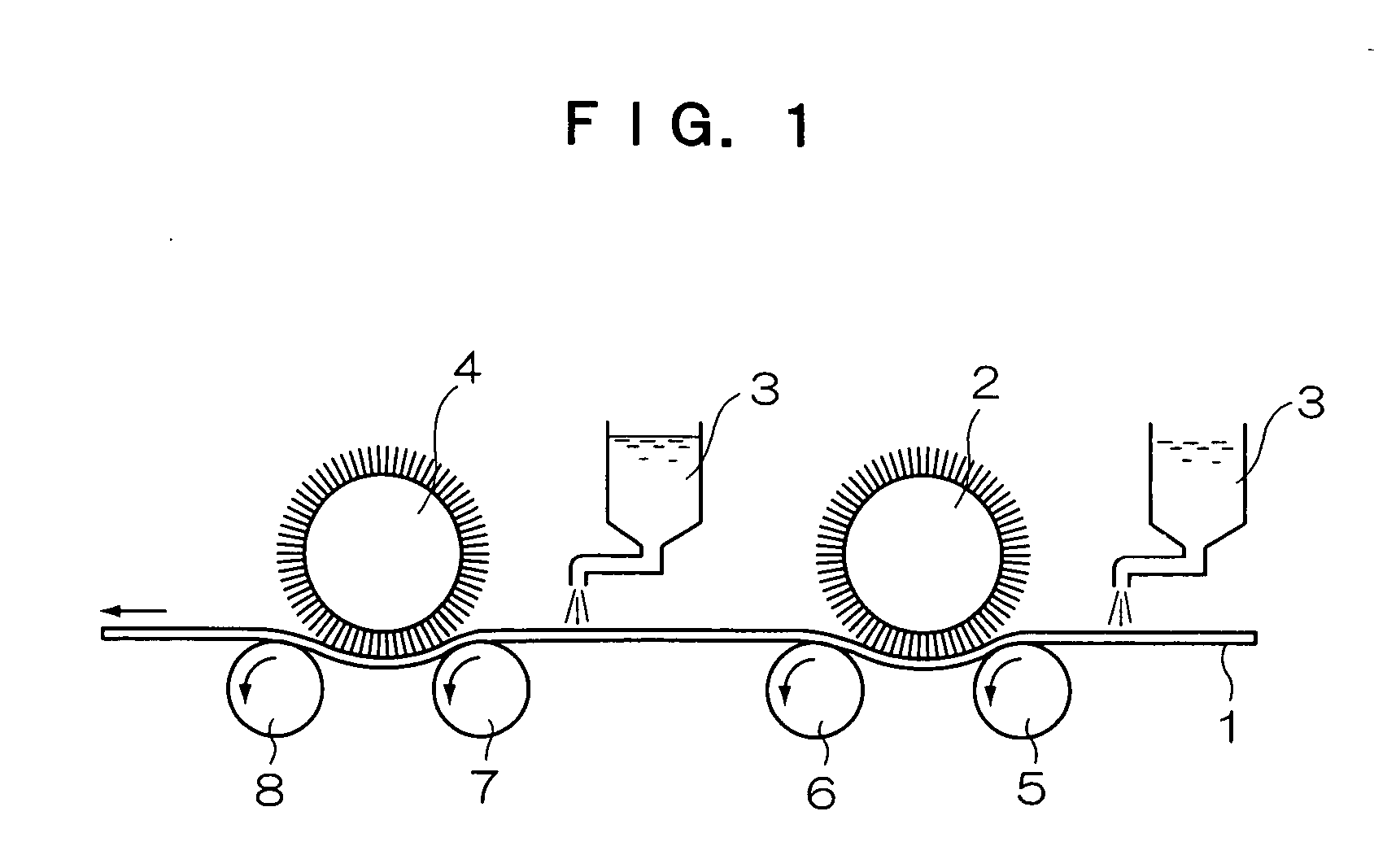

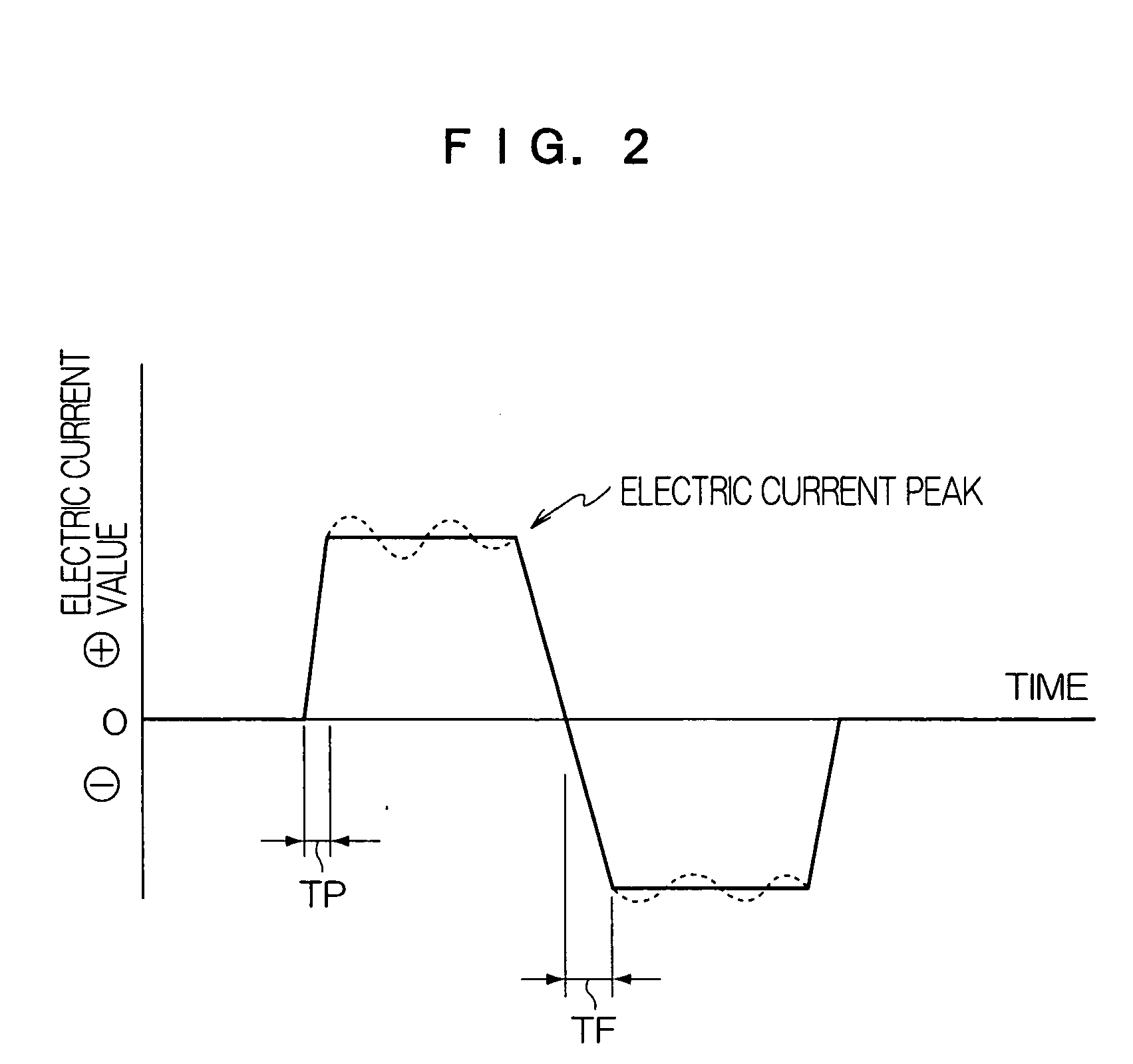

Planographic printing plate precursor

InactiveUS20050069812A1High printing durabilityGood chemical resistanceSilver salt compositionsLithographySolubilityHydrogen

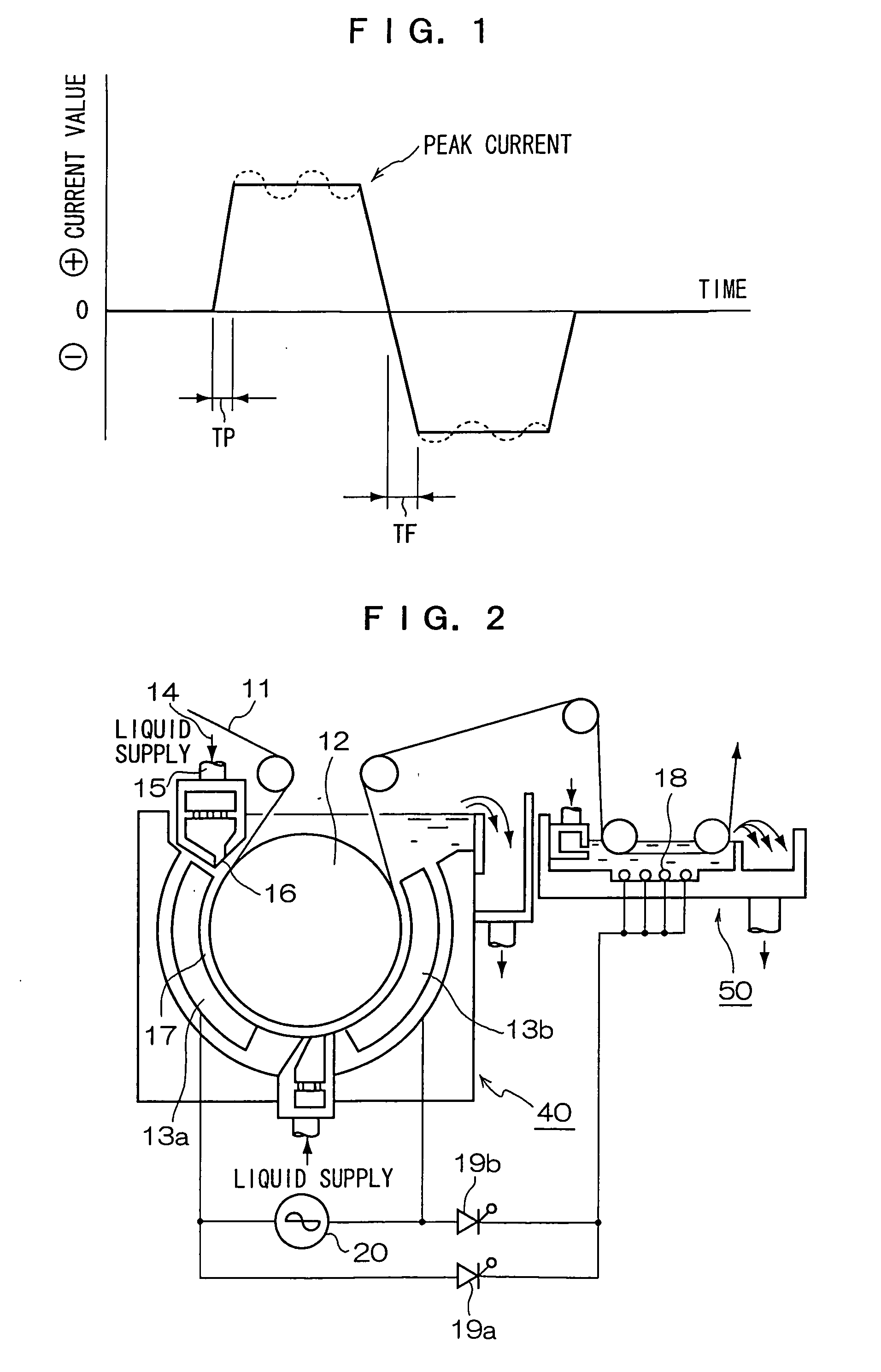

The present invention provides a planographic printing plate precursor including a support, and a recording layer which is formed on the support and includes a water-insoluble and alkali-soluble resin having active hydrogen in a main chain thereof and an infrared absorbent, the solubility of the recording layer in an aqueous alkaline solution being increased by exposure to light; and a planographic printing plate precursor including a support, and a recording layer formed on the support, wherein the recording layer includes a lower layer which is formed on the support and includes a water-insoluble and alkali-soluble resin having active hydrogen in a main chain thereof, and an upper layer which is formed on the lower layer and includes a water-insoluble and alkali-soluble resin and a development inhibitor, the solubility of the upper layer in an aqueous alkaline solution being increased by exposure to light, and at least one of the lower layer and the upper layer of the recording layer includes an infrared absorbent. According to the invention, there is provided is a positive planographic printing plate precursor which can provide a printing plate directly from scanning exposure based on digital signals and is excellent in printing durability and chemical resistance.

Owner:FUJIFILM CORP +1

Microwave synthesis method of fiber carbamate

The invention discloses a technology of a microwave heating synthesis method of fiber carbamate; the method is that: firstly, the fiber is soaked in carbamide aqueous solution for completely adsorbing the carbamide, the fiber / carbamide even mixture is obtained by filtering and drying, and then the fiber / carbamide mixture is placed in a microwave oven for being heated, thereby obtaining the fiber carbamate. The synthesis technology of the fiber carbamate provided by the invention has no solvent pollution, organic solvents and any catalyzers do not need, the reacting time is speed, and the energy consumption is low. The synthesized fiber carbamate products has good dissolubility in 6 to 10 wt% of NaOH aqueous solution within the temperature range of -10 to 5 DEG C, and the concentrated solution which is stable, transparent and is suitable for industrial spinning and membrane manufacturing can be prepared.

Owner:WUHAN UNIV

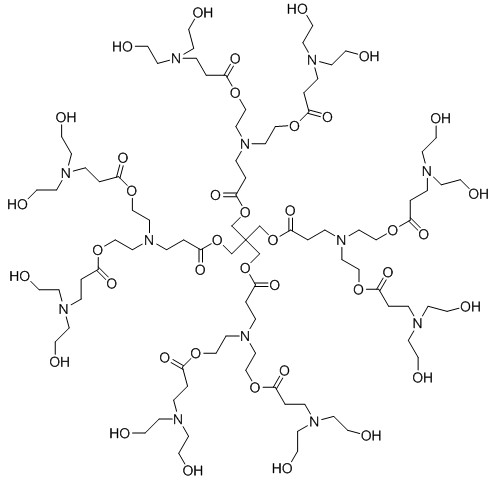

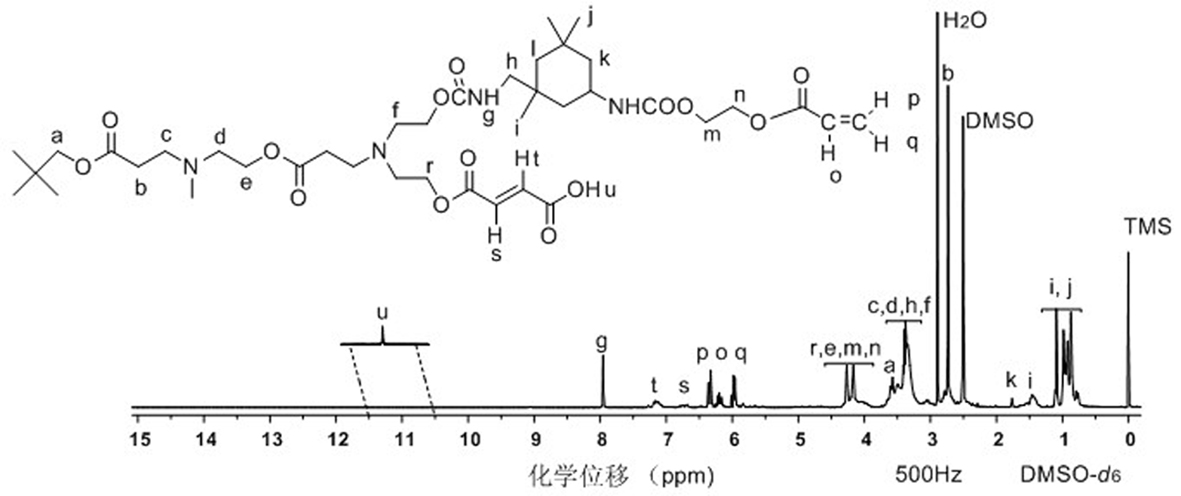

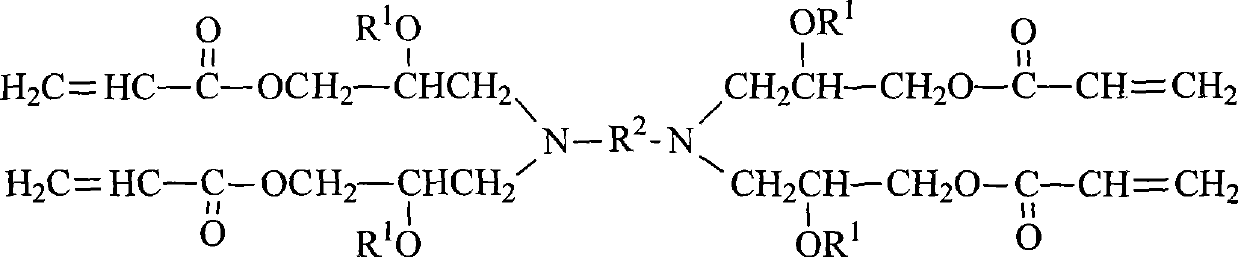

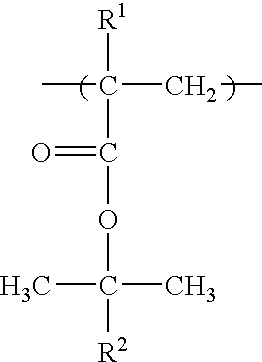

Acrylate containing carboxyl hyperbranched poly(amine-ester) and preparation method thereof

InactiveCN101993532ALow viscosityGood film formingPhotosensitive materials for photomechanical apparatusPolymer sciencePhotoresist

The invention discloses an acrylate containing carboxyl hyperbranched poly(amine-ester) used for a photoresist and a preparation method thereof, and is characterized in that hyperbranched poly(amine-ester) with different generations is synthesized through a step-by-step method by using polyalcohol and branched monomers, and then monohydroxy acrylate and diisocyanate react to obtain a semi-addition product; and the semi-addition product and maleic anhydride react with terminated hyperbranched poly(amine-ester) at a certain ratio to obtain the acrylate containing carboxyl hyperbranched poly(amine-ester). The synthesized product has the characteristics of low viscosity, good film forming performance and small contractibility rate of solidifying film and the like, has better alkali solubility for the addition of the carboxyl, and can obtain a clear image with higher resolution ratio, thereby better meeting the requirement when the synthesized product is used as a photoresist.

Owner:SOUTHEAST UNIV

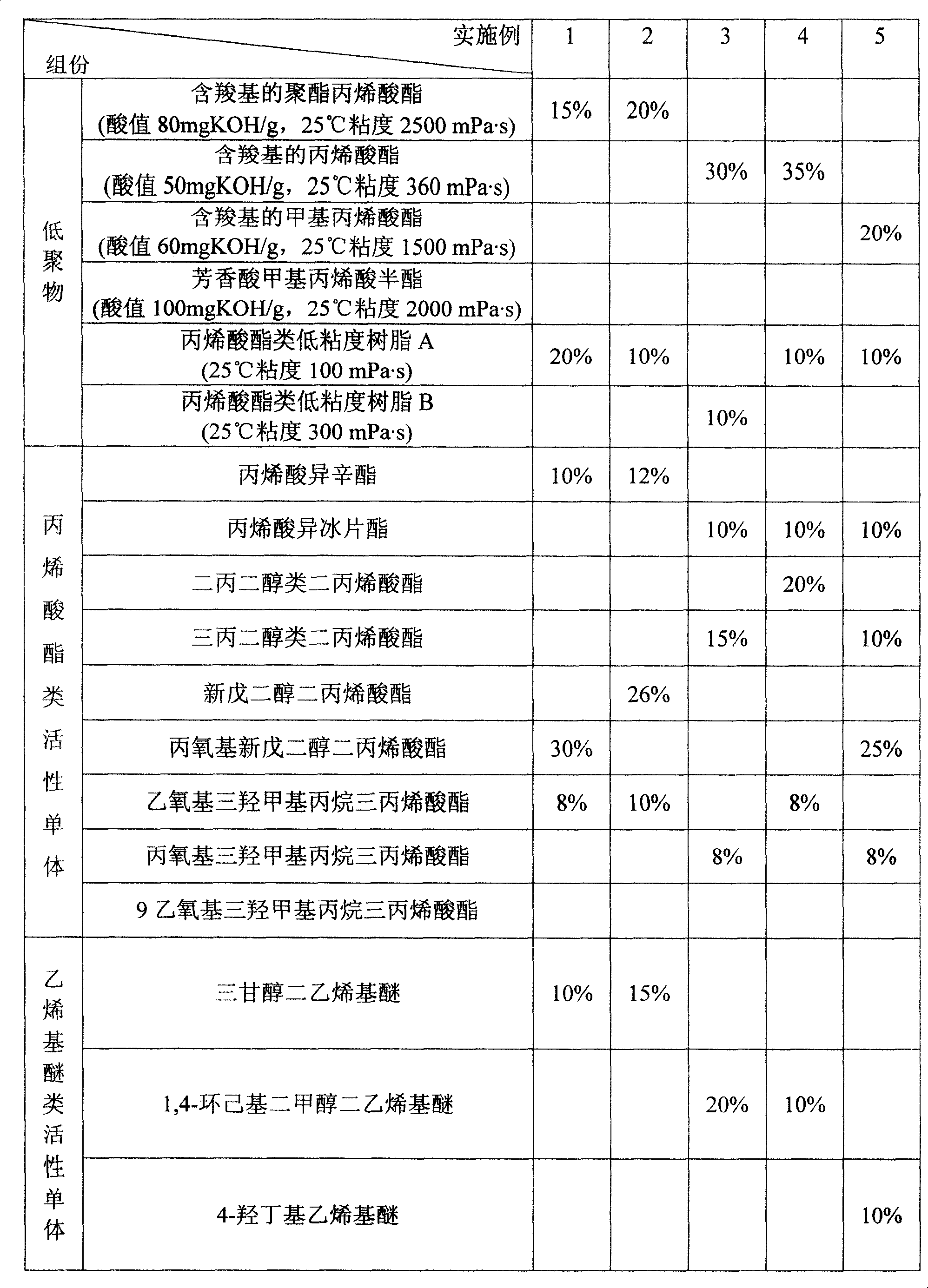

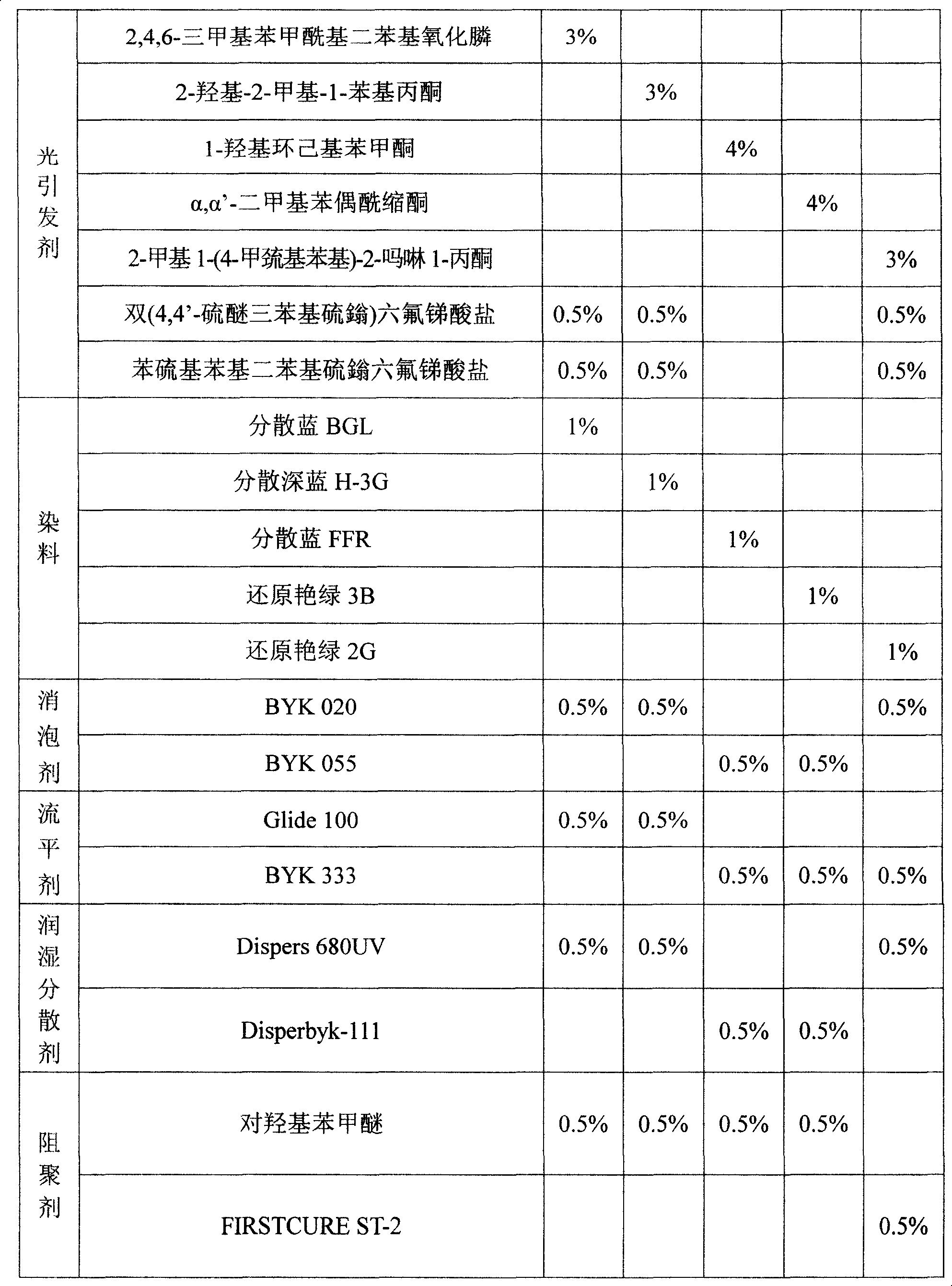

Photo-curing ink-jet resist for printing circuit board and preparation method thereof

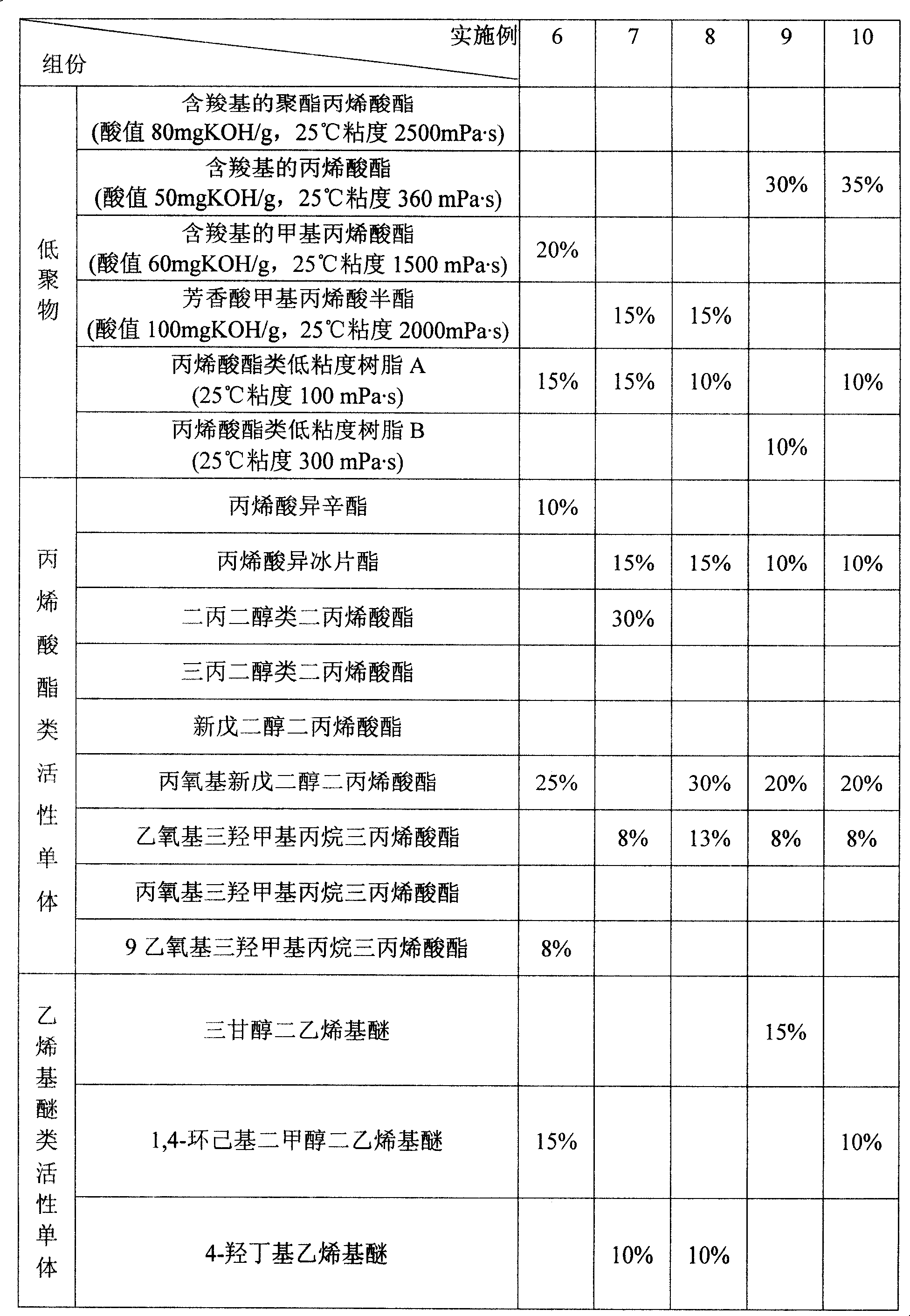

InactiveCN101201543ASimple preparation processMeet needsPhotosensitive materials for photomechanical apparatusResistOligomer

The invention relates to light-cured ink-jet resist for a print circuit board and a preparation method thereof. By adopting the solidification way of mixing acrylic oligomer containing carboxyl, acrylic low viscosity resin as well as free radical and cation, the resist has good film detachment, short solidification time and high resolving capability; the technology of ink-jet can be adopted to spray the ink-jet resist on the special area of a copper-clad plate and an anti-etching image can be formed after light-curing. The manufactured solidified film has high hardness and good flexibility as well as good anti-etching property.

Owner:BEIJING UNIV OF CHEM TECH

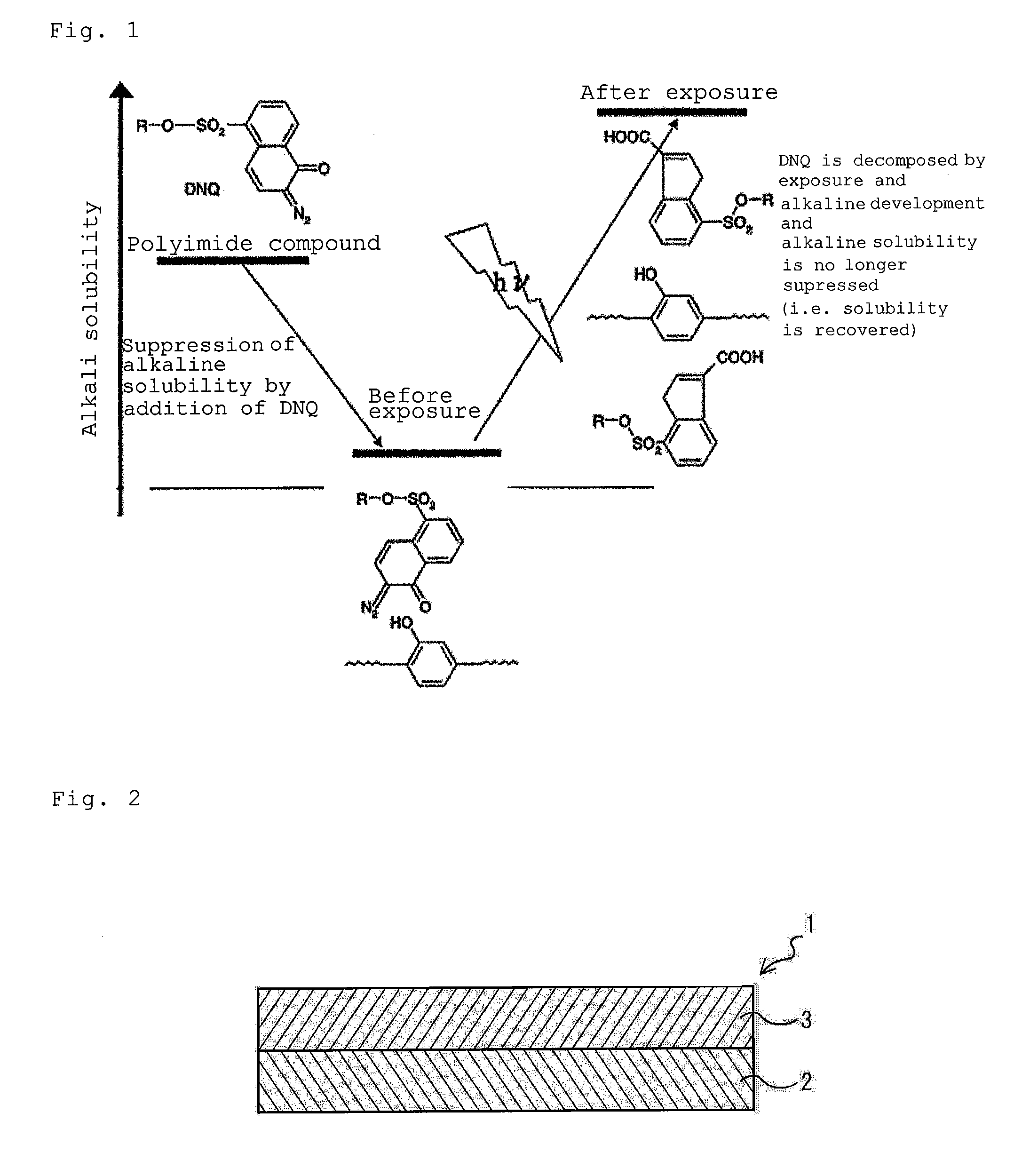

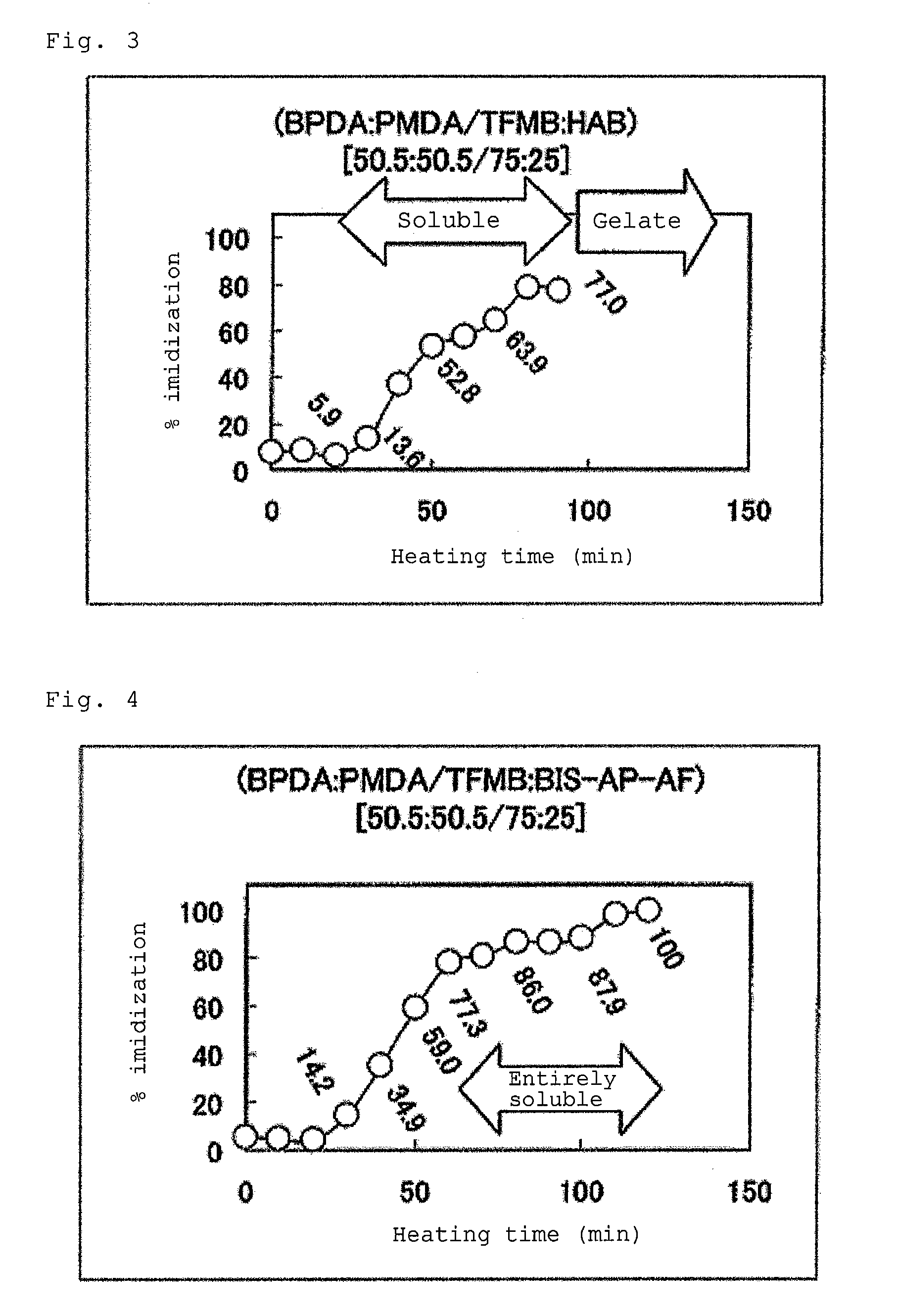

Polyimide Compound And Flexible Wiring Board

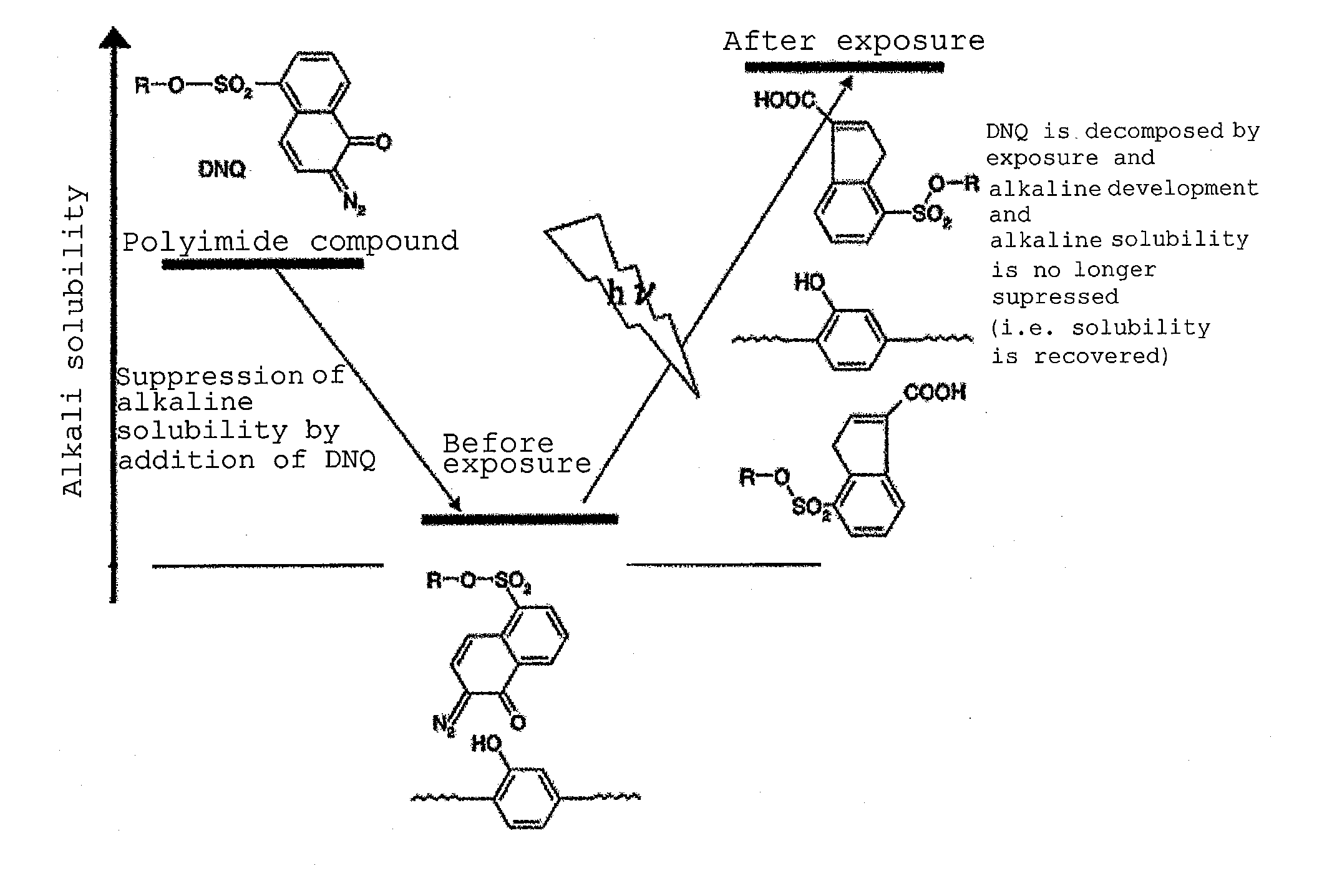

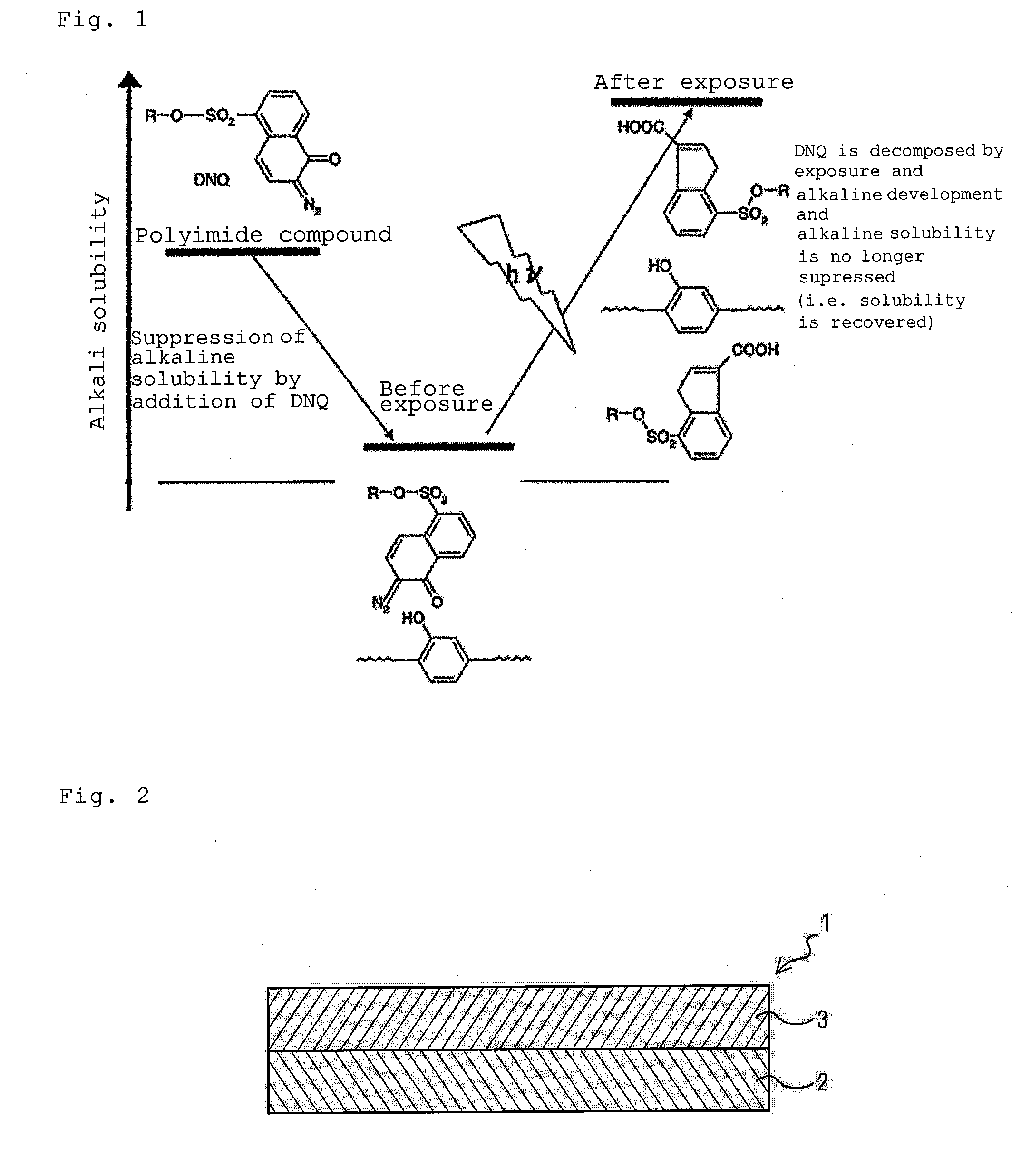

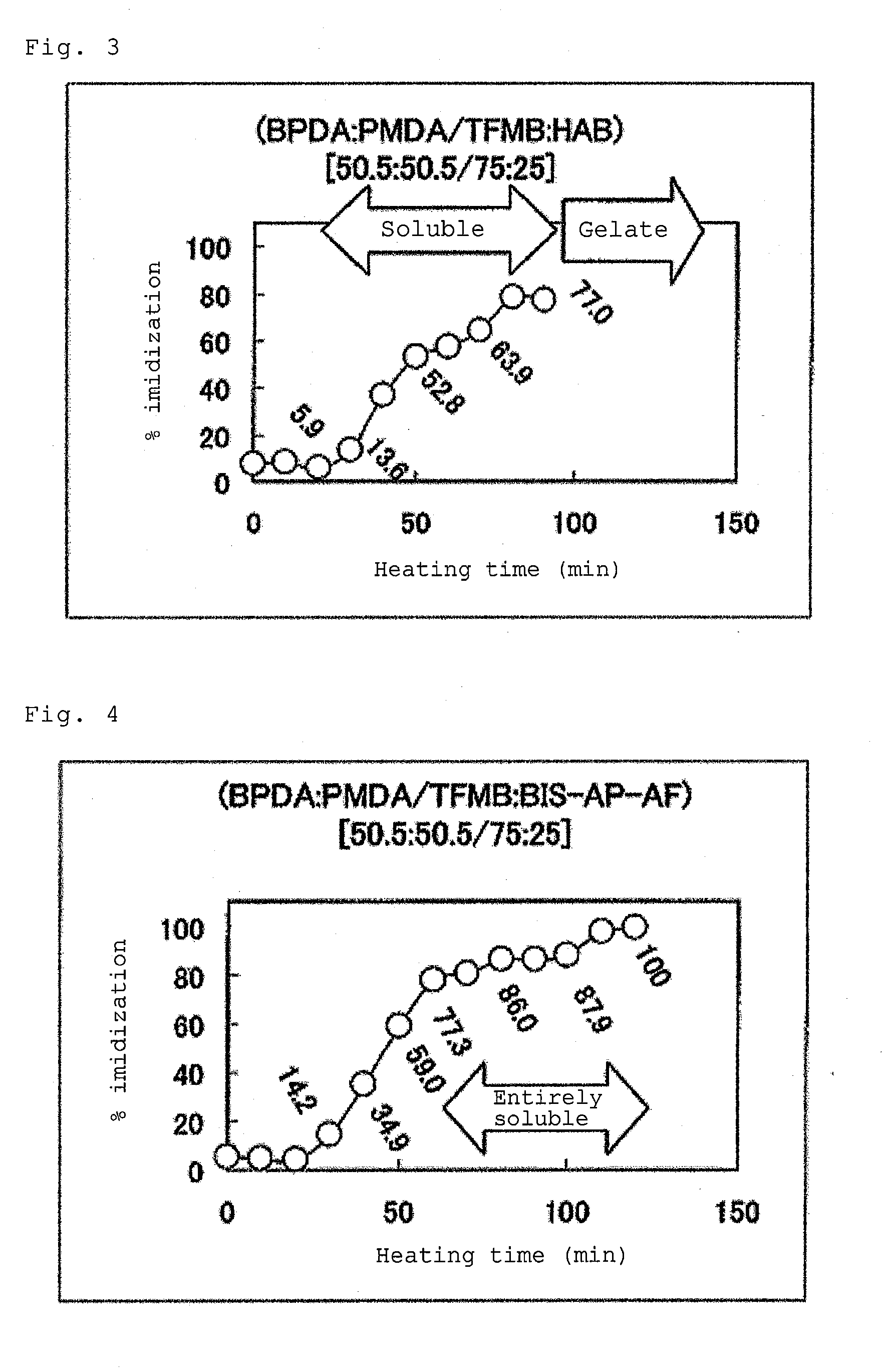

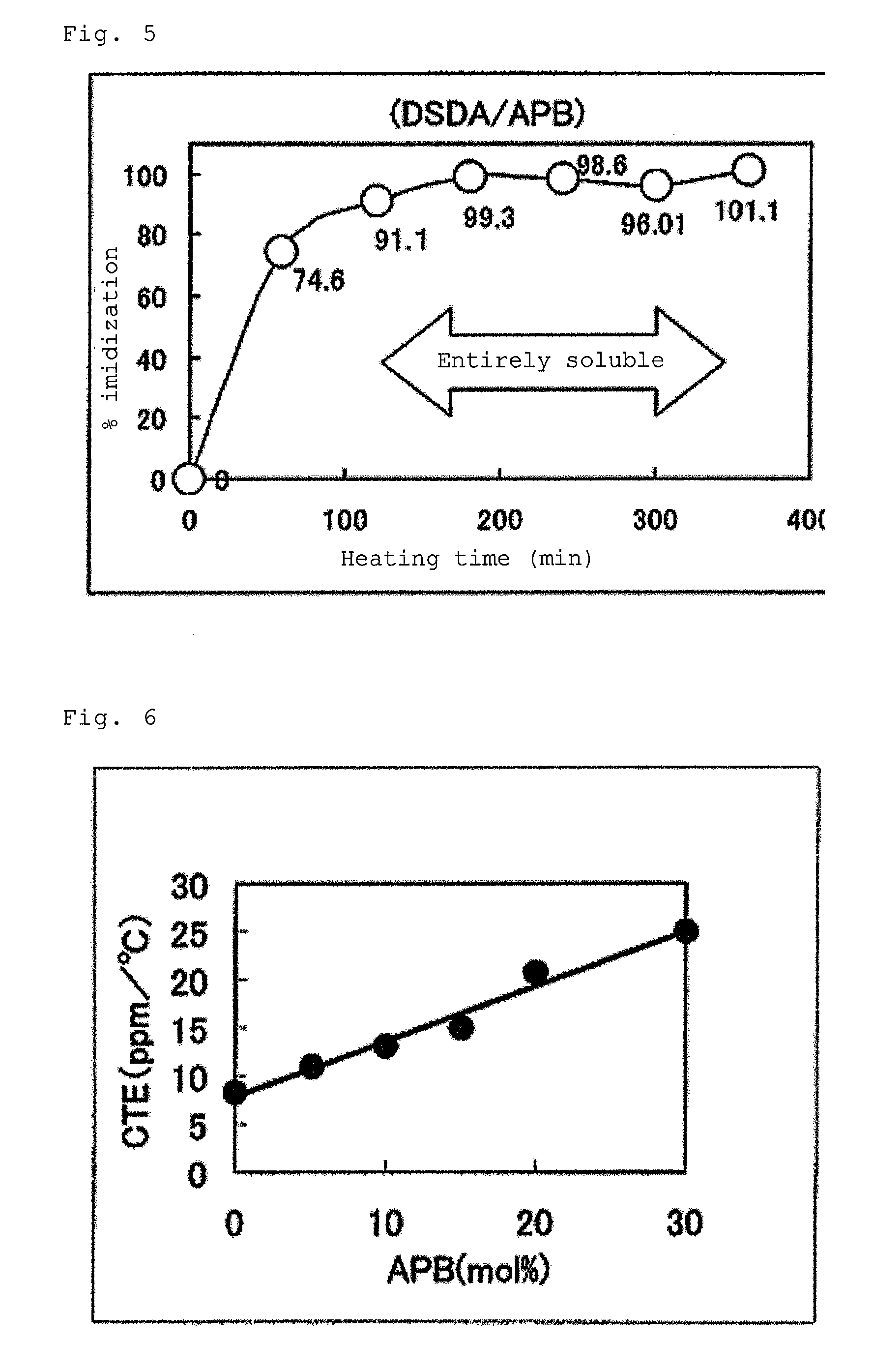

ActiveUS20080090927A1Reduce Shrinkage ProblemsLower glass transition temperaturePhotomechanical apparatusDiazo compound compositionsElectrical conductorThermal expansion

A polyimide compound has a low coefficient of linear thermal expansion comparable to the coefficient of linear thermal expansion of a conductor to be covered by the polyimide. The polyimide compound is less susceptible to contraction caused by dehydration process. The compound is obtained by the reaction of a highly linear acid dianhydride with a highly linear diamine and has a high imidization rate. Having a low coefficient of linear thermal expansion comparable to the conductor to be covered by the polyimide, the polyimide compound of the present invention is less susceptible to contraction that occurs during polyimide formation. The polyimide compound is suitable for making curl-free flexible wiring boards.

Owner:SONY CORP +1

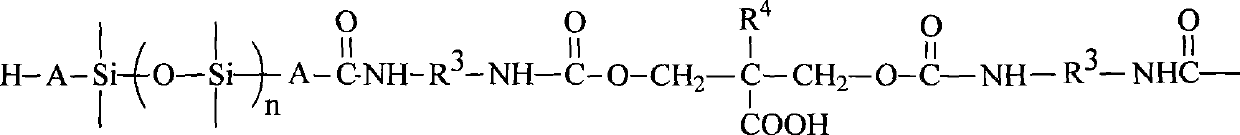

Alkali soluble light-sensitive organosilicon preformed polymer and preparation method thereof

InactiveCN101392062AGood alkali solubilityIncrease photosensitivityPhotomechanical apparatusInksSolubilityCarboxylic acid

The invention discloses an alkaline-solubility photosensitive organic silicon prepolymer and a preparation method thereof. The preparation method includes the following steps: (1) epoxide, a polymerization inhibitor 1, a catalyzer 1 and an olefinic monomer which can react with a epoxide group are added into a first reactor and react at 80 DEG C to 100 DEG C for 5 hours to 7 hours; (2) organic silicon, polybasic isocyanate, carboxylic acid or acid anhydride containing an active group, a polymerization inhibitor 2 and a catalyzer 2 are added into a second reactor at 50 DEG C to 80 DEG C for 5 hours to 8 hours, and then products obtained in the step (1) are added into the second reactor for reaction till termination; and (3) temperature is reduced to the room temperature and then materials are discharged and stored and reserved away from light. The organic silicon prepolymer of the invention has the advantages that: (1) the synthesized photosensitive organic silicon prepolymer has comparatively good resistance to high temperature as well as good light sensitivity and flexibility; (2) solder mask ink prepared by the prepolymer is developed by weak alkali liquor so as to avoid environmental pollution caused by mass use of organic solvents; and (3) the invention has simple synthetic method, easy operation and low-cost and easily available materials.

Owner:BEIJING UNIV OF CHEM TECH

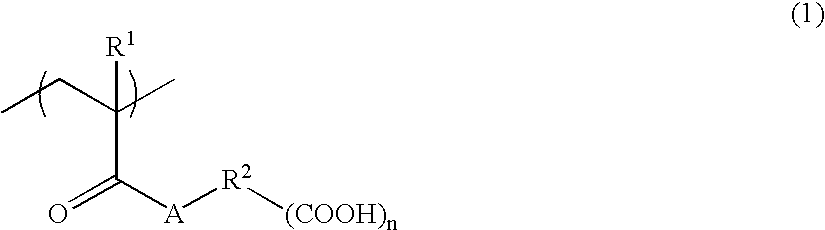

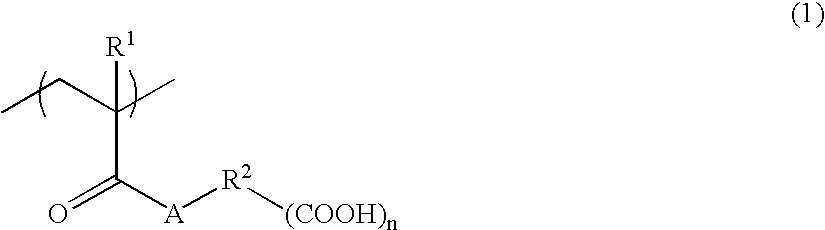

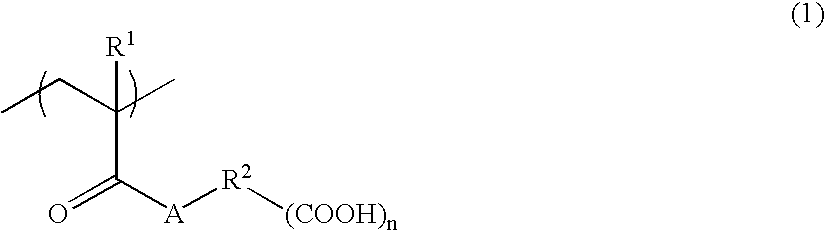

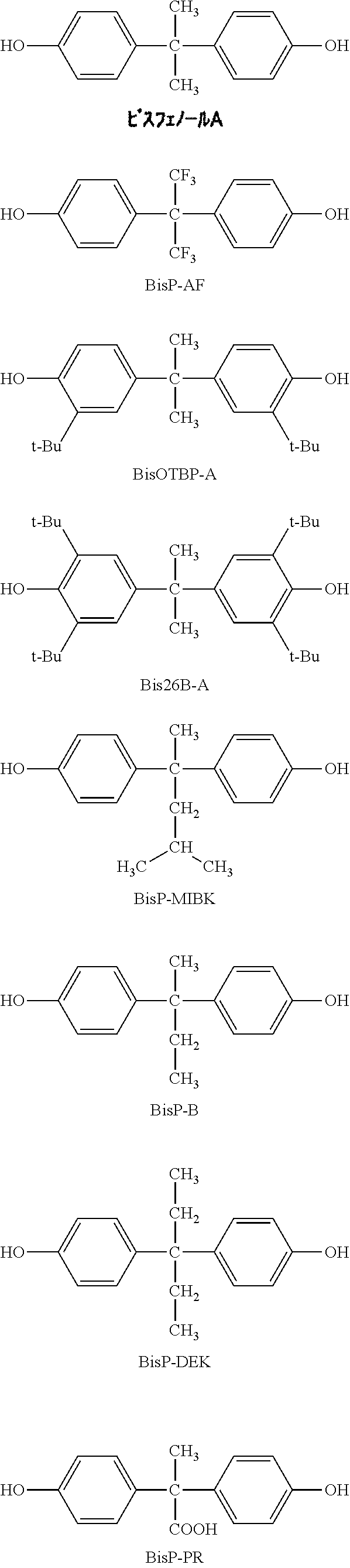

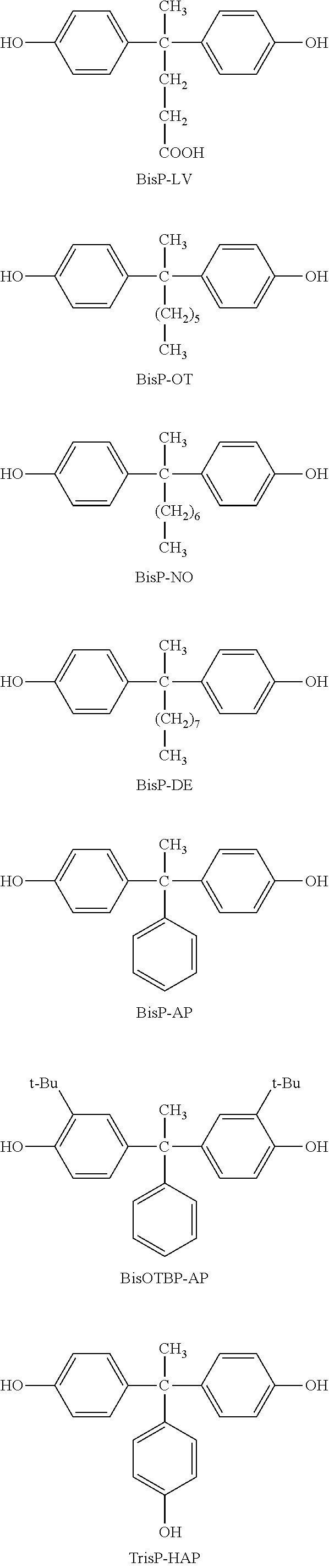

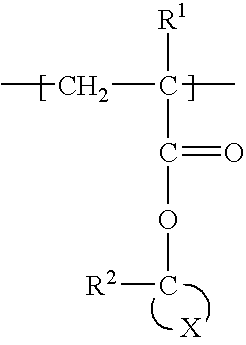

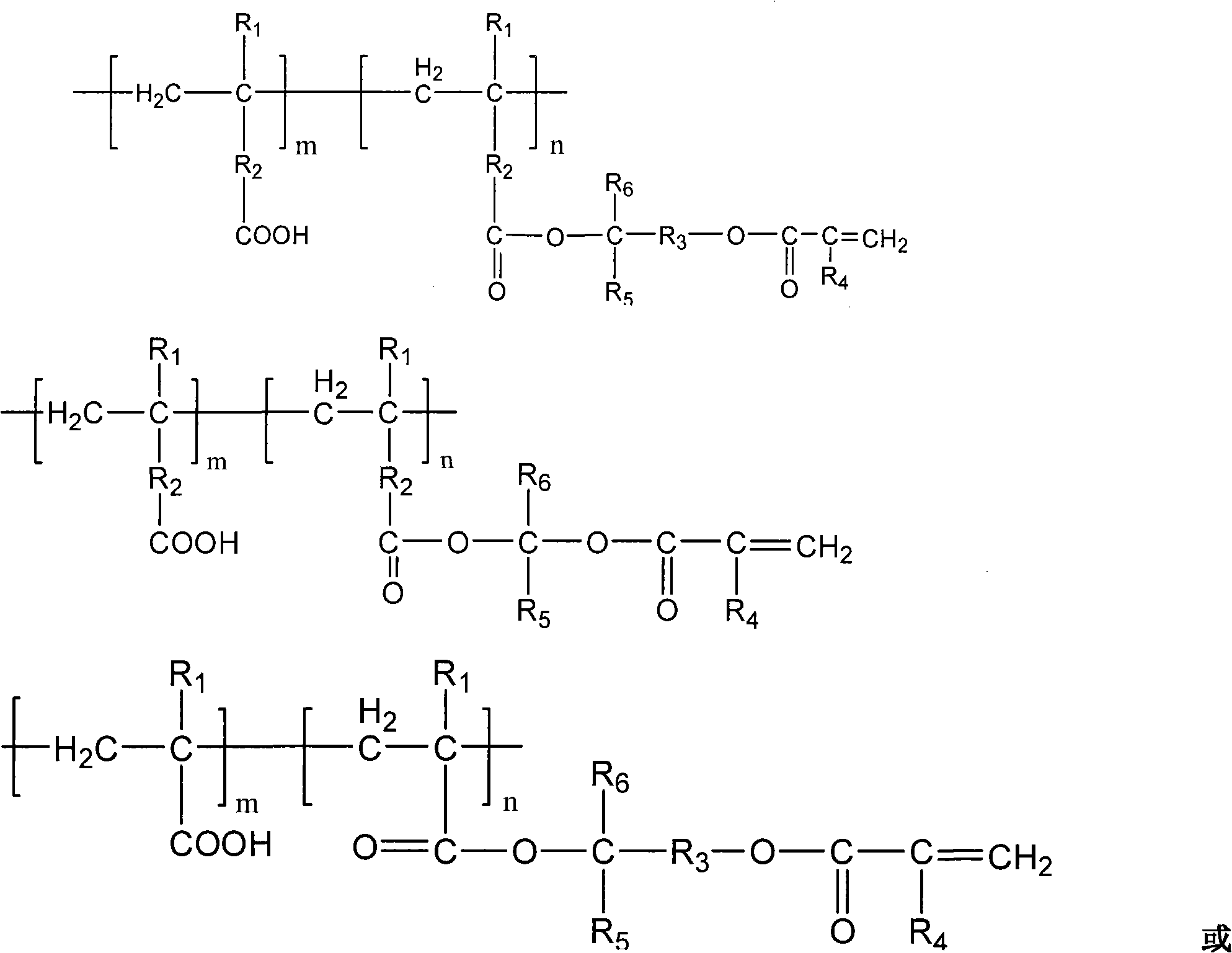

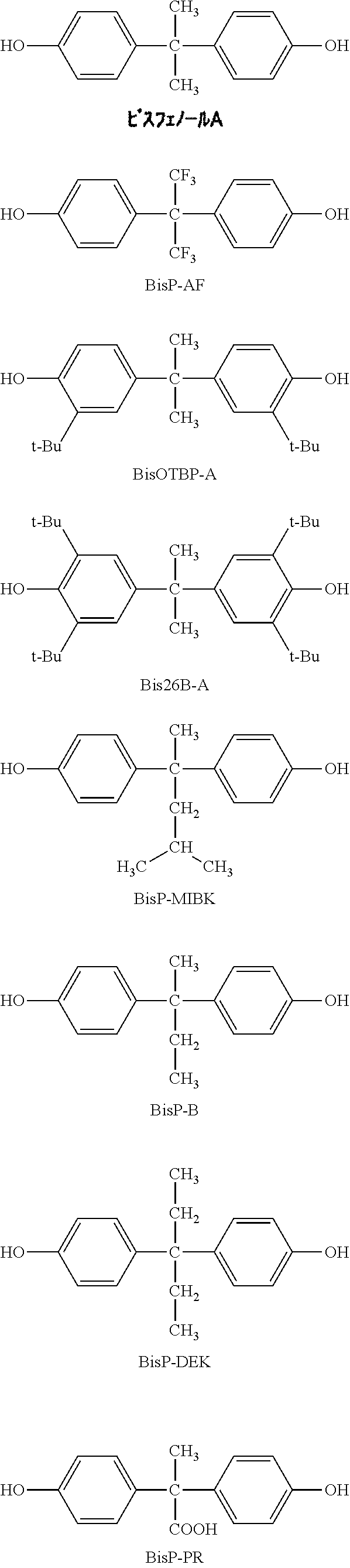

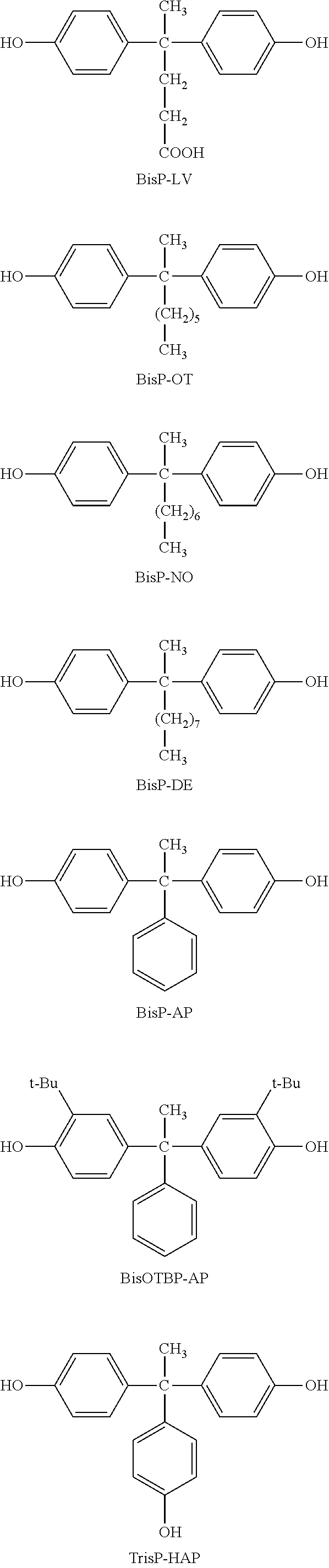

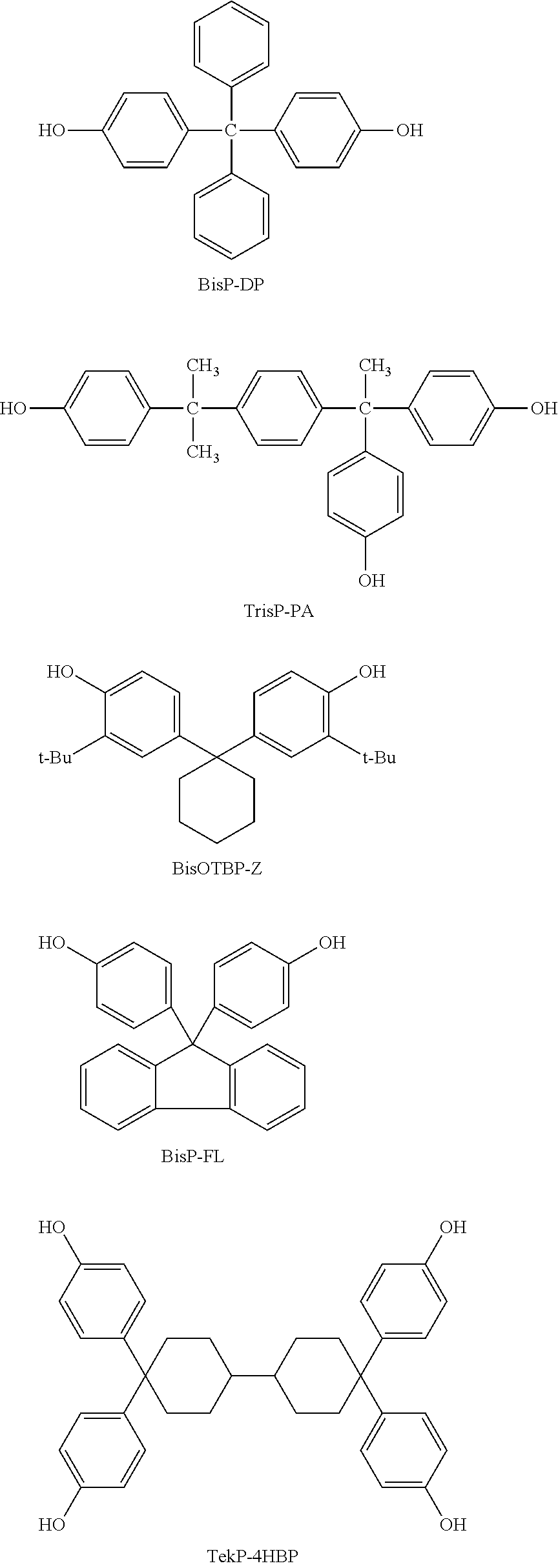

Alkali-soluble polymer and polymerizable composition thereof

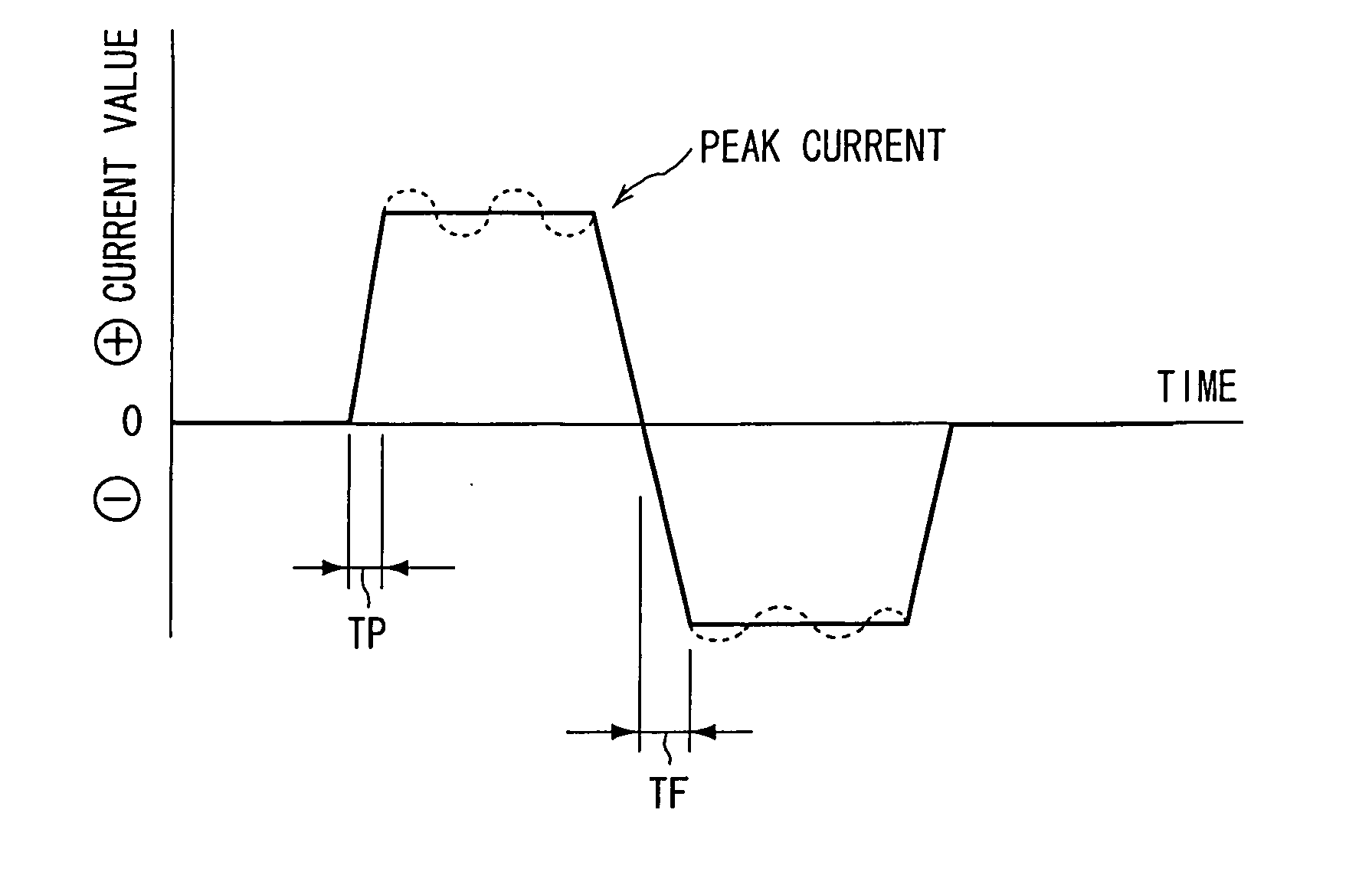

ActiveUS7122293B2Good alkali solubilityEnhance layeringRadiation applicationsSemiconductor/solid-state device manufacturingPolymer dissolutionAlkaline water

Owner:FUJIFILM CORP +1

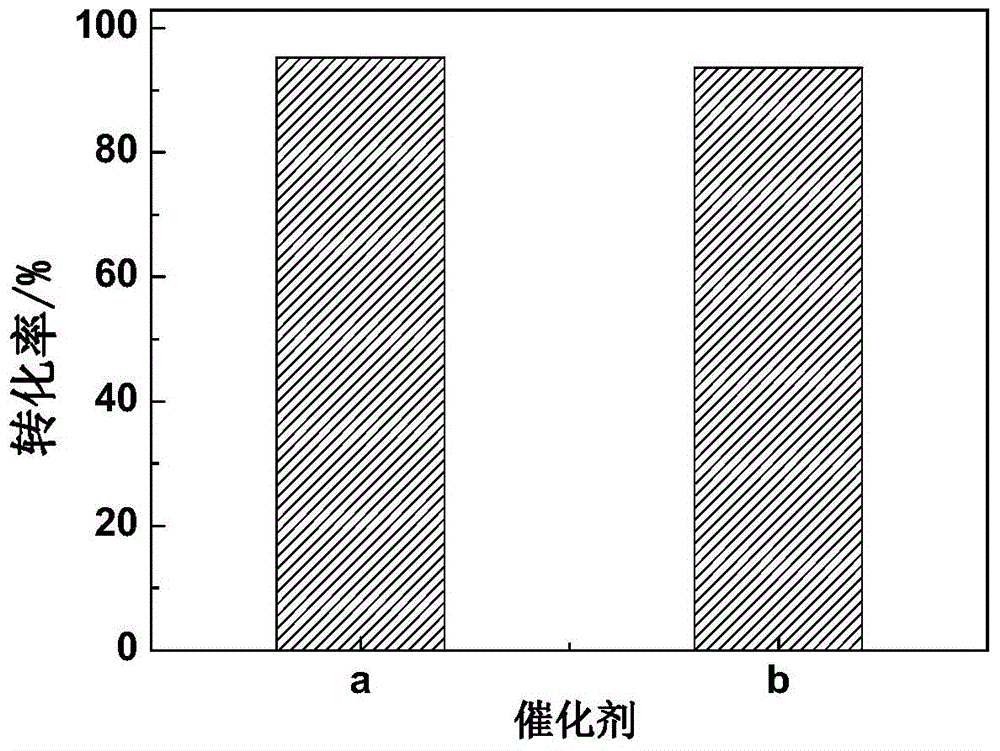

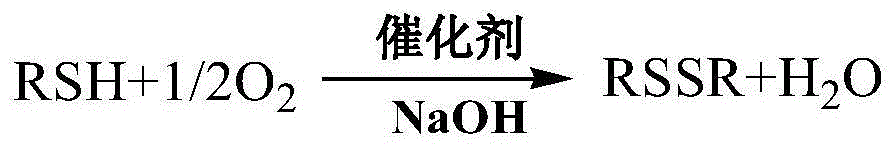

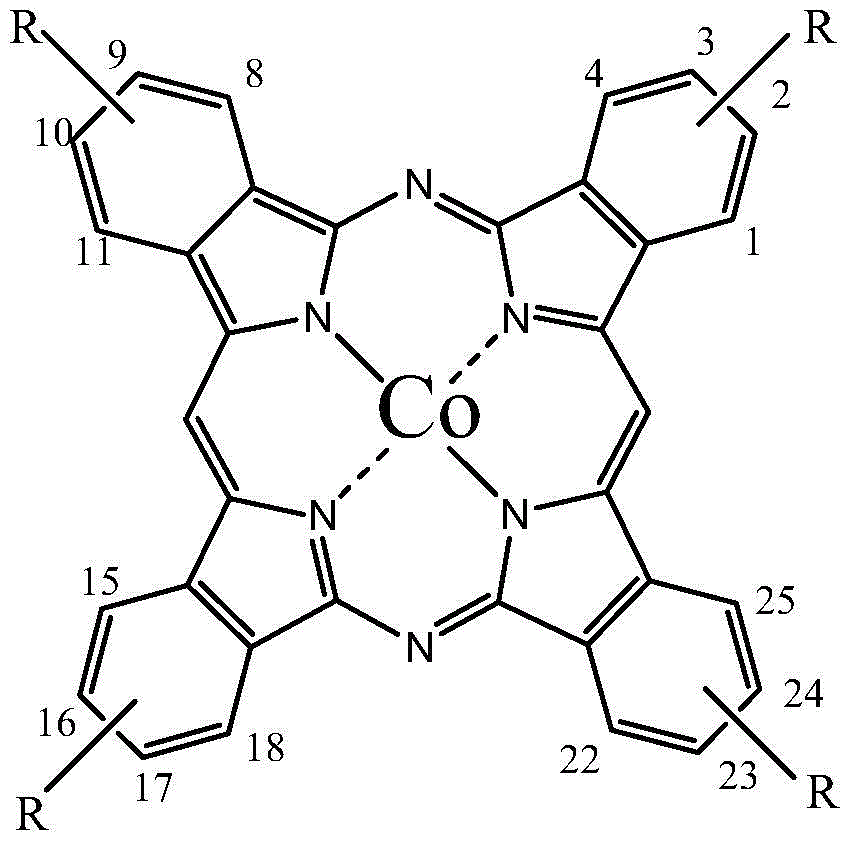

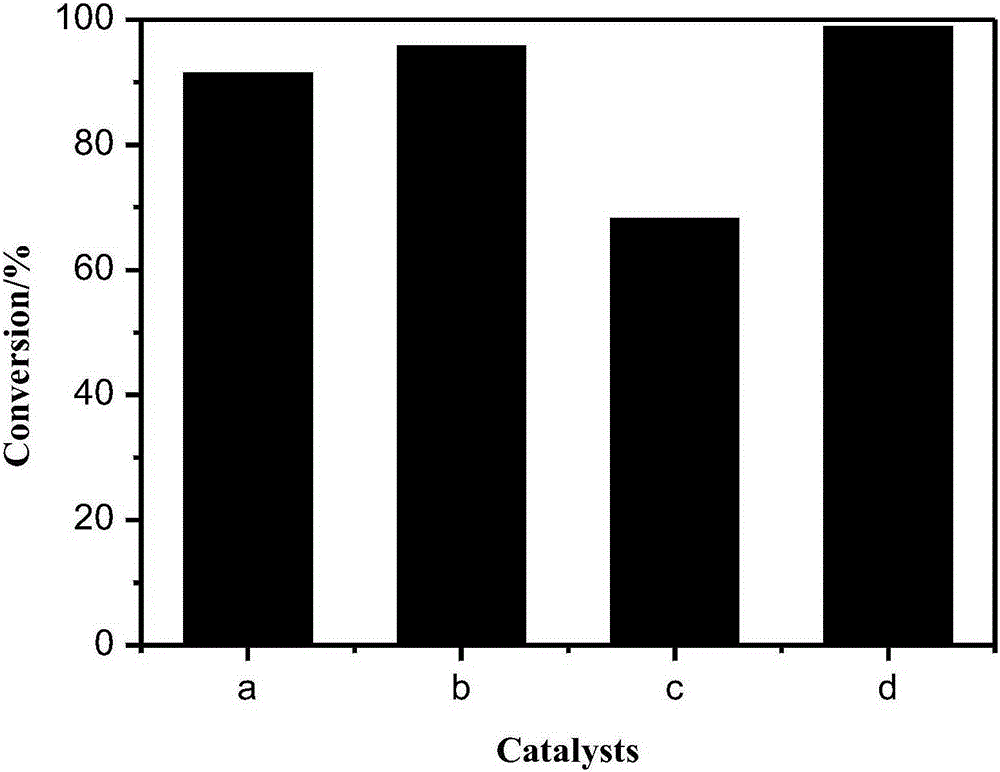

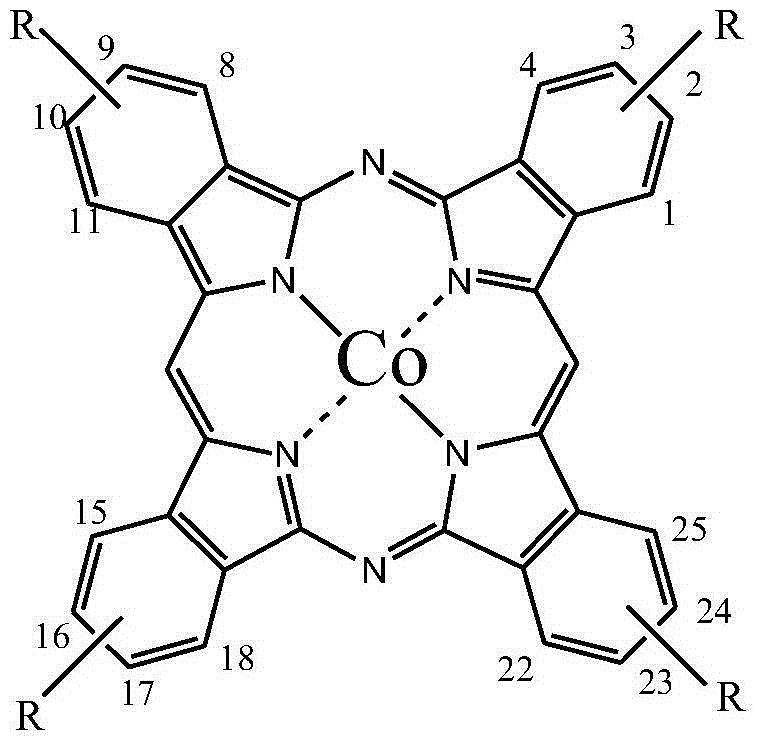

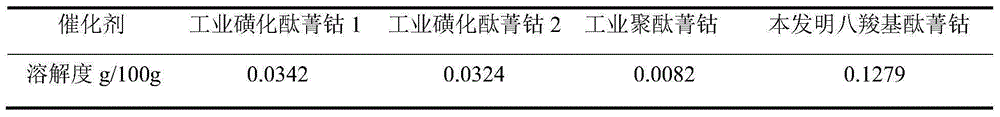

Liquid cobalt sulfonated phthalocyanine catalyst for liquefied petroleum gas mercaptan removal

ActiveCN104785296AImprove solubilityGood water solubilityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPhthalocyanineCobalt

The invention discloses a liquid cobalt sulfonated phthalocyanine catalyst for liquefied petroleum gas mercaptan removal; the liquid catalyst is composed of an active component tetra-beta-p-sulfonic phenoxy phthalocyanine cobalt, a stabilizer propylene glycol dimethyl ether, one or a combination of N-methyl diethanolamine or triethanolamine, an emulsifier octadecyl dimethyl benzyl ammonium chloride and an NaOH solution. The invention also discloses a tetra-beta-p-sulfonic phenoxy phthalocyanine cobalt structure designed for the first time, and a catalytic conversion effect of the liquid catalyst on liquefied gas mercaptan. The catalyst active component tetra-beta-p-sulfonic phenoxy phthalocyanine cobalt has extremely good solubility in water and alkali liquids, and has higher mercaptan removal activity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Photosensitive siloxane resin composition

ActiveUS20140335448A1Good alkali solubilityHigh sensitivityPhotosensitive materialsSemiconductor/solid-state device manufacturingSolubilityOrganic solvent

[Object] To provide a photosensitive siloxane resin composition excellent in alkali-solubility and in sensitivity, and also to provide a pattern-formation method employing that.[Means] The present invention provides a photosensitive siloxane resin composition comprising: a siloxane resin having silanol groups or alkoxysilyl groups, a crown ether, a photosensitive material, and an organic solvent. This photosensitive composition is cast on a substrate, subjected to imagewise exposure, treated with an alkali aqueous solution, and cured to form a pattern.

Owner:MERCK PATENT GMBH

Chemically amplified positive-type photoresist composition for thick film, and method for producing thick film resist pattern

InactiveUS20120141940A1Good alkali solubilityPhotosensitive materialsPhotomechanical exposure apparatusResistSolubility

A chemically amplified positive-type photoresist composition for a thick film capable of forming a thick film resist pattern having superior resolving ability and controllability of dimensions, and being favorable in rectangularity, as well as a method for producing a thick film resist pattern using such a composition. The photoresist composition comprises an acid generator including a cationic moiety and an anionic moiety, and a resin whose alkali solubility increases by the action of an acid.

Owner:TOKYO OHKA KOGYO CO LTD

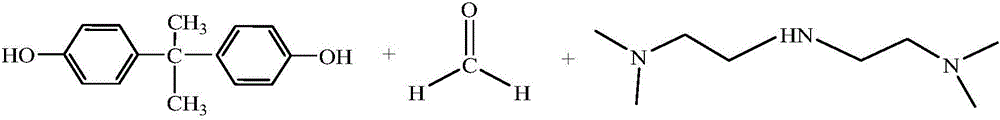

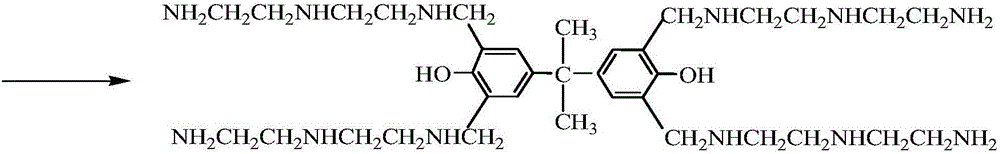

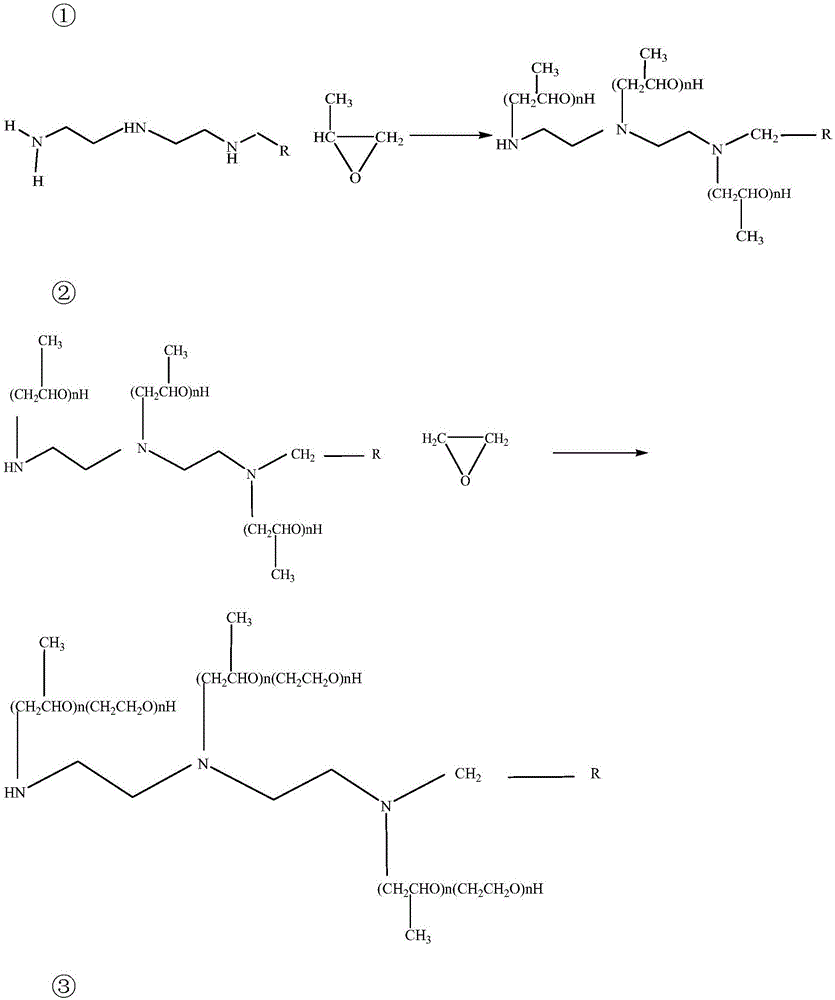

Preparation method of low-temperature demulsifier and low-temperature demulsifier prepared by means of method

InactiveCN106700059AGood alkali solubilityGood water performanceDewatering/demulsification with chemical meansHydrocarbon oils treatmentDemulsifierSolubility

The invention discloses a preparation method of a phenol amine aldehyde block polyether low-temperature demulsifier and the low-temperature demulsifier prepared by means of the method. The method comprises the following steps: firstly performing condensation polymerization on a phenol matter, an amine matter and an aldehyde matter to prepare phenol amine aldehyde resin; and then performing a reaction with an epoxy compound to obtain final product. The demulsifier prepared by the preparation method disclosed by the invention has the advantages of being good in alkaline solubility, good in cleaning effect, free of irritant smells, convenient for field use and the like. The most applicable temperature is 45 DEG C, but the demulsifier still has a relatively good effect when the temperature is low to 41 DEG C. The demulsifier has an excellent demulsifying effect, has a good effect on the condition that the demulsifying difficulty of a low-temperature produced liquid of crude oil in a superficial layer is great and the oil content of the demulsified aqueous phase is great, and is suitable for the condition that the demulsifying difficulty of the produced liquid at the low temperature is great and the oil content of the demulsified aqueous phase is great.

Owner:滨州市丰泰技术开发有限公司

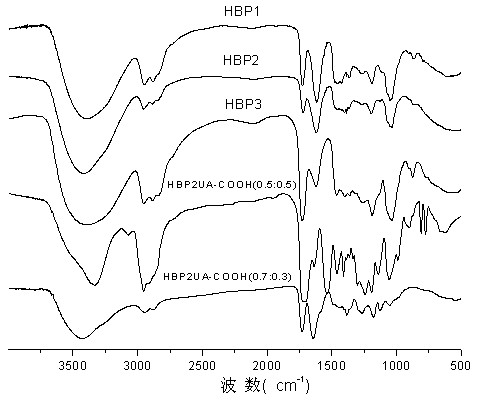

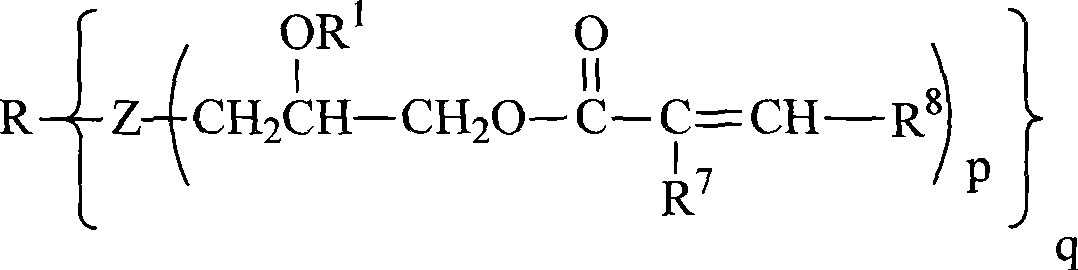

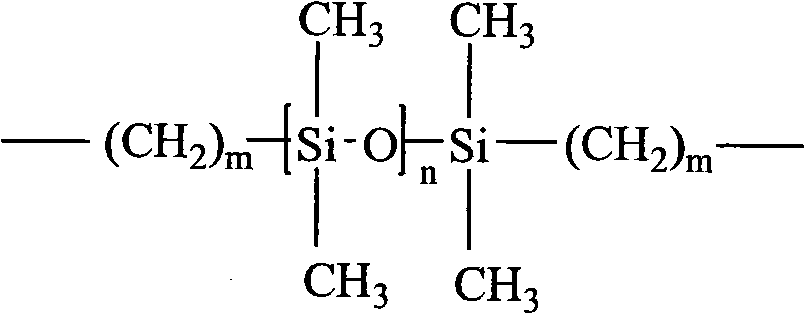

Alkali-soluble hyperbranched photosensitive organic silicon prepolymer and preparation method thereof

The invention discloses alkali-soluble hyperbranched photosensitive organic silicon prepolymer and a preparation method thereof. The preparation method comprises the following steps of: (1) adding organic silicon, polyisocyanate, carboxylic acid or anhydride containing an active group and a catalyst to a first reactor and reacting for 3-7 hours at the temperature of 50-60 DEG C; (2) adding a hydroxyl-ended hyperbranched polymer (HPB-OH) and a catalyst to a second reactor, then, adding a product in the first step, and reacting for 2-5 hours at the temperature of 30-70 DEG C; (3) adding the polyisocyanate, a gadoleic acid-hydroxyl ester compound, the catalyst and a polymerization inhibitor to a third reactor, and reacting for 5-8 hours at the temperature of 40-80 DEG C; (4) reacting the product in the second step, the product in the third step, the catalyst and the polymerization inhibitor for 2-6 hours at 30-80 DEG C; and (5) cooling to room temperature, discharging and keeping in a dark place for standby. The invention has the advantages that: (1) the synthesized alkali-soluble hyperbranched photosensitive organic silicon prepolymer has better high temperature resistance, better photosensitivity, better flexibility, higher light reaction activity and lower viscosity; (2) solder resist ink prepared by the prepolymer is developed by a diluted alkali solution, therefore, the environmental pollution caused by largely using an organic solvent is avoided; and (3) the synthetic method is simple and is easy to operate, and raw materials are cheap and are easy to obtain.

Owner:BEIJING UNIV OF CHEM TECH

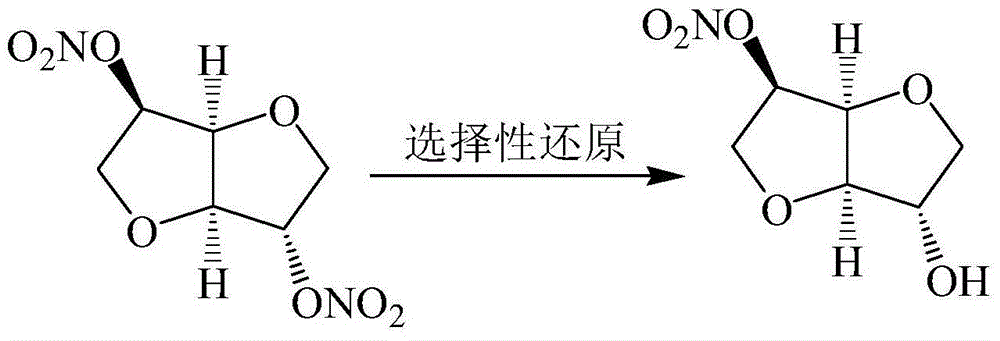

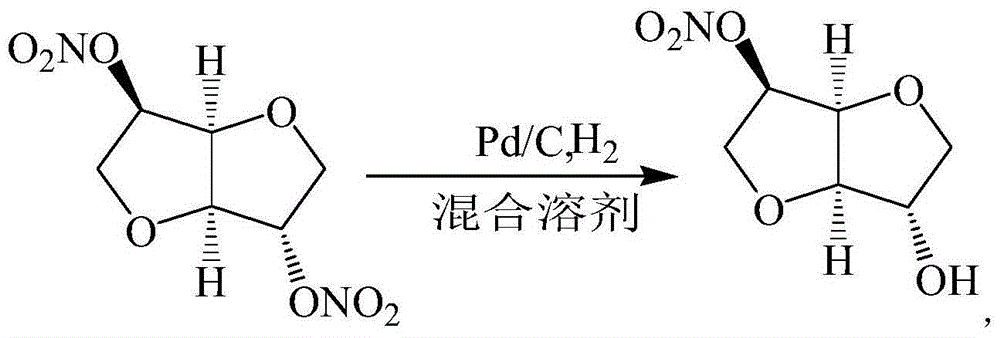

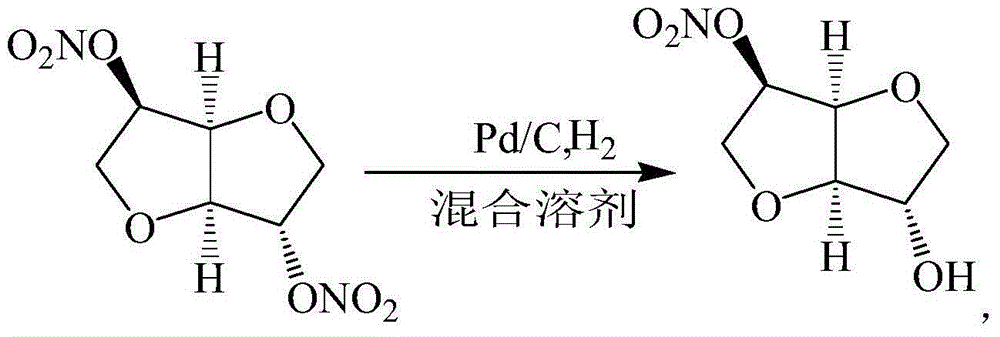

Preparation method for isosorbide 5-mononitrate

ActiveCN104892623AHigh yieldReduce manufacturing costOrganic chemistryIsosorbide-5-mononitrateSolvent

The invention provides a preparation method for isosorbide 5-mononitrate. The preparation method comprises the following steps: with isosorbide dinitrate as a raw materials and Pd / C as a catalyst in a special mixed solvent, carrying out selective hydrogenation reduction on 2-nitro, filtering after reaction, steaming to remove ethyl alcohol in filtrate, extracting residual concentrated liquid through ethyl acetate, washing extracting liquid through dilute acid, washing to be neutral through water, drying through anhydrous magnesium sulfate, filtering to remove a drying agent and steaming to remove ethyl acetate so as to obtain high-purity isosorbide 5-mononitrate. Compared with the prior art, the synthetic method provided by the invention is simple and easy to operate, impurities are easy to remove, the yield and purity are higher, the cost is reduced since the Pd / C and the solvent can be recycled and reused, isosorbide generated through over reduction can be recycled and the preparation method is suitable for industrial production.

Owner:SHANDONG NEWTIME PHARMA

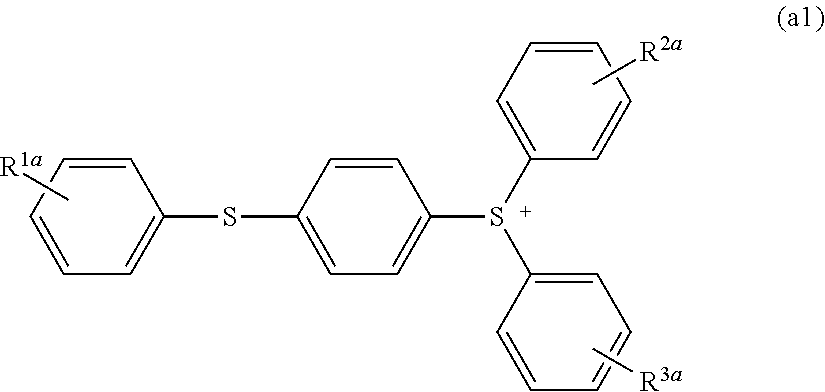

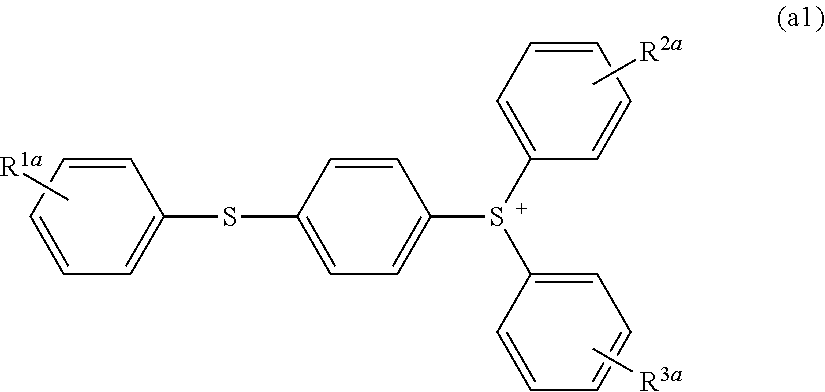

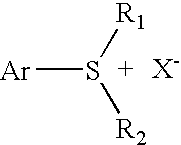

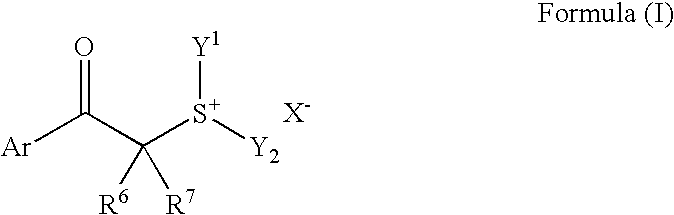

Lithographic printing starting plate

ActiveUS20050064340A1Excellent developing latitudeHigh sensitivityRadiation applicationsSemiconductor/solid-state device manufacturingOrganic acidAqueous solution

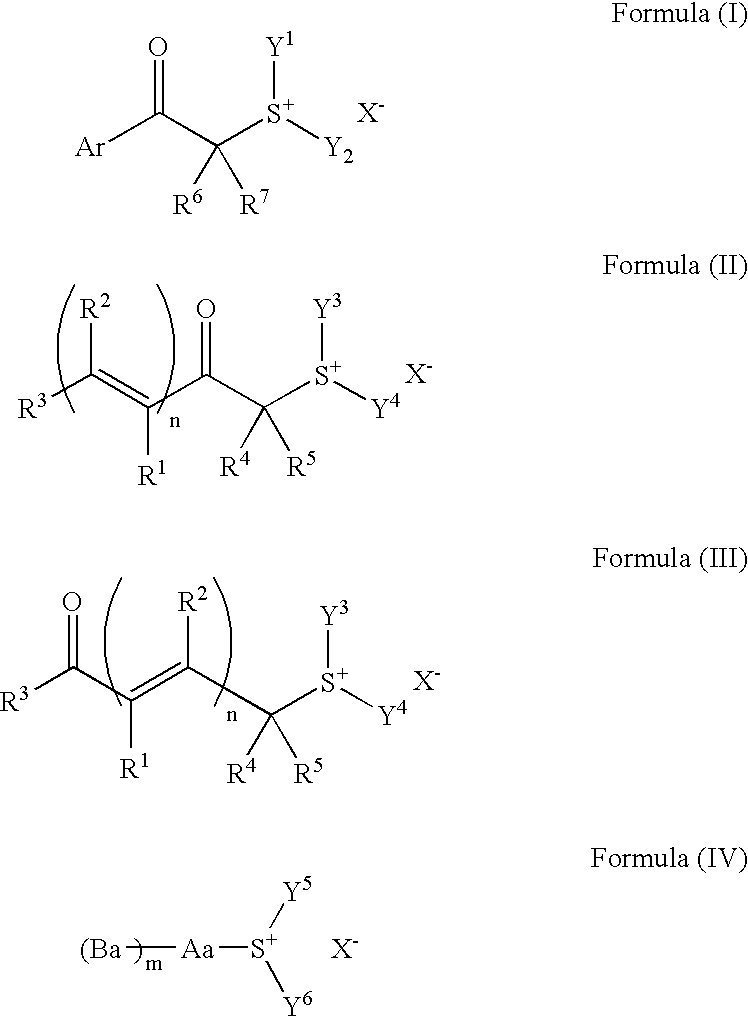

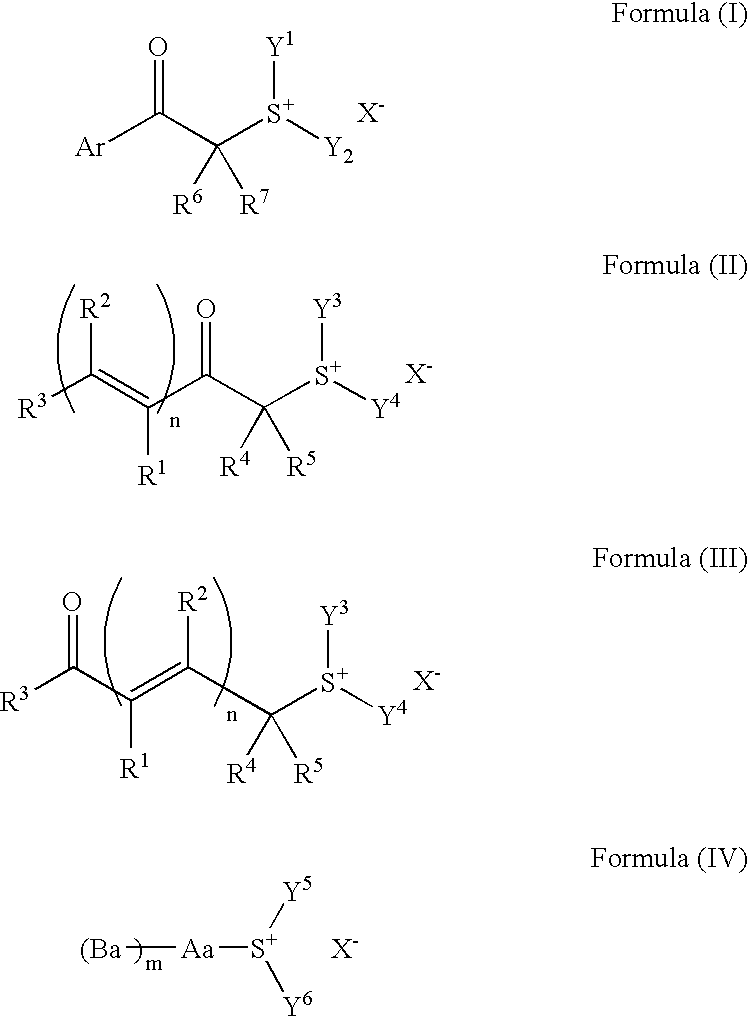

A positive-working lithographic printing starting plate for an infrared laser is provided that includes a support having a hydrophilic surface and a heat-sensitive layer provided above the support. The heat-sensitive layer includes a water-insoluble and alkali-soluble resin, an infrared-absorbing dye, and a sulfonium salt represented by Formula below. The heat-sensitive layer increases its solubility in aqueous alkaline solution upon exposure to an infrared laser. (In the formula, R1 and R2 independently denote an optionally substituted alkyl group having 1 to 12 carbons, an optionally substituted cycloalkyl group having 3 to 8 carbons, an optionally substituted aralkyl group having 7 to 12 carbons, or an optionally substituted aryl group having 6 to 15 carbons, R1 and R2 may bond to each other to form a cyclic structure; Ar denotes an optionally substituted aromatic hydrocarbon group having 6 to 15 carbons and having at least one OH group at the ortho- and / or para-position; and X− denotes an anion of an organic acid.)

Owner:FUJIFILM HLDG CORP +1

Chemical-amplification positive-working photoresist composition

InactiveUS20050170276A1Reduce solubilityAlkali-solubility of the copolymeric resin is increasedPhotomechanical apparatusSemiconductor/solid-state device manufacturingSolubilityResist

Disclosed is a chemical-amplification positive-working photoresist composition having compliability to various types of resist patterns with excellent sensitivity and pattern resolution exhibiting high exposure margin and focusing depth latitude. Of the essential components including (A) a resin capable of being imparted with increased alkali-solubility by interacting with an acid and (B) an acid-generating compound, the component (A) is a combination of (a1) a first resin and (a2) a second resin each as a hydroxystyrene-based copolymeric resin partially substituted for the hydroxyl hydrogen atoms with acid-dissociable solubility-reducing substituent groups. Characteristically, in addition to the difference in the mass-average molecular weight being high for (a1) and low for (a2), the acid-dissociability of the substituents in the (a1) resin is higher than that in the (a2) resin as in a combination of 1-ethoxyethyl for (a1) and tetrahydropyranyl for (a2).

Owner:TOKYO OHKA KOGYO CO LTD

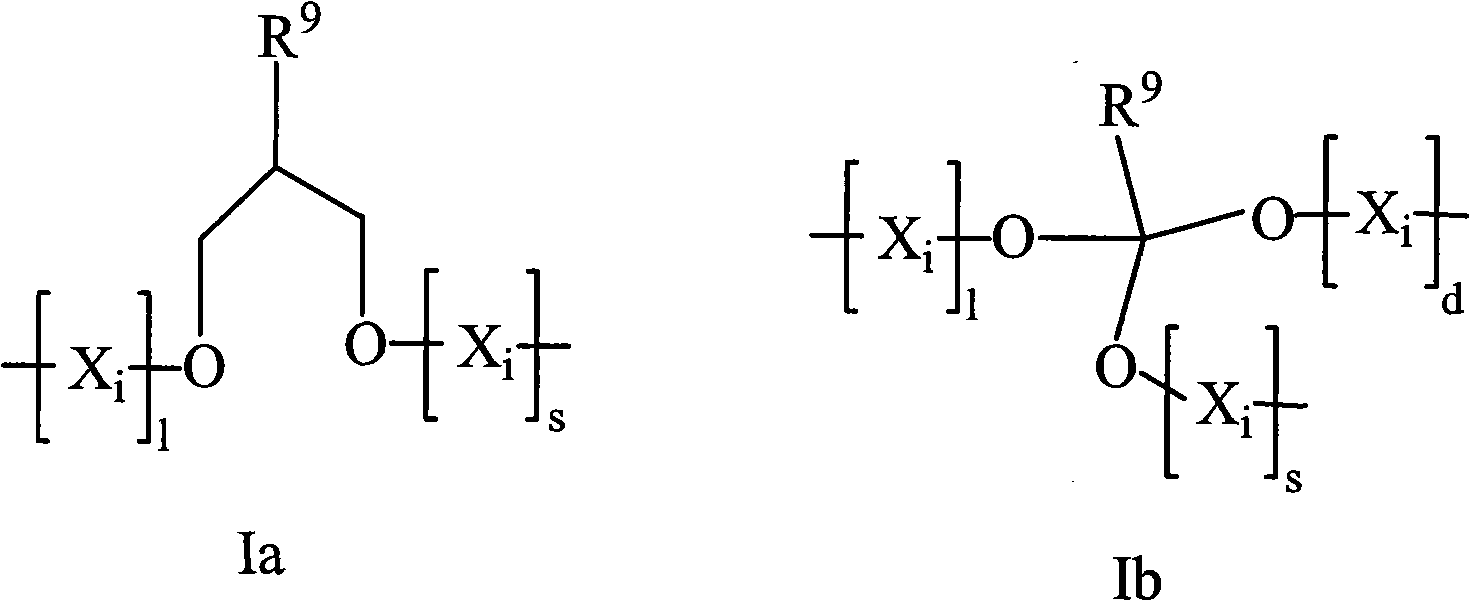

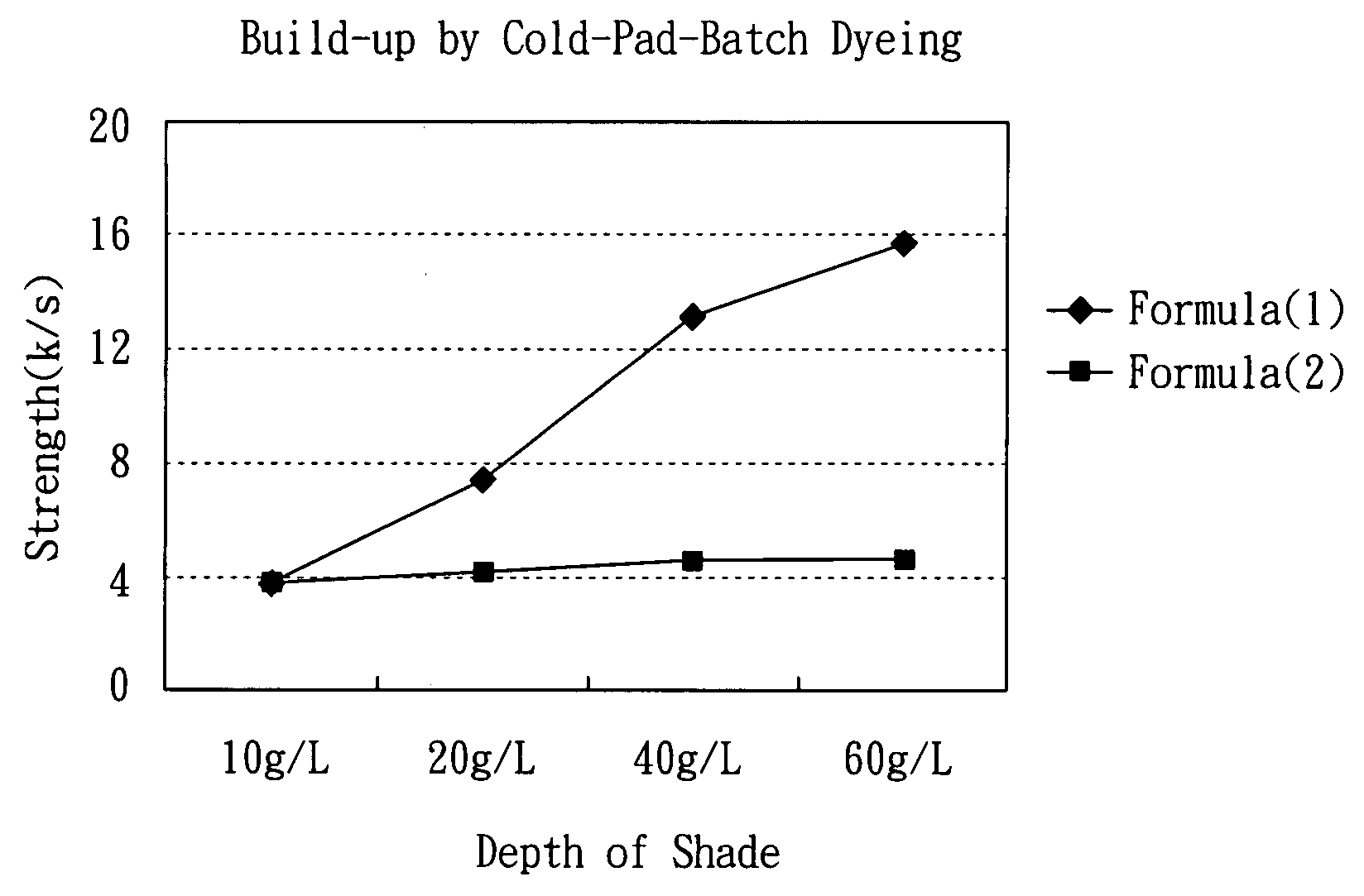

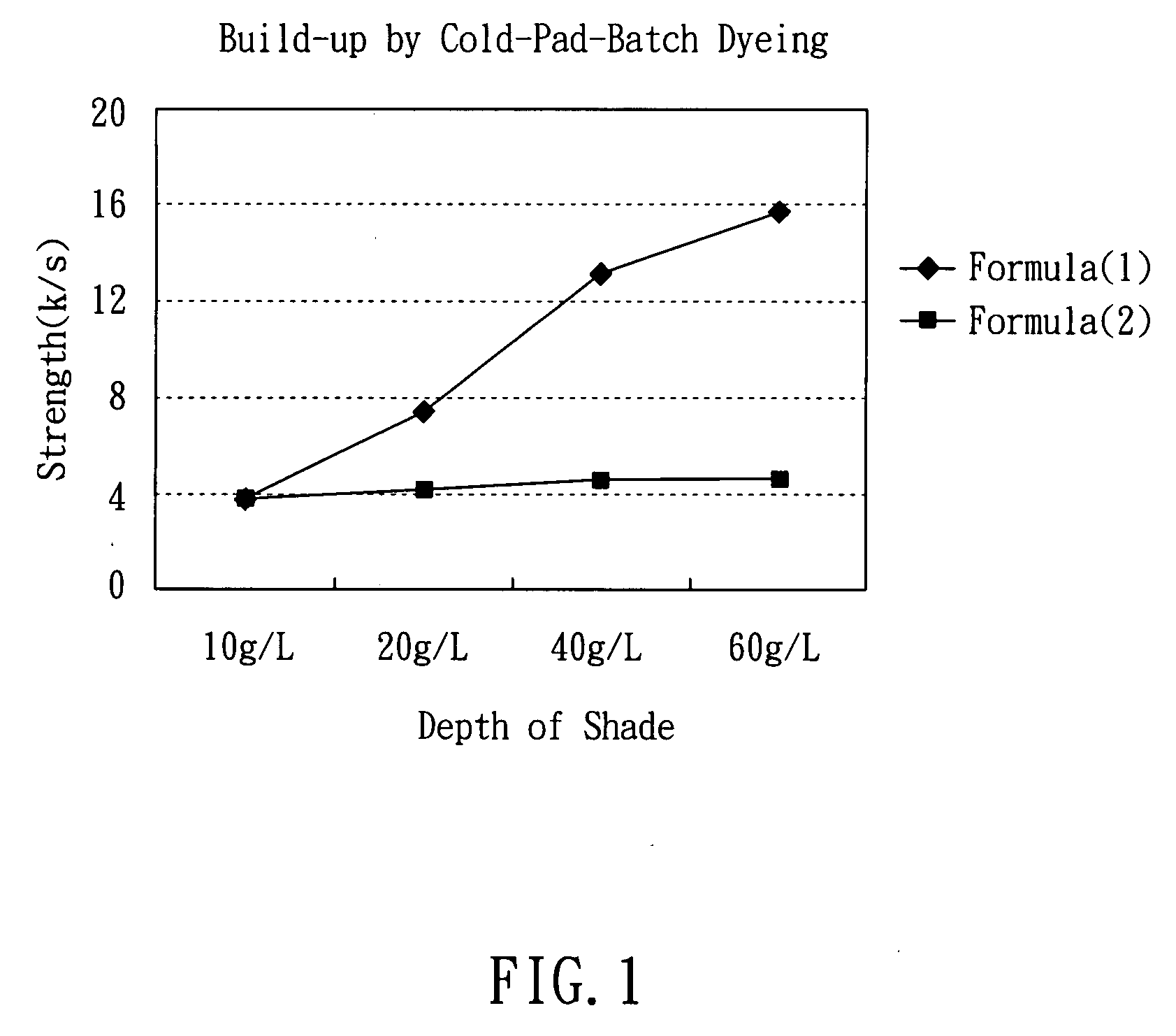

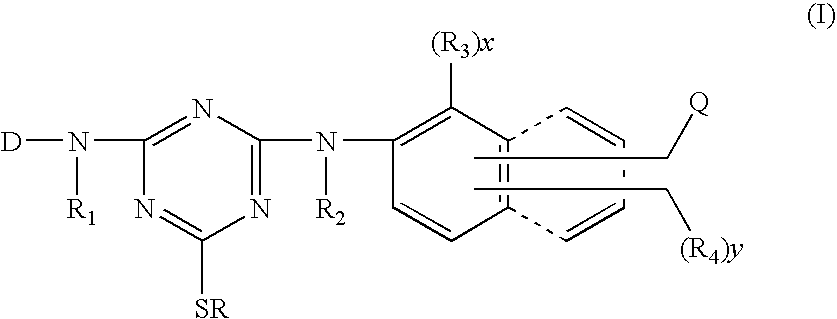

Reactive dyestuffs with alkylthio group and beta-sulfatoethysulfone group

InactiveUS20090018317A1Easy to fixGood body shapeMonoazo dyesOrganic chemistrySolubilityCellulose fiber

The present invention provides a reactive dyestuff with an alkylthio group and a β-sulfatoethylsulfone group, which is represented by formula (I),wherein D, R, R1, R2, R3, R4, Q, x, and y are defined the same as the specification. The reactive dyestuffs of the present invention not only have characteristics of high solubility, high alkali solubility, and easily being washed off for dyeing cellulose fiber, but also are suitably applied in cold-pad-batch dyeing, continuous-dyeing, printing, and digital printing.

Owner:EVERLIGHT USA INC

Positive-working photoresist composition for thick film formation

ActiveUS20080026321A1Improve adaptabilityExcellent peelabilityOrganic chemistryPhotosensitive materialsSolubilityOrganic solvent

The invention provides a chemical-amplification positive-working photoresist composition suitable for forming a resist film of a relatively large thickness on a substrate in addition to other advantages. The inventive composition contains (A) a photoacid-generating agent, (B) an alkali-insoluble resin capable of being imparted with increased alkali-solubility by interaction with an acid, (C) an alkali-soluble resin and (D) an organic solvent, wherein the component (C) is (C1) a polyhydroxystyrene or a copolymer having at least 80% by mass of the hydroxystyrene units in an amount not exceeding 15 parts by mass relative to 100 parts by mass of the total amount of the components (B) and (C).

Owner:TOKYO OHKA KOGYO CO LTD

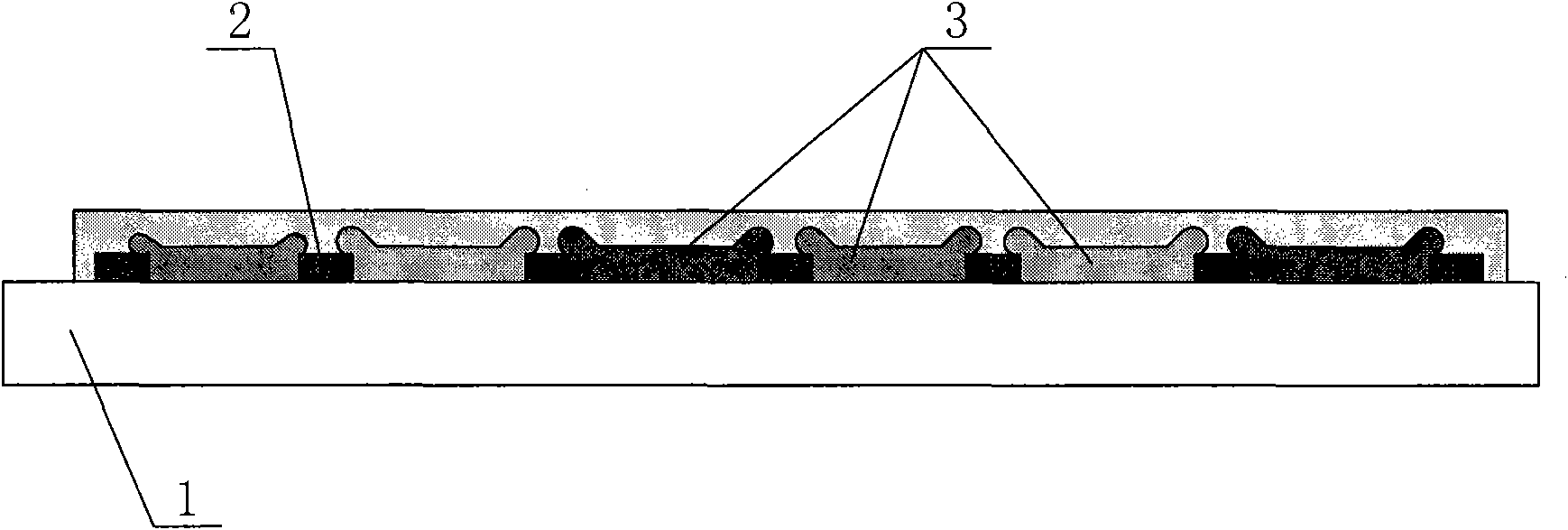

Protective printing ink for process of acid-etching glass as well as preparation method and application thereof

The invention relates to protective printing ink for the process of acid-etching glass. The resin components of the protective printing ink comprise the follow components in parts by weight: 45 to 60parts of o-alkyl phenolic epoxy acrylic acid resin, 5 to 10 parts of photopolymerizable monomer, 3 to 8 parts of photopolymerization initiator and 3 to 5 parts of epoxy resin. The printing ink obtained by taking the o-alkyl phenolic epoxy acrylic acid resin as a main component has excellent hydrofluoric acid corrosion resistance after being solidified on the surface of glass to form a film; compared with the traditional glass protective printing ink, the printing ink has the advantages that the hydrofluoric acid corrosion resistance is increased by one time, the adhesive force is 0 level and the hardness is moderate; compared with the traditional protective printing ink, the printing ink is more suitable for preparing 3D glass with AG effect; furthermore, the protective printing ink has excellent alkali dissolving property after being solidified on the surface of the glass to form a film, can be completely demolded and avoid residue when being soaked into a sodium hydroxide solution within 60 seconds, is favorable for improving the working efficiency and saves the aftertreatment working hours.

Owner:广州亦盛环保科技有限公司

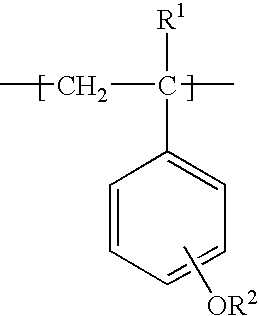

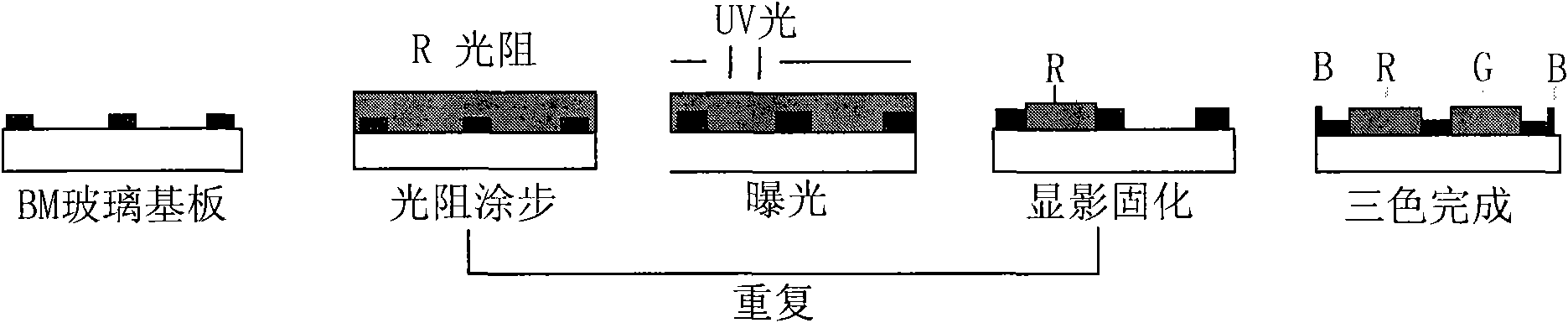

Color photoresist for color filter

InactiveCN101613276AGood colorGood alkali solubilityOrganic compound preparationCarboxylic acid esters preparationSolubilityPhotoinitiator

The invention discloses a color photoresist for a color filter, which comprises paint, a polyfunctional monomer, photoinitiator, dissolvent, alkali soluble resin, as well as an alkali soluble monomer. The polyfunctional monomer comprises at least two unsaturated bonds; and the alkali soluble monomer contains lots of carboxyl groups to increase the alkali solubility of photosensitive resin, greatly improve the unexposed part on a substrate and residual situation on a black matrix and boost the development speed. In addition, the compound contains lots of ethylene unsaturated groups, and the photosensitivity is excellent during exposing, thereby not only enhancing the dying power of the color photoresist, but also improving the performance of films.

Owner:SUZHOU TIANLILAN ENVIRONMENTAL PROTECTION TECH

Polyimide compound and flexible wiring board

ActiveUS7629091B2Good alkali solubilityReduction factorDiazo compound compositionsFilm packagingElectrical conductorDiamine

Owner:SONY CORP +1

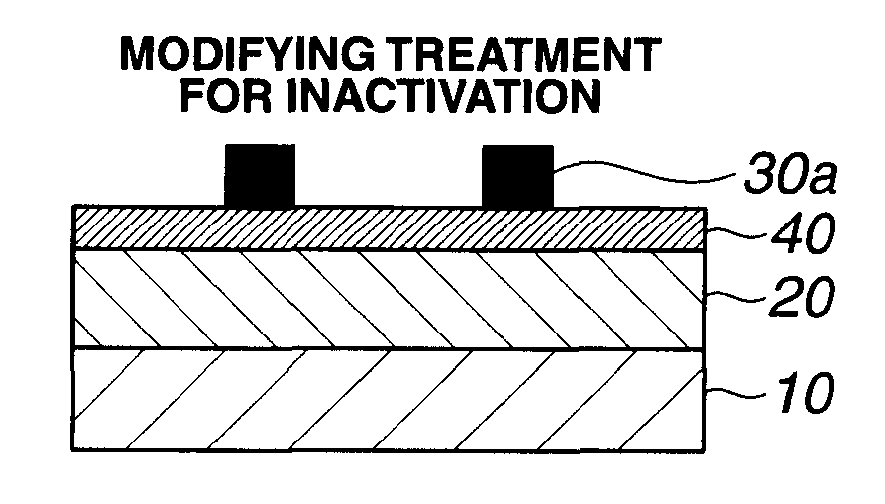

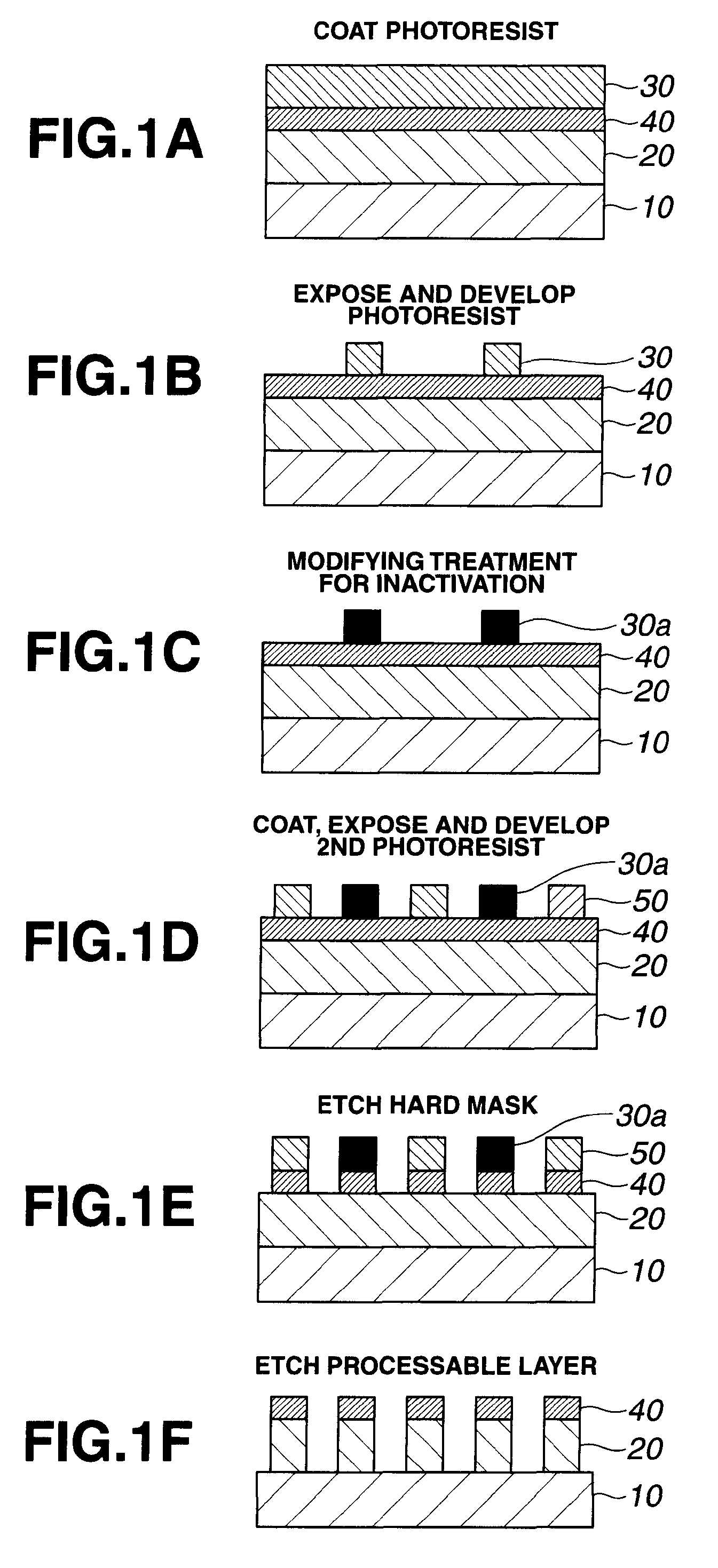

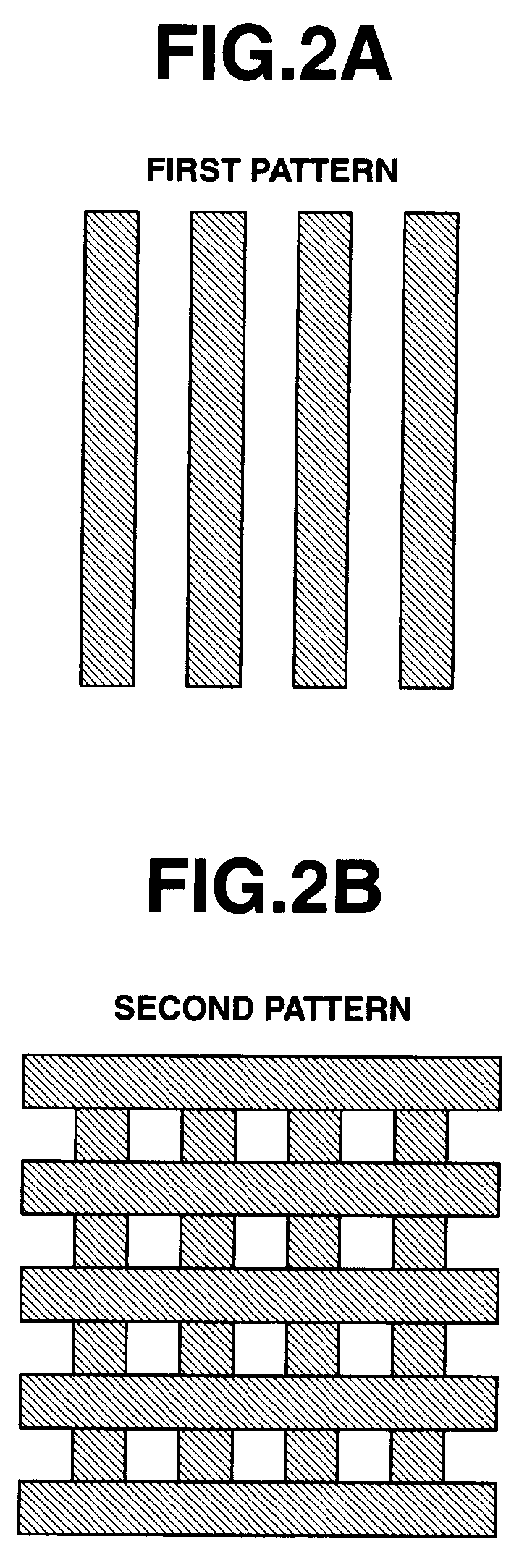

Pattern forming process, chemically amplified positive resist composition, and resist-modifying composition

ActiveUS8658346B2Good alkali solubilityPhotosensitive materialsSemiconductor/solid-state device manufacturingNanotechnologyChemistry

Owner:SHIN ETSU CHEM CO LTD

Process for preparation of dicarboxylic acid monoesters

InactiveUS6355830B1High selectivityLess deteriorationOrganic compound preparationPreparation by ester-hydroxy reactionOrganic solventAlcohol

A process for producing a dicarboxylic acid monoester which comprises subjecting a dicarboxylic acid monoester or an alkali metal salt of a dicarboxylic acid monoester and a metal alkoxide to transesterification in the presence of an organic solvent, or a process for producing a dicarboxylic acid monoester which comprises subjecting a dicarboxylic acid monoester or an alkali metal salt of a dicarboxylic acid monoester and an alcohol to transesterification in the presence of a metal alkoxide.

Owner:MITSUBISHI RAYON CO LTD

Image recording material

InactiveUS20050142484A1Good alkali solubilityFacilitated releaseRadiation applicationsPhotosensitive material auxillary/base layersChemical compoundImage recording

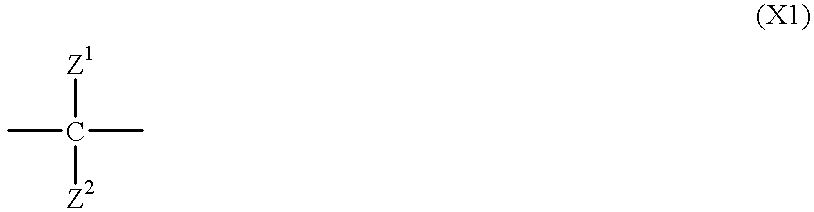

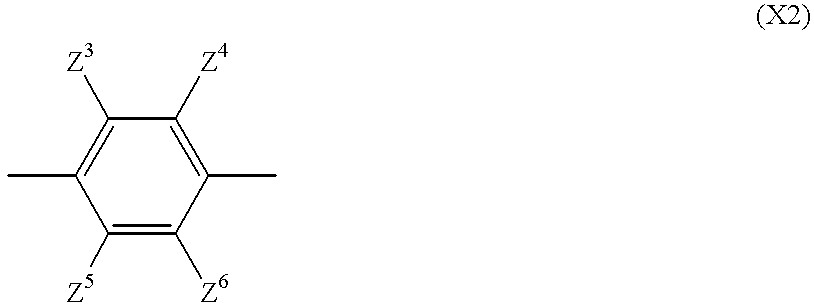

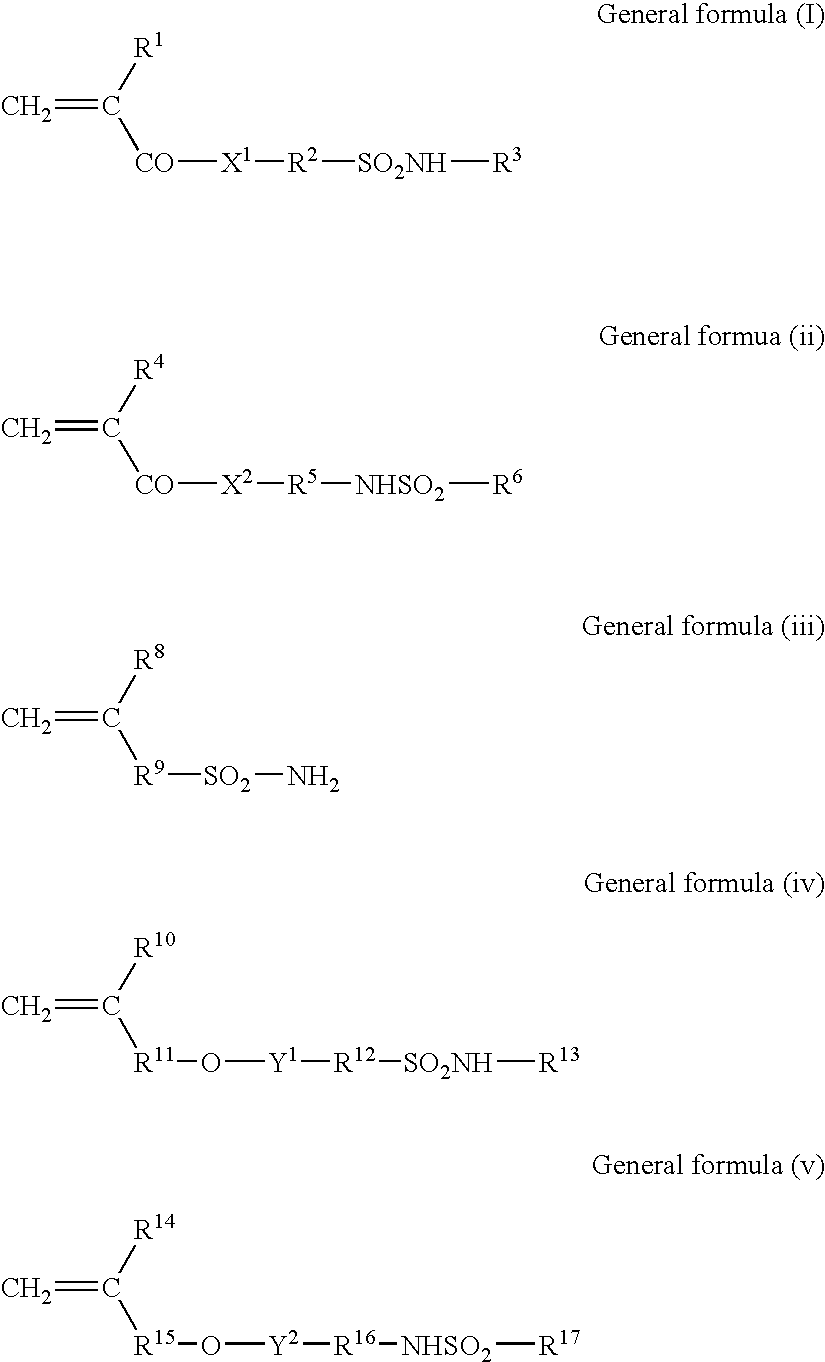

A positive image recording material applicable to infrared laser comprising a support whereon is formed a photosensitive / heatsensitive layer containing (A) an alkali-soluble resin, (B) a photothermal conversion substance, and (C) at least one compound selected from a group of compounds defined by the formulae (I), (II), (III), and (IV) exhibiting improved solubility to an alkaline developer following exposure with an infrared laser wherein the substituent groups of the formulae (I) to (IV) are specified in the specification for this invention.

Owner:FUJIFILM HLDG CORP +1

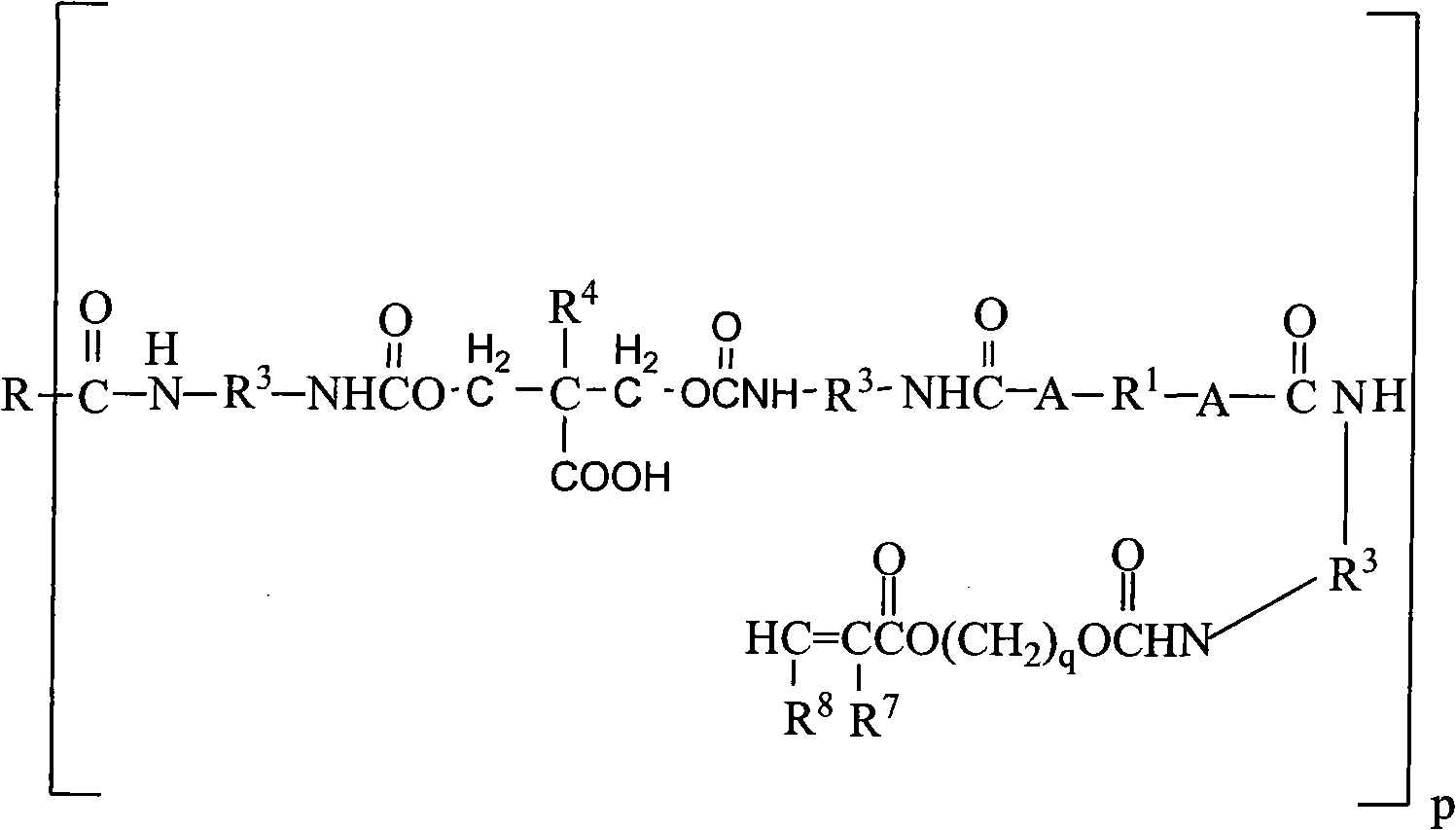

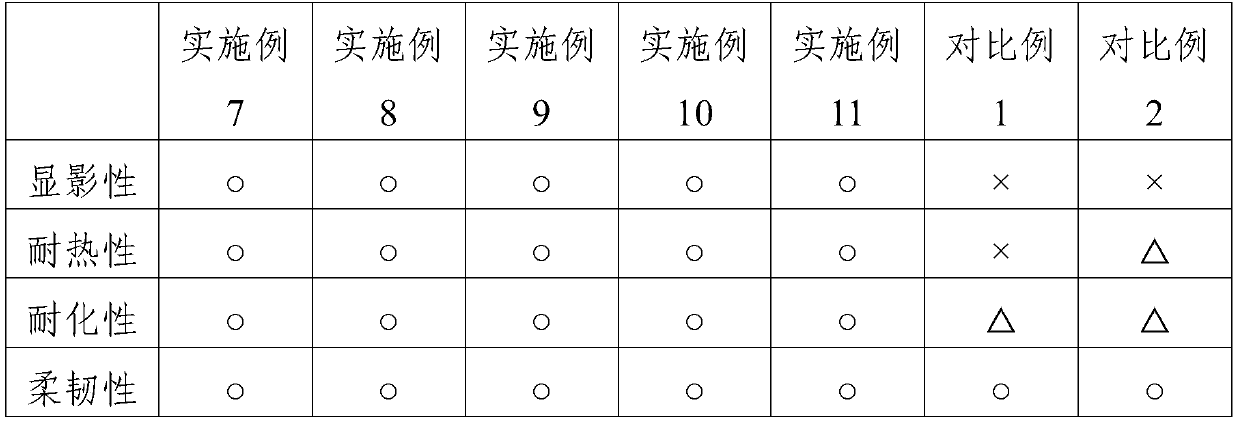

Acid anhydride modified epoxy acrylic resin, alkali-developable high-heat-resistance polyurethane resin and solder resist ink thereof

The invention belongs to the technical field of high polymer materials, and particularly discloses anhydride modified epoxy acrylic resin, alkali development high-heat-resistance polyurethane resin and solder resist ink thereof. The anhydride modified epoxy acrylic resin provided by the invention is prepared by jointly modifying epoxy resin with dimethylolcarboxylic acid and monobasic acid. According to the invention, the anhydride modified epoxy acrylic resin has the advantages of excellent heat resistance, chemical resistance, developability and the like, and is introduced into a polyurethane chain segment in a graft copolymerization manner to modify polyurethane, so that the epoxy acrylic modified polyurethane resin with heat resistance, chemical resistance, flexibility and developability is prepared. The solder resist ink containing the epoxy acrylic acid modified polyurethane resin is heat-resistant and chemical-resistant, has excellent developability and flexibility, and shows obvious performance advantages in practical application. In addition, the anhydride modified epoxy acrylic resin and the epoxy acrylic modified polyurethane resin provided by the invention are simple inpreparation method and suitable for industrial application.

Owner:SHANGHAI SHOWA HIGHPOLYMER CO LTD

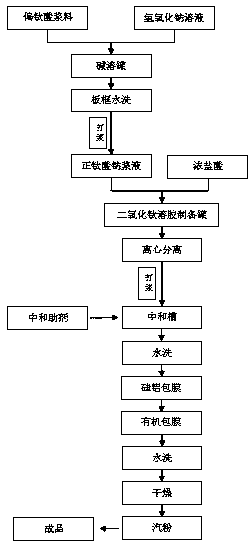

Preparation method of high-weatherability nanometer rutile titanium dioxide

ActiveCN108516582AImprove the effect of alkali dissolutionHigh dispersion propertiesMaterial nanotechnologyTitanium dioxideDissolution reactionTitanium dioxide

The invention relates to a preparation method of high-weatherability nanometer rutile titanium dioxide. The method has the following specific steps: respectively pumping metatitanic acid slurry and asodium hydroxide solution into a metering tank and preheating, mixing and stirring, heating and conducting an alkali dissolution reaction, cooling a mixture to room temperature, washing and discharging to obtain an alkali dissolution material; adding deionized water to the generated alkali dissolution material and stirring, adding concentrated hydrochloric acid and regulating pH of the slurry, heating the slurry, pressurizing the mixture and conducting a sol reaction, adding water to the mixture for dilution and stirring to obtain a nanometer rutile titanium dioxide crude product, pumping thecrude product into a centrifuge and centrifuging the slurry; neutralizing by adding a neutralizing agent and successively washing, coating, washing, drying and crushing so as to obtain the high-weatherability nanometer rutile titanium dioxide product. The method has the following advantages: synthesis temperature is low; the method is easy for industrial production; conditions are easy to control;and cost is low.

Owner:NANJING TITANIUM DIOXIDE CHEM

Photosensitive siloxane resin composition

ActiveUS9091920B2Good alkali solubilityHigh sensitivitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPolymer scienceAlkoxy group

[Object]To provide a photosensitive siloxane resin composition excellent in alkali-solubility and in sensitivity, and also to provide a pattern-formation method employing that.[Means]The present invention provides a photosensitive siloxane resin composition comprising: a siloxane resin having silanol groups or alkoxysilyl groups, a crown ether, a photosensitive material, and an organic solvent. This photosensitive composition is cast on a substrate, subjected to imagewise exposure, treated with an alkali aqueous solution, and cured to form a pattern.

Owner:MERCK PATENT GMBH

Planographic printing plate precursor

ActiveUS20050191577A1Improve solubilityGood alkali solubilityDuplicating/marking methodsSemiconductor/solid-state device manufacturingLaser lightChemical compound

A planographic printing plate precursor comprises a support and two or more positive recording layers which are formed on the support, contain a resin and an infrared absorbing agent and exhibit an increase in solubility in an aqueous alkali solution by exposure to infrared laser light, wherein the positive recording layer closest to the support among these two or more positive recording layers contains at least two types of resins among which at least one type forms a dispersion phase. It is preferable that the dispersion phase be formed of (1) a high-polymer compound incompatible with a high-polymer matrix or (2) a granular polymer selected from a microcapsule and a latex, and contains an infrared absorbing agent and an acid generator.

Owner:FUJIFILM HLDG CORP +1

Occarboxyl cobalt phthalocyanine catalyst for natural gas demercaptan

InactiveCN105195222AGood alkali solubilityImprove solubilityOrganic-compounds/hydrides/coordination-complexes catalystsGaseous fuelsThiolCobalt phthalocyanine

The invention belongs to the field of petroleum and natural gas, and discloses an occarboxyl cobalt phthalocyanine catalyst for natural gas demercaptan. The catalyst is specifically prepared from 4-beta-(dicarboxyl phenoxyl) cobalt phthalocyanine. The invention further discloses a structure of the 4-beta-(dicarboxyl phenoxyl) cobalt phthalocyanine which is designed for the first time and a catalytic conversion effect of the catalyst on natural gas mercaptan. The catalyst 4-beta-(dicarboxyl phenoxyl) cobalt phthalocyanine is good in solubleness in alkali liquor and has the high activity of catalytic demercaptan.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

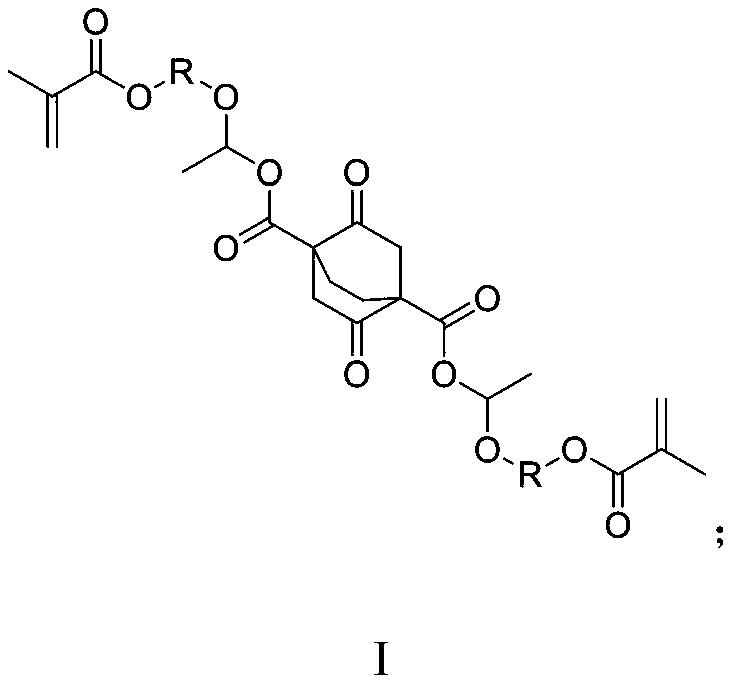

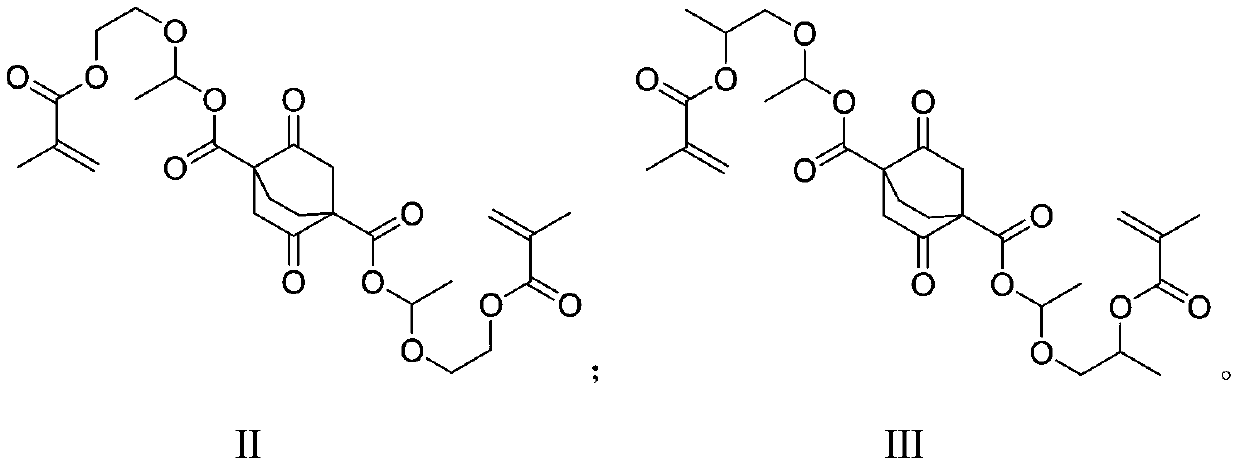

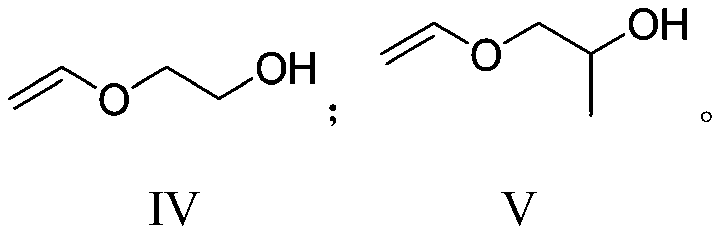

Photoresist resin monomer synthesized from carboxylic acid compound and synthesis method thereof

InactiveCN111100007AImprove edge roughnessHigh-resolutionOrganic compound preparationCarboxylic acid esters preparationVinyl etherChemical synthesis

The invention discloses a photoresist resin monomer synthesized from a carboxylic acid compound and a synthesis method of the photoresist resin monomer, and belongs to the field of chemical synthesisand photoetching materials. The structural general formula of the resin monomer is shown in the specification, wherein R is linear chain or branched chain alkyl. The synthesis method of the resin monomer comprises the following steps: carrying out esterification reaction on a vinyl ether alcohol compound and an acrylic acid compound to obtain an intermediate; and carrying out a reaction on the intermediate and 2, 5-dioxobicyclo[2.2. 2]octane-1, 4-dicarboxylic acid to generate the photoresist resin monomer. The resin monomer provided by the invention comprises an acetal structure and polycyclicand polyester structures, can prevent diffusion of a photoacid generator, improve edge roughness, increase contrast and improve resolution, has excellent etching resistance and fat solubility, and issimple and convenient in preparation method.

Owner:上海博栋化学科技有限公司

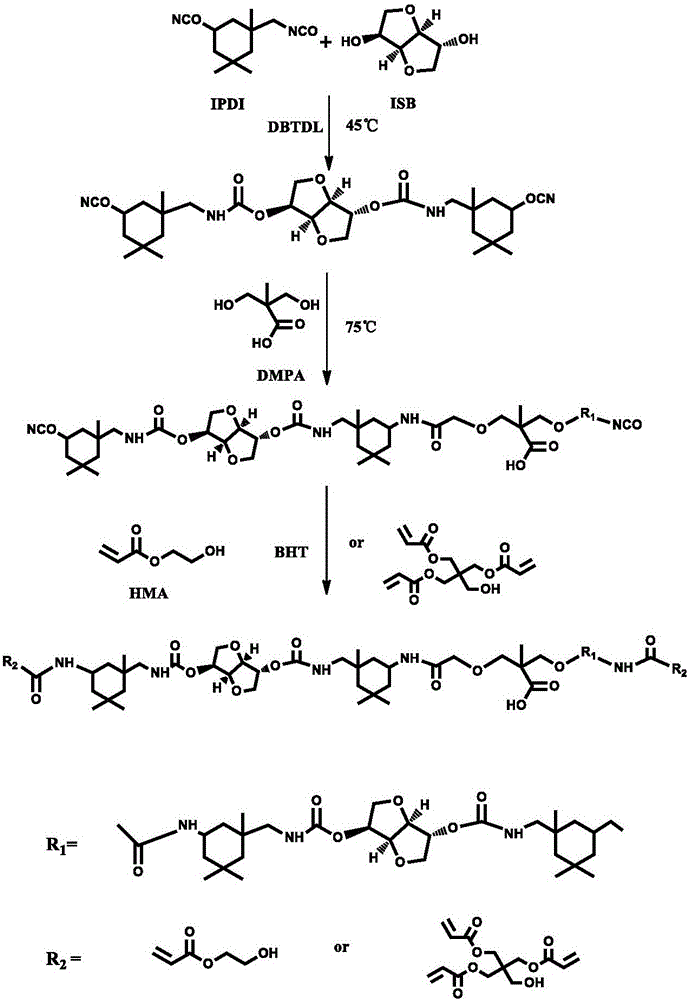

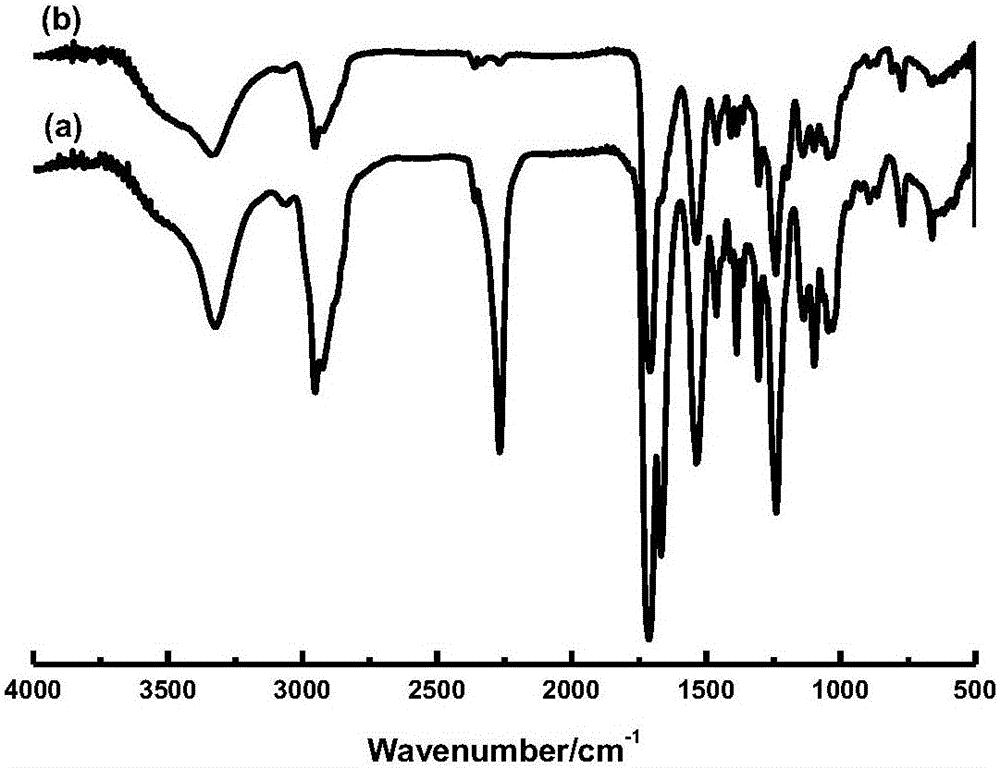

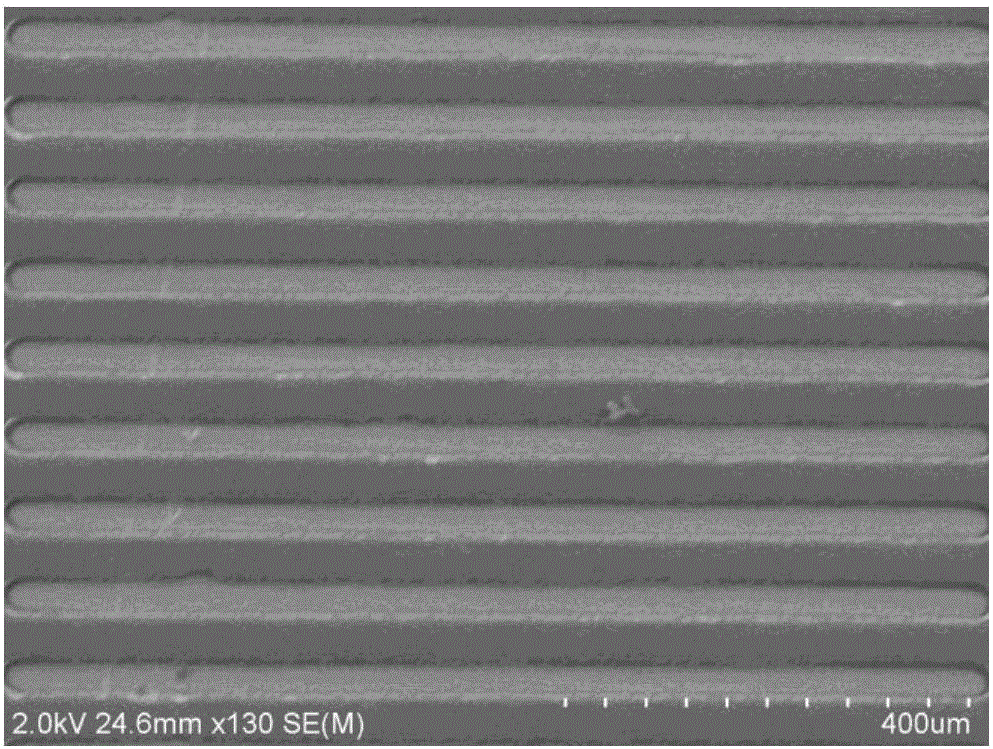

Bio-based photo-curable polyurethane and photoresist prepared with same

InactiveCN105885004AHigh glass transition temperatureImprove mechanical propertiesPhotosensitive materials for photomechanical apparatusDissolutionSolvent

The invention provides bio-based photo-curable polyurethane and a photoresist composition from the same and belongs to the field of photoresists. The photoresist composition is prepared by: reacting bio-based monomer isosorbide with a diisocyanate to obtain NCO-terminated monomer, reacting this monomer with dihydroxy acid to synthesize polyurethane prepolymer, terminating with acrylate monohydric alcohol to obtain bio-based photo-curable polyurethane, mixing the prepared polyurethane proportionally with a photoinitiator, a solvent, an active diluent and a pigment in the shade, and stirring well to enable full dissolution. By introducing the isosorbide, it is possible to improve corrosion resistance of the photoresist and improve its thermal performance and it is possible to produce an image with good comprehensive performance and high resolution.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com