Acid anhydride modified epoxy acrylic resin, alkali-developable high-heat-resistance polyurethane resin and solder resist ink thereof

A technology of epoxy acrylic and polyurethane resin, which is applied in ink, application, household appliances, etc. It can solve the problems of chemical resistance, poor image development, and inability to meet the requirements of polyurethane, and achieve improved heat resistance, excellent heat resistance, good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

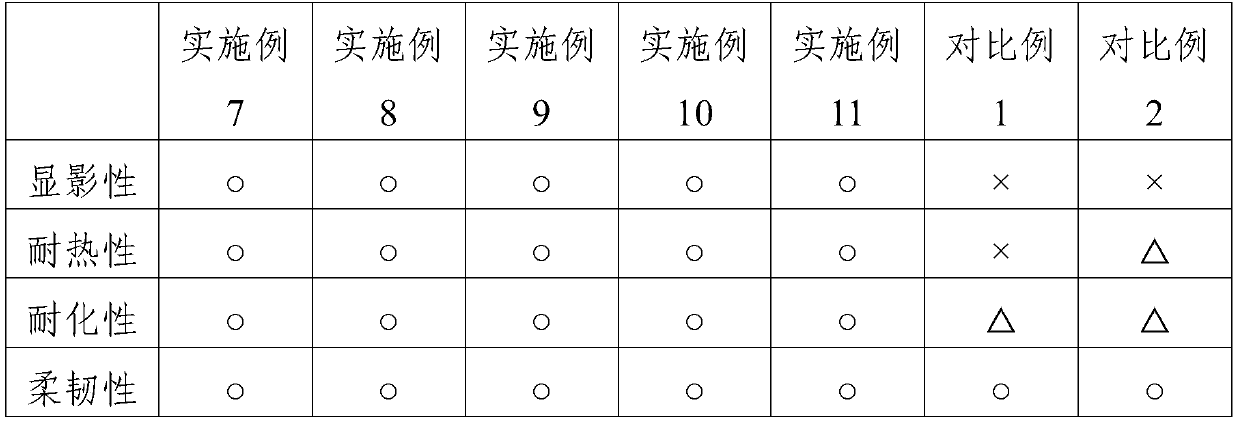

Examples

Embodiment 1

[0062] This embodiment provides an anhydride-modified epoxy acrylic resin, which is specifically prepared by the following steps:

[0063] Add raw materials in stages to react:

[0064] The first stage: 100 parts of bisphenol A novolac epoxy resin (epoxy equivalent: 190-200), 34 parts of dimethylol carboxylic acid, 64 parts of monobasic acid, 100 parts of diluent, 4 parts of Inhibitor, 4 parts of triphenylphosphine, the temperature is raised to 125°C, the acid value is less than 5KOHmg / g, and the temperature is lowered to 105°C.

[0065] The second stage: Add 68 parts of acid anhydride to the reaction system, keep the temperature at 105°C, detect by infrared until the anhydride peak disappears, and the reaction is completed, and the properties of the anhydride-modified epoxy acrylic resin are as follows: the acid value is 33-38KOHmg / g, The dynamic viscosity is 65-75dpa.s, the weight average molecular weight is 4000-5000, and the solid content is 50-70%.

[0066] Among them, ...

Embodiment 2

[0068] This embodiment provides an anhydride-modified epoxy acrylic resin, which is specifically prepared by the following steps:

[0069] Add raw materials in stages to react:

[0070] The first stage: 100 parts of bisphenol A novolac epoxy resin (epoxy equivalent: 190-200), 40 parts of dimethylol carboxylic acid, 58 parts of monobasic acid, 110 parts of diluent, 6 parts of The polymerization inhibitor and 6 parts of triphenylphosphine are heated up to 130°C, the acid value is less than 5KOHmg / g, and the temperature is lowered to 110°C.

[0071] The second stage: Add 75 parts of acid anhydride to the reaction system, keep the temperature at 110°C, detect by infrared until the anhydride peak disappears, and the reaction is completed, and the properties of the anhydride-modified epoxy acrylic resin are as follows: the acid value is 36-40KOHmg / g, The dynamic viscosity is 60-100dpa.s, the weight average molecular weight is 6000-7000, and the solid content is 50-70%.

[0072] Am...

Embodiment 3

[0074] This embodiment provides an anhydride-modified epoxy acrylic resin, which is specifically prepared by the following steps:

[0075] Add raw materials in stages to react:

[0076] The first stage: 100 parts of bisphenol A novolac epoxy resin (epoxy equivalent: 190-200), 30 parts of dimethylol carboxylic acid, 68 parts of monobasic acid, 90 parts of diluent, 2 parts of The polymerization inhibitor and 2 parts of triphenylphosphine are heated up to 120°C, the acid value is less than 5KOHmg / g, and the temperature is lowered to 100°C.

[0077] The second stage: Add 60 parts of acid anhydride to the reaction system, keep the temperature at 100°C, detect by infrared until the anhydride peak disappears, and the reaction is completed, and the properties of the anhydride-modified epoxy acrylic resin are as follows: the acid value is 30-34KOHmg / g, The dynamic viscosity is 50-70dpa.s, the weight average molecular weight is 5000-6000, and the solid content is 50-70%.

[0078] Amon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com