Liquid cobalt sulfonated phthalocyanine catalyst for liquefied petroleum gas mercaptan removal

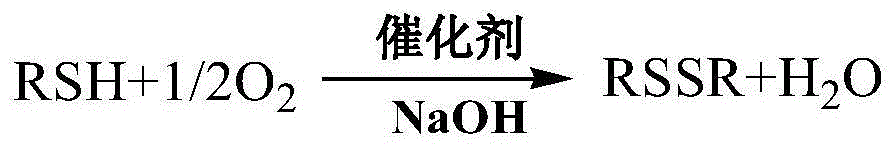

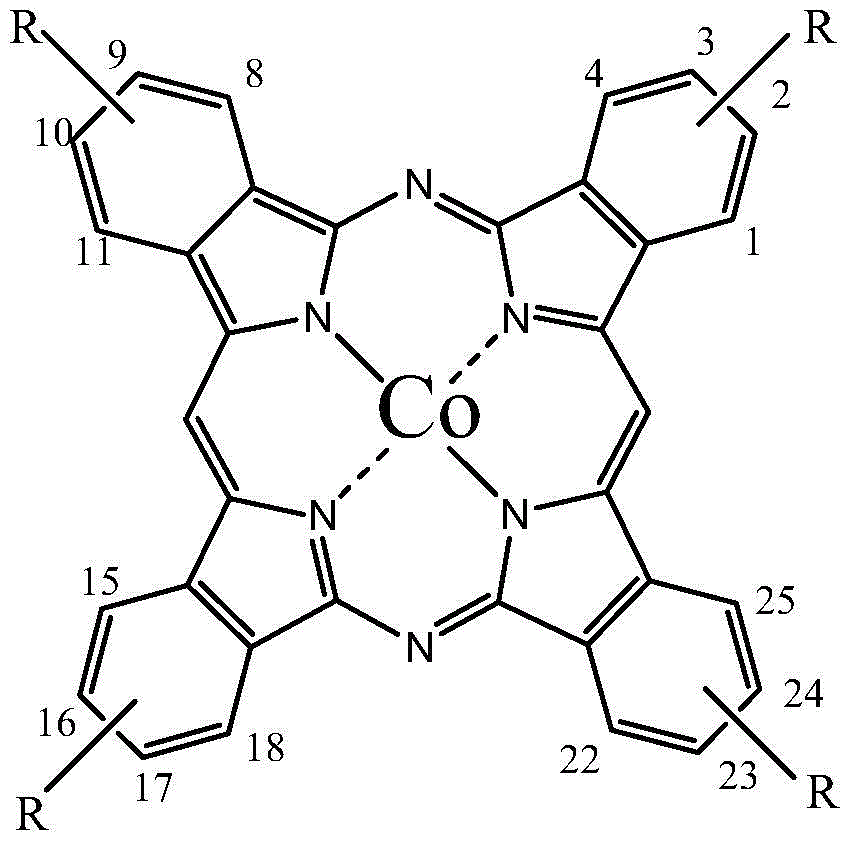

A technology of cobalt sulfonated phthalocyanine and liquid catalyst, which is applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, gas fuel, etc., and can solve the problem of poor solubility of liquefied petroleum gas sweetening catalyst , achieve excellent sweetening activity, solve poor solubility, and be easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

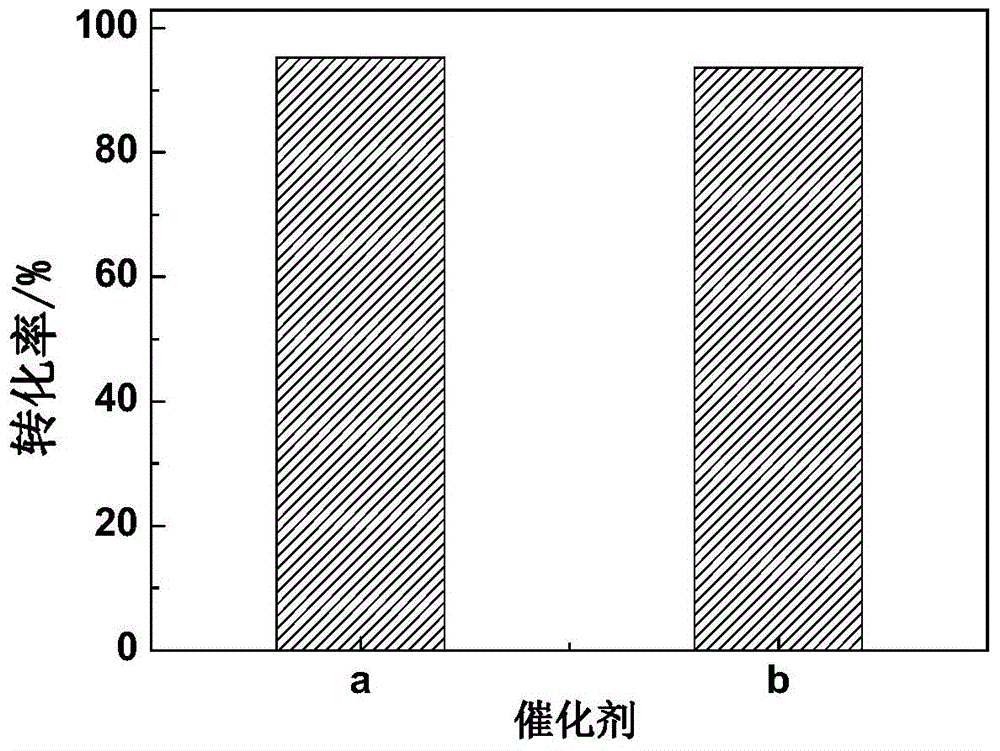

[0031] Test the solubility of the four-β-p-sulfonic acid group phenoxy cobalt phthalocyanine complex in water and 10% NaOH solution respectively, and compare with the solubility of the solid sulfonated cobalt phthalocyanine currently used in industry, The results are listed in Table 1.

[0032] Table 1 Solubility of cobalt phthalocyanine of the present invention in water and lye and contrast with solid sulfonated cobalt phthalocyanine

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com