Alkali soluble light-sensitive organosilicon preformed polymer and preparation method thereof

A silicone, alkali-soluble technology, applied in the field of alkali-soluble photosensitive silicone prepolymer

- Summary

- Abstract

- Description

- Claims

- Application Information

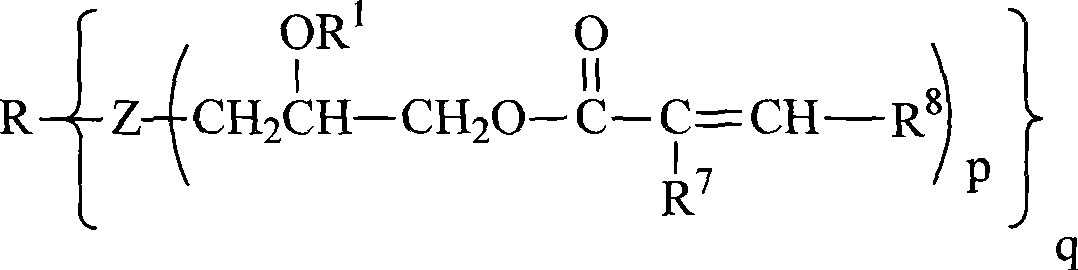

AI Technical Summary

Problems solved by technology

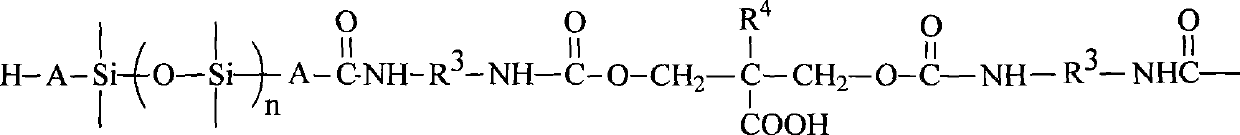

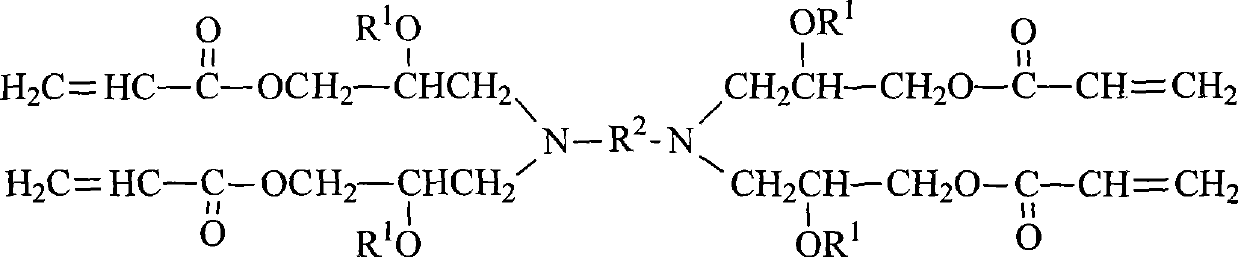

Method used

Image

Examples

Embodiment 1

[0104] In a 100ml three-necked flask equipped with a stirrer, a dropping funnel, and a condenser, add 2.10g AG-80, dissolve it in 6.0g DMF, add 0.1g polymerization inhibitor p-methoxyphenol, and heat to 90°C to Removal of peroxides from epoxies. Then the mixture of 1.44 g of acrylic acid containing 0.1 g of catalyst p-toluenesulfonic acid was slowly added dropwise, and the dropwise addition was completed within about 0.5 h. Measure the acid value of the system, stop heating and cool down when the acid value remains unchanged.

[0105] 18.25g Q4-3667, 8.88g isophorone diisocyanate (IPDI), 3.00g dimethylol propionic acid (DMPA), 0.2g inhibitor p-methoxyphenol, 0.6g catalyst dibutyl dilaurel Add tin (DBTDL) into the three-necked flask and react at 50°C. Measure the content of isocyanate by the di-n-butylamine-acetone method, monitor the progress of the reaction, and add the product of the first step to react to the isocyanate when the reaction reaches half. The value dropped to...

Embodiment 2~5

[0112] Repeat the steps of Example 1, the difference lies in the raw materials used and their consumption, as shown in Table 1.

[0113] Table 1

[0114] Example 1 Example 2 Example 3 Example 4 Example 5 AG-80 2.10 2.10 2.10 2.10 2.10 acrylic acid 1.44 1.80 2.10 1.44 1.44 p-methoxyphenol 0.3 0.3 0.3 0.3 0.3 p-Toluenesulfonic acid 0.1 0.1 0.1 0.1 0.1 Q4-3667 18.25 18.25 18.25 18.25 18.25 IPDI 8.88 8.88 8.88 8.88 8.88 DMPA 3.00 3.00 3.00 3.90 4.50 DBTDL 0.6 0.6 0.6 0.6 0.6

Embodiment 6

[0116] The purpose of this example is to illustrate that the alkali-soluble photosensitive silicone prepolymer prepared in Example 1 can be used to prepare solder resist ink, and its performance is measured.

[0117] Weigh 1.5 g of the alkali-soluble photosensitive silicone prepolymer in Example 1 and dissolve it in 5 g of β-hydroxyethyl acrylate (HEA), add 0.2 g of photosensitizer 2-hydroxyl-methylphenylpropane-1-one After (1173), the mixture is coated on a glass plate to obtain a thin film with a thickness of about 25 μm. Put a mask plate with a simple pattern on it, put it on a UV curing machine for exposure, make it photochemically react, and then immerse it in 1% sodium carbonate aqueous solution for 60s at room temperature to make it develop. Then bake it in a constant temperature drying oven at 100°C to a constant weight, measure the residual film rate from the film mass ratio before and after development, and measure the exposure amount required for the residual film r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com