Preparation method of low-temperature demulsifier and low-temperature demulsifier prepared by means of method

A technology of polyether demulsifier and phenolic aldehyde block, which is used in chemical dehydration/demulsification, treatment of hydrocarbon oil, petroleum industry, etc., can solve the problems of rising oil content in water phase and increasing difficulty of demulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

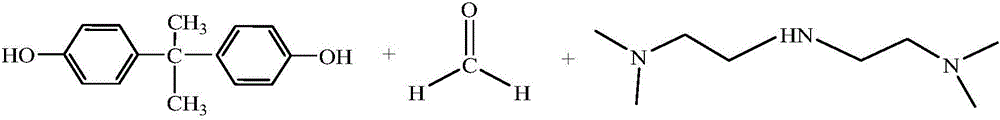

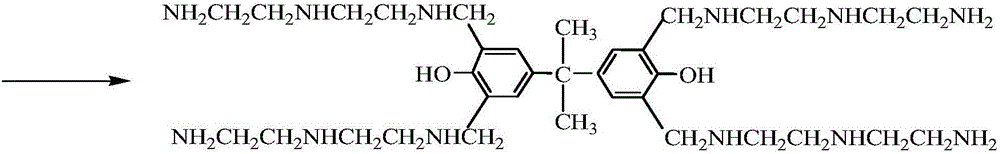

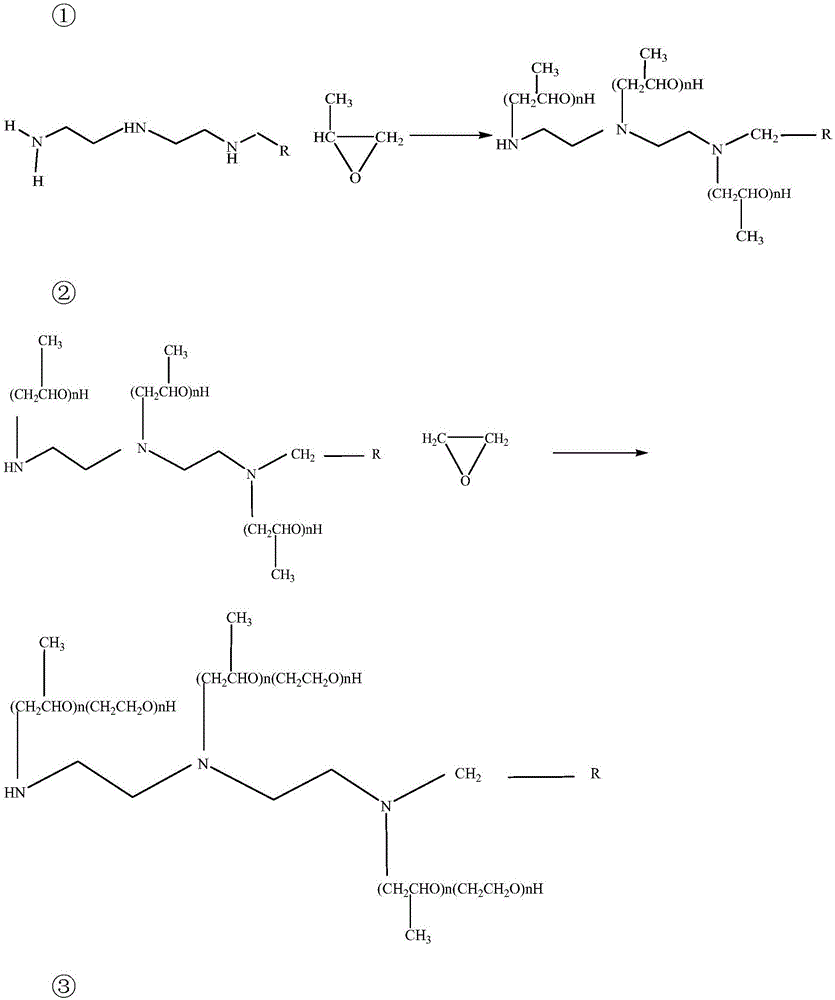

Method used

Image

Examples

Embodiment 1

[0031] 1) Preparation of phenamine-aldehyde block polymer: Add 30 g of the reaction mixture of bisphenol A and diethylenetriamine into a four-necked bottle, wherein the weight ratio of bisphenol A and diethylenetriamine is 1:3.7, and start stirring Heat up, when the temperature is 95-100°C, stir for 10 minutes, then, when cooled to 35°C, use a constant pressure dropping funnel to drop the weight of the reaction mixture of bisphenol A and diethylenetriamine at a rate of 1 drop / second 24%, that is, 20g, formaldehyde solution (36% (W / W)), where the weight ratio of 24% is calculated according to the amount of formaldehyde, after the dropwise addition, it needs to be kept warm for 30 minutes. Then add 1 / 2 xylene of the total amount of the material, heat up and reflux for 2 hours, then distill the xylene out to obtain a reddish-brown viscous liquid, which is a new type of phenamine-aldehyde resin.

[0032] 2) Then drop into the stainless steel reaction kettle with the phenamine-alde...

experiment Embodiment 1

[0034] Experimental Example 1: Measurement of Dehydration Rate

[0035] Pour 80ml of prepared crude oil emulsion (from Shengli Oilfield) into a 100ml stoppered measuring cylinder, preheat it for 15min, so that the liquid level of the stoppered measuring cylinder is not lower than the water bath level, when the emulsion in the stoppered measuring cylinder When the temperature reaches the general dehydration temperature (55°C or 60°C), continue to preheat for 30 minutes, and then add the products with better application effects in the current market: the block polymer with alcohol as the initiator produced by Binhua Group Ether TA-1031, SP169, block polyether AP116 and AE9901 produced by Shengli Chemical Group with amines as the initiator, and the demulsifier prepared according to Example 1. After covering the lid, fully shake it up and down by hand for 5 minutes , loosen the lid to release the air inside, put the lid on again, place it on a horizontal shaker, shake at the maxim...

experiment Embodiment 2

[0044] Experimental Example 2: Measurement of Low Temperature Dehydration Rate

[0045] Except that the dehydration temperature was set at 40 to 42° C., the dehydration rate was measured in the same manner as in Experimental Example 1, and the results are listed in Table 2 below.

[0046] Table 2 Demulsifier low temperature dehydration rate test results

[0047]

[0048]It can be seen from Table 2 that although the demulsifier prepared according to Example 1 of the present invention has little difference in the demulsification effect of TA-1031 and AP116 at room temperature, it is much better than TA-1031 and AP116 at low temperature , so it is more suitable for crude oil demulsification under low temperature conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com