Color photoresist for color filter

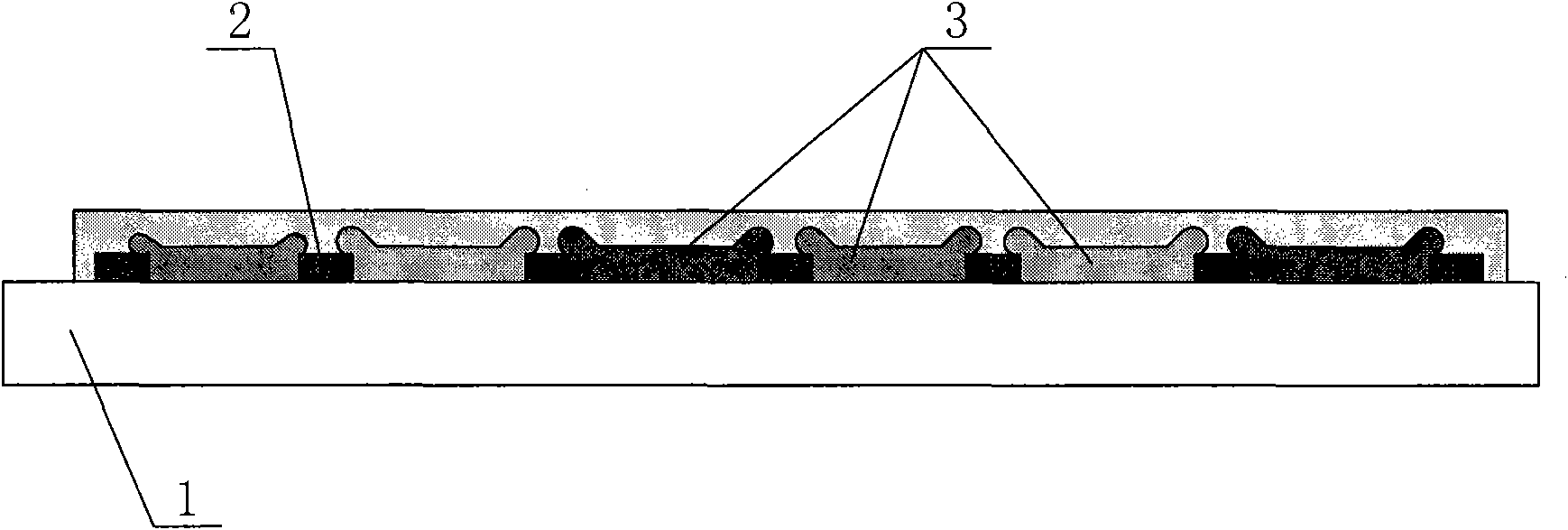

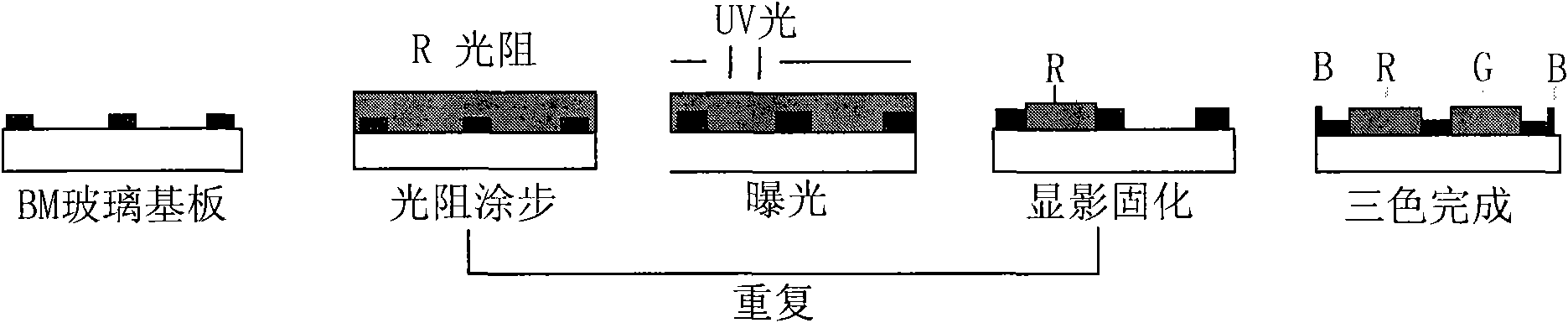

A color photoresist, monomer technology, applied in the fields of filters, optics, optomechanical equipment, etc., can solve the problems of inability to meet production requirements, reduction, and decline in curing performance in exposure areas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

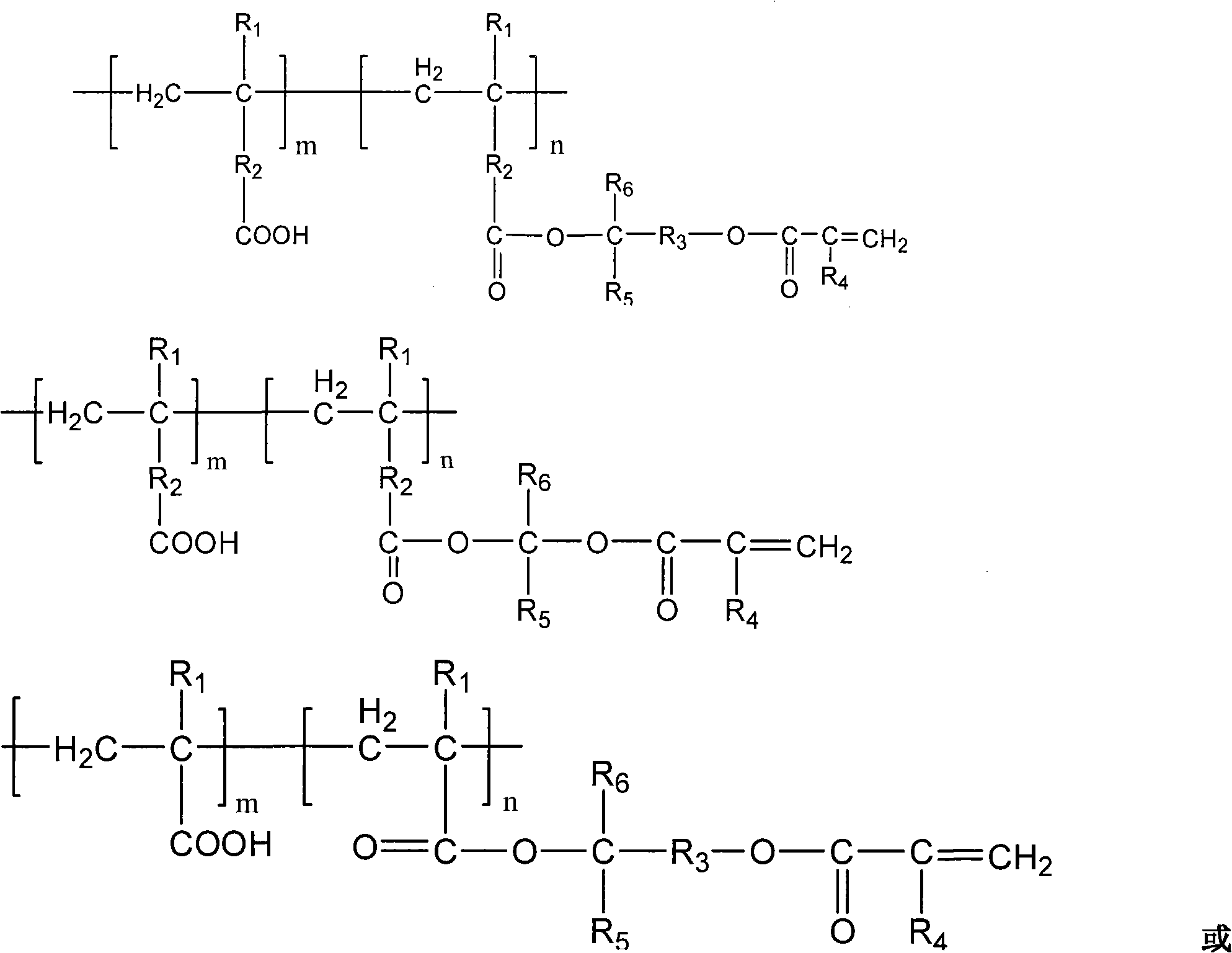

Method used

Image

Examples

Embodiment 1

[0098] Embodiment one: the synthesis 1 of alkali-soluble resin,

[0099] Add 300 grams of cyclohexanone into the three-necked flask, add the following raw materials in proportion, pass nitrogen into the reaction system, repeat 3 times to ensure that the oxygen is completely discharged, raise the temperature of the reaction system to 80-100 ° C, and react 6-8 After hours, the polymer was precipitated in excess methanol and dried, and the yield was calculated.

[0100] Methacrylic acid 10g

[0101] Styrene 30g

[0102] Methyl methacrylate 30g

[0103] Butyl methacrylate 30g

[0104] Azobisisobutyronitrile 0.1 g

Embodiment 2

[0105] Embodiment two, the synthesis 2 of alkali-soluble resin,

[0106] Add 300 grams of cyclohexanone into the three-necked flask, add the following raw materials in proportion, pass nitrogen into the reaction system, repeat 3 times to ensure that the oxygen is completely discharged, raise the temperature of the reaction system to 80-100 ° C, and react 6-8 After hours, the polymer was precipitated in excess methanol and dried, and the yield was calculated.

[0107] Acrylic 20g

[0108] Styrene 20 g

[0109] Phenyl Acrylate 30g

[0110] Butyl methacrylate 30g

[0111] Azobisisobutyronitrile 0.1 g

Embodiment 3

[0112] Embodiment three, the synthesis 3 of alkali-soluble resin,

[0113] Add 300 grams of cyclohexanone into the three-necked flask, add the following raw materials in proportion, pass nitrogen into the reaction system, repeat 3 times to ensure that the oxygen is completely discharged, raise the temperature of the reaction system to 80-100 ° C, and react 6-8 After hours, the polymer was precipitated in excess methanol and dried, and the yield was calculated.

[0114] Methacrylic acid 10g

[0115] Vinyl Acrylate 30g

[0116] Methyl methacrylate 40g

[0117] Butyl methacrylate 20g

[0118] Azobisisobutyronitrile 0.1 g

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com