Acrylate containing carboxyl hyperbranched poly(amine-ester) and preparation method thereof

A technology of monohydroxy acrylate and hyperbranched polymerization is applied in the synthesis field of photosensitive polymer materials, which can solve the problems of high shrinkage rate, poor alkali solubility and high viscosity of photoresist, and achieve low viscosity and increase alkali solubility. , high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

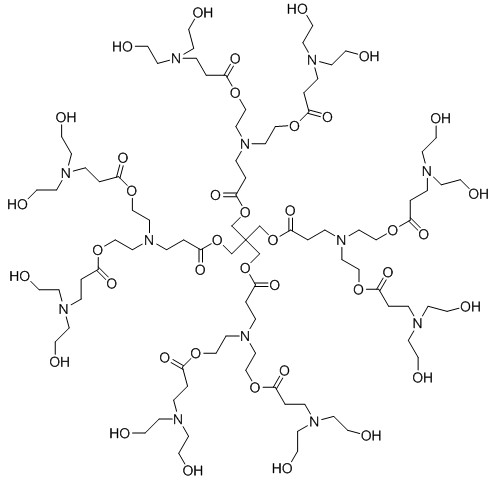

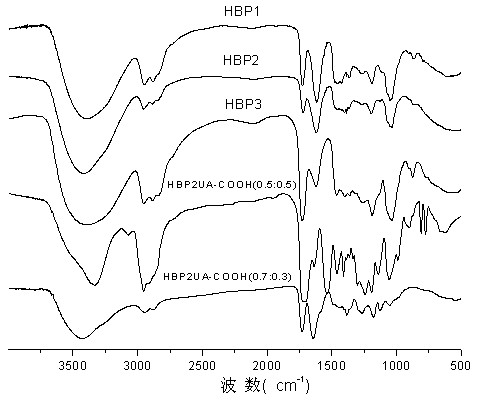

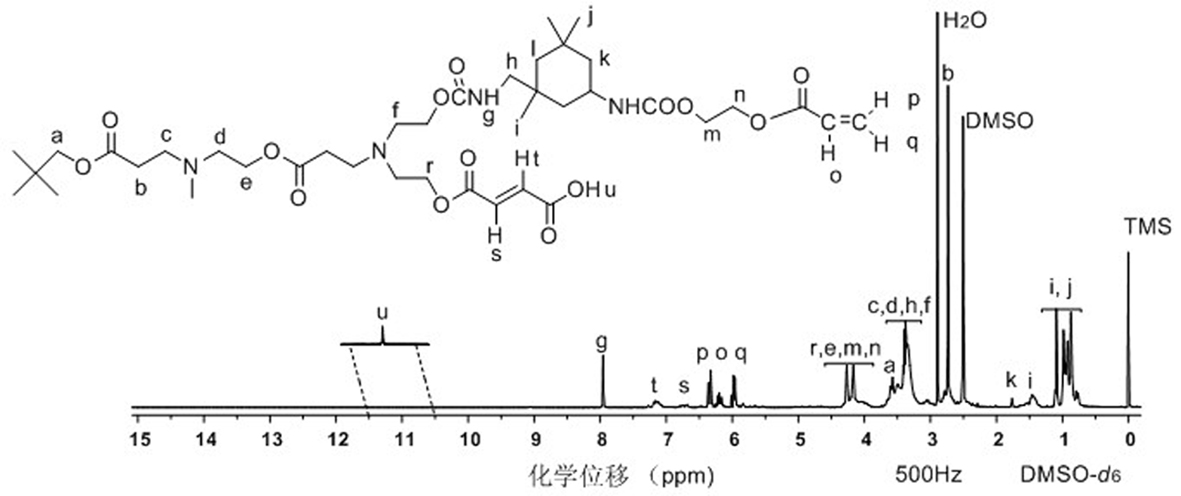

[0020] The synthesis of the first generation of hyperbranched poly(amine-ester) mainly consists of the following three steps: First, add methyl acrylate (8.61g, 0.1mol) and diethanolamine (10.51g, 0.1mol) to a magnetic stirrer, In the three-necked flask at the inlet and outlet of the condenser and nitrogen, the reaction was carried out at 35°C for 4 hours with methanol as the solvent. After the reaction, the methanol was distilled off under reduced pressure to obtain methyl N,N-dihydroxyethyl-3-aminoacrylate. Secondly, dissolve pentaerythritol (2.72g, 0.02mol) in 20ml DMF, add N,N-dihydroxyethyl-3-aminoacrylate (15.29 g, 0.08mol) into the reaction vessel, and p-toluenesulfonic acid The catalyst was reacted at 120°C for 3 hours to distill off DMF under reduced pressure to obtain the first generation of hyperbranched poly(amine-ester). Finally, put the synthesized first-generation hyperbranched poly(amine-ester) into a vacuum drying oven to fully dry, remove the moisture, and di...

Embodiment 2

[0022] Dissolve the first generation hyperbranched poly(amine-ester) (7.72g, 0.01mol) in 20ml of DMAC, and add N,N-dihydroxyethyl-3-aminoacrylate (15.29g, 0.08mol) to In the reaction vessel, use p-toluenesulfonic acid as a catalyst to react at 120°C for 3 hours to distill off the solvent under reduced pressure to obtain the second generation hyperbranched poly(amine-ester). The dried second generation hyperbranched poly(amine-ester) ) Dissolve 1,4-dioxane, and slowly add the dissolved second-generation hyperbranched poly(amine-ester) to the ether solvent to make the second-generation hyperbranched poly(amine-ester) in the ether The collected precipitates are separated, and then washed three times with a mixed solution of ether / acetone (V / V=1:1), and the washed second-generation hyperbranched poly(amine-ester) is placed in a vacuum drying oven to remove Solvent to obtain purified second-generation hyperbranched poly(amine-ester), named HBP2.

Embodiment 3

[0024] The second-generation hyperbranched poly(amine-ester) (2.05g, 0.001mol) was dissolved in 20ml of NMP, and N,N-dihydroxyethyl-3-amino acrylate (3.06g, 0.016mol) was added to In the reaction vessel, use p-toluenesulfonic acid as a catalyst to react at 120°C for 3 hours to distill off NMP under reduced pressure to obtain the third-generation hyperbranched poly(amine-ester). The dried third-generation hyperbranched poly(amine-ester) ) Dissolve in 1,4-dioxane, and slowly add the dissolved third-generation hyperbranched poly(amine-ester) to the ether solvent to make the third-generation hyperbranched poly(amine-ester) in the ether The collected precipitates are separated, and then washed three times with a mixed solution of ether / acetone (V / V=1:1), and the washed third-generation hyperbranched poly(amine-ester) is placed in a vacuum drying oven to remove Solvent, obtain purified third-generation hyperbranched poly(amine-ester), named HBP3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com