Patents

Literature

122 results about "Pentaerythritol tetraacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pentaerythritol tetraacrylate contains 350 ppm monomethyl ether hydroquinone as inhibitor CAS Number 4986-89-4. Linear Formula (H 2 C=CHCO 2 CH 2) 4 C . Molecular Weight 352.34 . MDL number MFCD00015334. PubChem Substance ID 24865554

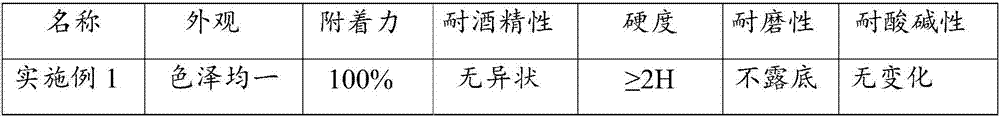

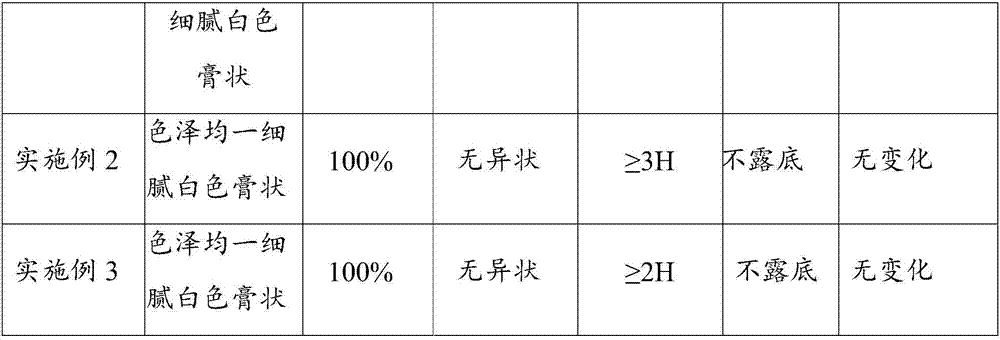

Automotive UV (Ultraviolet) light-cured camouflage coating and preparation method thereof

ActiveCN104004451ALow costHigh hardnessPolyurea/polyurethane coatingsEpoxy resin coatingsExtinctionAccelerant

The invention discloses an automotive UV (Ultraviolet) light-cured camouflage coating and a preparation method thereof. The camouflage coating comprises a UV light-cured resin, a reactive diluent, a camouflage paint composition, addition agents and a photoinitiator, wherein the UV light-cured resin is formed by four-functionality urethane acrylates and epoxy acrylates; the reactive diluent is formed by pentaerythritol tetraacrylate (PETA) and triethylene glycol divinyl ether (DVE-3); the addition agents comprise an accelerant, a coupling agent, a flatting agent, defoaming agent and extinction powder; the photoinitiator is formed by Irgacure651 and 2-chloridized thioxanthone. The camouflage coating disclosed by the invention has the characteristics of rapid curing speed, energy conservation, air pollution reduction, good adhesive force, high rigidity and the like.

Owner:JIANGSU LITIAN TECH

High gloss high abrasion resistance ultra-violet curing overprinting varnish of mobile phone and preparation method thereof

InactiveCN101967338AImprove wear resistanceHigh gloss and high wear resistancePolyurea/polyurethane coatingsPolyester coatingsIsooctyl acrylatePolyester

The invention discloses a high gloss high abrasion resistance ultra-violet (UV) curing overprinting varnish of mobile phone and a preparation method thereof. The method of the invention uses low-viscosity polyester acrylate and aliphatic polyurethane acrylate as base resin which combines with ethoxylated pentaerythritol tetraacrylate, Trimethylolpropane triacrylate, Tri(propylene glycol) diacrylate, 1,6-hexanediol diacrylate and 2-ethylhexyl acrylate which are used as active diluent, alcohol and ethyl acetate which are used as diluent, benzophenone and 1-hydroxycyclohexyl phenyl ketone which are used as photoinitiator, reactive amine coinitiator, defoaming agent, flatting agent, slip agent and other agents to mix evenly and prepare the UV overprinting varnish. The overprinting varnish of the invention adopts the special raw material formula and has good lustrousness, adhesive force and mechanical stability; as some polyfunctional resins and resins with special functional groups are added, the crosslink density of the UV varnish is increased in the curing process and the hardness of the product is up to 5-7H; and as solid wax powder used as the slip agent is added, the coefficients of friction can be reduced and the product can have extremely high wear resistance.

Owner:苏州凯康化工科技有限公司

High-dielectric constant composite material

The invention relates to a high-dielectric constant composite material. Bismaleimide resin monomer, maleic anhydride, octamethylcyclotetrasiloxane, pentaerythritol tetraacrylate, phenoxy resin, iso-tridecanol polyoxyethylene ether, polycaprolactam resin, filler and ethylene glycol are taken as materials, a resin-based compound system is prepared; the resin-based compound system is then put into a mold and hot-pressed, and thereby the high-dielectric constant composite material is obtained. The high-dielectric constant composite material has excellent mechanical property and heat resistance, and the development and application of high-dielectric constant composite materials can be met.

Owner:苏州凯欧曼新材料科技有限公司

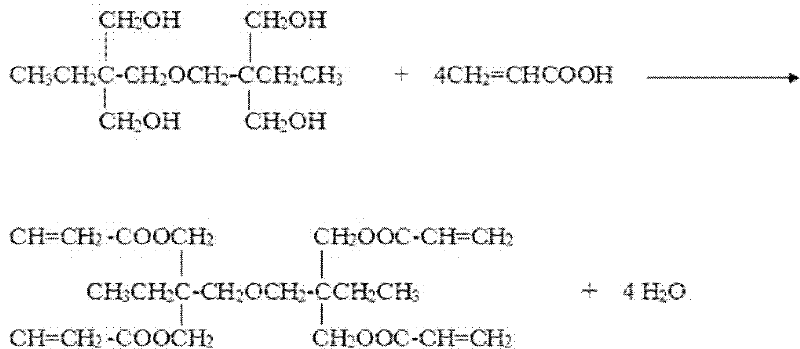

Cleaning production method for di-trimethylolpropane tetra-acrylic ester or pentaerythritol tetra-acrylic ester

ActiveCN102643197ANo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters separation/purificationSorbentSolvent

The invention belongs to the field of photo-curing material, and relates to a cleaning production method for di-trimethylolpropane tetra-acrylic ester or pentaerythritol tetra-acrylic ester. The method specifically comprises the following steps of: (1) dehydrating di-trimethylolpropane / pentaerythritol, crylic acid, catalyst, solvent, polymerization inhibitor and antioxygen by means of esterification and backflow; (2) adding sheet alkali and a small quantity of water to neutralize; (3) adding magnesium polysilicate adsorbent to adsorb and neutralize the generated salt; (4) dehydrating in a pressure reducing way, and removing solvent; (5) carrying out filter pressing, filtering out the magnesium polysilicate and salt adsorbed by the magnesium polysilicate; (6) adding alkaline calcium bentonite and calcium oxide, to remove color, trace moisture and trace acid; (7) carrying out filter pressing; and (8) detecting the indexes of a product. The invention belongs to a cleaning production method for the di-trimethylolpropane tetra-acrylic ester or the pentaerythritol tetra-acrylic ester, which is good in economic benefit and environmental benefit, so that the problem of organic waste water pollution when the di-trimethylolpropane tetra-acrylic ester or the pentaerythritol tetra-acrylic ester is produced can be basically solved.

Owner:JIANGSU LITIAN TECH

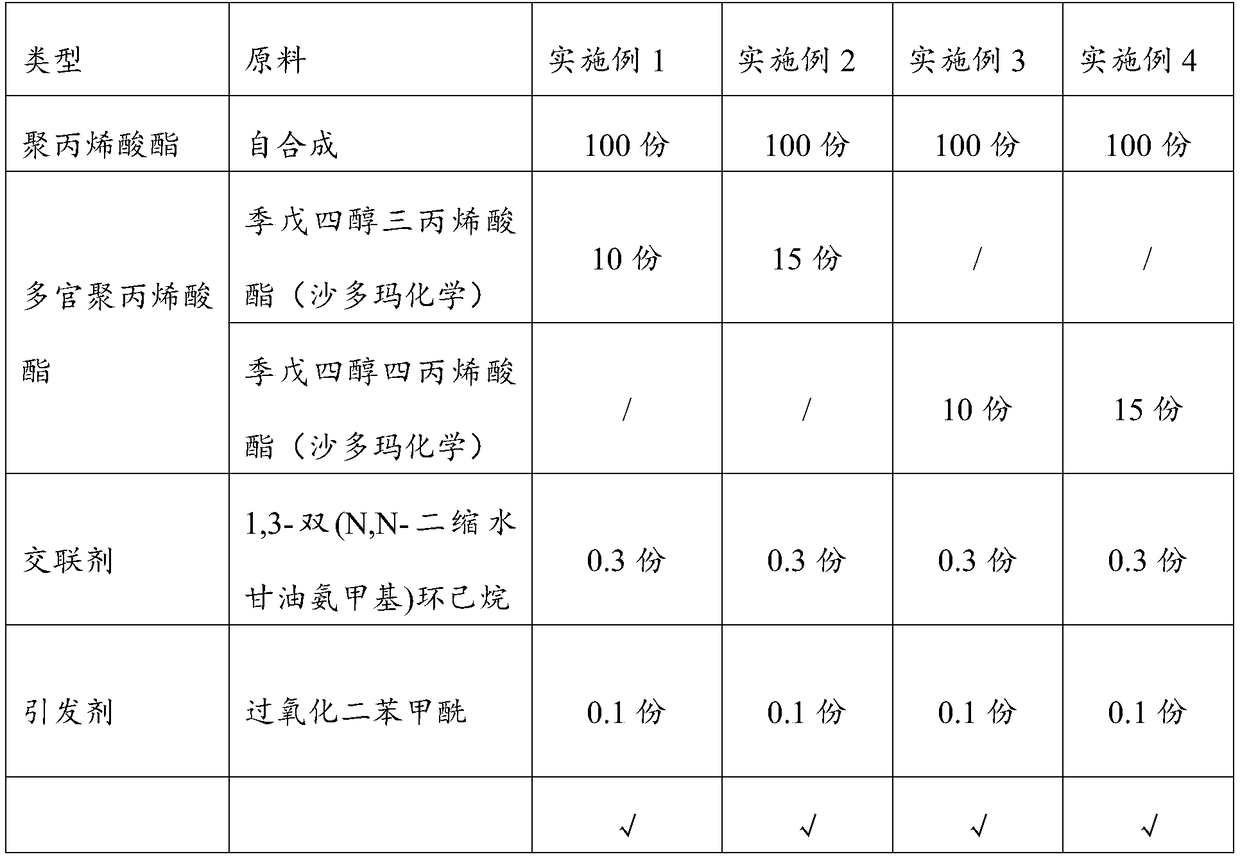

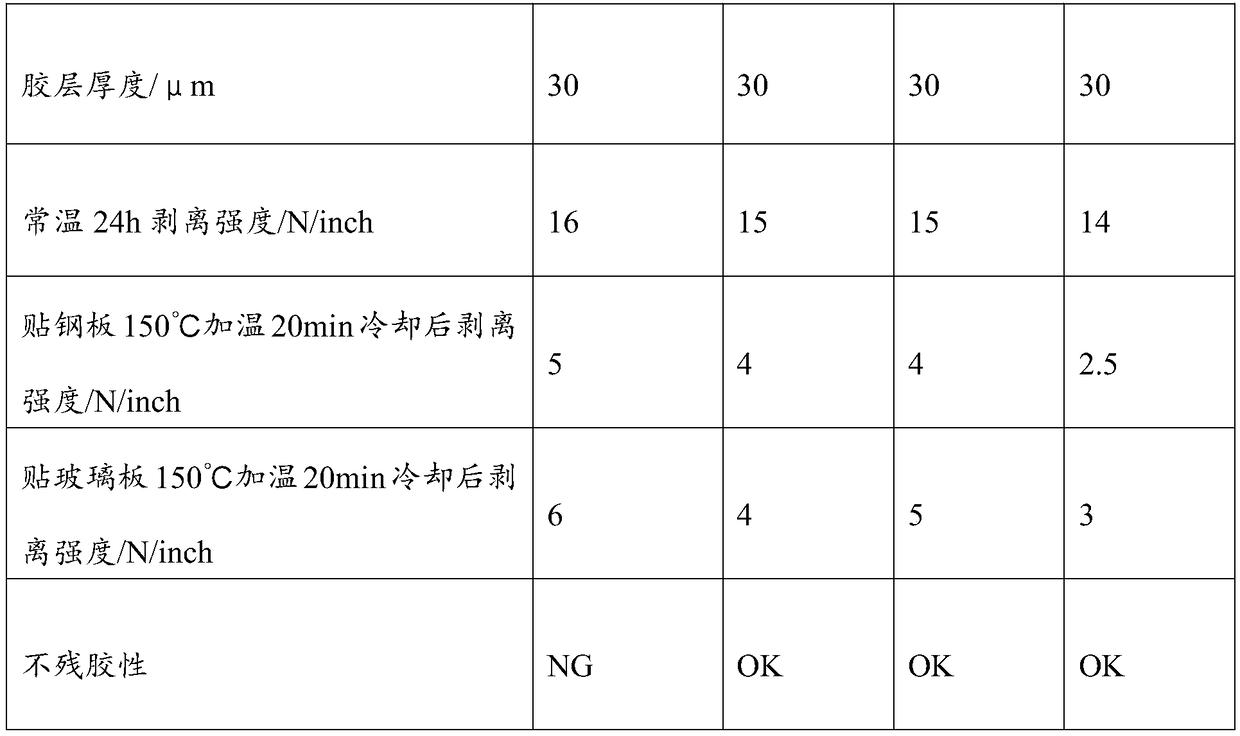

High-temperature-resistence viscosity-reducing adhesive tape and preparation method thereof

ActiveCN109266236ASmall peeling forceEasy to peelOrganic non-macromolecular adhesivePressure sensitive film/foil adhesivesCross-linkPentaerythritol

The invention relates to a high-temperature-resistence viscosity-reducing adhesive tape. The high-temperature-resistence viscosity-reducing adhesive tape comprises a base material membrane and high-temperature-resistence viscosity-reducing polyacrylate pressure sensitive adhesive smeared on the base material membrane; and the high-temperature-resistence viscosity-reducing adhesive tape is preparedfrom 100 parts of polyacrylate, 10 to 15 parts of multi-functional acrylate, 0.3 part of cross-linking agent and 0.1 part of initiator; and the multi-functional acrylate is any one of pentaerythritoltriacrylate or pentaerythritol tetraacrylate. The base material membrane is any one of a PET membrane or PI membrane. The polyacrylate comprising the high-temperature-resistence cross-linked functional group in the high-temperature-resistence viscosity-reducing adhesive tape is further cross-linked with the multi-functional acrylate at a high temperature, so that the stripping force is greatly reduced, and the high-temperature prepared adhesive tape is easier to strip; and the high-temperature-resistence viscosity-reducing adhesive tape disclosed by the invention is heated and used for 20 to30 minutes at 120 to 160 DEG C, the stripping force is apparently reduced, the adhesive tape is easier to strip, the adhesive residue risk is reduced, and the production efficiency is improved.

Owner:YANTAI DARBOND TECH

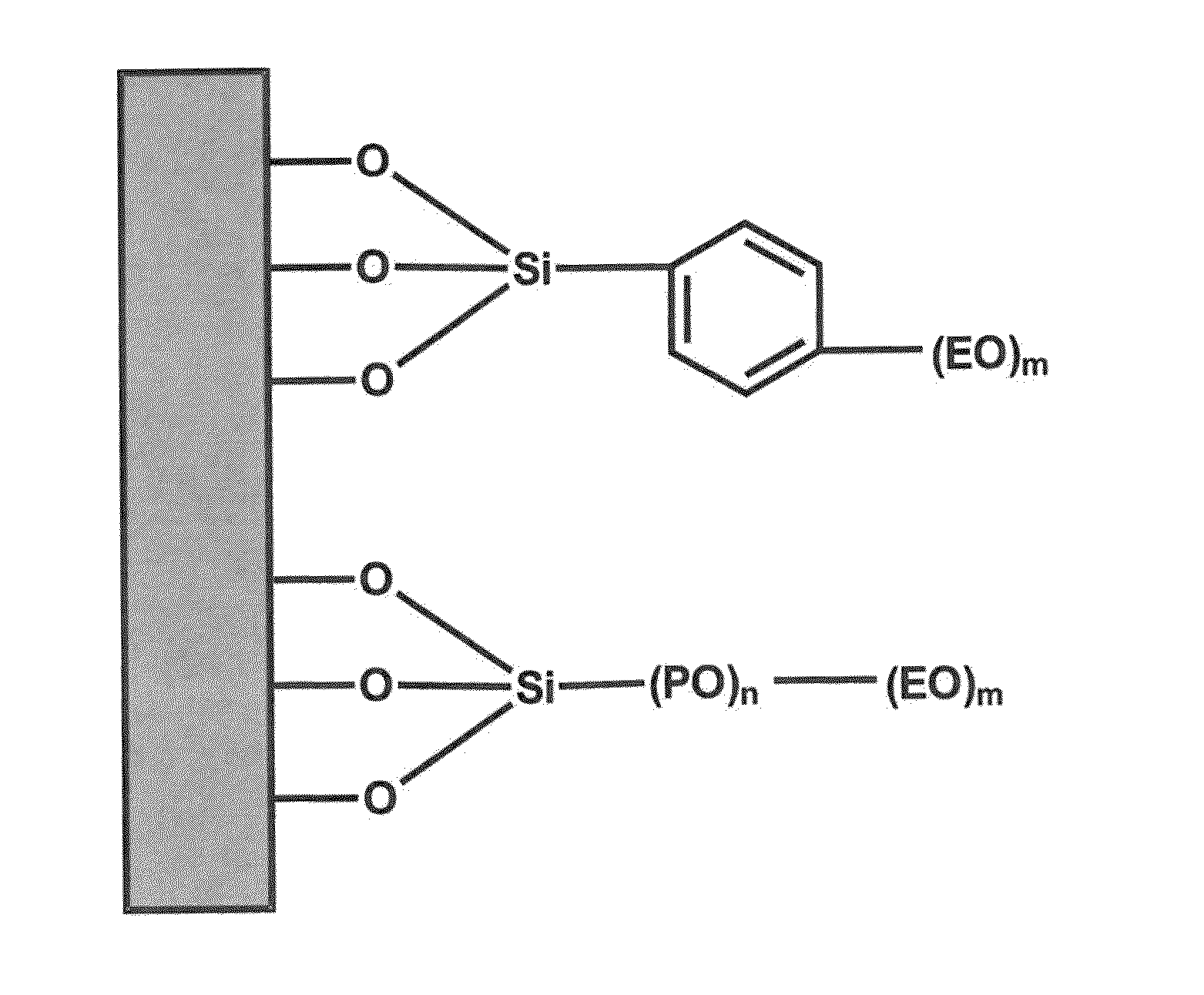

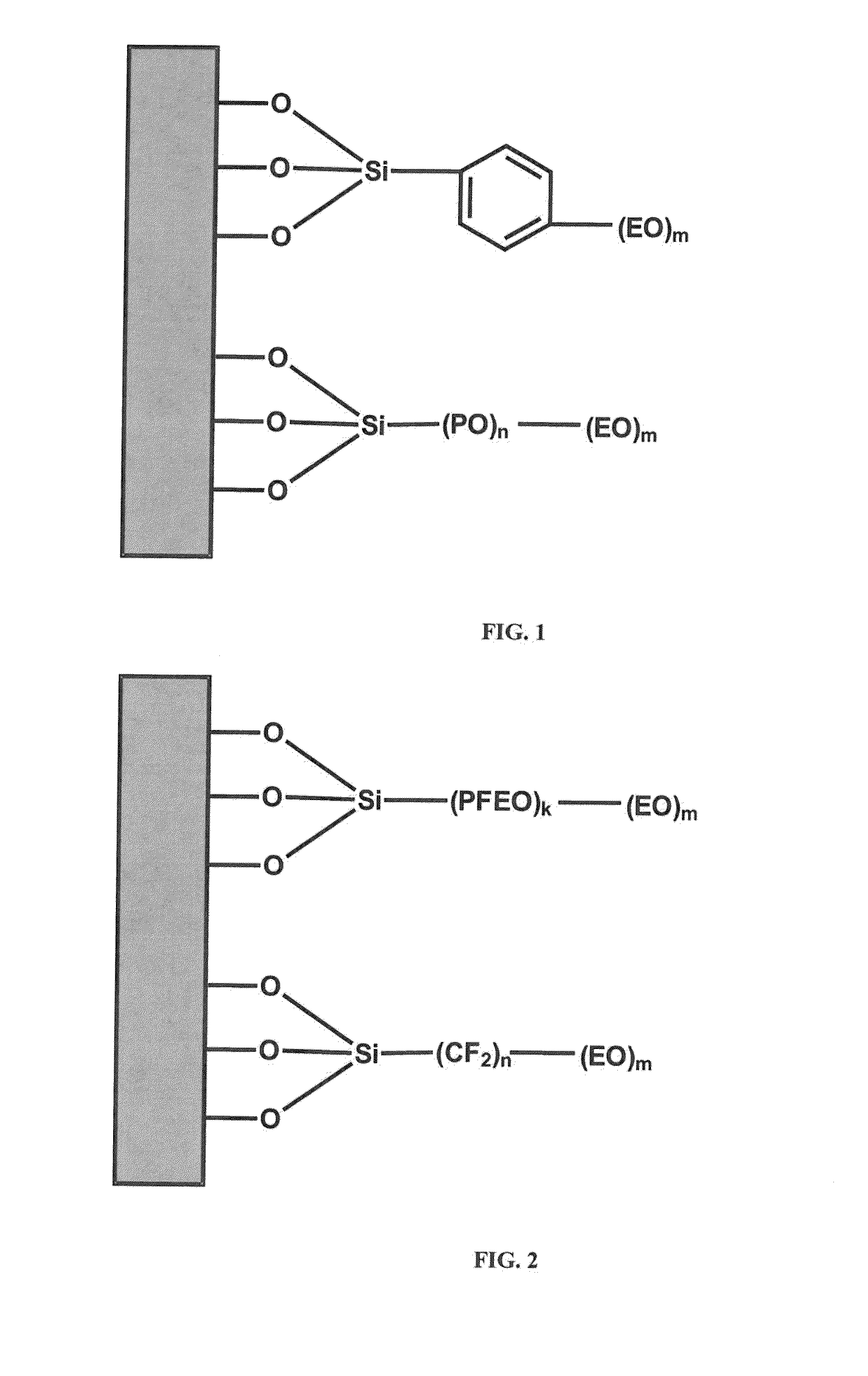

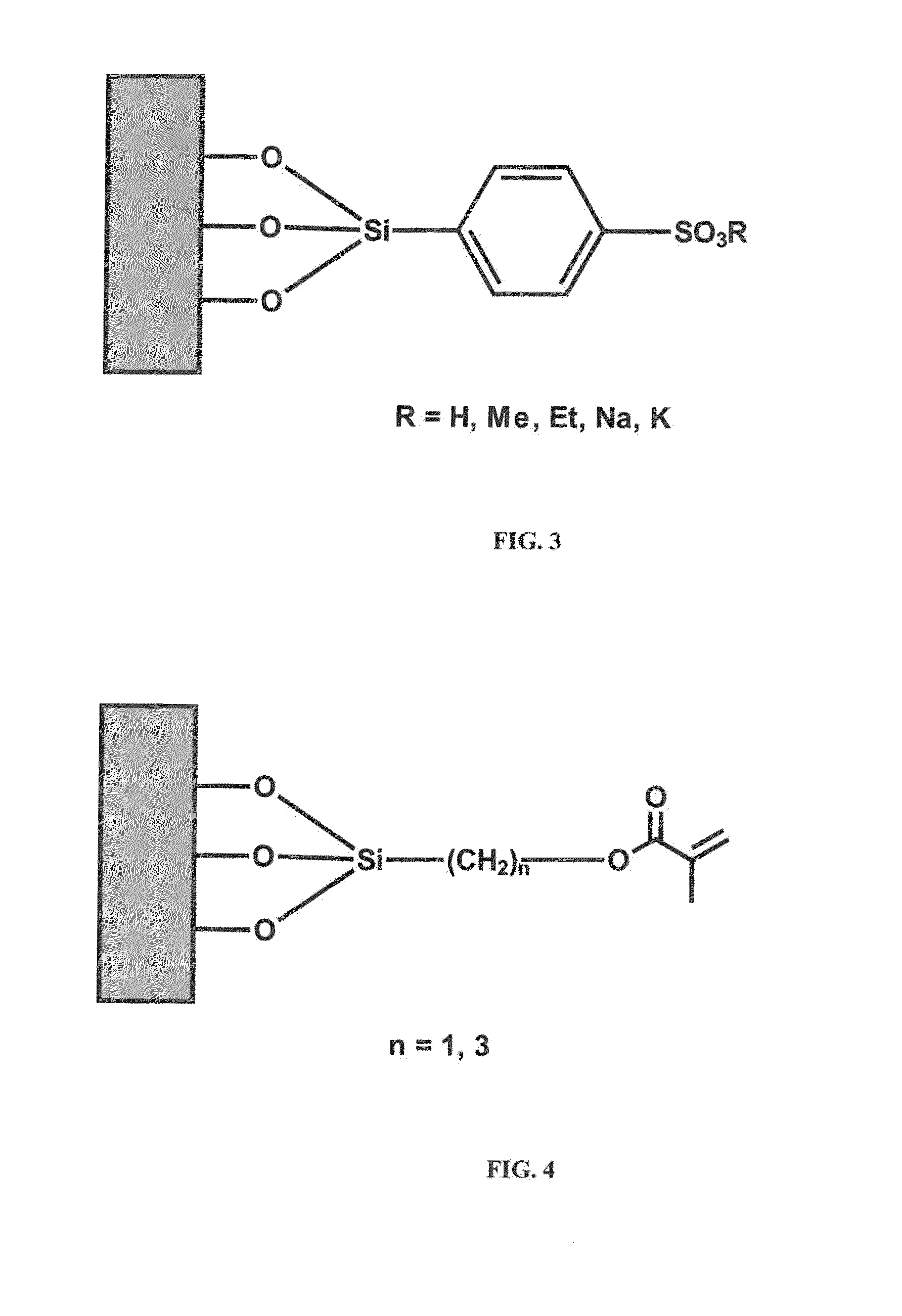

Anti-fog coating

ActiveUS20130308189A1Improve stabilityImprove shielding effectSpecial surfacesCoatingsMethacrylateSilanes

An optical component having an anti-fog coating obtainable by covalent attachment of a silane RoXmSiAn to the surface of the optical component, whereinm=1-3, n=1-2 and o=0-1, with the proviso that m+n+o=4;X is halogen or C1-4-alkoxy, and for m=2 or 3 the individual radicals X may be identical or different,R is C1-4-alkyl,A has the structure -A1-A2, in which -A1-is a hydrophobic group bonded to Si, and -A2 represents a terminal hydrophilic group bonded to A1, -A1-is selected from -arylene-; —C1-6-alkylene-arylene-; -arylene—C1-6-alkylene-; —C1-6-alkylene-arylene—C1-6-alkylene-; -poly(C3-6-alkoxylene)-, fluorinated or perfluormated -alkylene-, fluorinated or perfluormated -poly(C2-6-alkoxylene)-, or a combination thereof,and -A2 is poly(meth)acrylate,and for n=2 the individual radicals A may be identical or different,and where -A2 comprises monomer units selected from CH2═C(CH3)COOC1-4-alkyl, CH2═C(H)COOC1-4-alkyl hydroxyethylene methacrylate, 2-acrylamido-2-methylpropanesulphonic acid, trimethylolpropane triacrylate and pentaerythritol tetraacrylate or mixtures thereof.

Owner:CARL ZEISS VISION INT GMBH

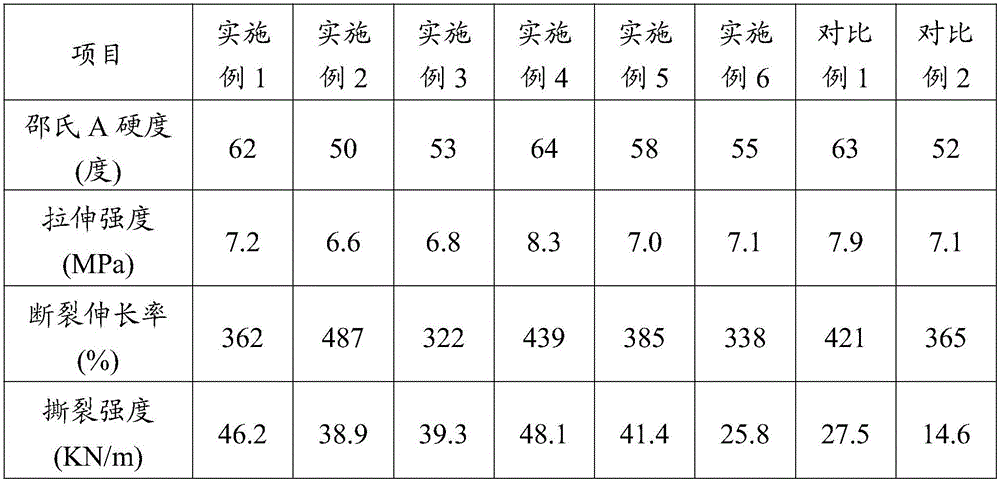

High-tearing-intensity high-temperature vulcanized silicon rubber, and preparation method and application thereof

The invention relates to high-tearing-intensity high-temperature vulcanized silicon rubber, and a preparation method and application thereof. Preparation raw materials of the high-tearing-intensity high-temperature vulcanized silicon rubber comprise the following ingredients including vulcanizing-agent-free mixing materials, polyvinyl cross linking auxiliary agents and vulcanizing agents; the vulcanizing-agent-free mixing materials comprise the following ingredients including methyl vinyl silicon rubber raw rubber, filling materials and structuring prevention agents; the polyvinyl cross linking auxiliary agents are selected from at least one from triallyl isocyanurate, tetravinyl tetramethylcyelo tetrasiloxane, ethoxylated trimethylolhexane triacylate, ethoxylated pentaerythritol Tetraacrylate, ditrimethylolpropane acrylate, propoxylated pentaerythritol tetraacrylate, dipentaerythritol pentaacrylate, propoxylated glyceryl triacrylate, pentaerythritol tetraacrylate, tri(trimethylolpropane) tetraacrylate, propoxylated tri(trimethylolpropane) tetraacrylate and triallyl cyanurate.

Owner:GUANGZHOU BAIYUN CHEM IND

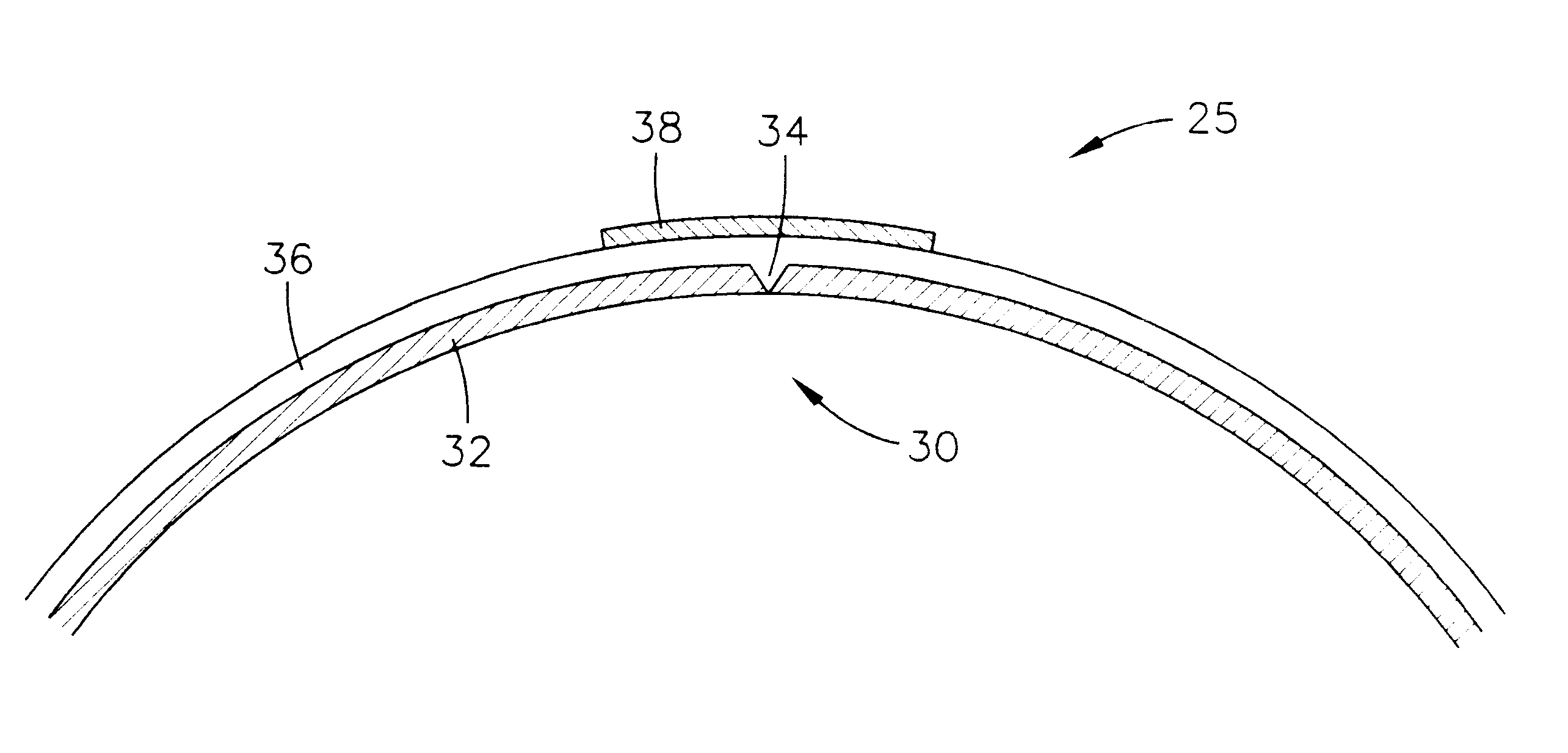

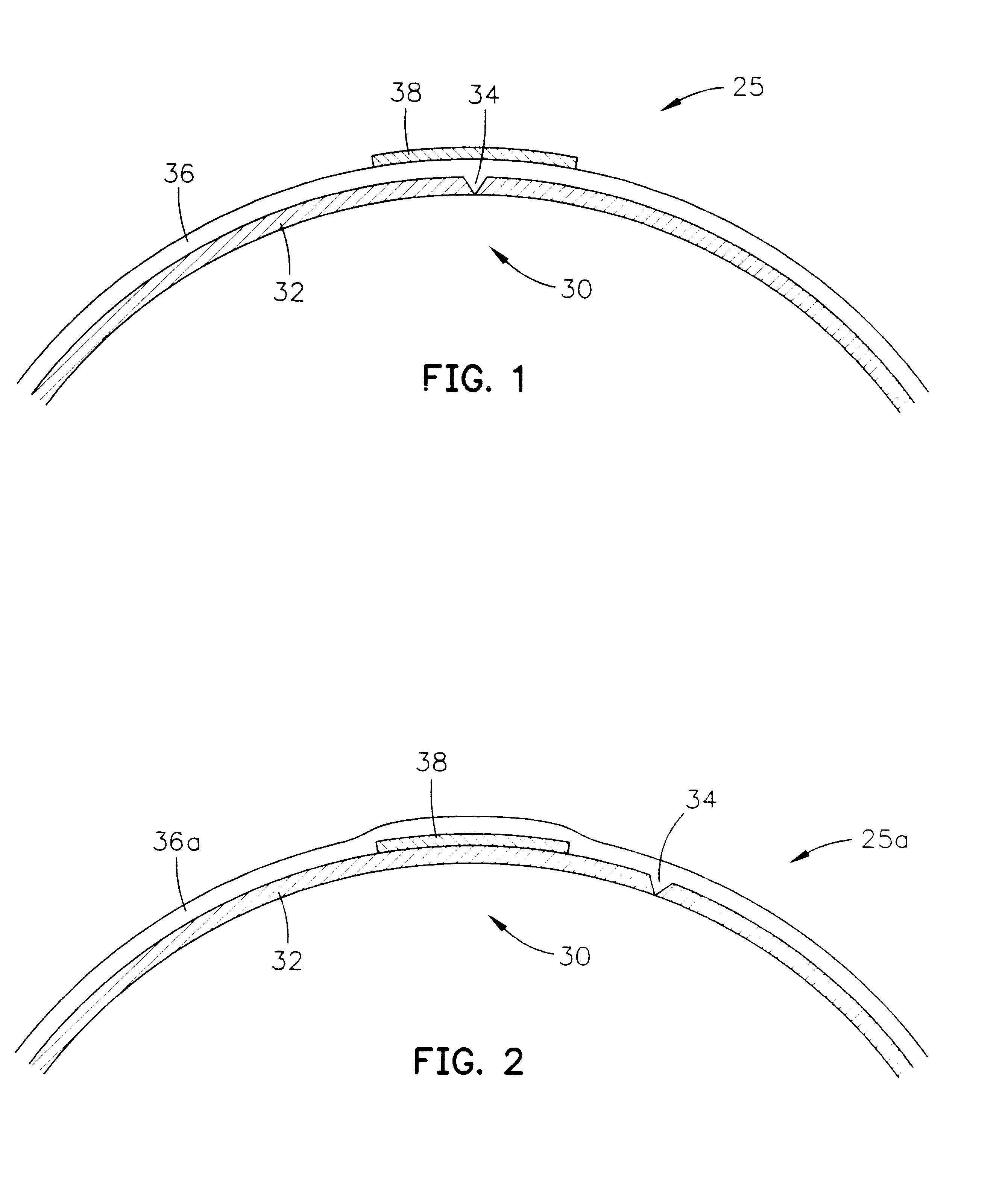

Dual curable coating

InactiveUS6485377B1Liquid surface applicatorsPolyurea/polyurethane coatings(Hydroxyethyl)methacrylateUV curing

The present invention is directed at a dual curable coating that exhibits superior adhesion to ultraviolet curable inks and base coats. The present invention is preferably utilized as a top coat for a golf ball. The dual curable coating may be a tinted top coat or a clear coat. The dual curable coating includes a dual-curing component that is selected from the group of pentaerythritol tetraacrylate, hydroxy ethyl acrylate, hydroxy ethyl methacrylate, hydroxy propyl acrylate, hydroxy propyl methacrylate, caprolactone acrylate and polyproplene glycol monomethacrylate.

Owner:CALLAWAY GOLF CO

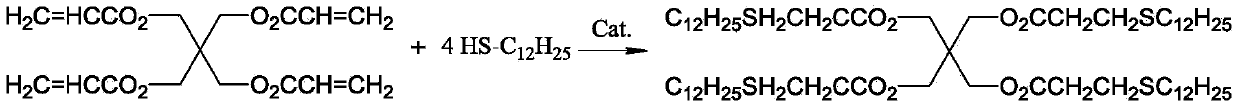

Preparation method of pentaerythritol tetra(3-n-dodecylthiopropionate)

The invention provides a preparation method of pentaerythritol tetra(3-n-dodecylthiopropionate), which initially provides a one-step synthesis method of pentaerythritol tetra(3-n-dodecylthiopropionate) from pentaerythritol tetraacrylate and 1-dodecyl mercaptan. The method comprises the following steps: adding 1-dodecyl mercaptan and a catalyst into a reactor, dropwisely adding pentaerythritol tetraacrylate at 40-60 DEG C to react, distilling out excessive 1-dodecyl mercaptan under reduced pressure, adding formic acid or glacial acetic acid to regulate the pH value to 6-7, adding a crystallization solvent to recrystallize, filtering, and drying to obtain the white crystalline powder product. Compared with the prior art, the novel method provided by the invention has the advantages of simple technique, low equipment and operation cost, energy saving, environmental protection, high product quality and high yield.

Owner:RIANLON

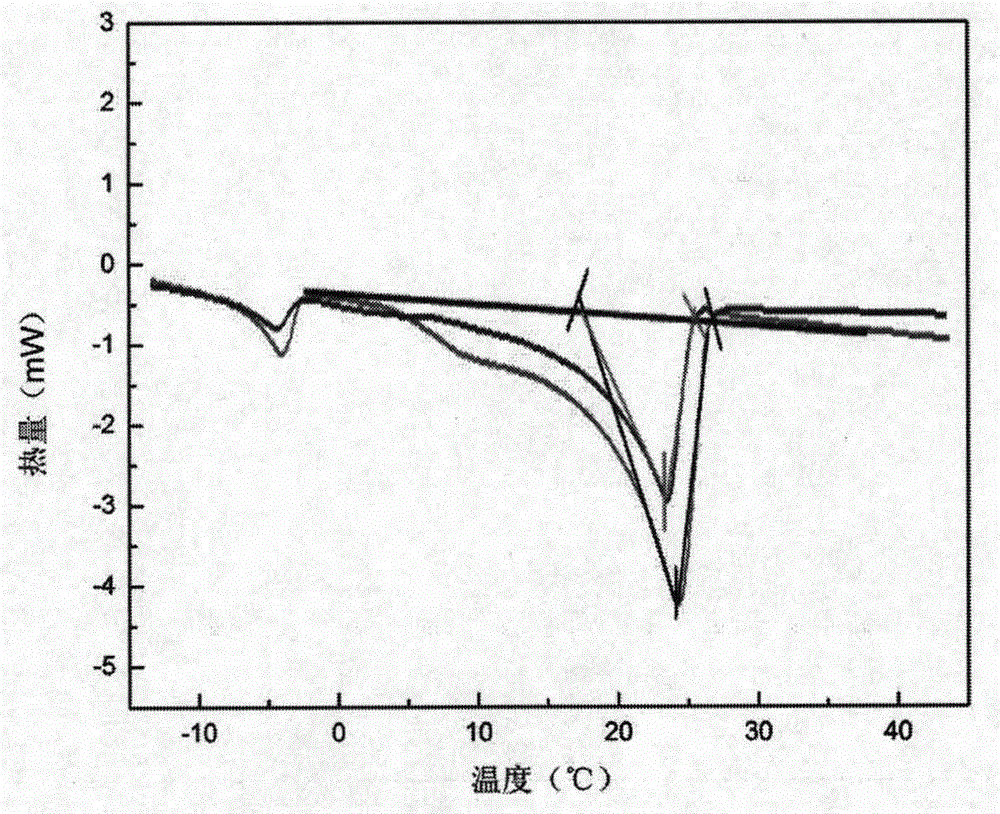

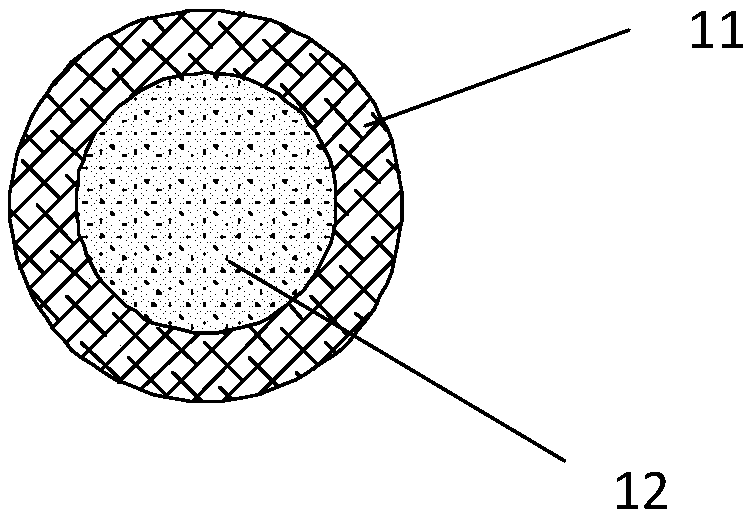

Flame-retardant microcapsule phase-change material

InactiveCN105112020AWon't happenNot volatileHeat-exchange elementsMicroballoon preparationBenzoyl peroxideSolvent

The invention relates to a flame-retardant microcapsule phase-change material. The flame-retardant microcapsule phase-change material is prepared from a core material, a flame-retardant wall material, an emulsifier, benzoyl peroxide (BPO) and deionized water, wherein the core material is fatty acid ester, the flame-retardant wall material is a crosslinking polymer of reactive phosphonate monomer and tetramethylol methane tetraacrylate, and the emulsifier is a mixture of nonionic surfactant and ionic surfactant. The flame-retardant microcapsule phase-change material provided by the invention has excellent performance and is safe and environment-friendly; since reactive phosphonate-modified acid ester polymer is used as the microcapsule wall material, good flame retardation effect, good water resistance and good solvent resistance are obtained, and reduction in phase change enthalpy of the phase-change material caused by an additive flame retardant can be avoided; and since aliphatic ester is used as a phase-change material, better thermal stability and chemical stability are obtained, and a heat release rate is lower.

Owner:NINGBO GREENTECH ENERGY SAVING TECH

Phase-change energy-storage microcapsules and preparation method thereof

InactiveCN106147718AReduce surface tensionNarrow particle size distributionHeat-exchange elementsMicroballoon preparationCross-linkBenzoyl peroxide

The invention relates to phase-change energy-storage microcapsules and a preparation method thereof; the phase-change energy-storage microcapsules are prepared from a core material, a wall material, an emulsifier, an initiator and deionized water; the core material is fatty acid ester, the wall material comprises methyl methacrylate and pentaerythritol tetraacrylate, the emulsifier is formed by mixing a nonionic surfactant and an ionic surfactant with the ratio of 1 to 1, the initiator is benzoyl peroxide, the mass ratio of the core material to the wall material is 1:1-1:4, the content of the emulsifier is 5-10% of the total mass of the core material and the wall material, the content of the initiator is 2-5% of the mass of the wall material, and the ratio of the total mass of the core material and the wall material to the mass of the deionized water is 1:4-1:6; a low-cost fatty acid ester is used as a phase change material, a mixture of the ionic surfactant and the nonionic surfactant is used as the emulsifier, a capsule wall is formed through cross-linking polymerization with combination of a suspension polymerization technology, and the phase-change microcapsules with smooth surface, uniform particles and high phase change material content are obtained.

Owner:NINGBO GREENTECH ENERGY SAVING TECH

Wear-resistant organic glass and preparing method thereof

The invention discloses wear-resistant organic glass. The wear-resistant organic glass comprises, by weight, 60-80 parts of methyl methacrylate, 20-40 parts of isobornyl methacrylate, 50-60 parts of toluene-2,4-diisocyanate, 70-80 parts of polyethylene glycol, 3-5 parts of pentaerythritol tetraacrylate, 3-5 parts of modified diatomite, 12-14 parts of wear-resistant agent, 8-12 parts of fire retardant, 4-6 parts of dibutyl phthalate, 10-12 parts of rubber particles, 3-5 parts of maleic anhydride grating compatilizer, 0.48-0.64 part of azodiisobutyronitrile, 0.3-0.5 part of dibutyltin dilaurate, and 6-8 parts of ethanethiol. The invention further discloses a preparing method of the wear-resistant organic glass. The wear-resistant organic glass is good in wear-resistant performance, high in rigidity and good in mechanical properties.

Owner:安徽亚克力实业有限公司

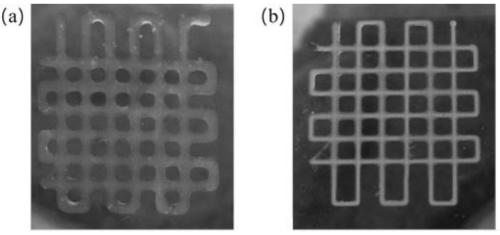

Photocuring auxiliary direct-writing 3D printed silicone rubber ink, preparation method thereof and silicone rubber of three-dimensional structure

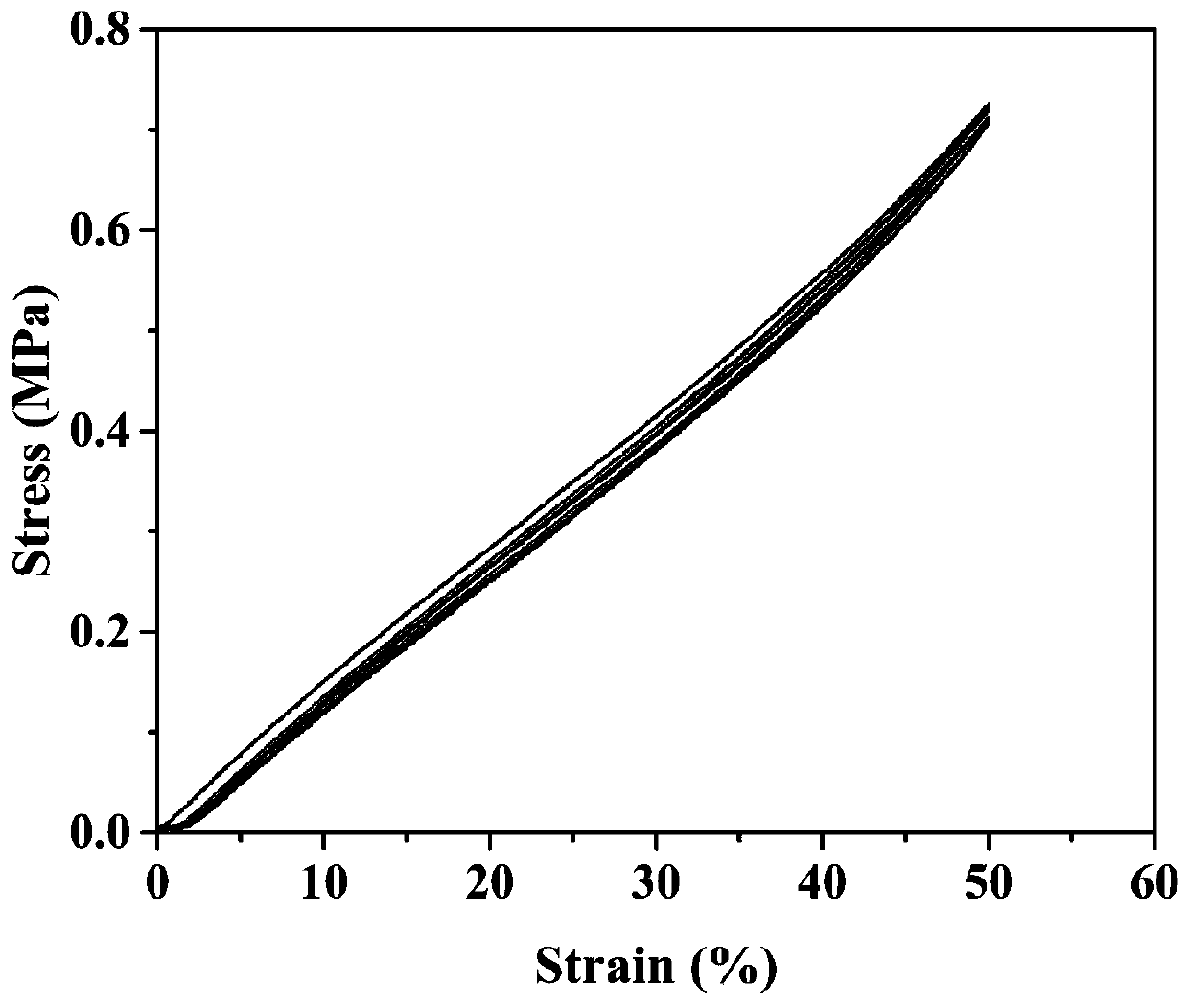

ActiveCN109810514AHigh viscoelasticityHigh mechanical strengthAdditive manufacturing apparatusElastomerPolymer science

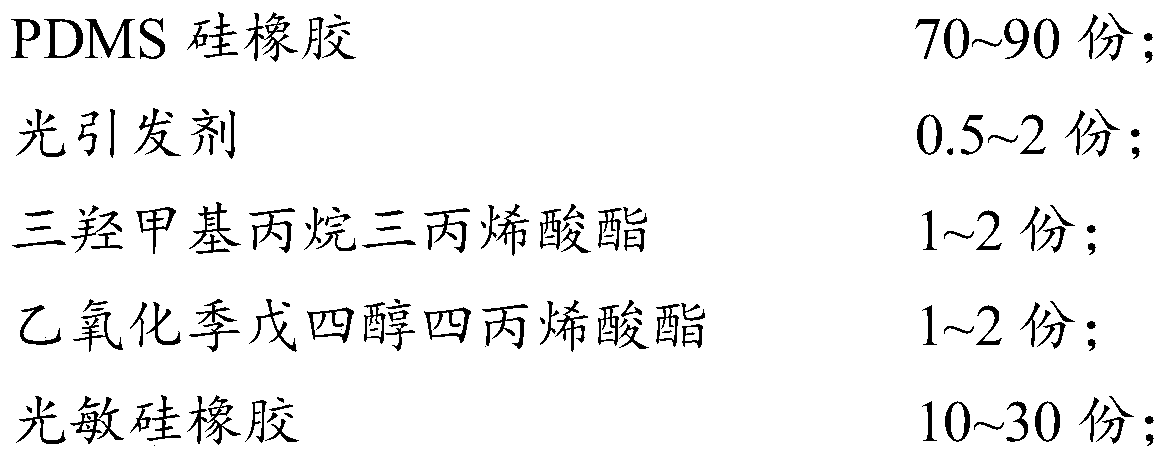

The invention relates to the field of photocuring elastomers, and provides photocuring auxiliary direct-writing 3D printed silicone rubber ink. The photocuring auxiliary direct-writing 3D printed silicone rubber ink is prepared from the following components in parts by weight: 70-90 parts of PDMS silicone rubber, 0.5-2 parts of a photoinitiator, 1-2 parts of trimethylolpropane triacrylate, 1-2 parts of ethoxylated pentaerythritol tetraacrylate, and 10-30 parts of photosensitive silicone rubber. The silicone rubber ink has appropriate viscosity and excellent photocuring performance, and 3D printing of the PDMS silicone rubber of the complex structure can be achieved. The invention provides a preparation method of the silicone rubber ink. The preparation method is simple in step and easy tooperate. The invention further provides silicone rubber of a three-dimensional structure. The silicone rubber ink is subjected to photocuring auxiliary direct-writing 3D printing and then subjected toheat treatment, and thus the silicone rubber of the three-dimensional structure can be obtained. The silicone rubber of the three-dimensional structure can be of any complex structure, and is high inmechanical strength, and good in elasticity and scalability performance.

Owner:烟台润创工业科技有限公司

Single-component water-based acrylic dispersoid and preparation method thereof

The invention provides a single-component water-based acrylic dispersoid and a preparation method thereof. The provided single-component water-based acrylic dispersoid comprises the following components: isopropanol, (methyl) acrylate, a vinyl monomer, an acrylic acid / or a methacrylic acid, pentaerythritol tetraacrylate, an initiator, a neutralizer and deionized water. The provided single-component water-based acrylic dispersoid is convenient to use and operate, the link of preparing paint is saved compared with double-component paint, the performance of the single-component water-based acrylic dispersoid rivals that of a middle and low hydroxyl second-level dispersoid, and the single-component water-based acrylic dispersoid has the characteristics of high glossiness, high fullness, high hardness, good water resistance, good weather fastness and the like. More importantly, the VOC (volatile organic compound) in the provided single-component water-based acrylic dispersoid reaches 0, sothat the single-component water-based acrylic dispersoid is quite environmentally-friendly.

Owner:湖北双键精细化工有限公司

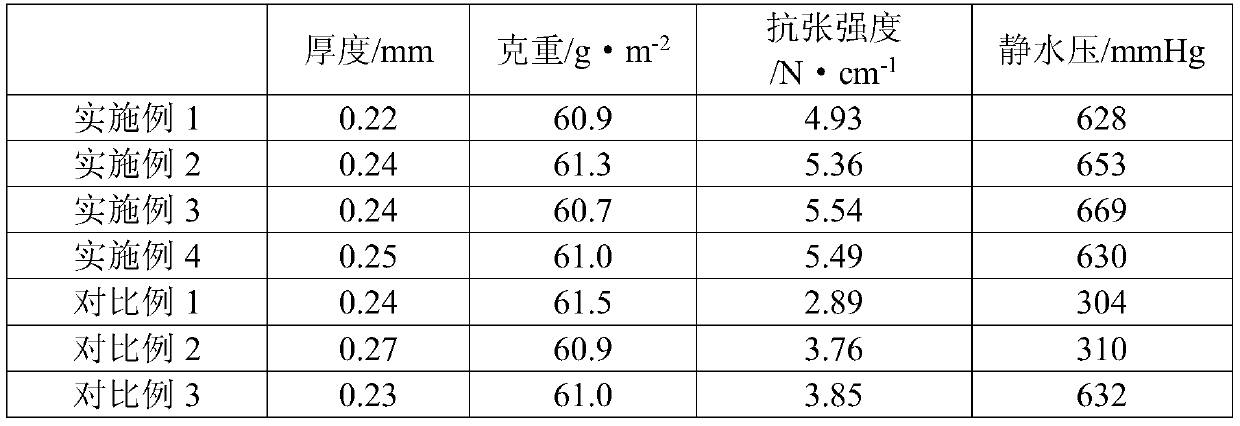

High-strength hydrophobic non-woven fabric and preparation method thereof

ActiveCN111560772AHigh strengthIncreased durabilityTextile/flexible product manufactureLiquid repellent fibresPolymer scienceMeth-

The invention relates to the technical field of non-woven fabrics, and discloses a high-strength hydrophobic non-woven fabric and a preparation method thereof. The non-woven fabric comprises the following raw materials in parts by weight: 100 parts of cellulose fibers, 5-10 parts of a trimethylol aminomethane-methyl acrylate-dipentaerythritol copolymer, 30 to 35 parts of 1,6-bi(acryloyloxy)-2,2,3,3,4,4,5,5-octafluorohexane, 2-2. 5 parts of pentaerythritol tetraacrylate. The high-strength hydrophobic non-woven fabric disclosed by the invention is internally added with the trimethylol aminomethane-methyl acrylate-dipentaerythritol copolymer so that the strength of the non-woven fabric is enhanced; and the surface of the non-woven fabric is grafted with the 1,6-bi(acryloyloxy)-2,2,3,3,4,4,5,5-octafluorohexane and the pentaerythritol tetraacrylate so that the strength and the hydrophobicity of the non-woven fabric are improved.

Owner:MEIWA PLASTIC SHANGHAI

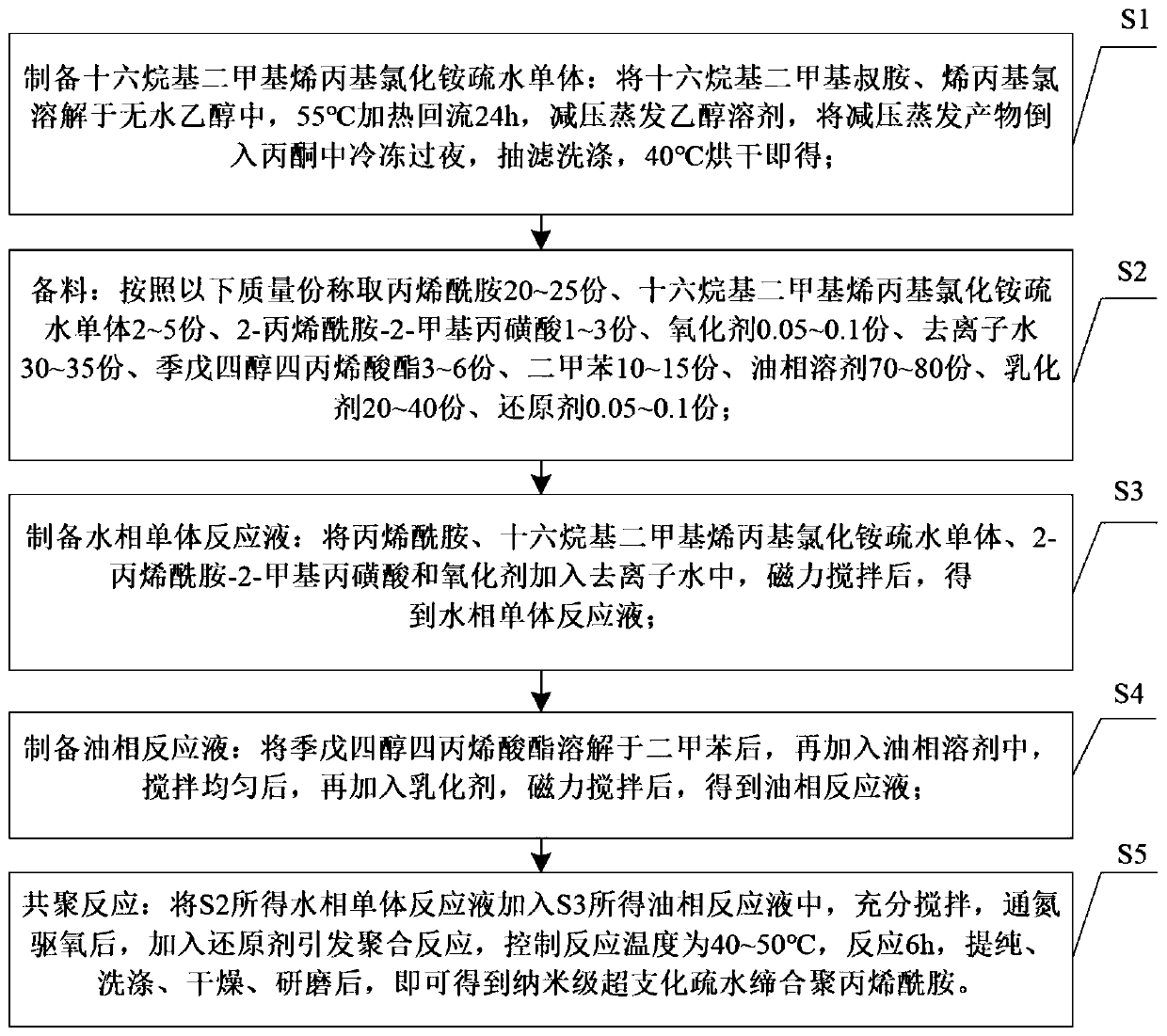

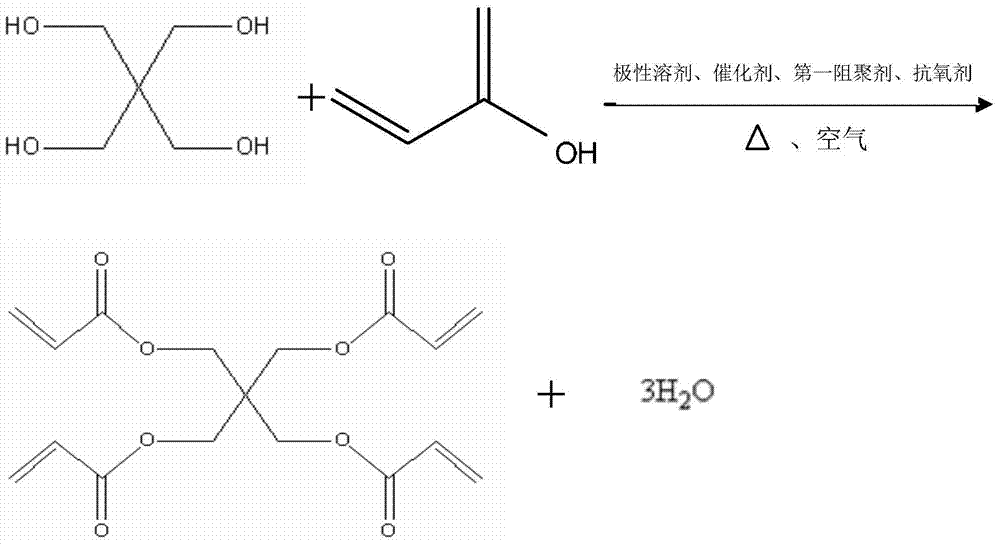

Preparation method of nanoscale hyperbranched hydrophobically associating polyacrylamide

ActiveCN111592616AImprove shear resistanceEnhanced overall recoveryClimate change adaptationDrilling compositionXylylenePolymer science

The invention discloses a preparation method of nanoscale hyperbranched hydrophobically associating polyacrylamide, wherein the polyacrylamide is a nanoscale hyperbranched multi-arm hydrophobically associating polymer formed by grafting acrylamide, hexadecyl dimethyl allyl ammonium chloride and a 2-acrylamide-2-methylpropanesulfonic acid copolymer with pentaerythritol tetraacrylate as an inner core; S1, preparing a hexadecyl dimethyl allyl ammonium chloride hydrophobic monomer; S2, preparing materials; S3, preparing a water-phase monomer reaction solution; S4, preparing an oil-phase reaction liquid: dissolving pentaerythritol tetraacrylate in xylene, adding the obtained solution into the oil-phase solvent, uniformly stirring, adding an emulsifier, and magnetically stirring the mixture to obtain the oil-phase reaction liquid; S5: carrying out copolymerization reaction. According to the invention, the nanoscale hyperbranched hydrophobically associating polyacrylamide prepared by using aninverse microemulsion polymerization method has excellent shear resistance, hydrophobicity and salt resistance, has nanoscale size, and improves the crude oil recovery ratio.

Owner:ANHUI TIANRUN CHEM CO LTD

Visible-light-cured adhesive and preparation method thereof

ActiveCN103740286ALiquidLiquidityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveGlycidyl methacrylatePentaerythritol

The invention provides a visible-light-cured adhesive including the following components: by weight, 20-50% of methacrylate monomer, 10-30% of a methacrylate diluent, less than 5% of a visible light initiator, 30-68% of silica, glass powder or alumina powder and 0.1-5% of nano fumed silica, the methacrylate monomer is at least one substance from bisphenol A-glycidyl dimethacrylate, ethoxylated bisphenol A dimethacrylate, pentaerythritol tetraacrylate, dipentaerythritol pentaacrylate and dipentaerythritol hexaacrylate, and the invention also provides a preparation method of the visible-light-cured adhesive. The visible-light-cured adhesive is low in mobility, short in curing time, highin bonding strength, and suitable for industrial application.

Owner:BEIJING POLYSTAR HITECH CO LTD

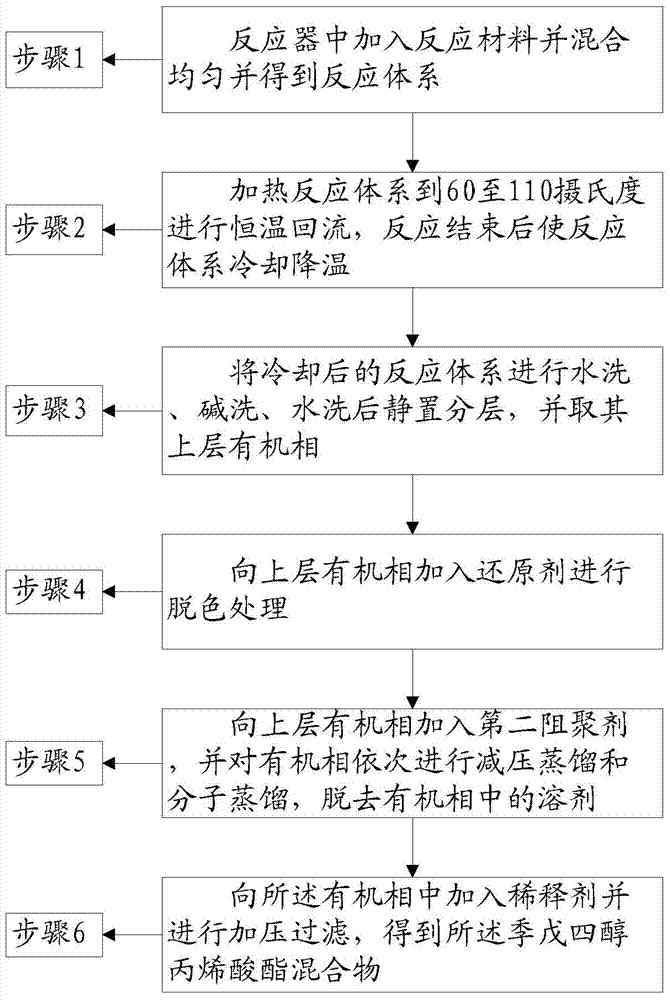

Preparation method of pentaerythritol tetraacrylate mixture

ActiveCN104513161AThe preparation method has few stepsEasy to makeOrganic compound preparationCarboxylic acid esters separation/purificationDistillationFiltration

The invention discloses a preparation method of a pentaerythritol tetraacrylate mixture and belongs to the field of chemical engineering. The preparation method comprises following processes: (1) feeding reaction materials into a reactor and mixing the reaction materials uniformly; (2) heating the reaction system to perform constant-temperature reflux to obtain reaction products; (3) cooling the reaction products and washing the reaction products, allowing the reaction products to stand for being layered and obtaining an upper-layer organic phase; (4) adding a reducing agent to the organic phase for decoloration; (5) adding a polymerization inhibitor and removing solvents in the organic phase in a manner of reduced pressure distillation and molecular distillation; and (6) adding a diluent with mixing and performing pressurized filtration to obtain a finish product. The preparation method is free of generation of harmful gases, thereby avoiding air pollution. By means of the washing process, residual acrylic acid and other impurities in the reaction system are removed. By means of the reduced pressure distillation for separating the solvents and the reaction system and the molecular distillation for removing residual solid impurities, the pure finish product is obtained. By means of usage of an anti-oxidizing agent, feeding of a protective gas and the decoloration, yield of the finish product is increased and chroma of the finish product is reduced. By means of addition of the diluent, the finished product is enhanced in stability, is improved in application performances and is wider in application range.

Owner:ANQING FEIKAI NEW MATERIAL CO LTD

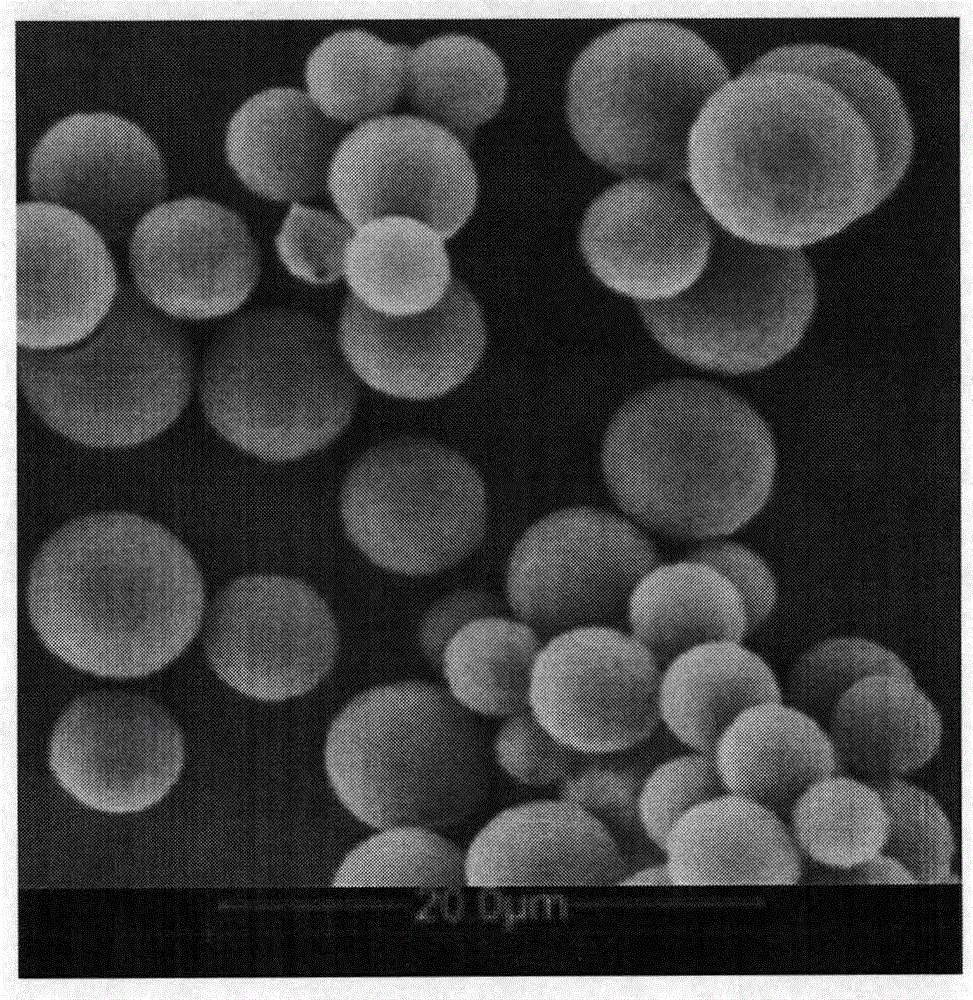

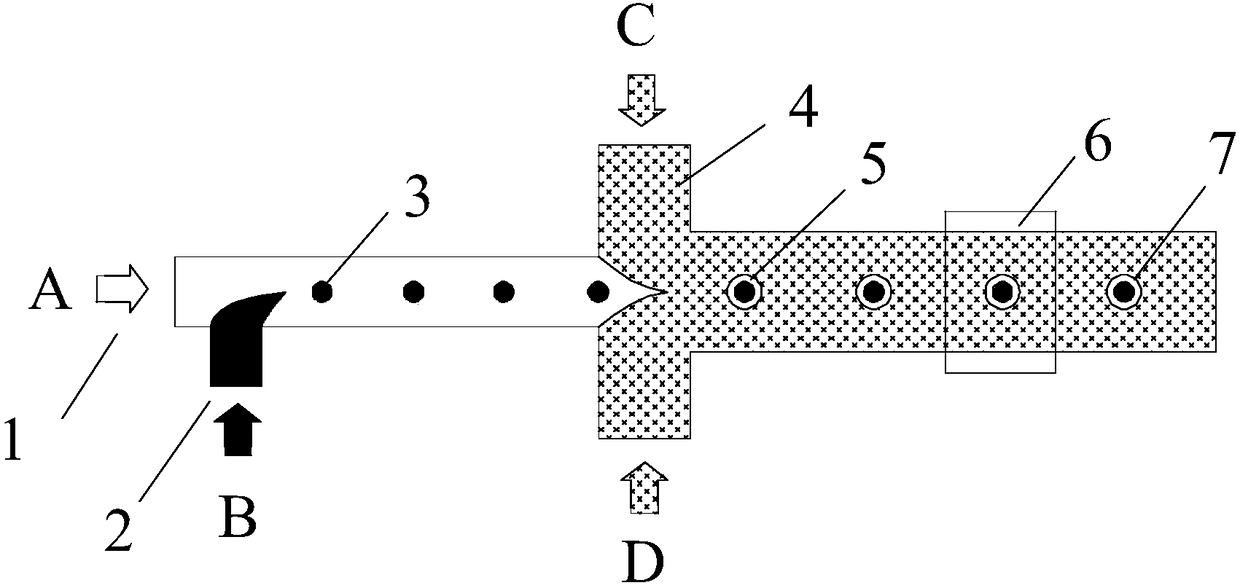

Method for preparing micron-level crosslinked polystyrene microsphere

The invention discloses a method for preparing a micron-level crosslinked polystyrene microsphere. The method is characterized by comprising the following steps of: dissolving a styrene monomer, pentaerythritol tetra-acrylate serving as a crosslinking agent and azodiisobutyronitrile serving as an evocating agent in ethanol which is an environmentally-friendly solvent, vibrating at the constant temperature for reaction, performing centrifugal separation on polymerisate, washing the polymerisate with absolute ethanol, and drying to constant weight. Through the preparation method disclosed by the invention, the crosslinked polystyrene microsphere with good single dispersion and particle diameter range between 0.3 and 1 micron can be obtained and can be applied to the fields of biological medicament, chromatographic packing, chemical analysis and the like.

Owner:LUDONG UNIVERSITY

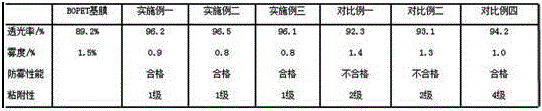

Transmittance-increasing anti-haze coating material for optical BOPET film and preparation method thereof

The invention discloses a transmittance-increasing anti-haze coating material for an optical BOPET film. The coating material is prepared from reaction monomers, inorganic nanoparticles, a silane coupling agent and an initiating agent, wherein the reaction monomers are composed of acrylic acid, methacrylic acid, ethylene glycol dimethacrylate, trimethylolpropane triacrylate and pentaerythritol tetraacrylate. The total light transmittance of the optical BOPET film coated with the coating material is larger than or equal to 96%, and the haze of the optical BOPET film is smaller than or equal to 1%; compared with a BOPET base film, the light transmittance is increased by nearly 7%, and the haze is slightly decreased; no VOC is emitted in the coating drying process, and thus environmental friendliness is achieved; meanwhile, a coating has large adhesive force to the BOPET base film.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

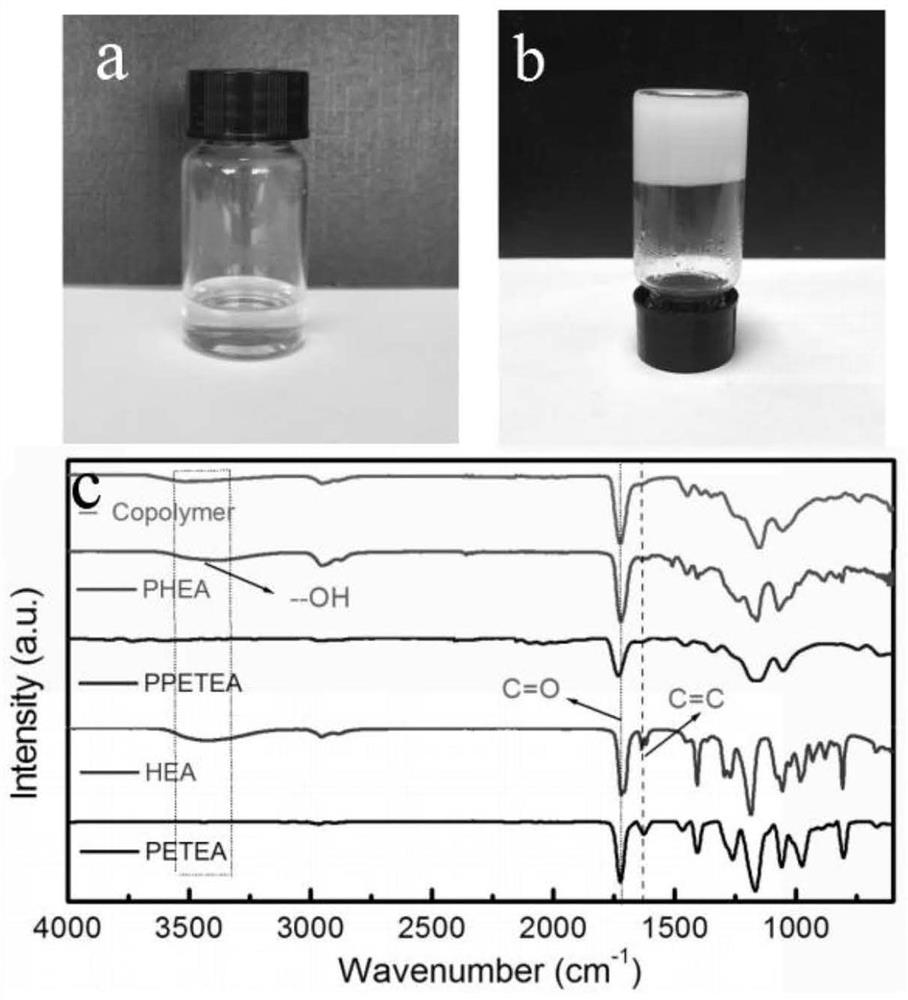

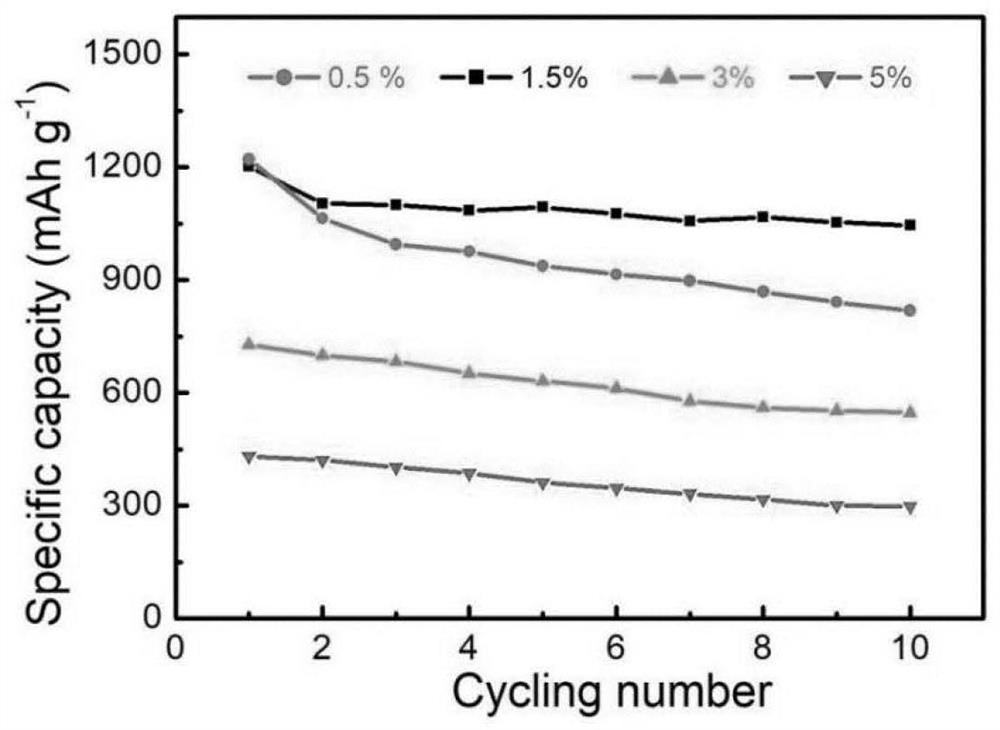

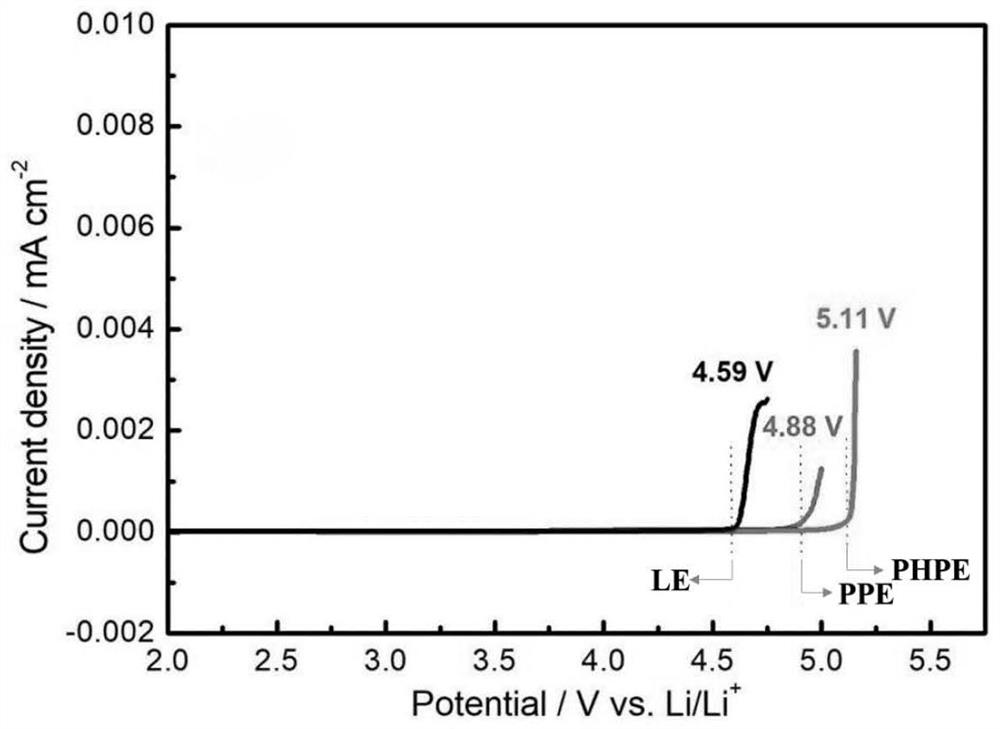

Preparation method of in-situ polymerized solid electrolyte

InactiveCN111883824AGood film formingInhibition of the shuttle effectSolid electrolytesLi-accumulatorsSolid state electrolyteAcrylic acid

The invention relates to the field of polymer materials, and discloses a preparation method of an in-situ polymerized solid electrolyte, which aims at the problems of shuttle effect and loss of activesubstances caused by diffusion of discharge products in the prior art. The preparation method comprises the following steps: (1) dissolving lithium bis(trifluoromethanesulfonyl)imide into a mixed solution of ethylene glycol dimethyl ether and 1,3-dioxolane; (2) dissolving pentaerythritol tetraacrylate and 2-hydroxyethyl acrylate in the electrolyte, adding azodiisobutyronitrile, and uniformly stirring the electrolyte at room temperature; and (3) assembling the polymer slurry, a sulfur positive electrode and a lithium negative electrode into a button battery, and heating the button battery to cure the polymer slurry in situ in the battery to obtain a finished product. According to the present invention, the polysulfide shuttle effect in the lithium-sulfur battery is effectively reduced, theinterface problem of the negative electrode lithium dendrites and the battery is significantly improved, and the hydroxyl-containing polymer structure unit is introduced to prepare the in-situ polymerization type multi-block polymer electrolyte, such that the solid polymer lithium-sulfur battery has excellent electrochemical performance.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +1

Method for preparing high oil absorption resin

InactiveCN102060962APerfect cross-linking structureMild conditionsOther chemical processesCross-linkN dimethylformamide

The invention discloses a method for preparing high oil absorption resin, which is characterized by comprising the following steps of: firstly, preparing a polystyrene microsphere macroinitiator modified by chlorosulfonic acid, n-propylamine and sodium hypochlorite; then dissolving a catalyst and a ligand into N,N-dimethylformamide as a solvent; adding the polystyrene microsphere macroinitiator, ascorbic acid as a reductant and tetramethylol methane tetraacrylate as a cross-linking agent into an acrylic monomer; charging nitrogen for deoxidizing; undergoing polymerization reaction for a period of timeat a certain temperature; washing, filtering, drying, extracting by a Soxhlet extractor and vacuum drying to obtain the high oil absorption resin. By dint of the method disclosed by the invention, high oil absorption resin with three-dimensional structure can be obtained, and therefore, the invention has a favorable environment-protection application value.

Owner:LUDONG UNIVERSITY

Glass fiber reinforced nylon material and preparation method therefor

InactiveCN105176069AImprove mechanical propertiesAvoid prone to wear problemsVinyl etherPolymer science

The invention discloses a glass fiber reinforced nylon material and a preparation method therefor. The glass fiber reinforced nylon material is prepared from the following ingredients, by weight, 80-88 parts of nylon, 8-12 parts of glass fibers, 5-10 parts of polyarmide fibers, 6-10 parts of amide modified hydrogenated castor oil, 5-9 parts of dipentaerythritol hexavinyl ether, 5-8 parts of propoxide pentaerythritol tetraacrylate, 5-7 parts of trimethyl metasilicate, 1-2 parts of triethanolamine, 0.5-1.5 parts of graphene and 0.5-1 part of dicumyl peroxide. The invention also provides a preparation method for the glass fiber reinforced nylon material.

Owner:SUZHOU YUNSHU NEW MATERIAL TECH

Safety document and/or valuable document with scratch-proof covering layer

InactiveCN102529492AImprove scratch resistanceGood chemical resistanceOther printing matterCoatingsMethacrylateLacquer

The invention relates to a security and / or valuable document containing a scratch-resistant coating obtained from a lacquer composition comprising I) from 12 to 70 parts by wt. of a C2-C12-diol diacrylate or C2-C12-diol dimethacrylate, II) from 12 to 40 parts by wt. of an alkoxylated mono-, di-, tri-, tetra-, penta- or hexaacrylate or alkoxylated mono-, di-, tri-, tetra-, penta- or hexamethacrylate, III) from 0 to 40 parts by wt. of a monomer selected from the group consisting of pentaerythritol triacrylate, pentaerythritol tetraacrylate, dipentaerythritol tetraacrylate, dipentaerythritol pentaacrylate, dipentaerythritol hexaacrylate, pentaerythritol trimethacrylate, pentaerythritol tetramethacrylate, dipentaerythritol tetramethacrylate, dipentaerythritol pentamethacrylate, dipentaerythritol hexamethacrylate, reaction products thereof with aliphatic or aromatic diisocyanates, and mixtures thereof, IV) from 5 to 60 parts by wt. of a further mono-, di- or triacrylate or mono-, di- or trimethacrylate, and further comprises V) from 0.1 to 10 parts by wt. of a photoinitiator.

Owner:COVESTRO DEUTSCHLAND AG

Flame-retardant insulating composite and preparation method thereof

The invention relates to a flame-retardant insulating composite and a preparation method thereof.The method includes the steps of adding glass fiber to ethyl alcohol, adding iso-tridecanol polyoxyethylene ether, removing ethyl alcohol to obtain active glass fiber, adding 5,5'-bis(triethoxysilyl)-3,3'-dipyridyl, N,N-dimethylformamide and pentaerythritol tetraacrylate to unsaturated polyester resin, then adding magnesium hydroxide powder and antimonous oxide powder to be stirred, adding di-n-hexylamine and m-aminoacetanilide, adding 4-acetamidophenol to obtain a resin material, adding the active glass fiber to the resin material to be mixed through a kneading machine to obtain flame-retardant insulating composite raw materials, adding the flame-retardant insulating composite raw materials into a preheated die to be heated to 60 DEG C , keeping the temperature for 35 minutes, conducting hot-pressing for 11 minutes at 105 DEG C and 1.5 Mpa, and storing the materials at the constant temperature of 90 DEG for 3 days to obtain the flame-retardant insulating composite.The flame-retardant insulating composite has excellent mechanical performance and flame retardance and meets the development application of the flame-retardant insulating composite.

Owner:SUZHOU JIN TENG ELECTRONICS TECH

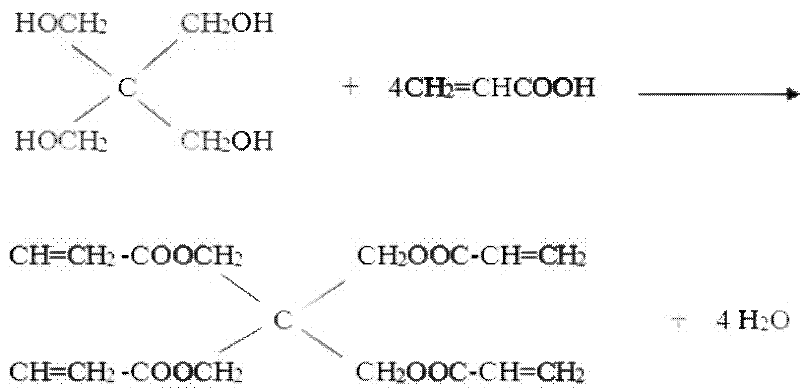

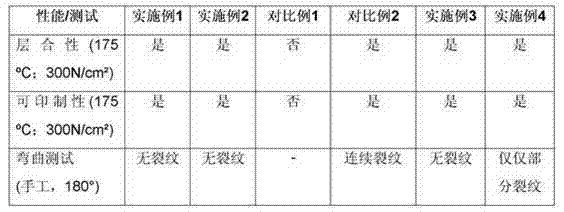

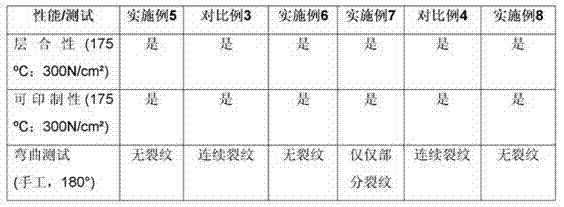

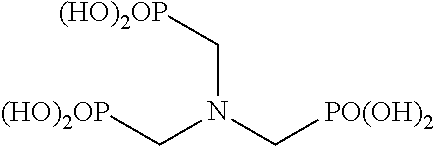

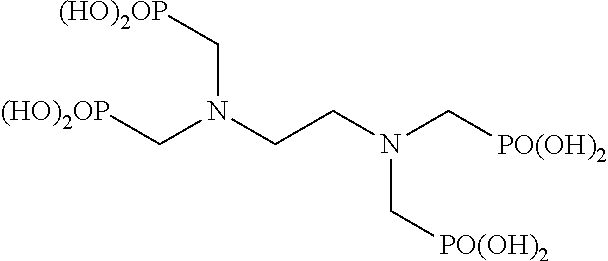

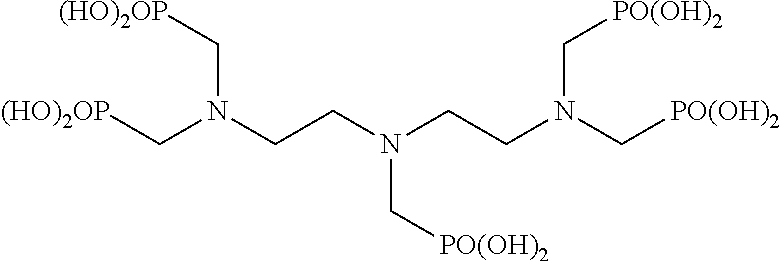

Pentaerythritol core, phosphonic acid terminated dendrimer and its preparation method

ActiveUS20140332471A1Prevent scalingGood calcium toleranceWaste water treatment from quariesOrganic chemistryDendrimerReverse osmosis

A pentaerythritol core, phosphonic acid terminated dendrimer, its preparation method and application are provided. A preparation method of the pentaerythritol core, phosphonic acid terminated dendrimer (PETA-ADA-12PO3H2) comprises steps of processing Michael addition reaction on pentaerythritol tetraacrylate (C(CH2OCOCH2=CH2)4) and alkylidene diamine (NH2CH2(CH2)nNH2), wherein n is an integer from 1 to 5, so as to obtain pentaerythritol core, amino group terminated dendrimer, and modifying the amino group by methylene phosphonic acid to obtain the PETA-ADA-12PO3H2 having a chemical formula of C[CH2OCOCH2CH2N(CH2PO3H2)CH2(CH2)nN(CH2PO3H2)2]4, wherein n is an integer from 1 to 5. The PETA-ADA-12PO3H2 has a high calcium tolerance, and excellent inhibiting efficiency of calcium carbonate, calcium sulfate and barium sulfate, which is applied in inhibiting the formation and deposition in the industrial water systems of circulating cooling water, oilfield flooding and reverse osmosis, and particularly suitable for water treatment with high calcium tolerance.

Owner:TONGJI UNIV

Wear-resisting anti-oxidation ultraviolet light curing exterior wall coating and preparation method thereof

The invention discloses wear-resisting anti-oxidation ultraviolet light curing exterior wall coating. The wear-resisting anti-oxidation ultraviolet light curing exterior wall coating is characterized by being prepared from the following raw materials in parts by weight: 30-35 parts of polyester acrylate, 19-23 parts of amino acrylate, 13-14 parts of trimethylolpropane triacrylate, 2-3 parts of lignocellulose, 4-5 parts of light initiator 1173, 10-13 parts of pentaerythritol tetraacrylate, 5-7 parts of phenyl glycidyl ether, 4-6 parts of acetic ether, 1-2 parts of cobalt naphthenate, 1-2 parts of accelerant TMTD (tetramethyl thiuram disulfide), 1-2 parts of grape seed oil, 5-7 parts of monazite powder, 2-3 parts of chromium trioxide, 3-5 parts of magnesium silicate and 4-5 parts of addtivie. The wear-resisting anti-oxidation ultraviolet light curing exterior wall coating has the advantages that due to addition of the grape seed oil which is a natural antioxidant ingredient, the ageing-resistance performance of the coating can be improved, and the coating is safe and non-toxic; due to addition of the monazite, the hardness of a paint film is improved, and the paint film has good wear resistance; and due to addition of the additive, the coating has good leveling property, hardness and very strong adhesive force, is fast in curing speed, wear-resistant and can be used as the exterior wall coating.

Owner:江苏舜昶新型建材有限公司

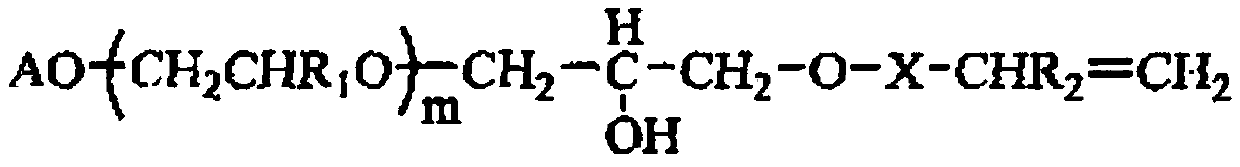

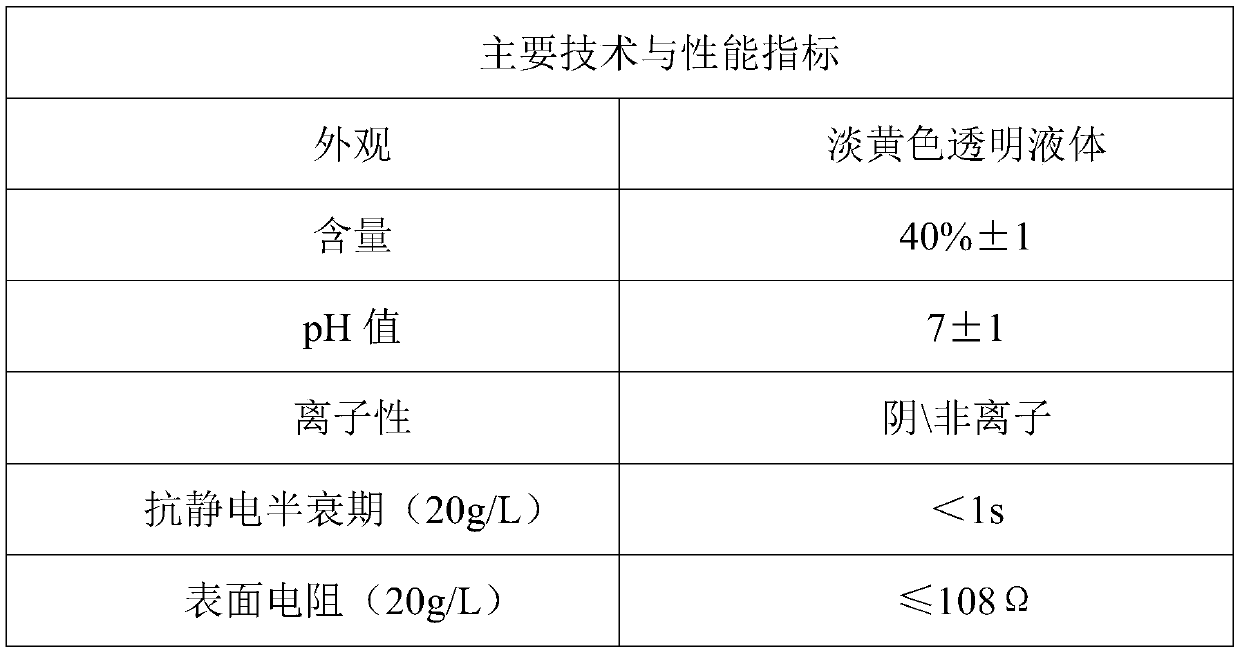

Process method for preparing polyester antistatic agent from pentaerythritol tetraacrylate wastewater

The invention discloses a process method for preparing a polyester antistatic agent from pentaerythritol tetraacrylate wastewater. The method comprises the steps: taking waste liquid generated by synthesizing pentaerythritol tetraacrylate as a raw material; taking the waste liquid, alkoxy polyether containing a double bond at the tail end and an initiator, carrying out free radical reaction, neutralizing with sodium hydroxide, and preparing the macromolecular antistatic agent for polyester fabrics. The technological process is complete, the preparation method is simple, the raw materials are cheap, the operation is easy, the final reaction liquid is directly output as a product, the waste liquid treatment investment is saved, the prepared polyester fabric antistatic agent has an obvious antistatic effect after being compared with other similar products on the market, has the use effect not less than that the similar products and even superior to that of the similar products.

Owner:DUPLUS CHEM OF ZHANGJIAGANG CITY

Temperature-sensitive flame-retardant microcapsule, preparation method thereof, and silica gel foamed material containing temperature-sensitive flame-retardant microcapsule

ActiveCN108250487AGood compatibilityTo achieve the purpose of flame retardantMicroballoon preparationMicrocapsule preparationPolymer scienceCombustion

The invention more specifically relates to a temperature-sensitive flame-retardant microcapsule, a preparation method thereof, and a silica gel foamed material containing the temperature-sensitive flame-retardant microcapsule. The preparation method is mainly used for solving problems in the prior art that increasing of the flame resistance of silica gel foamed materials is limited by conventionalfire retardant adding method, and material mechanical properties and physical mechanical properties are influenced. The temperature-sensitive flame-retardant microcapsule comprises a capsule wall anda core layer; the core layer is coated by the capsule wall; the core layer is a fire retardant; the capsule wall is composed of ultraviolet light cured polysiloxane, a middle and high temperature foaming agent, a surfactant, a photoinitiator, and tetramethylol methane tetraacrylate. The compatibility of the temperature-sensitive flame-retardant microcapsule with silica gel is excellent; flame resistance is achieved through release of the fire retardant in the temperature-sensitive flame-retardant microcapsule; when indoor combustion is caused, expansion of the middle and high temperature foaming agent in the capsule wall is realized, the capsule wall is broken, the fire retardant in the core material is released, so that flame retardation is realized effectively.

Owner:陕西西科守安科技有限公司

Ultraviolet-cured plastic printing ink and preparation method thereof

The invention discloses ultraviolet-cured plastic printing ink which is prepared from the following ingredients in mass percent content: 10 to 15% of monomer, 30 to 50% of photosensitive resin, 3 to 8% of photoinitiator and 30 to 44% of powder. The monomer is a mixture of ethoxylated pentaerythritol tetraacrylate and trimethylolpropane triacrylate, and the photoinitiator is a mixture of benzophenone and isopropylthioxanthone. The ultraviolet-cured plastic printing ink disclosed by the invention has the characteristics of quick curing, excellent adhesion, no faultage and strong base material adaptability, has excellent adhesion with plastic cement of PP, PE, PVC, PMMA, PC, PAS, PET, ABS and the like which are common plastics in printing, avoids varieties of method of leaky white, overprint and the like in continuous printing, is especially suitable for being applied to plastic base materials of cosmetics industry and has excellent adhesion. Meanwhile, the invention further discloses a preparation method of the ultraviolet-cured plastic printing ink.

Owner:广州市尤特新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com