Phase-change energy-storage microcapsules and preparation method thereof

A phase change energy storage, microcapsule technology, applied in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., can solve the problems of high cost, inability to emulsion, single surfactant, etc., to reduce surface tension, improve Stable, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of phase change energy storage microcapsules, comprising the following steps:

[0024] a. The preparation process of phase change energy storage microcapsules includes two phases: the continuous phase includes deionized water and emulsifier, and the discontinuous phase includes core material, wall material and initiator;

[0025] b. Under gentle stirring, uniformly mix the continuous phase and the discontinuous phase respectively;

[0026] c. Add the discontinuous phase to the continuous phase reactor, stir rapidly for 5 minutes, and the stirring speed is 3000rpm;

[0027] d. Reduce the stirring speed in step c to 300rpm, raise the temperature to 70°C, keep it for 2 hours, then adjust the temperature to 85°C, and keep it for 5 hours;

[0028] e, stop heating, and naturally cool to room temperature;

[0029] f. Take out the suspension of phase-change energy storage microcapsules, wash them three times to remove unreacted monomers and uncoated monom...

Embodiment 1

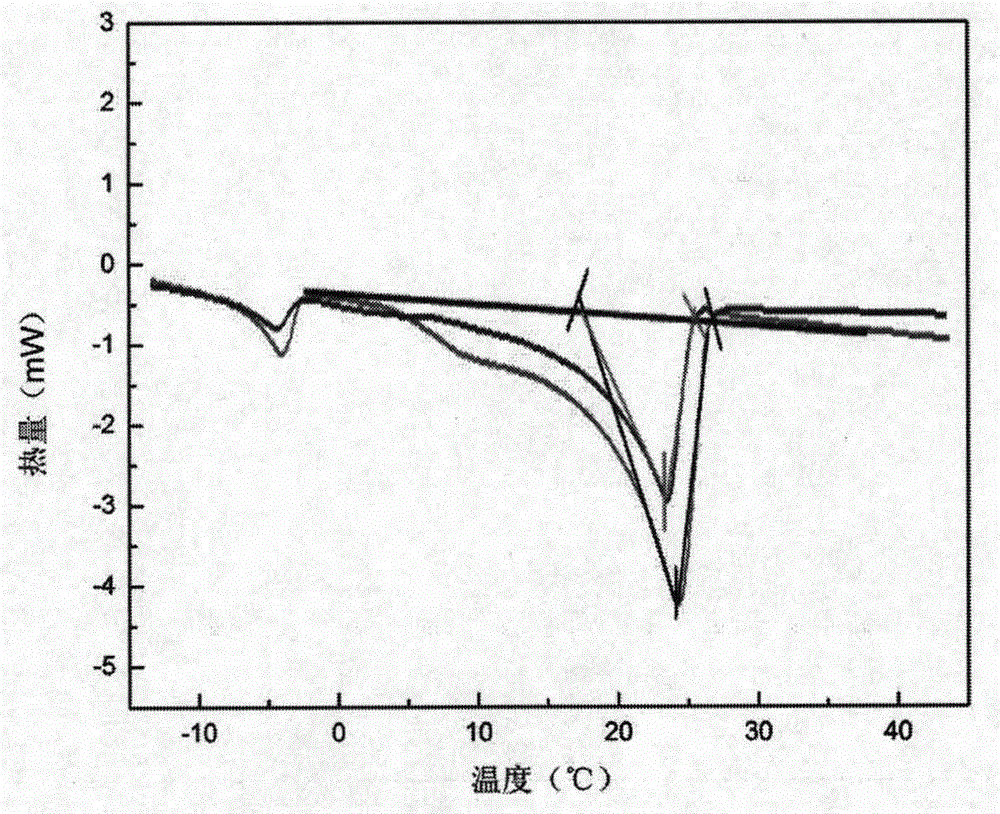

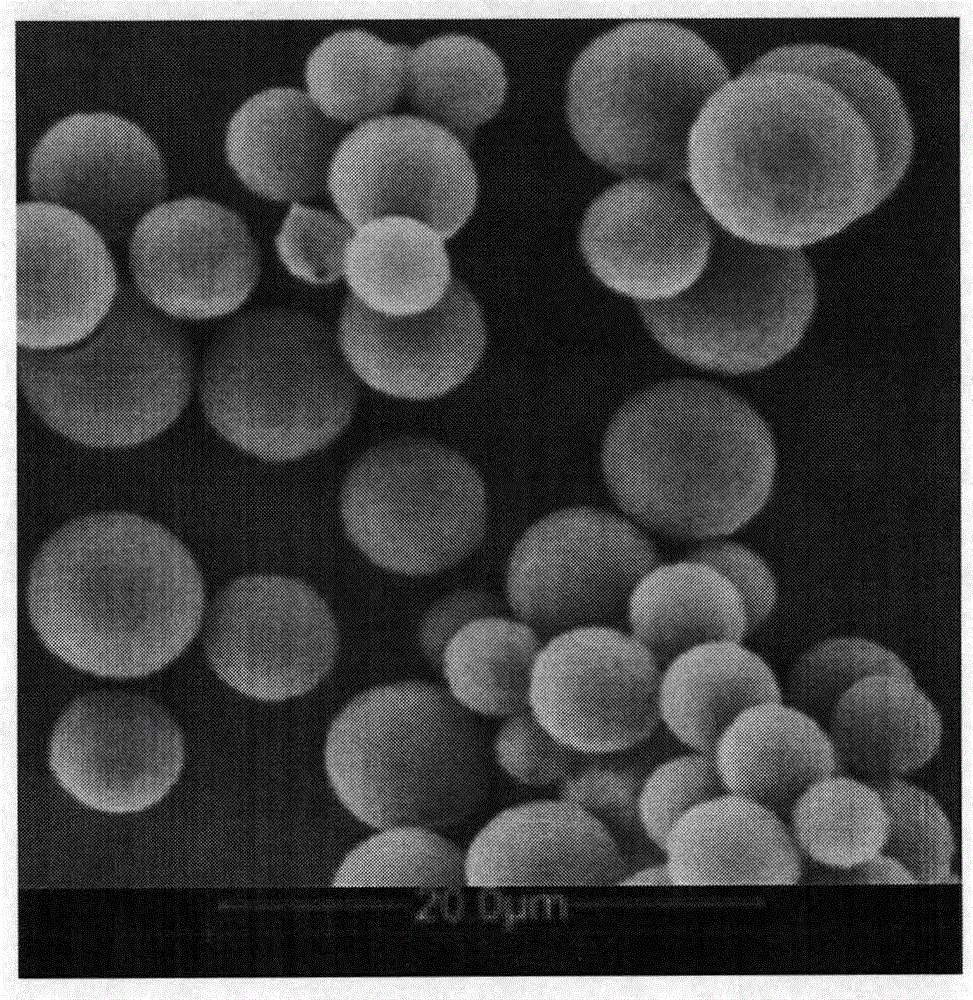

[0033]Under gentle stirring, stir the discontinuous phase 50g tallow propyl ester, 25g methyl methacrylate (MMA), 25g pentaerythritol tetraacrylate (PETRA) and 2.5g benzoyl peroxide (BPO) until well mixed , the continuous phase 400g deionized water, 2.5g polyvinylpyrrolidone (PVP) and 2.5g sodium dodecyl sulfate (SDS) are mixed uniformly in another reactor, and the above-mentioned discontinuous phase is added in the continuous phase reactor, Then stir rapidly for 5 minutes, wherein the stirring speed is 3000rpm, then reduce the stirring speed to 300rpm, and increase the temperature to 70°C, hold for 2 hours, then adjust the temperature to 85°C, and hold for 5 hours, then stop heating , naturally cool down to room temperature, take out the suspension of phase change material microcapsules, wash 3 times to remove unreacted monomers and uncoated monomers, and then dry in an oven at 50°C for 48 hours to obtain the product phase Change material microcapsules, the phase transition t...

Embodiment 2

[0035] Under gentle stirring, stir the discontinuous phase 50g tallow methyl ester, 8g methyl methacrylate (MMA), 8g pentaerythritol tetraacrylate (PETRA) and 0.3g benzoyl peroxide (BPO) and mix well , the continuous phase 400g deionized water, 3.3g polyvinyl alcohol (PVA) and 3.3g sodium dodecyl sulfate (SDS) are mixed uniformly in another reactor, and the above-mentioned discontinuous phase is added in the continuous phase reactor, Then stir rapidly for 5 minutes, wherein the stirring speed is 3000rpm, then reduce the stirring speed to 300rpm, and raise the temperature to 70°C and keep it for 2 hours, then adjust the temperature to 85°C and keep it for 5 hours, then stop Heating, cooling down to room temperature naturally, taking out the suspension of phase change material microcapsules, washing 3 times to remove unreacted monomers and uncoated monomers, and drying in an oven at 50°C for 48 hours to obtain the product Phase change material microcapsules, the microcapsules ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| latent heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com