Ultraviolet-cured plastic printing ink and preparation method thereof

A technology of plastic ink and ultraviolet light, which is applied in ink, household utensils, applications, etc., can solve the problems of reducing industrial production efficiency, unfavorable environmental protection, worker injury, etc., achieve excellent adhesion and fast curing ability, save cost and space, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

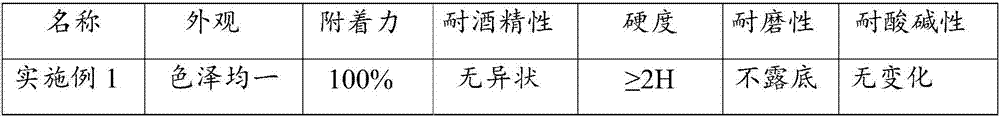

Embodiment 1

[0029] An embodiment of the ultraviolet-cured plastic ink of the present invention, the ink for the composite board described in this embodiment comprises the following components in mass percentage: 15% monomer, 30% photosensitive resin, 8% photoinitiator, Auxiliary 3%, powder 44%, of which:

[0030] Monomer: ethoxylated pentaerythritol tetraacrylate 8%, trimethylolpropane triacrylate 7%;

[0031] Photosensitive resin: 25% aliphatic polyester, 5% polyester acrylate;

[0032] Photoinitiator: benzophenone 5%, isopropyl thioxanthone 3%;

[0033] Additives: silane coupling agent YCK-6010 2%, defoamer YCK-670 0.9%, wetting and leveling agent YCK-12200.1%;

[0034] Powder: titanium dioxide (R-6618) 20%, calcium carbonate 20%, fumed silica 4%.

[0035] Mix the above-mentioned raw materials uniformly in a mixer, grind them in a three-roller machine until the fineness of the ink is less than 10 μm to form a uniform mixed phase, and then filter with a 300-mesh mesh cloth to obtain t...

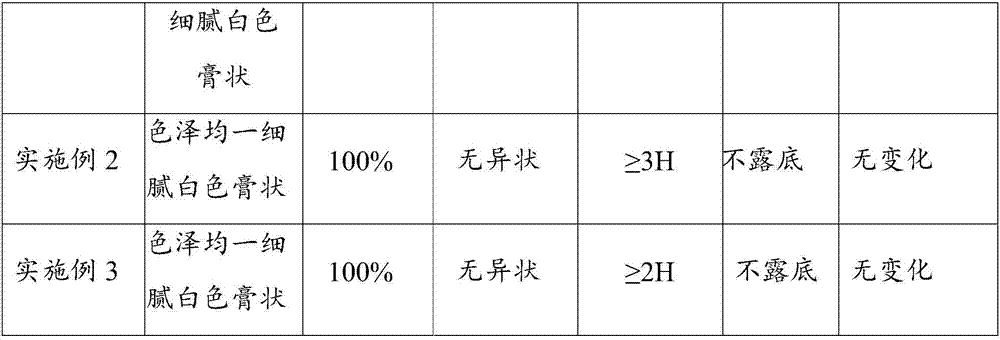

Embodiment 2

[0037] An embodiment of the ultraviolet-cured plastic ink of the present invention, the ink for the composite board described in this embodiment includes the following components in mass percentage: 10% monomer, 46% photosensitive resin, 7% photoinitiator, Auxiliary 3%, powder 34%, of which:

[0038] Monomer: Ethoxylated pentaerythritol tetraacrylate 5%, trimethylolpropane triacrylate 5%;

[0039] Photosensitive resin: 38% aliphatic polyester, 8% polyester acrylate;

[0040] Photoinitiator: benzophenone 4%, isopropyl thioxanthone 3%;

[0041] Additives: silane coupling agent YCK-6010 2%, defoamer YCK-670 0.9%, wetting and leveling agent YCK-12200.1%;

[0042] Powder: titanium dioxide (R-6618) 20%, calcium carbonate 10%, fumed silica 4%.

[0043] Mix the above-mentioned raw materials uniformly in a mixer, grind them in a three-roller machine until the fineness of the ink is less than 10 μm to form a uniform mixed phase, and then filter with a 300-mesh mesh cloth to obtain th...

Embodiment 3

[0045] An embodiment of the ultraviolet-cured plastic ink of the present invention, the ink for the composite board described in this embodiment comprises the following components in mass percentage: 14% monomer, 50% photosensitive resin, 3% photoinitiator, Auxiliary 3%, powder 30%, of which:

[0046] Monomer: Ethoxylated pentaerythritol tetraacrylate 7%, trimethylolpropane triacrylate 7%;

[0047] Photosensitive resin: 40% aliphatic polyester, 10% polyester acrylate;

[0048] Photoinitiator: 2% benzophenone, 1% isopropylthioxanthone;

[0049] Additives: silane coupling agent YCK-6010 2%, defoamer YCK-670 0.9%, wetting and leveling agent YCK-12200.1%;

[0050]Powder: titanium dioxide (R-6618) 15%, calcium carbonate 14%, fumed silica 1%.

[0051] Mix the above-mentioned raw materials uniformly in a mixer, grind them in a three-roller machine until the fineness of the ink is less than 10 μm to form a uniform mixed phase, and then filter with a 300-mesh mesh cloth to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com