Preparation method of nanoscale hyperbranched hydrophobically associating polyacrylamide

A technology of polyacrylamide and hydrophobic association, applied in chemical instruments and methods, drilling compositions, climate change adaptation, etc., can solve the problem of excessive molecular chain size, affecting the effect of polymer flooding, unstable molecular chain structure, etc. problems, to achieve the effect of improving shear resistance and enhancing oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

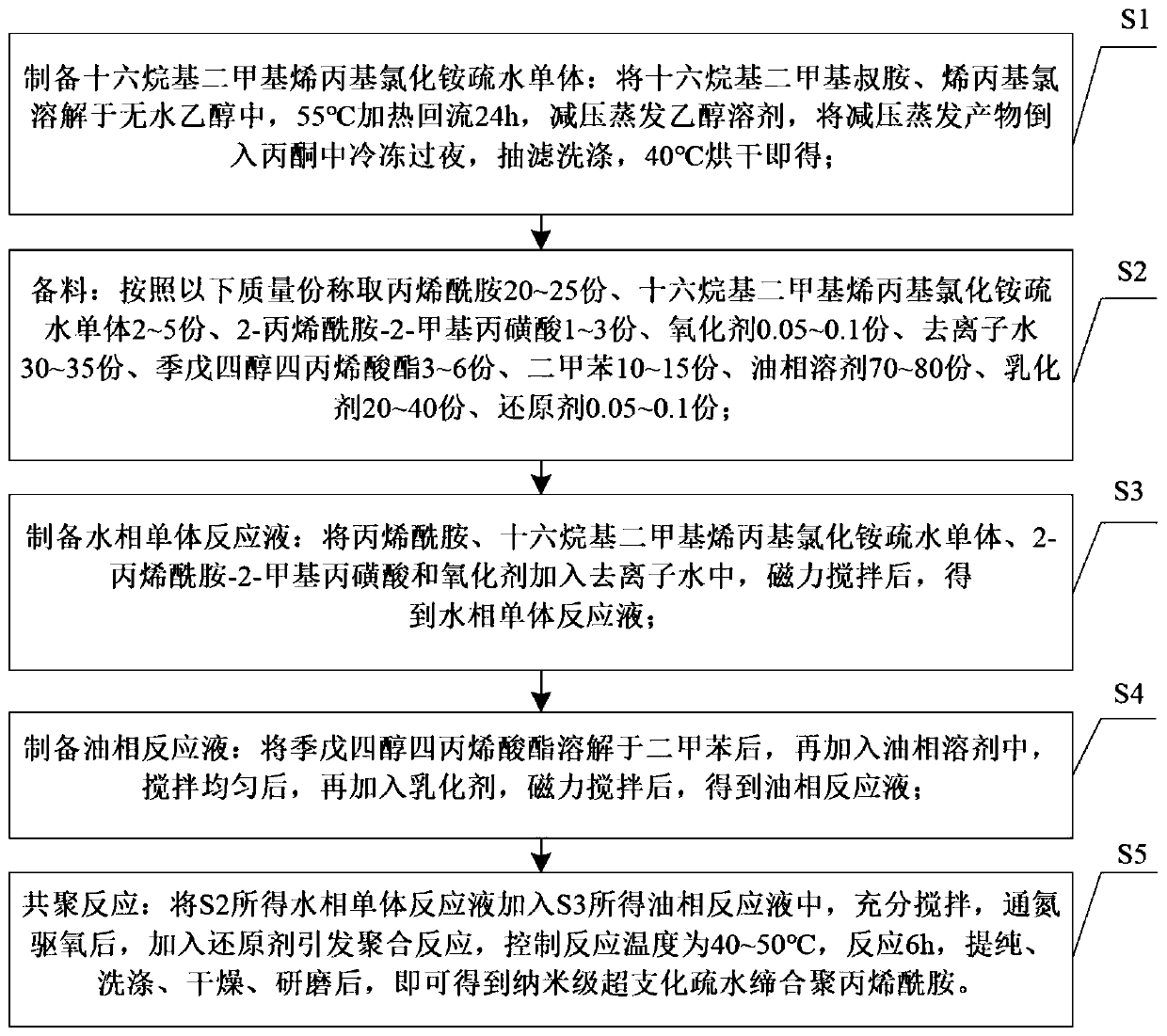

Method used

Image

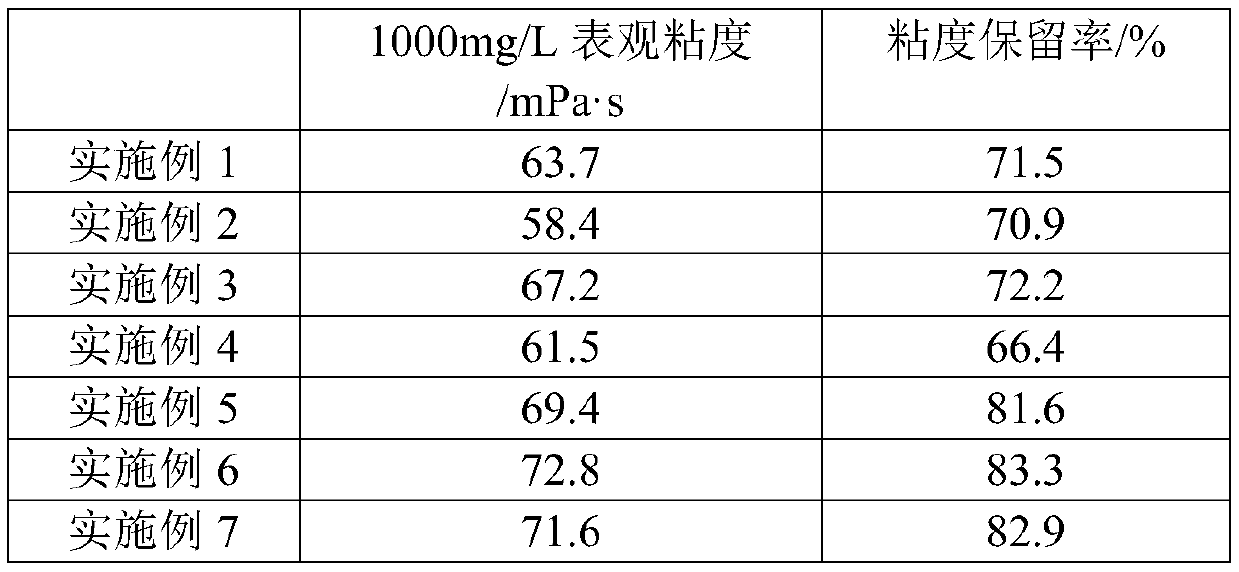

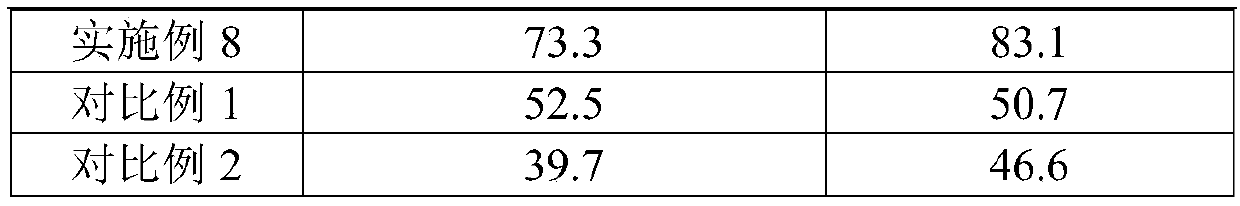

Examples

Embodiment 1

[0023] The synthesis of A, hexadecyl dimethyl allyl ammonium chloride hydrophobic monomer

[0024] Add 100g of hexadecyldimethyl tertiary amine, 30g of allyl chloride and 200mL of absolute ethanol into a three-neck flask, fully dissolve and then heat up to 55°C, and heat to reflux at 55°C for 24h, then evaporate the ethanol solvent under reduced pressure , and then pour the evaporated product under reduced pressure into acetone with 8 times the mass, freeze it overnight and then wash it with suction filtration. Dimethyl allyl ammonium chloride hydrophobic monomer;

[0025] B. Preparation of Nanoscale Hydrophobic Association Polyacrylamide

[0026] After dissolving 4.00g of pentaerythritol tetraacrylate in 15.00g of xylene, add 80.00g of diesel oil, after stirring evenly, add the emulsifier compounded by 20.00g of Span80 and 7.00g of Tween80, and mix uniformly with a magnetic stirrer to obtain Oil phase reaction liquid, then 20.00g of acrylamide, 2.00g of 2-acrylamide-2-methy...

Embodiment 2

[0028] Same as Example 1, the difference is that the amount of cetyl dimethyl allyl ammonium chloride hydrophobic monomer is replaced by 2.00 g from 4.00 g.

Embodiment 3

[0030] Same as Example 1, the difference is that the amount of cetyl dimethyl allyl ammonium chloride hydrophobic monomer is replaced from 4.00 g to 8.00 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com