Preparation method of pentaerythritol tetraacrylate mixture

A technology of pentaerythritol acrylate and pentaerythritol, which is applied in the field of preparation of pentaerythritol acrylate mixtures, can solve the problems of many impurities, high chroma, and low yield, and achieve high purity, simple preparation process, and less impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

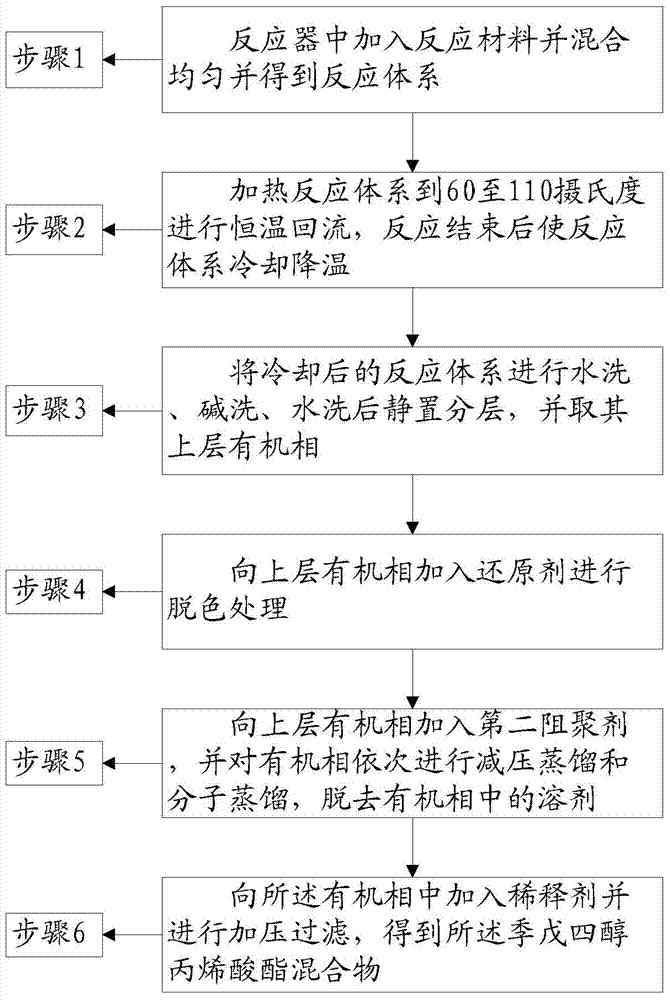

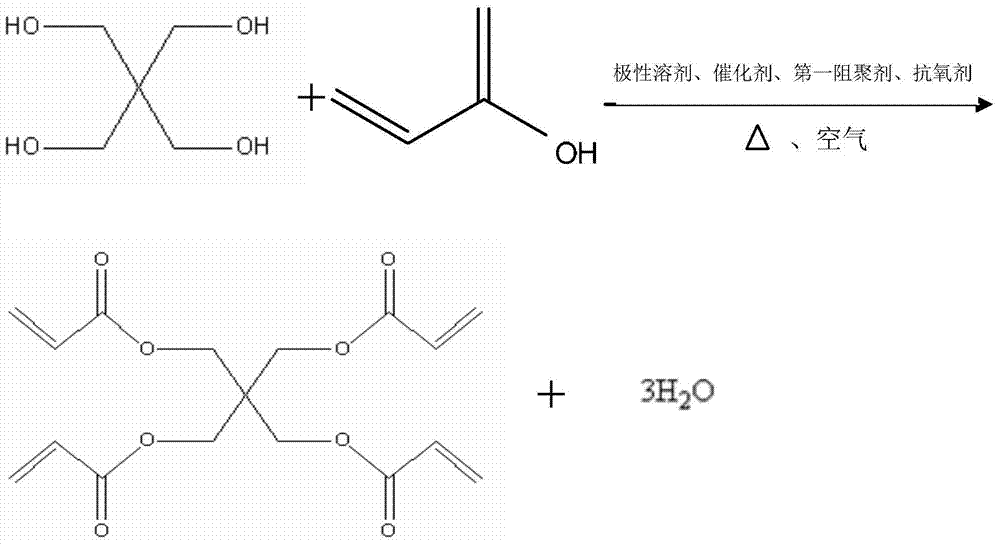

[0029] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a pentaerythritol acrylate mixture, and the method for preparing the pentaerythritol acrylate mixture includes:

[0030] Step 1: Add pentaerythritol, acrylic acid, solvent, catalyst, first polymerization inhibitor and antioxidant to the reactor in sequence, and mix the above materials uniformly to obtain a reaction system, wherein the reactor is equipped with a thermometer, a water separator, a snake Four-necked flask with shaped condenser, stirring paddle and vent pipe;

[0031] Step 2: Turn on the heating device and heat the reactor to keep the temperature of the reaction system at 60-110°C and reflux the reaction system at a constant temperature. At the same time, a protective gas is introduced into the reaction system. The protective gas adopts a process The mixed gas of air and nitrogen keeps the flow of the mixed gas at 0.1~1000m3 / h. The mixed gas of process air and nitr...

Embodiment 2

[0121] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a pentaerythritol acrylate mixture, and the method for preparing the pentaerythritol acrylate mixture includes:

[0122] Step 1: Add 60.0g pentaerythritol, 114.4g acrylic acid, 47.0g toluene, 82.3g cyclohexane, 1.85g formaldehyde into a four-necked flask equipped with thermometer, water trap, serpentine condenser, stirring blade and vent pipe. Sulfonic acid, 1.85g p-toluenesulfonic acid, 0.3g copper sulfate pentahydrate, 0.01g p-hydroxyanisole, 0.7g 2,6-di-tert-butyl-p-cresol and mixed uniformly to obtain a reaction system;

[0123] Among them: the mass ratio of pentaerythritol and acrylic acid is 1:1.9, the solvent is toluene and cyclohexane, the ratio of toluene and cyclohexane is 1:1.75, the total solvent is 129.3g, and the solvent is 41.9% of the total mass of the reaction system. The catalyst is methanesulfonic acid and p-toluenesulfonic acid. The total catalyst is 3.7g, ...

Embodiment 3

[0135] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a pentaerythritol acrylate mixture, and the method for preparing the pentaerythritol acrylate mixture includes:

[0136] Step 1: Add 60.0g pentaerythritol, 130.7g acrylic acid, 76g benzene, 76g toluene, 2.86g methanesulfonic acid, into a four-necked flask equipped with a thermometer, a water trap, a serpentine condenser, a stirring blade, and a vent pipe. 2.86g solid super acid, 0.7g hydroquinone, 0.25g copper acetate, 1.28g 2,6-di-tert-butyl-p-cresol and mixed uniformly to obtain a reaction system;

[0137] Among them: the mass ratio of pentaerythritol and acrylic acid is 1:2.12, the solvent is benzene and toluene, the ratio of benzene to toluene is 1:1, the total solvent is 152g, and the solvent is 43.3% of the total mass of the reaction system, and the catalyst is methylsulfonate Acid and solid super acid, the total catalyst is 5.72g, and the catalyst is 3% of the total mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| color hue | aaaaa | aaaaa |

| color hue | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com