A split core column for diamond synthesis and its preparation method

A technology of diamond and core pillars, which is applied in the field of split core pillars for diamond synthesis and its preparation, can solve the problems of affecting the quality of synthetic materials, low heat energy utilization efficiency, and low diamond output, and achieve easy operation, reduced growth speed, and mold Uniform cavity feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention also relates to a method for preparing a split core column for diamond synthesis, the steps are as follows:

[0044] (1) Mix the graphite powder and catalyst powder according to the weight ratio of 30-65% of the catalyst powder in the raw material of the core column 4, add them to the mixer and mix for 3 to 5 hours, mix the materials thoroughly, and obtain the mixture a;

[0045] (2) The graphite powder and the catalyst powder are mixed according to the weight ratio of the catalyst powder in the raw materials on the periphery of the core column 4, and the weight ratio of the catalyst powder in the raw materials on the periphery of the core column 4 is higher than that in step (1) The weight ratio of the catalyst powder in the raw materials is 4~8% higher, and it is added to the mixer and mixed for 3~5h to make the materials fully mixed to obtain the mixture b;

[0046] (3) The mixture a obtained in step (1) is subjected to cold isostatic pressing to form blocks a...

Embodiment 1

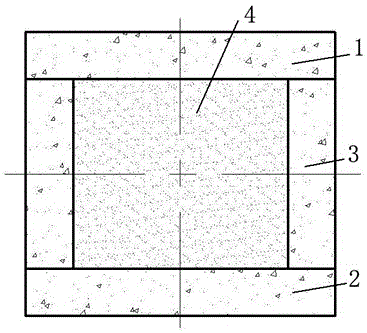

[0065] A split core column for diamond synthesis, comprising a core column tube 3, a core column 4 is arranged in the core column tube 3, a first core column sheet 1 is arranged at the upper end of the core column tube 3, and a second core column is arranged at the lower end of the core column tube 3 Sheet 2, the diameter of the first core pillar sheet 1, the diameter of the second core pillar sheet 2 and the outer diameter of the stem tube 3 are the same, the thickness of the first core pillar sheet 1 and the thickness of the second core pillar sheet 2 and the core pillar The wall thickness of the tube 3 is the same, and the ratio of the wall thickness of the core column tube 3 to the diameter of the core column 4 is 1:1; the periphery of the core column 4 and the raw materials of the core column 4 are composed of catalyst powder and graphite powder, and the raw material of the core column 4 The weight ratio of the catalyst powder in the core column 4 is 30%, and the weight rat...

Embodiment 2

[0067] A split core column for diamond synthesis, comprising a core column tube 3, a core column 4 is arranged in the core column tube 3, a first core column sheet 1 is arranged at the upper end of the core column tube 3, and a second core column is arranged at the lower end of the core column tube 3 Sheet 2, the diameter of the first core pillar sheet 1, the diameter of the second core pillar sheet 2 and the outer diameter of the stem tube 3 are the same, the thickness of the first core pillar sheet 1 and the thickness of the second core pillar sheet 2 and the core pillar The wall thickness of the tube 3 is the same, and the ratio of the wall thickness of the core column tube 3 to the diameter of the core column 4 is 1:3; the periphery of the core column 4 and the raw materials of the core column 4 are composed of catalyst powder and graphite powder, and the raw material of the core column 4 The weight ratio of the catalyst powder in the core column 4 is 65%, and the weight rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com