Temperature-sensitive flame-retardant microcapsule, preparation method thereof, and silica gel foamed material containing temperature-sensitive flame-retardant microcapsule

A microcapsule and temperature-sensitive technology, applied in the field of flame retardant silica gel, can solve the problems of limited flame retardant performance, deterioration of material mechanical properties and physical and mechanical properties, large addition amount, etc., to achieve good compatibility, fast curing characteristics, and improved The effect of curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] First, mix 100 parts of KH570 silane coupling agent with 100 parts of hexamethyldisiloxane evenly, stir, add 0.6 parts of trifluoromethanesulfonic acid and 0.6 parts of hydroquinone, react for half an hour, and then drop 22 Parts of deionized water, dripped in half an hour, reflux for 1.5 hours, add 200 parts of dilute hydrochloric acid (5% concentration) to react for 1 hour, let stand to separate layers, separate the lower polymer layer, and remove the water inside with a water separator parts to obtain UV-curable polysiloxane.

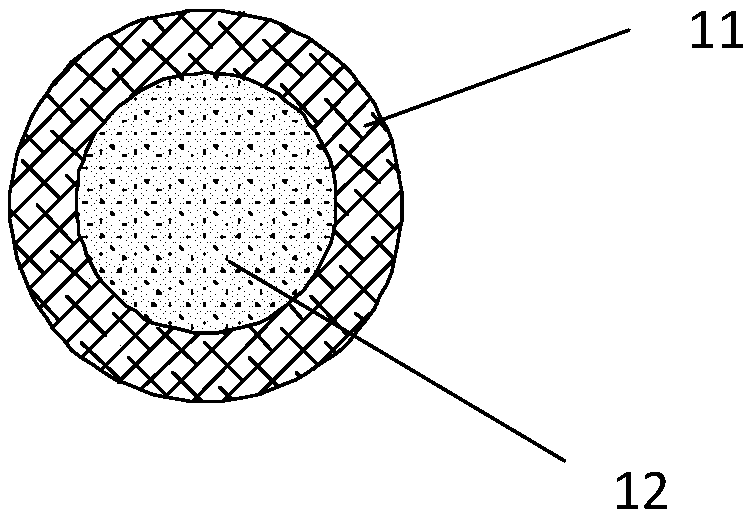

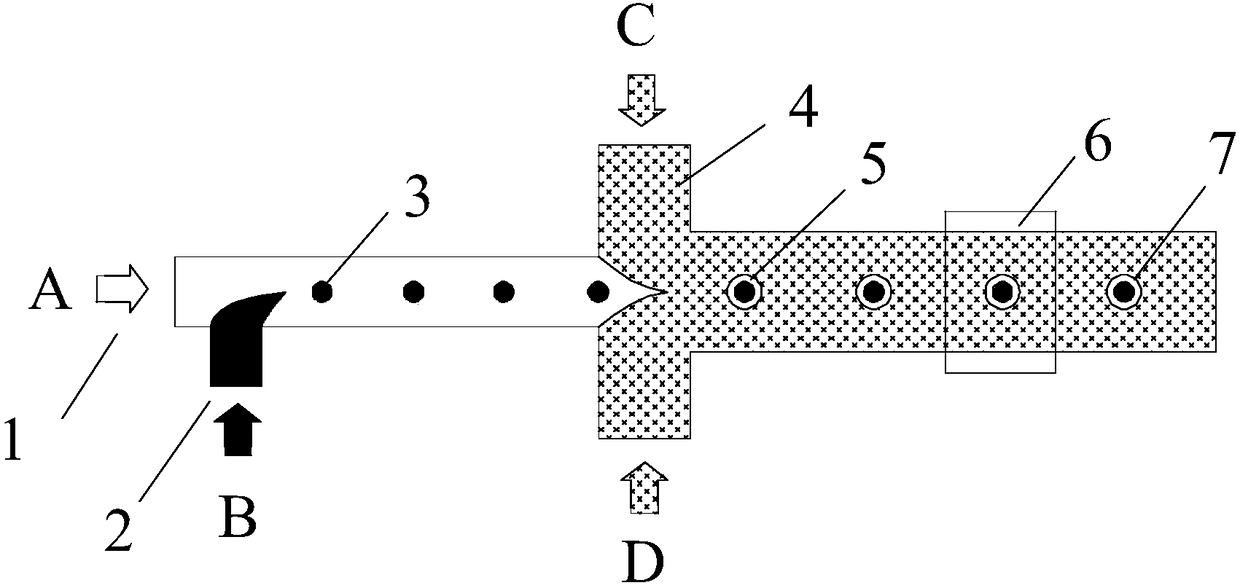

[0047] Take 100 parts of UV-curable polysiloxane, 1 part of medium-high temperature foaming agent, 2 parts of surfactant (Tween 80), 2 parts of photoinitiator (2-hydroxy-2-methyl-1-phenyl- 1-acetone), 1.5 parts of pentaerythritol tetraacrylate were mixed uniformly to form solution A, and the flame retardant was wrapped in solution A by microfluidic technology to prepare a microemulsion, and the microemulsion was cured by ultraviolet light to o...

Embodiment 2

[0049] First, mix 100 parts of KH570 silane coupling agent with 100 parts of hexamethyldisiloxane evenly, stir, add 0.6 parts of trifluoromethanesulfonic acid and 0.6 parts of polymerization inhibitor (hydroquinone); react for half an hour , then add 22 parts of deionized water dropwise, finish dripping in 40 minutes, reflux for 2 hours, add 200 parts of dilute hydrochloric acid (5% concentration) to react for 1.5 hours, let stand for stratification, separate the lower polymer layer, and use a water separator to remove Remove the moisture inside to obtain UV-curable polysiloxane.

[0050] Get 100 parts of UV-curable polysiloxane, 2 parts of medium-high temperature foaming agent, 2 parts of surfactant (Tween 80), 3 parts of photoinitiator (2-hydroxy-2-methyl-1-phenyl- 1-acetone), 1.5 parts of pentaerythritol tetraacrylate were mixed uniformly to form solution A, and the flame retardant was wrapped in solution A by microfluidic technology to prepare a microemulsion, and the micr...

Embodiment 3

[0052] First, mix 100 parts of KH570 silane coupling agent with 100 parts of hexamethyldisiloxane evenly, stir, add 0.6 parts of trifluoromethanesulfonic acid, and 0.6 parts of polymerization inhibitor (hydroquinone), and react for 20 minutes , then add 22 parts of deionized water dropwise, finish dripping in 20 minutes, reflux for 1 hour, add 200 parts of dilute hydrochloric acid (5% concentration) to react for 40 minutes, let stand to separate layers, separate the lower polymer layer, and remove it with a water separator The moisture inside, get UV-curable polysiloxane.

[0053] Take 100 parts of UV-curable polysiloxane, 2 parts of medium-high temperature foaming agent, 1 part of surfactant (Tween 80), 1 part of photoinitiator (2-hydroxy-2-methyl-1-phenyl- 1-acetone), 1.5 parts of pentaerythritol tetraacrylate were mixed uniformly to form solution A, and the flame retardant was wrapped in solution A by microfluidic technology to prepare a microemulsion, and the microemulsion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com